Self-supporting diaphragm, preparation method thereof, composite pole piece and secondary battery

A self-supporting, diaphragm technology, used in secondary batteries, battery pack parts, non-aqueous electrolyte battery electrodes, etc. Stability, improve practicability, reduce the effect of short positive and negative electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

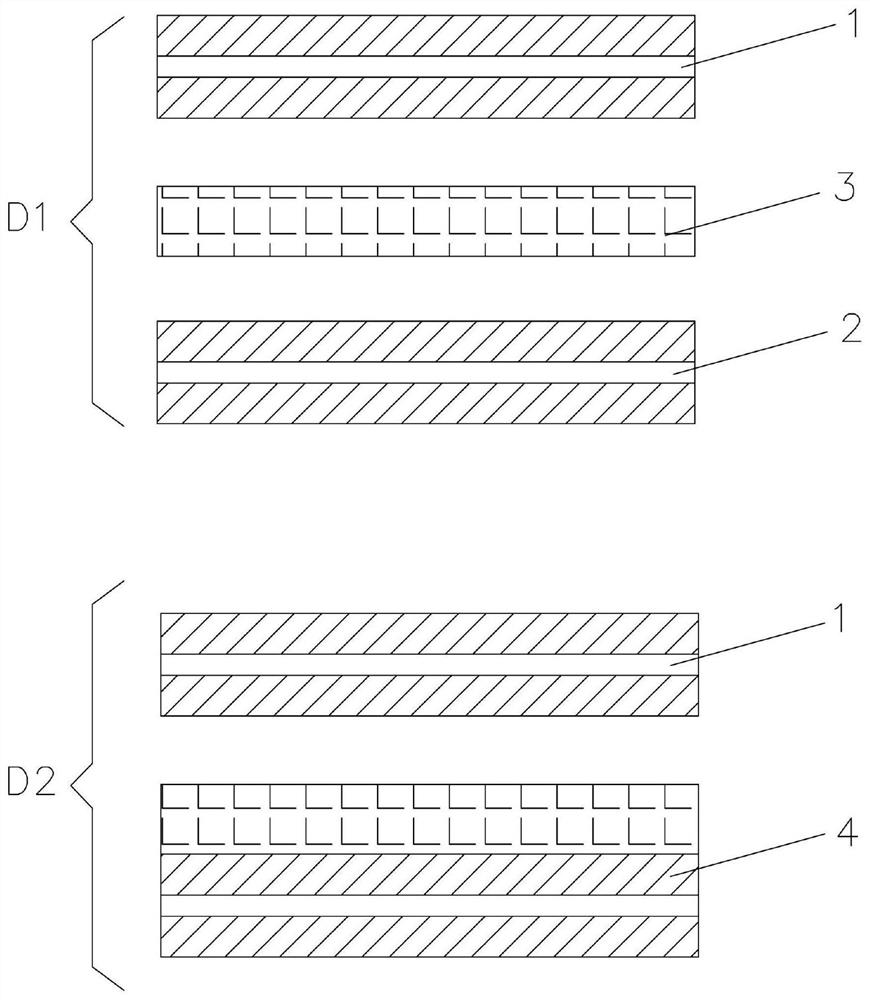

[0036] A method for preparing a self-supporting diaphragm 3, comprising the following steps:

[0037] Step (A): adding the ionic liquid into the first solvent and stirring evenly to obtain the first solution;

[0038] Step (B): adding lignocellulose to the second solution and grinding to obtain the second solution;

[0039] Step (C): adding the binder into the third solvent and stirring evenly to obtain the third solution;

[0040] Step (D): adding the second solution into the first solution and stirring evenly, adding the third solution and stirring evenly to obtain a mixed slurry; the prepared mixed slurry has a solid content of 40%.

[0041] Step (E): coating the mixed slurry on the surface of the carrier and drying to obtain the self-supporting membrane 3 .

[0042] Wherein, in step (B), a ball mill jar is used for grinding, the ball-to-material ratio for grinding is 50:1, and the rotation speed is 1032r / min.

[0043] Among them, the ionic liquid is [BMIM]BF 4 (1-butyl...

Embodiment 2

[0048] The difference with embodiment 1 is:

[0049] The weight ratio of ionic liquid, lignocellulose and binder is 50 parts: 40 parts: 10 parts.

[0050] The rest are the same as in Embodiment 1, and will not be repeated here.

Embodiment 3

[0052] The difference with embodiment 1 is:

[0053] The weight ratio of the ionic liquid, lignocellulose and binder is 40 parts: 50 parts: 10 parts.

[0054] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com