Lithium supplementing composite diaphragm and preparation method thereof

A composite diaphragm and lithium replenishment technology, applied in the field of lithium replenishment composite diaphragm and its preparation, can solve the problems of low initial charge and discharge efficiency of lithium ion batteries, decrease of reversible capacity of lithium ion batteries, consumption of active lithium ions, etc., so as to avoid thermal runaway. problems, improving rate performance and cycle performance, and the effect of increasing gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

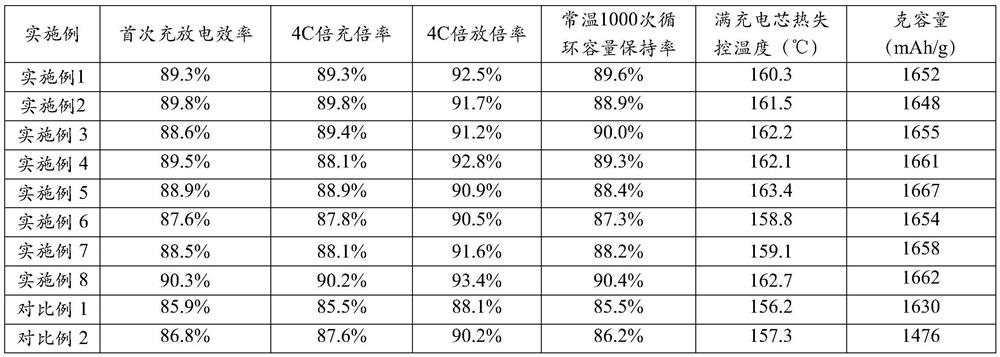

Examples

preparation example Construction

[0032] In another aspect, a method for preparing the above-mentioned lithium-supplementing composite separator is provided, comprising the steps of:

[0033] S1: Add the lithium-replenishing active material and the binder into the solvent, and mix uniformly in an environment with a humidity of less than 1% and a temperature of 15-30°C to obtain a lithium-replenishing slurry;

[0034] S2: Coating the lithium-replenishing slurry on the side of the base film facing the positive electrode, and drying at a temperature of 35-100° C., to prepare a lithium-replenishing composite membrane.

[0035] In the embodiment of the present invention, the solvent in step S1 is selected from one of water or N-methylpyrrolidone (NMP).

Embodiment 1

[0038] A lithium-replenishing composite diaphragm, which includes a polyethylene base film, the thickness of the base film is 9 μm, the side of the base film facing the positive electrode is coated with a lithium-replenishing layer, the thickness of the lithium-replenishing layer is 1.5 μm, and the lithium-replenishing layer includes lithium-replenishing active materials and binder, the lithium supplement active material is Li with a particle size of 100nm 2 TiO 3 , where Li 2 TiO 3 The mass percentage is 80%, the binder is sodium hydroxymethyl cellulose, and the mass percentage of sodium hydroxymethyl cellulose is 20%.

[0039] The preparation method of the above-mentioned lithium-supplementing composite diaphragm comprises the following steps:

[0040] S1: 200g of Li with a particle size of 100nm 2 TiO 3 Add 800g of water solvent and stir for 30min, then add 50g of hydroxymethylcellulose sodium and continue to stir for 2.5h, and mix evenly in an environment with a humid...

Embodiment 2

[0043] Based on Example 1, the only difference is that in Example 2, the lithium supplement active material is Li 4 SiO 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com