Diaphragm containing organic-inorganic coating for lithium battery and preparation method of same

An inorganic coating and lithium battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of battery cycle performance and safety performance degradation, inorganic particles without mechanical strength, positive and negative electrode material corrosion damage, etc. , to achieve good rate and long-term cycle stability, improve the safety of the battery interface, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

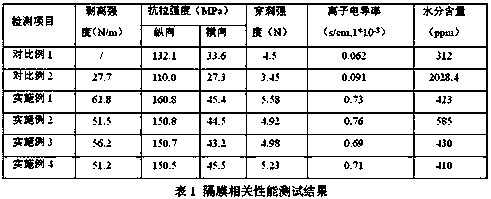

Examples

Embodiment 1

[0030] (1) First weigh 100g of THF solvent into a 250mL beaker, then quickly weigh 2g of tea polyphenols into the above THF solvent, stir with a magnetic stirrer under heating at 60°C until the tea polyphenols are completely dissolved to prepare tea polyphenols / THF solution, add 25gAl to the above solution 2 O 3 Placed in an ultrasonic bath, there are no precipitated particles at the bottom of the inclined beaker;

[0031] (2) Then take 5g of cyclopentyl isocyanate and add it to the above mixture, and react with the hydroxyl and carboxyl groups on the ceramic surface for 3 hours under ultrasonic conditions to obtain the isocyanate-functionalized ceramic composite mixture, which is then washed with ethanol and dried by suction Obtain isocyanate functionalized ceramic composite;

[0032] (3) Weigh 100g of a mixed solvent of water and ethanol (water: ethanol = 1:1), disperse the prepared isocyanate-functionalized ceramic composite in the mixed solvent under ultrasonic conditio...

Embodiment 2

[0035] (1) First weigh 100g of NMP solvent in a 250mL beaker, then quickly weigh 1g of ferulic acid and add it to the above NMP solvent, stir with a magnetic stirrer under heating at 60°C until the ferulic acid is completely dissolved to prepare ferulic acid / NMP solution; add 20g SiO to the above solution 2 Placed in an ultrasonic bath, ultrasonic frequency 60HZ, under ultrasonic conditions until SiO 2 It is basically modified completely, and no precipitated particles can be seen at the bottom of the solution;

[0036] (2) Then take 2g of 3-thiophene isocyanate and add it to the above mixed solution, and react with the hydroxyl and carboxyl groups on the ceramic surface under ultrasonic conditions for 3 hours to obtain a mixed solution of isocyanate-functionalized ceramic composites, which is then washed with ethanol, suction filtered and dried to obtain Isocyanate functionalized ceramic composites;

[0037] (3) Weigh 100g of a mixed solvent of water and ethanol (water:ethan...

Embodiment 3

[0040] (1) First, weigh 100g of glycerol solvent in a 250mL beaker, then quickly weigh 15g of chlorogenic acid and add it to the above glycerin solvent, stir with a magnetic stirrer under heating at 60°C until the chlorogenic acid is completely dissolved to form a chlorogenic acid. / Glycerol solution; add 50g of titanium oxide to the above solution and place it in an ultrasonic bath, ultrasonic frequency 60HZ, under ultrasonic conditions until the titanium oxide is basically modified completely, and no precipitated particles can be seen at the bottom of the solution;

[0041] (2) Then take 20 g of vinyl isocyanate and add it to the above mixed solution, and react with the hydroxyl and carboxyl groups on the surface of titanium oxide under ultrasonic conditions for 3 hours to obtain a mixed solution of isocyanate-functionalized titanium oxide composite, which is then washed with ethanol Suction filtration and drying to obtain isocyanate functionalized titanium oxide composite; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com