Preparation method of high-melt strength polypropylene resin with long-chain branched structure characteristic

A high-melt-strength, polypropylene resin technology, applied in the field of preparation of high-melt-strength polypropylene resin, can solve the problems of high cost, practicability to be improved, and low melting point of polymers, and achieve strong strain hardening effect, melting The effect of improved body elasticity and high melt strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

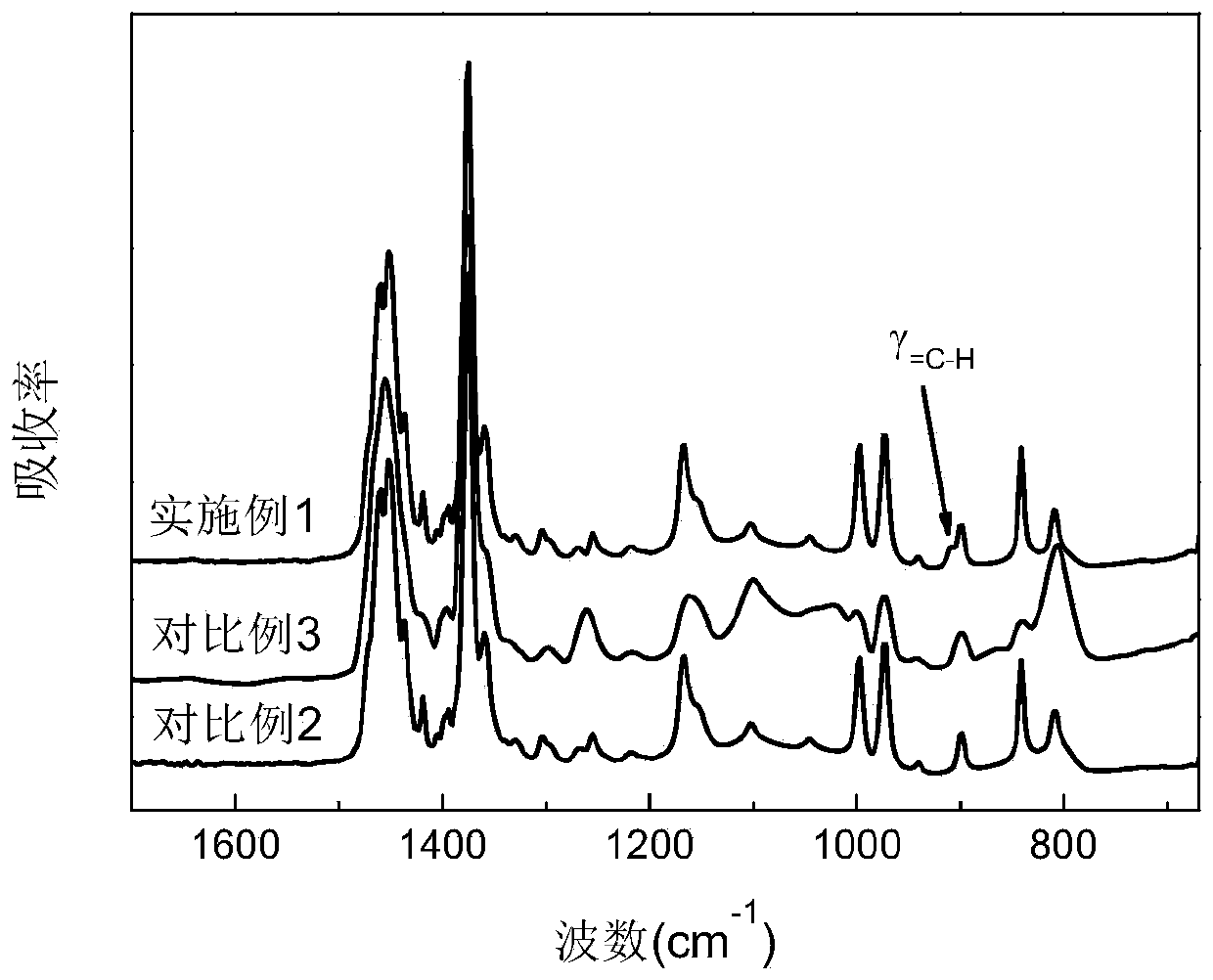

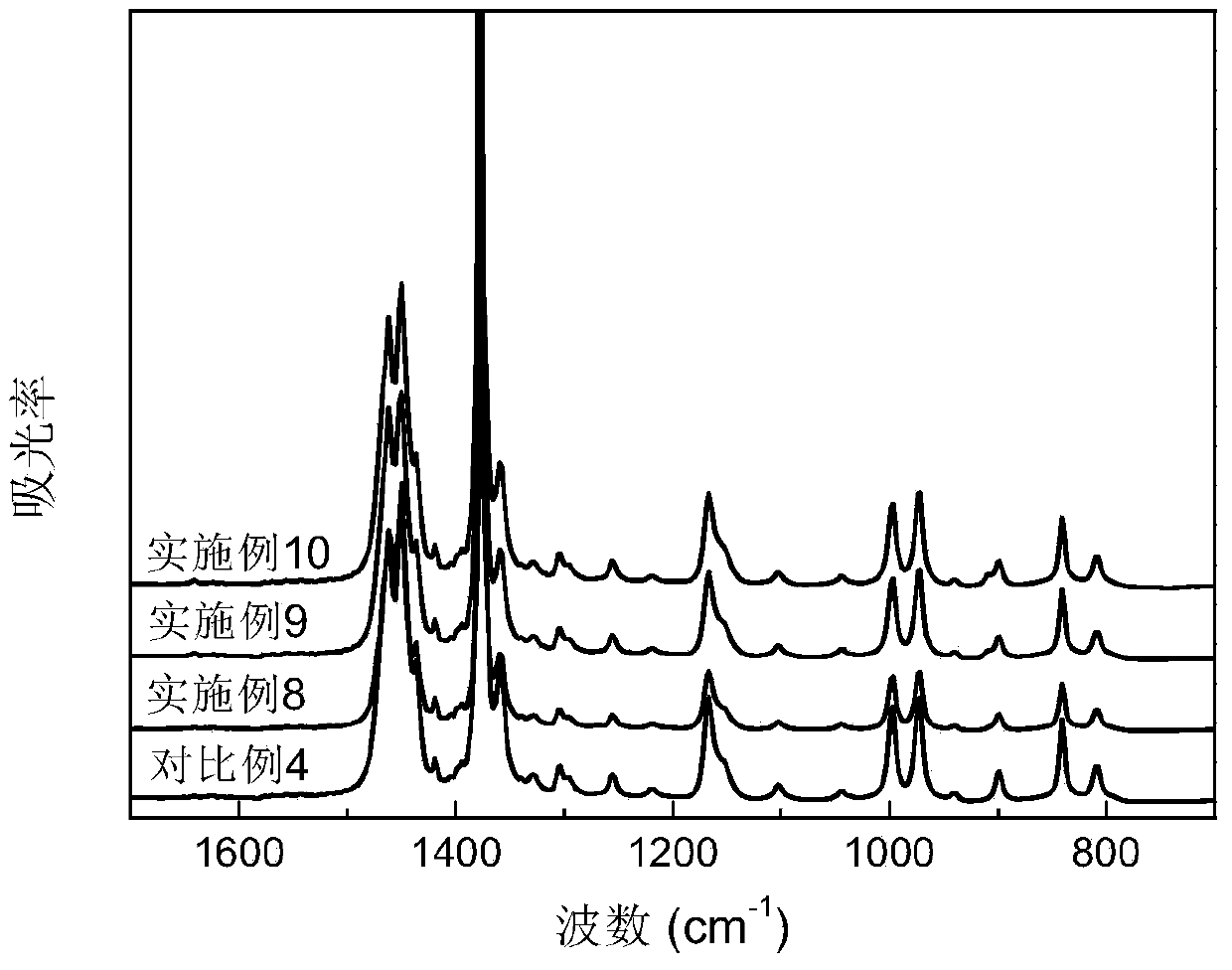

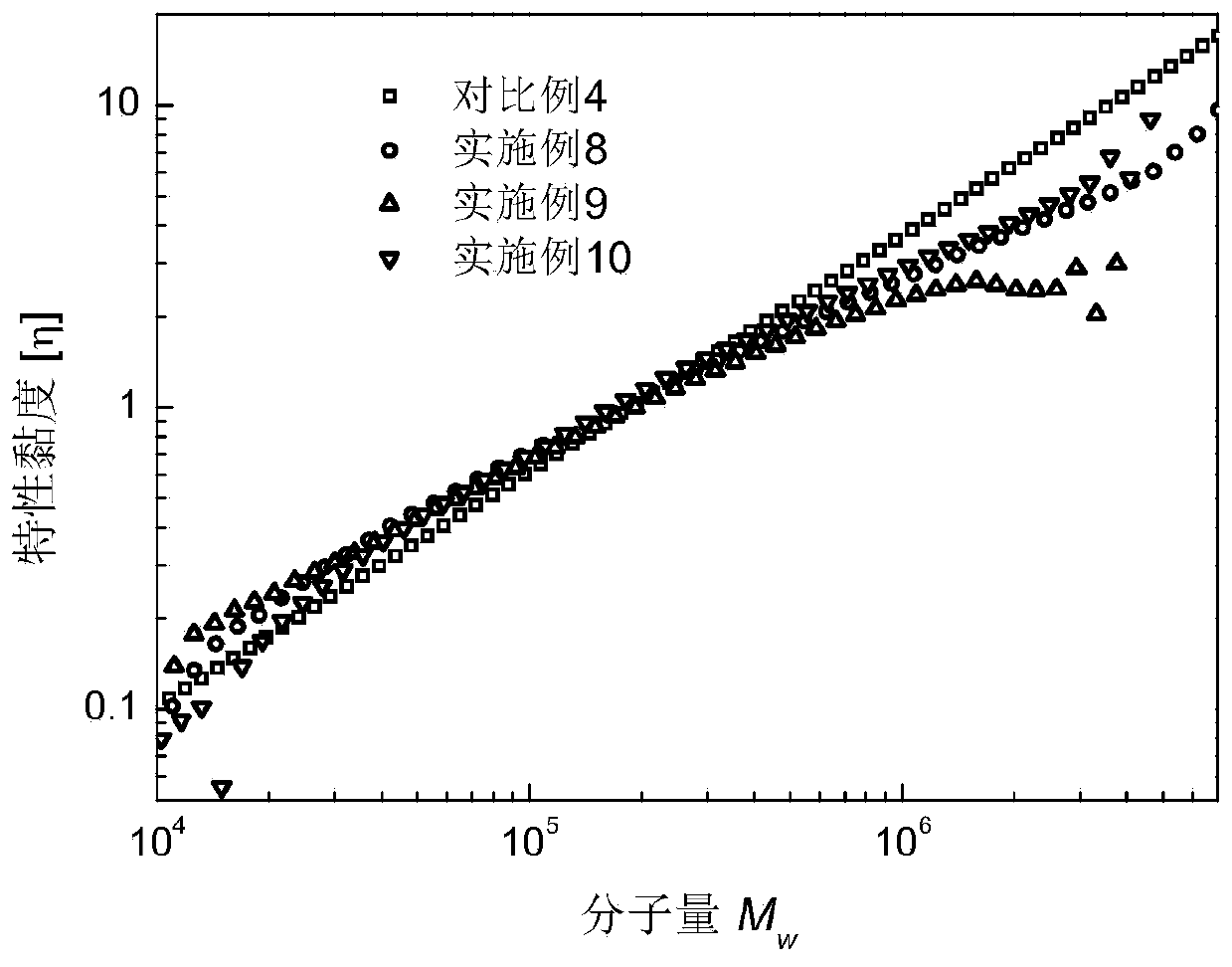

Embodiment 1

[0069] Before the polymerization starts, use high-purity nitrogen (nitrogen purity 99.99%) to replace the air and traces of water in the polymerization reactor, and inject H into the 2L polymerization reactor at normal temperature and pressure. 2 , so that the H in the polymerization reactor 2 The pressure is 0.05MPa, then sequentially add 250g of liquid propylene, 4ml of TEA solution and 14.7mg of the Ziegler-Natta catalyst prepared above, and then add 200g of liquid propylene to rinse the addition funnel to ensure that the Ziegler-Natta catalyst is completely added to the polymerization