All-purpose lubricating oil for motor and gear case of mini-tiller

An engine and gear box technology, applied in the field of lubricating oil, to achieve the effect of simplifying oil use, good usability and convenience for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment -

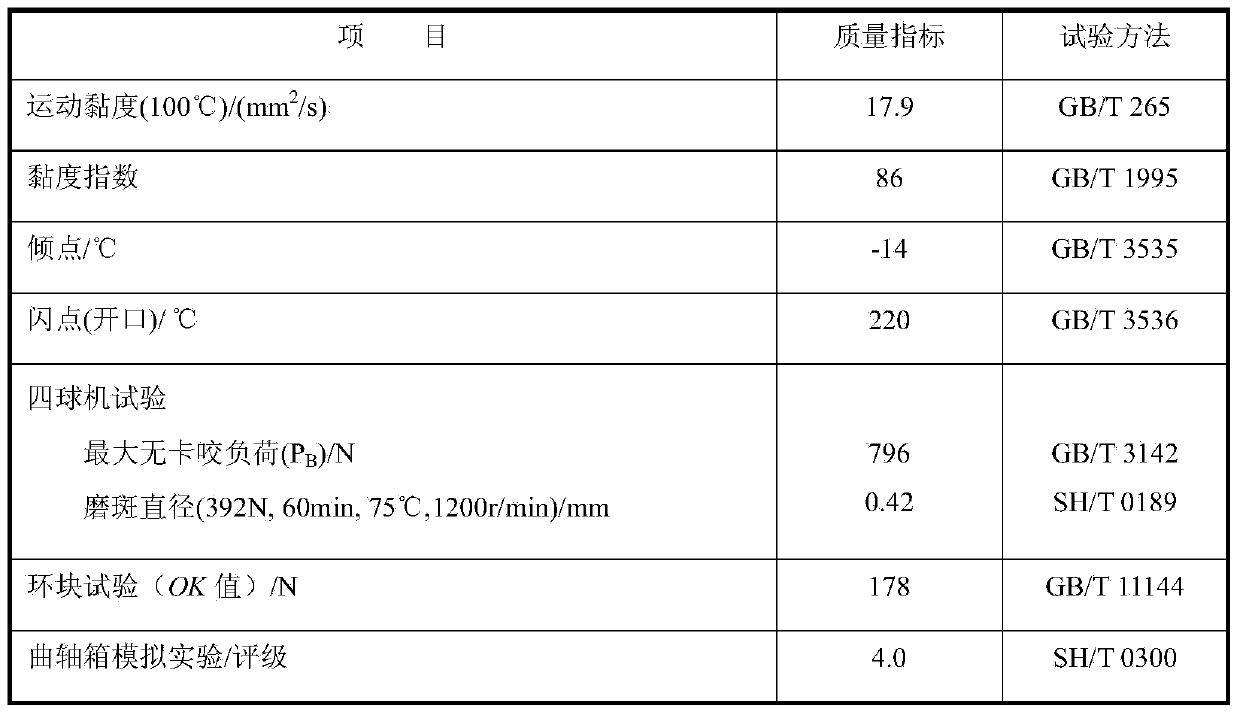

[0045]Feed by mass percentage. Type I base oil is 90.8%, the first additive - high base value synthetic calcium sulfonate is 1.5%, the second additive - high base value sulfurized alkyl phenate calcium is 3.0%, the third additive - polyisobutylene dibutylene Diimide is 1.7%, the fourth additive - thiophosphobutoctyl zinc salt is 1.3%, the fifth additive - aminothioester is 1.0%, the sixth additive - ethylene, propylene and non-conjugated di The terpolymer of olefin is 0.7%, and the seventh additive - polydimethylsiloxane is 0.0002%.

Embodiment 1

[0046] The preparation method of a kind of tillage machine engine and gear box universal lubricating oil described in embodiment one comprises the following steps:

[0047] In the first step, first heat the base oil to 50-60°C, then add the sixth additive ethylene, propylene and non-conjugated diene terpolymer according to the mass percentage and stir evenly to obtain the first mixture;

[0048] In the second step, the first additive high alkali value synthetic calcium sulfonate, the second additive high alkali value sulfurized alkylphenate calcium, the third additive, polyisobutylene bis-succinimide, the Four kinds of additives, thionyl octyl zinc salt and the fifth additive aminothioester are added to the first mixture, and fully stirred to obtain the second mixture;

[0049] The third step is to disperse the seventh additive polydimethylsiloxane in kerosene under stirring according to the percentage by mass. The relative mass ratio of polydimethylsiloxane to kerosene is 1:2...

