Coating device for PVDF diaphragm for lithium battery

A coating device and lithium battery technology, which can be applied to devices for coating liquid on the surface, battery pack components, and cleaning methods using tools, etc., which can solve the problems of production process interruption, low coating efficiency, and inability to continue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

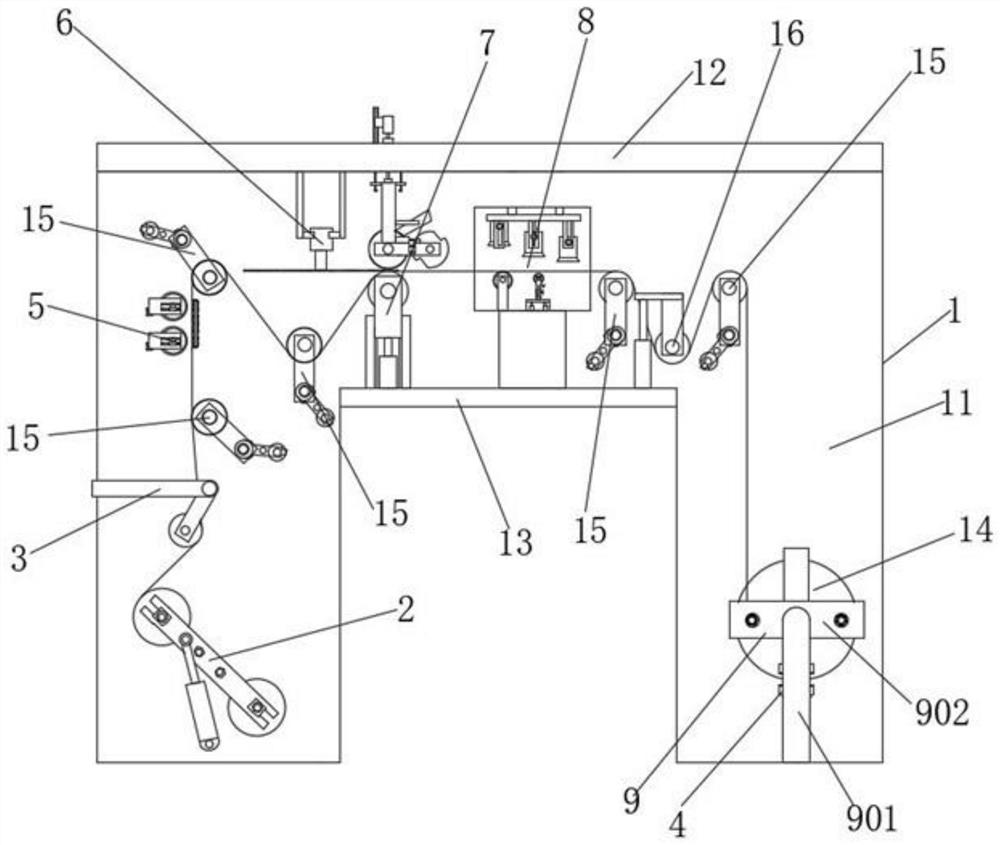

[0046] Attached below Figure 1-16 The embodiments of the present invention are described in detail.

