Modified epoxy resin and preparation method thereof, as well as modified epoxy resin composition and preparation method thereof

A technology of epoxy resin and composition, applied in the field of resin, can solve the problems of poor thermal stability and low shrinkage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

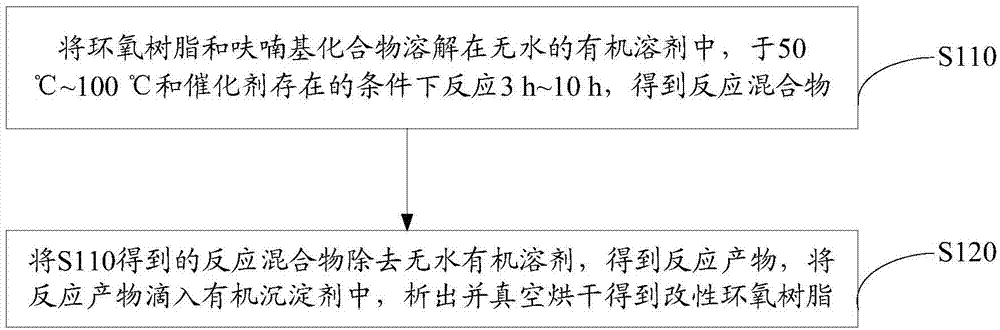

[0039] Such as figure 1 The preparation method of the modified epoxy resin of one embodiment shown comprises the steps:

[0040] S110, dissolving the epoxy resin and the furyl compound in an anhydrous organic solvent, and reacting at 50° C. to 100° C. in the presence of a catalyst for 3 h to 10 h to obtain a reaction mixture.

[0041] The epoxy resin is an epoxy resin having at least 2 epoxy groups in the molecule, and the furyl compound is a furyl compound having at least 1 active hydrogen atom in the molecule.

[0042] Epoxy resin has excellent bonding performance and mechanical properties, and has a large number of reactive groups, which is conducive to the introduction of polar groups.

[0043] Preferably, the molar ratio of active hydrogen atoms to epoxy groups is 0.6˜1.2:1.

[0044] Specifically, the epoxy resin may be at least one of bisphenol A epoxy resin, bisphenol F epoxy resin, bisphenol glycidyl ether, aliphatic glycidyl ether and novolak epoxy resin.

[0045] ...

Embodiment 1

[0067] Preparation of modified epoxy resin.

[0068] Mix 2.6g of novolac epoxy resin DEN431 and 6mL of tetrahydrofuran in a three-necked flask, stir at 65°C for 0.5h, then add 1g of furan methanol and 0.05mL of triethylamine, and react at 65°C for 8h to obtain a reaction mixture . Evaporate the obtained reaction mixture under vacuum conditions to remove tetrahydrofuran to obtain a reaction product, drop the reaction product into diethyl ether to precipitate, and dry to obtain a modified epoxy resin.

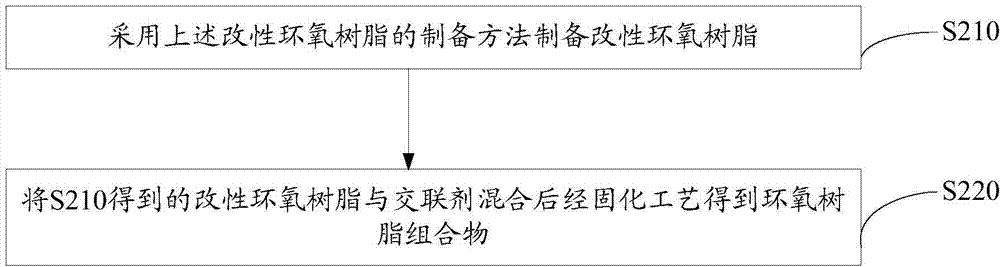

[0069] Preparation of modified epoxy resin compositions.

[0070] The obtained modified epoxy resin was dissolved in 50mL dimethylformamide, and a certain amount of N,N'-(4,4'-methylenediphenyl)bismaleimide was added, wherein the modified The molar ratio of epoxy resin to N,N'-(4,4'-methylenediphenyl)bismaleimide is 1:1, stir well and transfer it to a preheated to 60°C placed in a tetrafluoroethylene mold and dried in a vacuum oven to obtain the modified epoxy resin compositio...

Embodiment 2

[0074] Preparation of modified epoxy resin.

[0075] Mix 2.6g of novolac epoxy resin DEN431 and 6mL of tetrahydrofuran in a three-necked flask, stir at 65°C for 0.5h, then add 1g of furan methanol and 0.05mL of triethylamine, and react at 65°C for 8h to obtain a reaction mixture . Evaporate the obtained reaction mixture under vacuum conditions to remove tetrahydrofuran to obtain a reaction product, drop the reaction product into diethyl ether to precipitate, and dry to obtain a modified epoxy resin.

[0076] Preparation of modified epoxy resin compositions.

[0077] The obtained modified epoxy resin was dissolved in 50mL dimethylformamide, and a certain amount of N,N'-(4,4'-methylenediphenyl)bismaleimide was added, wherein the modified The molar ratio of epoxy resin to N,N'-(4,4'-methylenediphenyl)bismaleimide is 2:1, stir well and transfer it to a preheated to 60℃ placed in a tetrafluoroethylene mold and dried in a vacuum oven to obtain a modified epoxy resin composition D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com