Trans-rubber fiber material, preparation method and applications thereof

A rubber fiber and rubber technology, applied in the field of fiber materials, can solve the problems of trans-rubber electrospinning that have not yet been seen, and achieve the effects of eliminating spinning, short molding process and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Prepare a solution of trans-1,4-polyisoprene (relative molecular mass 80000g / mol, trans 1,4 structure mole fraction greater than 98%) with a concentration of 3.0w / v% (g / mL) 25mL. What wherein bath agent selects for use is trichloromethane. The prepared solution was stirred in a constant temperature water bath at 45°C for 24 hours to obtain a uniformly dissolved and transparent solution, which was cooled to room temperature for use.

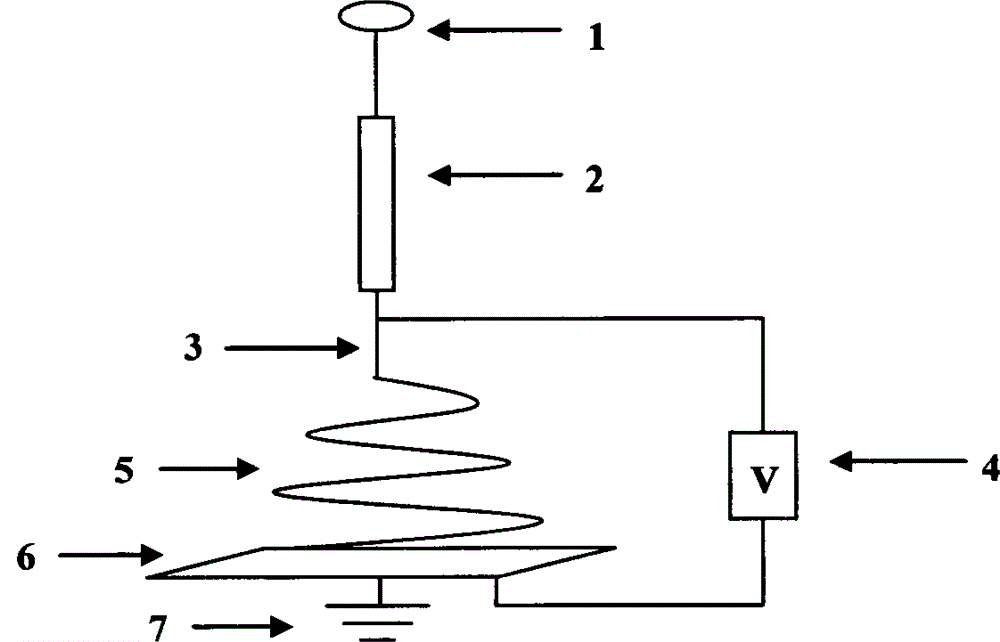

[0042] (2) The schematic diagram of the spinning equipment is shown in figure 1 . Take about 5mL of the above rubber solution, put it into the liquid storage device, remove the air, connect the spinneret (0.5mm inner diameter), and connect the spinneret to the positive pole of the high voltage power supply. A 5cm×15cm grounded aluminum plate is used as the receiving device, and the aluminum plate is covered with aluminum foil to facilitate fiber reception. Adjust the distance between the spinneret and the collecting device to 15cm, ...

Embodiment 2

[0046] (1) Prepare 250 mL of trans-1,4-polybutadiene (relative molecular mass 70,000 g / mol, trans 1,4 structure molar fraction greater than 95%) with a concentration of 5.0 w / v% (g / mL) . Wherein the solvent is a mixed solvent of toluene and N,N-dimethylformamide with a volume ratio of 9:1. The prepared solution was stirred in a constant temperature water bath at 40°C for 30 hours to obtain a uniformly dissolved and transparent solution, which was cooled to room temperature for use.

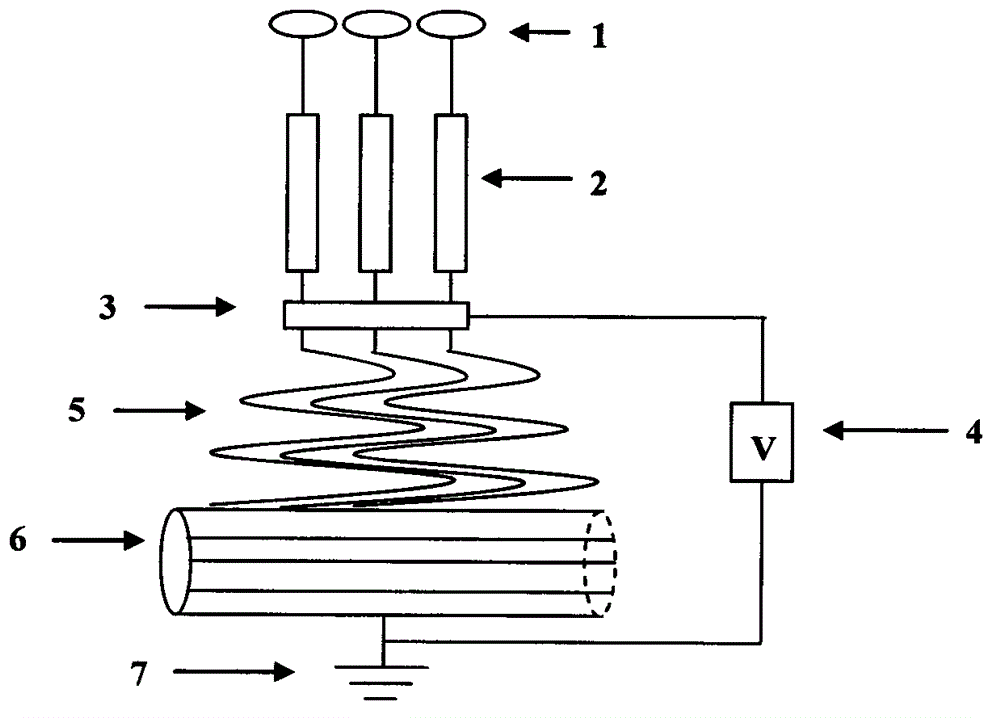

[0047] (2) The schematic diagram of the spinning equipment is shown in image 3 . Choose a multi-spinneret device, the number of spinnerets is 3, respectively take about 5mL of the above-mentioned rubber solution, put them into their respective liquid storage devices, remove the air, connect the spinneret (inner diameter 0.5mm) at the same time, and put the spinneret Connect to the positive terminal of the high voltage power supply. A grounded rotating frame with a diameter of 10 cm and a leng...

Embodiment 3

[0051] (1) trans-1,4-butadiene-isoprene copolymer rubber (relative molecular mass 70000g / mol, trans 1,4 structure mole fraction Greater than 90%) solution 300mL. Wherein the solvent is selected from chloroform, toluene, N,N-dimethylformamide mixed solvent with a volume ratio of 8:1:1. The prepared solution was stirred in a constant temperature water bath at 50°C for 24 hours to obtain a uniformly dissolved and transparent solution, which was cooled to room temperature for use.

[0052] (2) The schematic diagram of the spinning equipment is shown in Figure 5 . Choose a multi-spinneret device, the number of spinnerets is 5, respectively take about 10mL of the above rubber solution, put them into their respective liquid storage devices, remove the air, connect the spinneret (inner diameter 0.5mm) at the same time, and put the spinneret Connect to the positive terminal of the high voltage power supply. A grounded rotating drum with a diameter of 10 cm and a length of 20 cm is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

| Relative molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com