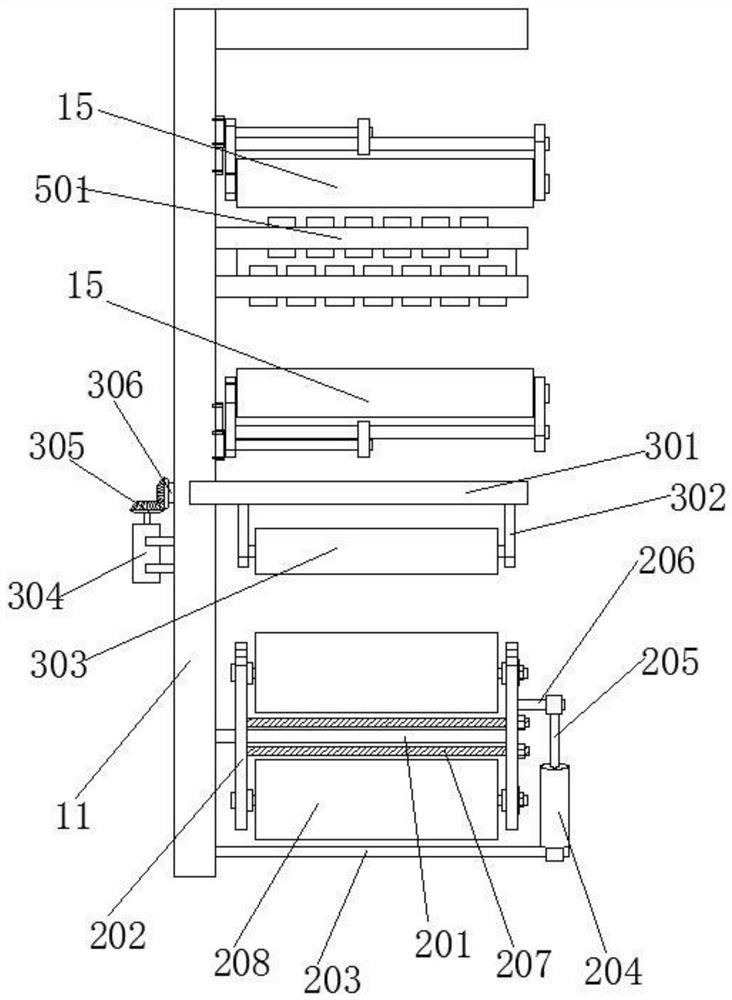

[0047] A coating device for a PVDF diaphragm for a lithium battery, comprising a frame 1 on which an unwinding mechanism 2, a swinging mechanism 3, a cleaning mechanism 5, a coating conversion mechanism 6, and a coating mechanism are arranged according to the advancing direction of the diaphragm 7. Drying mechanism 8, cutting mechanism 4 and winding mechanism 9. The frame 1 includes a vertical plate 11, a top plate 12 and a support plate 13 vertically installed on the vertical plate 11. Several vertical plates are provided on the vertical plate 11 for guiding Guide roller 15 in the direction of membrane transport.

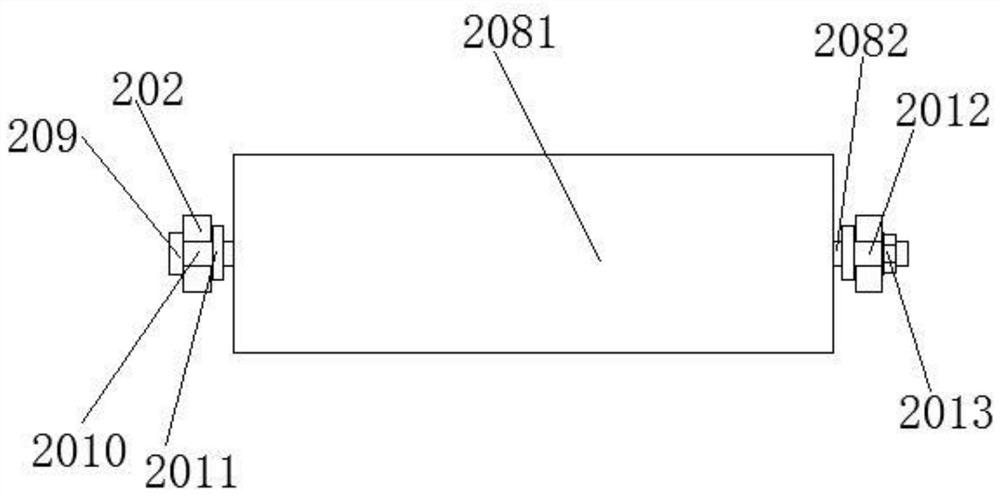

[0048] The unwinding mechanism 2 comprises a rotating rod 201 and a support rod 203 fixed on the vertical plate 11, two mounting plates 202 are rotated on the rotating rod 201, and two connecting rods 207 are connected between the two mounting plates 202. The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com