Method for preparing high vinyl solution polymerized butylbenzene by high temperature continuous polymerization technique

A polymerization process and high vinyl technology, which is applied in the high-temperature continuous polymerization process to prepare high vinyl solution-polymerized styrene-butadiene. It can solve the problems of no application reports and no actual research results on regulators, and achieve high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

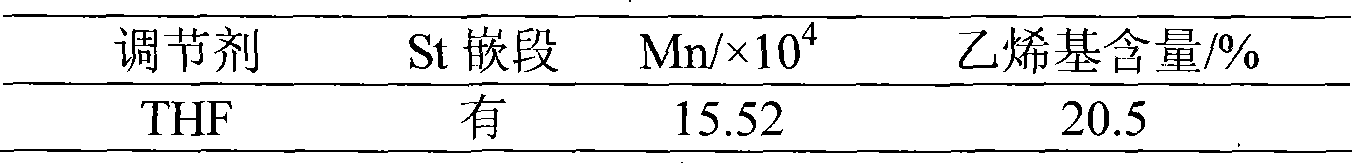

[0025] On the four-tank series continuous polymerization model test device, replace it with high-purity nitrogen for 3 times, turn on the stirring, and add solvent, butadiene, styrene, polar additive THF, and initiator n-butyl with a metering pump under the protection of high-purity nitrogen. lithium. The polymerization temperature is 110°C. When the polymerization reaches a steady state and the outlet molecular weight reaches the set value, the terminator isopropanol and antioxidant BH are added to terminate the reaction. The SSBR glue was condensed and dried by water vapor, and its microstructure test results are shown in Table 1.

[0026] Table 1 Effect of THF on the microstructure of SSBR

[0027]

Embodiment 2

[0029] Same example 1, difference is to add polar additive diethylene glycol diethyl ether. The results of the microstructure test are shown in Table 2.

[0030] Table 2 Effect of diethylene glycol diethyl ether on the microstructure of SSBR

[0031]

Embodiment 3

[0033] Same as example 1, the difference is to add polar additive 1G / GSA. The results of the microstructure test are shown in Table 3.

[0034] Table 3 Effect of 1G / GSA on the microstructure of SSBR

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com