Ultrathin coated diaphragm and preparation method thereof

A coating and diaphragm technology, applied in the direction of structural parts, electrical components, battery pack parts, etc., can solve the problems of irreversibility, affecting high-power charging and discharging, and unsatisfactory safety, so as to achieve good discharge capacity and improve ion conductivity The effect of increasing the interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

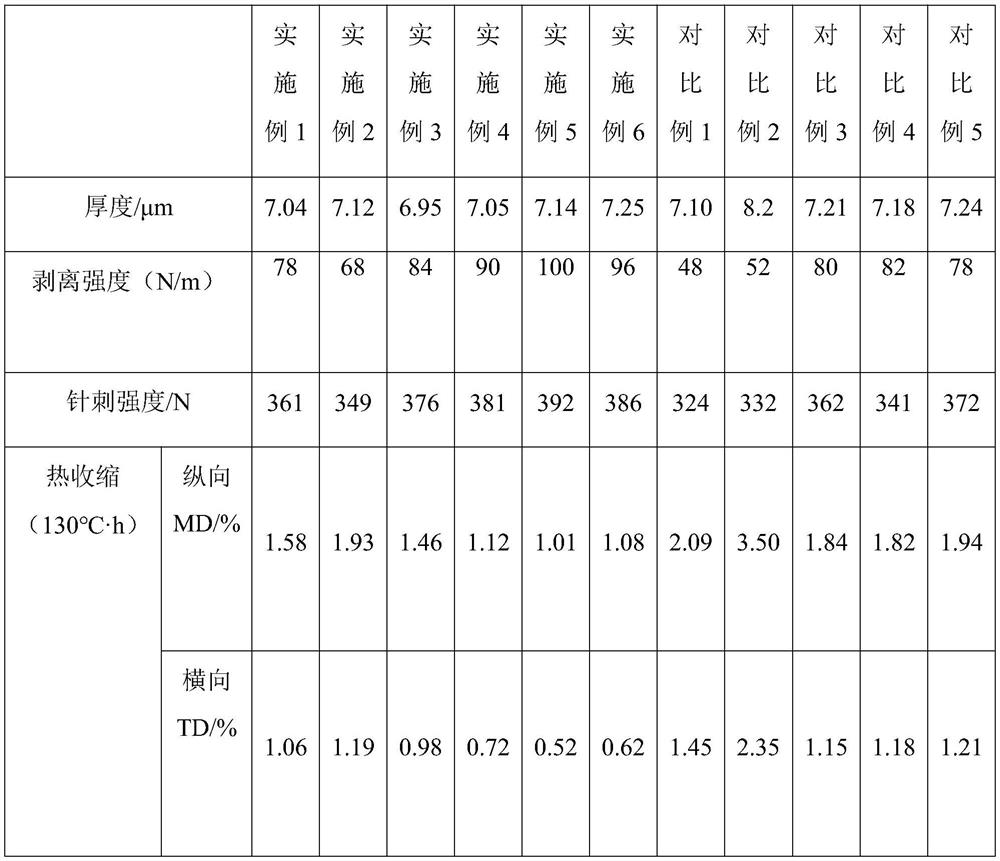

Examples

Embodiment 1

[0048] S1: Mix 60 parts of ultrapure water and 0.35 parts of dispersant according to the parts by mass, and then add 30 parts of small-particle alumina, after stirring, add 0.7 parts of multi-walled carbon nanotubes and stir evenly; Add 5 parts of thickener and mix evenly; grind the obtained slurry through a sand mill, and finally add 4 parts of binder and 0.1 part of wetting agent and stir to obtain a coating slurry;

[0049] The dispersing agent is polyacrylic acid, the thickening agent is hydroxymethyl cellulose, the binder is polyethanol, and the wetting agent is isomerized tenol alkoxylate; the D50 of the alumina powder is 0.4 μm; The diameter of the wall carbon nanotubes is 30nm and the length is 1μm;

[0050] The preparation of carboxylic acid-modified multi-walled carbon nanotubes includes the following steps: adding 1 part by weight of multi-walled carbon nanotubes to 22 parts by weight of sulfuric acid, stirring at 130° C. for 16 hours, washing with deionized water, ...

Embodiment 2

[0053] S1: Mix 60 parts of ultrapure water and 0.35 parts of dispersant according to the parts by mass, and then add 20 parts of small-particle alumina, after high-speed stirring, add 0.9 parts of multi-walled carbon nanotubes and stir evenly; Then add 5 parts of thickener and mix it evenly; grind the obtained slurry through a sand mill, and finally add 4 parts of binder and 0.1 part of wetting agent and stir evenly to obtain a coating slurry;

[0054] The dispersing agent is polyacrylic acid, the thickening agent is hydroxymethyl cellulose, the binder is polyethanol, and the wetting agent is isomeric tenol alkoxylate; the D50 of the alumina powder is 0.5 μm; The diameter of the wall carbon nanotube is 50nm and the length is 1μm;

[0055] The preparation of carboxylic acid-modified multi-walled carbon nanotubes includes the following steps: adding 1 part by weight of multi-walled carbon nanotubes to 22 parts by weight of sulfuric acid, stirring at 130° C. for 16 hours, washing...

Embodiment 3

[0058] S1: Mix 60 parts of ultrapure water and 0.35 parts of dispersant according to parts by mass, and then add 40 parts of small-particle alumina, after high-speed stirring, add 0.6 parts of multi-walled carbon nanotubes and stir evenly; Then add 5 parts of thickener and mix it evenly; grind the obtained slurry through a sand mill, and finally add 4 parts of binder and 0.1 part of wetting agent and stir evenly to obtain a coating slurry;

[0059] The dispersing agent is polyacrylic acid, the thickening agent is hydroxymethyl cellulose, the binder is polyethanol, and the wetting agent is isomeric tenol alkoxylate; the D50 of the alumina powder is 0.5 μm; The diameter of the wall carbon nanotube is 60nm and the length is 2μm;

[0060] The preparation of carboxylic acid-modified multi-walled carbon nanotubes includes the following steps: adding 1 part by weight of multi-walled carbon nanotubes to 22 parts by weight of sulfuric acid, stirring at 130° C. for 16 hours, washing wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com