Threaded hollow revolution type travelling wave ultrasound motor

An ultrasonic motor, rotary type technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. The relative movement of the diaphragm and other problems can achieve the effect of large hollow diameter and large output torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

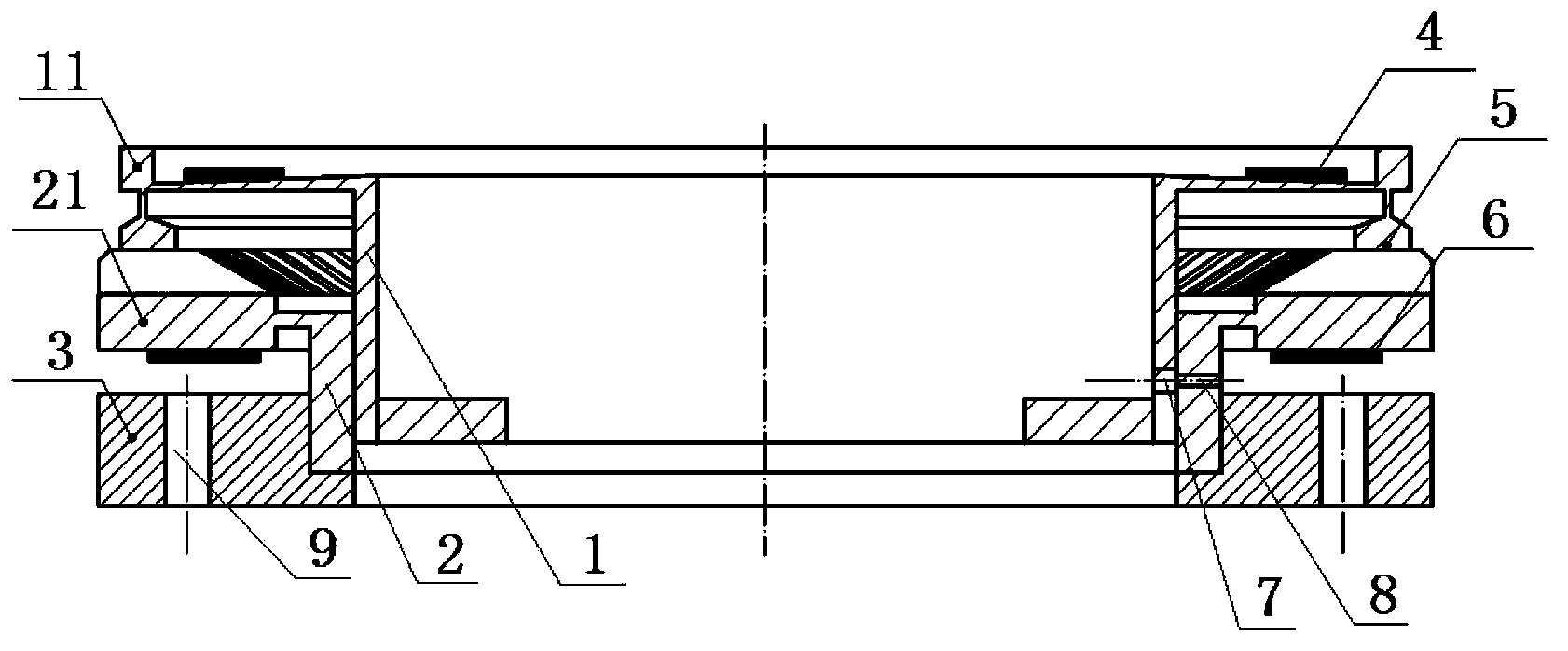

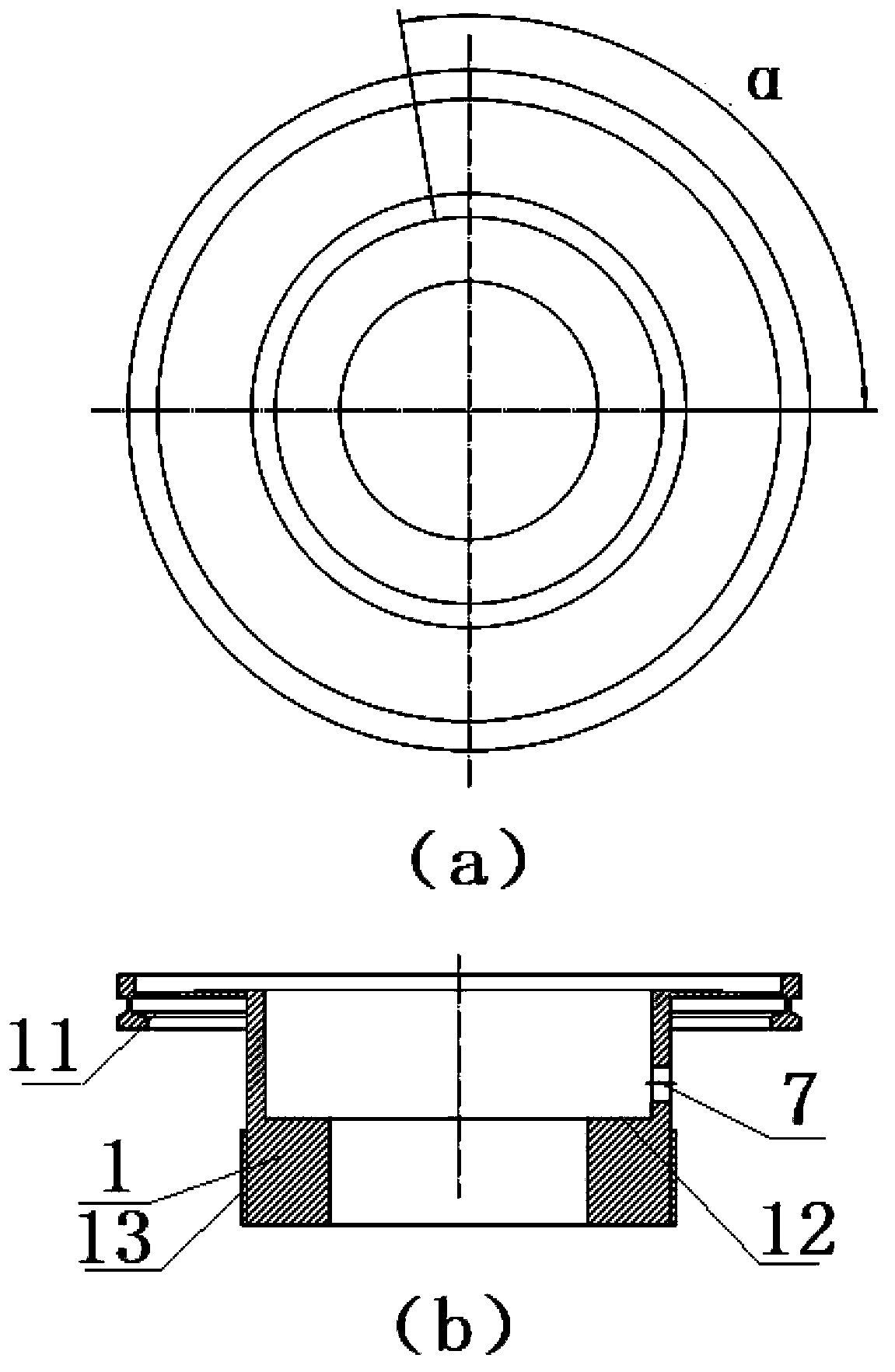

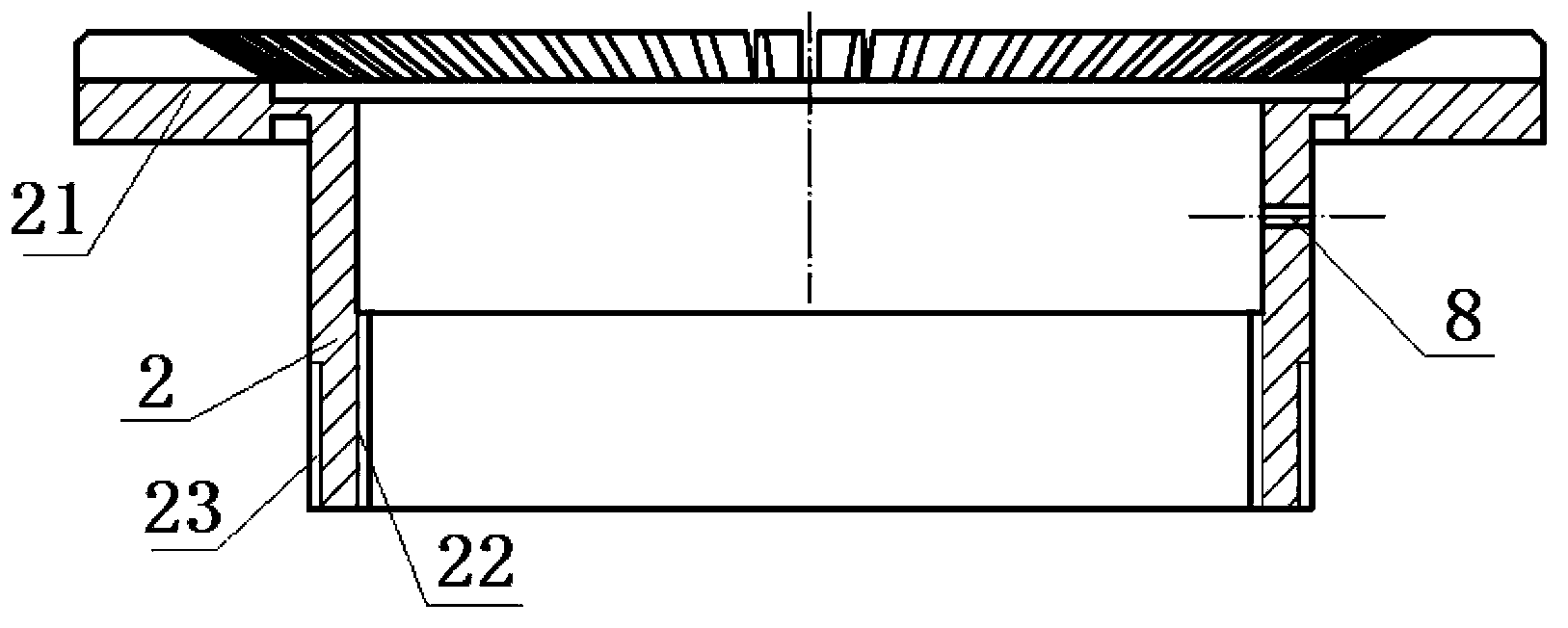

[0024] A threaded hollow rotary traveling wave ultrasonic motor of this embodiment is as follows: Figure 1-4 As shown, it is used to adjust the diaphragm. The diaphragm includes a fixed diaphragm and a moving diaphragm with a connecting rod. This embodiment includes a base, a stator shaft and a rotor shaft. The stator shaft and the rotor shaft are both along the The axis is hollow, and the rotor shaft is placed in the cavity of the stator shaft. At the same time, the outer wall of the rotor shaft is threadedly connected with the inner wall of the stator shaft. The rotor shaft is a flexible rotor shaft with a flexible deformation structure; one end of the stator shaft It is fixedly connected with the base, and the other end extends outwards to set the stator annular flange, and the end of the rotor shaft adjacent to the stator annular flange extends outwards to set the rotor annular flange; the stator shaft is fixed on the inner side of one end of the base and is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com