Method for producing ultralow-sulfur cleaning gasoline through full-distilling hydrogen desulfurization of catalytic gasoline

A catalytic gasoline and whole distillate technology, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, and can solve problems such as loss of octane number, loss of liquid yield, and reduction of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

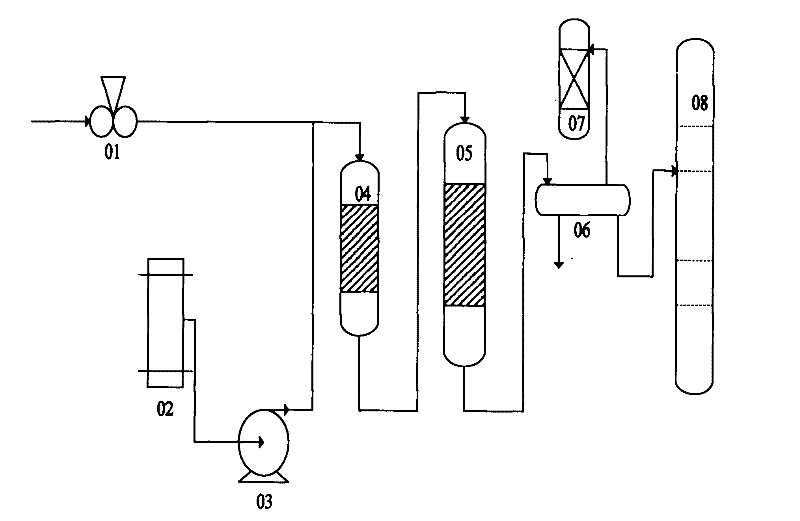

Image

Examples

Embodiment Construction

[0022] This example shows the effect of catalytic gasoline to produce S≯50ppm and S≯10ppm clean gasoline. Those skilled in the art can formulate specific reaction conditions according to the properties of raw materials and product quality requirements.

[0023] The catalyst is an industrialized catalyst produced by Jiangsu Jiayuxin Company.

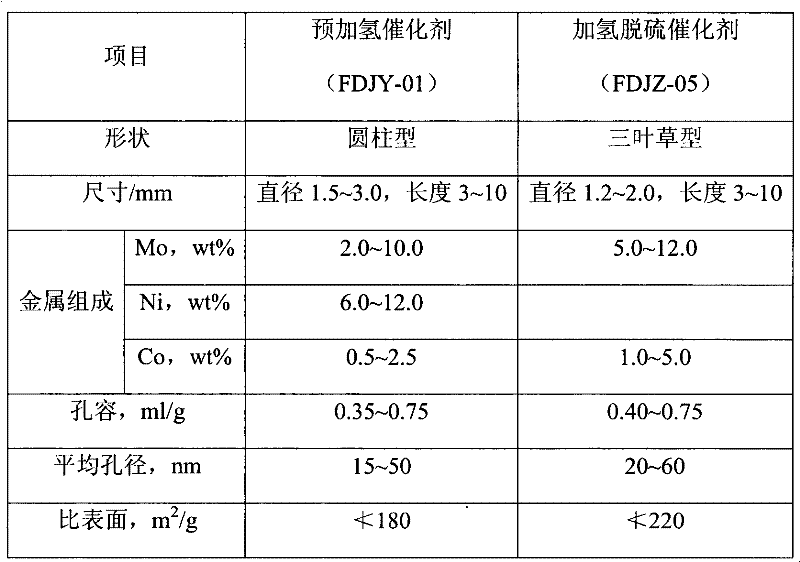

[0024] Table 1 Basic physicochemical properties of the catalyst

[0025]

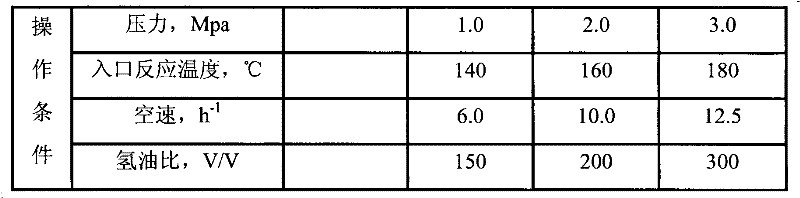

[0026] 1) Pre-hydrotreating of feedstock oil

[0027] The raw material oil pre-hydrogenation section adopts the FDJY-01 commercial catalyst produced by Jiangsu Jiayuxin Company. The catalyst is packed in the pre-hydrogenation reactor in a dense phase to remove diolefins in the catalytic gasoline raw material and to cause isomerization of some hydrocarbons. reaction. The operating conditions are: reaction hydrogen partial pressure 1.0~3.0Mpa, inlet reaction temperature 140~180℃, liquid hourly space velocity 6.0~12.5h -1 , The volume ratio of hydrogen to oil is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com