Embodiment 2

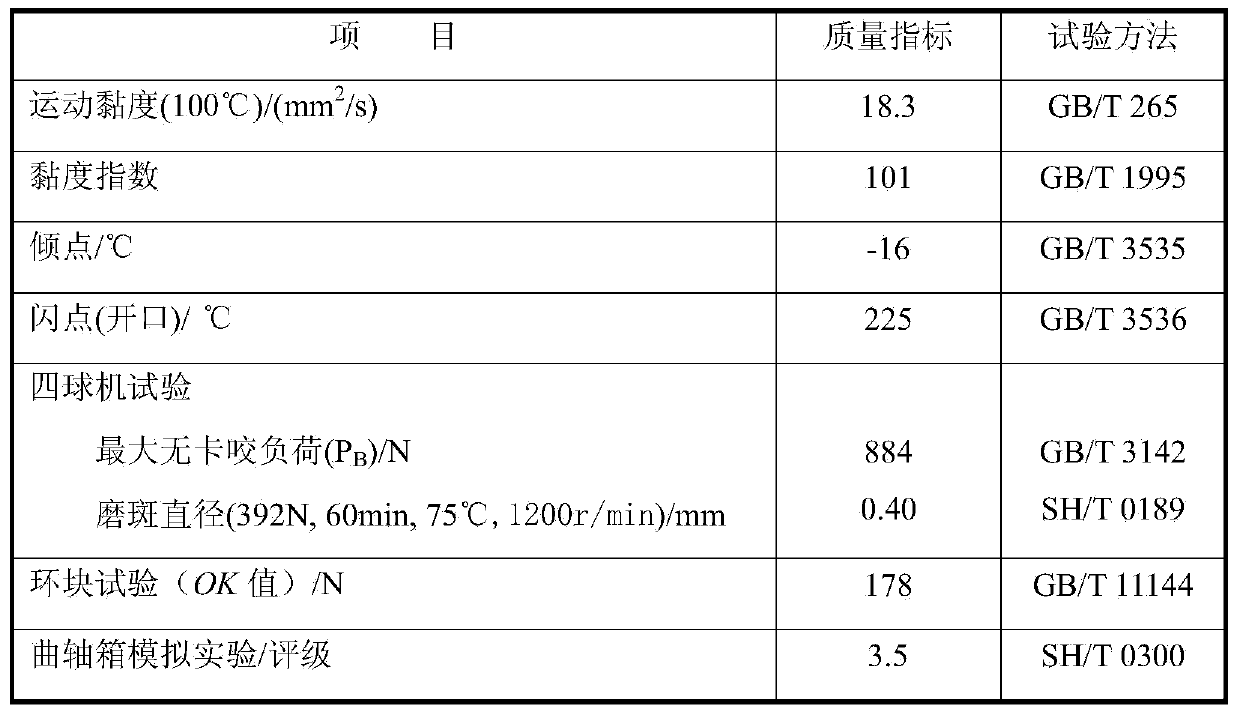

[0054] Feed by mass percentage. Type II base oil is 92.6%, the first additive - high base value synthetic calcium sulfonate is 1.2%, the second additive - high base value sulfurized alkyl phenate calcium is 2.4%, the third additive - polyisobutylene dibutylene Diimide is 1.0%, the fourth additive - thiophosphobutoctyl zinc salt is 1.0%, the fifth additive - aminothioester is 1.0%, the sixth additive - ethylene, propylene and non-conjugated di The terpolymer of olefin is 0.5%, and the seventh additive - polydimethylsiloxane is 0.0001%.

[0055] The preparation method of a kind of tillage machine engine and gear box universal lubricating oil described in embodiment two is the same as embodiment one.

[0056] Table 2 The measured results of key indicators in Example 2

[0057]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com