Porous composite diaphragm for lithium ion secondary battery and preparation method thereof

A technology for secondary batteries and composite diaphragms, which is applied to battery components, circuits, electrical components, etc., and can solve the problem of less pore structure in coatings, difficulty in ensuring effective dispersion and adhesion of inorganic particles, uneven pore size distribution and dense coatings, etc. Problems, to achieve the effect of ensuring adhesion, excellent safety performance, and small thermal shrinkage

Inactive Publication Date: 2011-05-18

FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

View PDF4 Cites 66 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The coating liquid does not contain a dispersant or coupling agent for the binder and electrically insulating oxide particles, so it is difficult to ensure the effective dispersion of the inorganic particles and the adhesion between them and the binder, and the patent describes The coating liquid is coated on the polyethylene-based film and then directly dried to remove the solvent to obtain a coating. This method of directly relying on volatilization of the solvent to form a porous structure of the coating has less pore structure, uneven pore size distribution and easy formation of a dense coating. Layer problem, difficult to consider as effective method of forming porous coating composition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

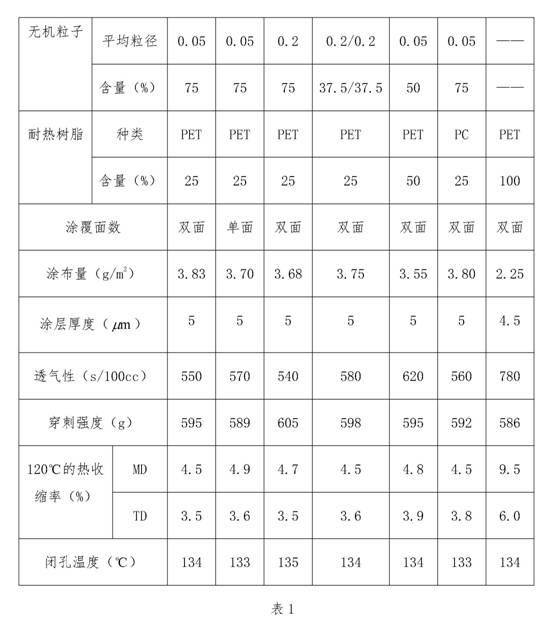

The invention discloses a porous composite diaphragm for a lithium ion secondary battery and a preparation method thereof. The porous composite diaphragm comprises a polyethylene microporous membrane; and single surface or two surfaces of the polyethylene microporous membrane is / are covered with a heat-resistant coating layer containing heat-resistant resin and inorganic non-conductive insulated particles. Due to use of the composite diaphragm, the mechanical performance, the aperture and the porosity of a base layer can be controlled, the thickness, the aperture and the porosity of the coating layer can be similarly controlled. The diaphragm has the advantages of low hole-closing temperature, high diaphragm-breaking temperature and less heat shrinkage; and the diaphragm used for the lithium ion secondary battery has excellent safety performance.

Description

technical field [0001] The patent of the present invention relates to the manufacturing technology of battery diaphragm, especially a kind of porous composite diaphragm for lithium-ion secondary battery and its preparation method. Background technique [0002] Rechargeable lithium-ion secondary batteries are a new generation of rechargeable batteries born in the early 1990s in the last world. They have the advantages of high working voltage, high capacity density, long cycle life, no memory effect, no pollution, and fast charging and discharging. Therefore, it has become a hot spot in the research of new power supply technology in recent years. A common lithium-ion secondary battery is composed of electrodes, electrolyte, polymer separator, and outer casing. Lithium-ion batteries can be divided into three categories: commonly used liquid lithium-ion batteries, new polymer lithium-ion batteries and the latest development of power lithium-ion batteries. In the structure o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M2/16

CPCY02E60/12Y02E60/10

Inventor 邱均峰王松钊吴耀根蔡朝辉

Owner FOSHAN JINHUI HIGH TECH OPTOELECTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com