In the reaction kettle, after the feeding is completed, raise the temperature to 70°C for propylene homopolymerization for 12 minutes, and obtain a mixed solution containing a linear polypropylene resin with a linear structure in the polymerization reaction kettle; then add 55.15 mmol of 1,9-decadiene Monomer, at a temperature of 70°C, polymerize the unpolymerized liquid propylene and 1,9-dec...

Embodiment 2

[0074] Before the polymerization starts, use high-purity nitrogen (nitrogen purity 99.99%) to replace the air and traces of water in the polymerization reactor. In a 500ml dry polymerization reactor, first add 50ml of dry n-hexane, and then add the concentration of 1ml of 1.8mol / L triethylaluminum, and 24.8mg of the above-prepared Ziegler-Natta catalyst; then feed propylene gas, under the pressure of 0.4MPa, carry out the polymerization reaction at 60°C for 30 minutes, then vent the polymerization The pressure in the reaction kettle reaches an atmospheric pressure, and a linear polypropylene resin with a linear structure is obtained in the polymerization reaction kettle; 5.52mmol of dry 1,4-pentadiene monomer is added, propylene gas is introduced, and then the pressure of 0.4MPa At a temperature of 60°C, polymerize propylene monomer and 1,4-pentadiene monomer for 5 minutes to generate long-chain branched and partially cross-linked copolymerized polypropylene. After the polymeri...

Embodiment 3

[0077] Before the polymerization starts, use high-purity nitrogen (nitrogen purity 99.99%) to replace the air and traces of water in the polymerization reactor. In a 500ml dry polymerization reactor, first add 50ml of dry n-hexane, and then add the concentration of 1ml of 1.8mol / L triethylaluminum, and 24.6mg of the above-prepared Ziegler-Natta catalyst; then feed propylene gas, under the pressure of 0.4MPa, carry out the polymerization reaction at 60°C for 30 minutes, then vent the polymerization The pressure in the reaction kettle reaches one atmospheric pressure, obtains the linear polypropylene resin with linear structure in the polymerization reaction kettle; Add 16.56mmol dry 1,4-divinylbenzene monomer, pass into propylene gas, then in 0.4MPa Under pressure, at a temperature of 60°C, polymerize propylene monomer and 1,4-divinylbenzene monomer for 5 minutes to generate long-chain branched and partially cross-linked copolymerized polypropylene. After the polymerization reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com