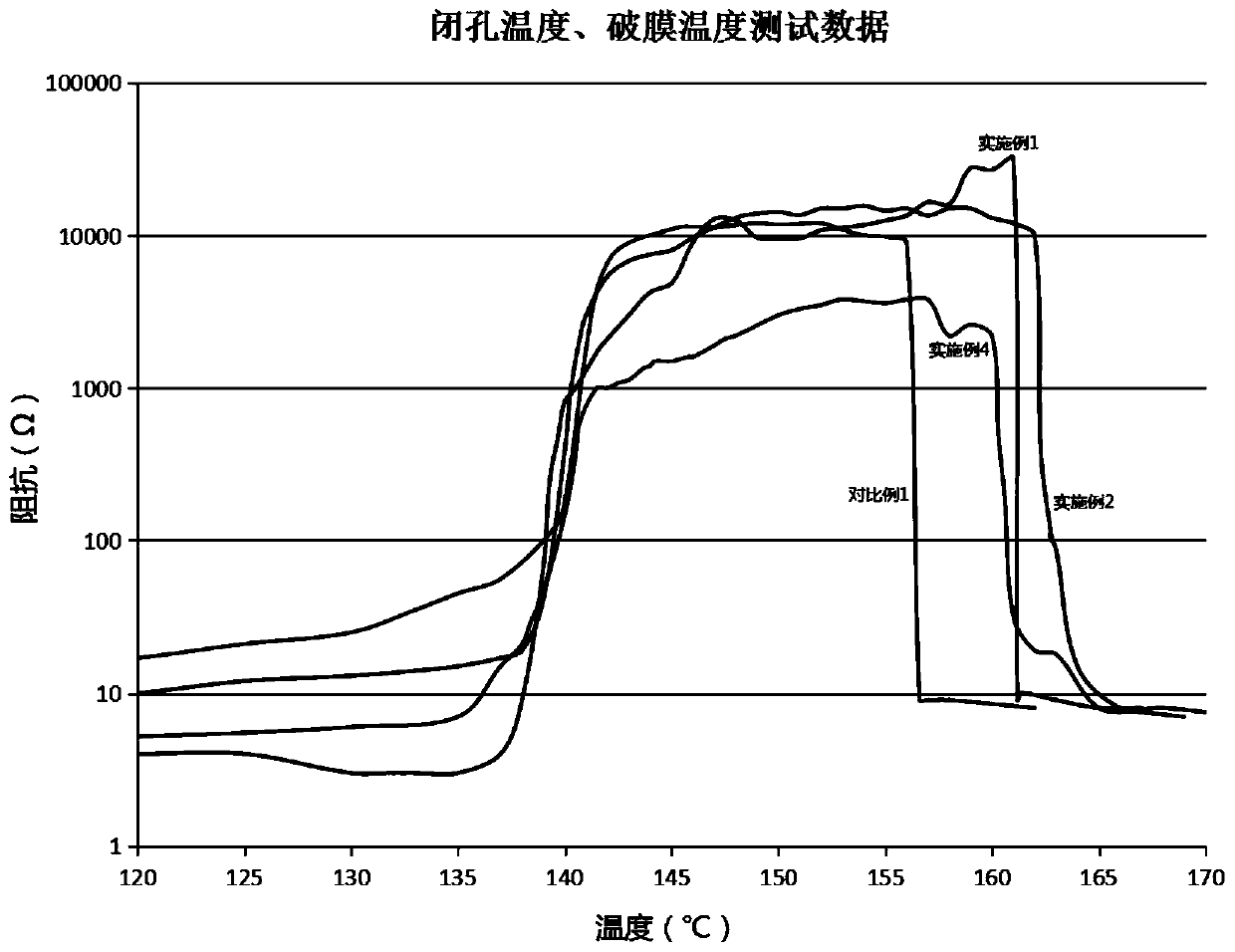

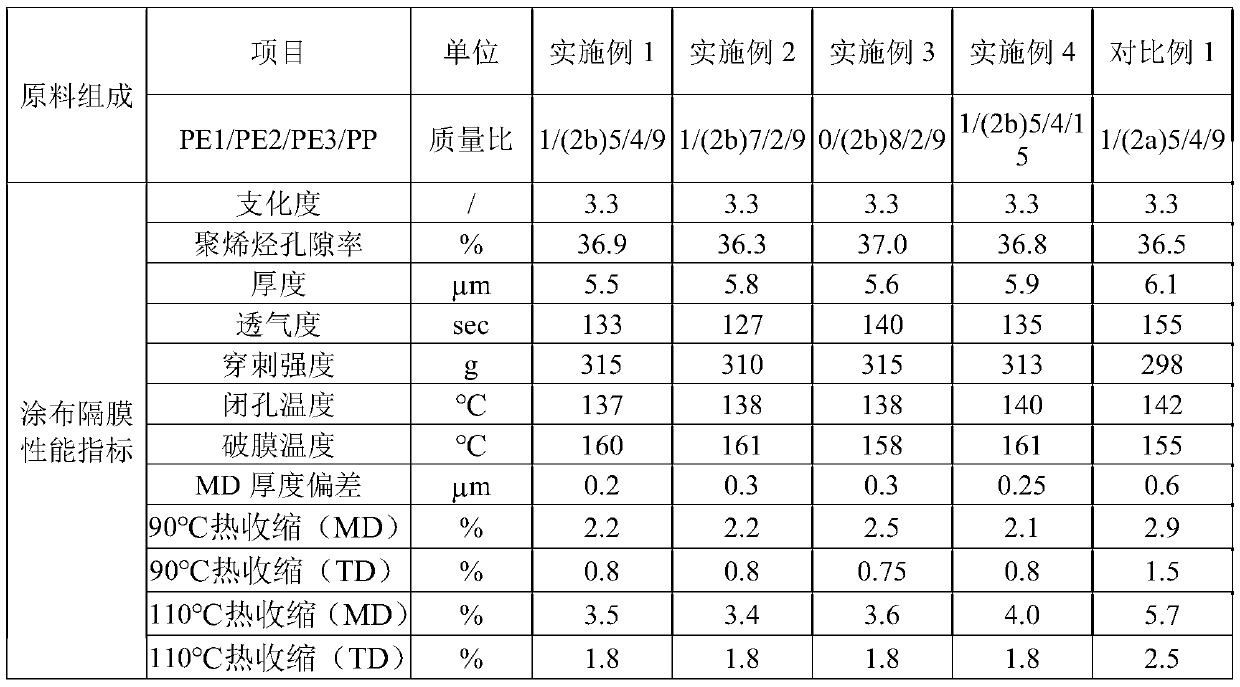

Low-pore closing high-diaphragm splitting polyolefin diaphragm and preparation method thereof

A polyolefin membrane, polyethylene technology, applied in structural parts, electrical components, battery pack components and other directions, can solve the problems of low closed-cell temperature characteristics, affecting the uniformity of mixing, high film breaking temperature characteristics, etc. Duration, reduction of grain boundary defects, effect of high film breaking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First, branched polyethylene (PE2a) with a melting point of 125°C and a branching degree of 3.3 is mixed with a compound containing methacrylate-perfluorophenyl azide, and the azide group is activated by ultraviolet radiation to form an active azide compound, and linked to branched polyethylene through covalent bonds. Then the perfluorophenyl azide grafted branched polyethylene is dissolved in the cyclohexane solvent, and by ultrasonic treatment for about 0.5h, under anaerobic conditions, 0.3wt% triethylaluminum is added as an initiator, and The solution is heated to 70° C., propylene monomer is passed through, and reacted at this temperature for 5 hours to obtain polypropylene grafted branched polyethylene.

[0030] a. Ingredients melting: Polyethylene with a melting point of 109°C (denoted as PE1), polypropylene grafted branched polyethylene with a melting point of 125°C (denoted as PE2b), and polyethylene with a melting point of 135°C (denoted as PE3) , Polypropylen...

Embodiment 2

[0039] Embodiment 2 differs from Embodiment 1 in that: PE1, PE2b, PE3, and PP are arranged in a mass ratio of 1:7:2:9.

Embodiment 3

[0041] Embodiment 3 differs from Embodiment 1 in that: PE1, PE2b, PE3, and PP are arranged in a mass ratio of 0:8:2:9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com