Patents

Literature

33results about How to "Reduce grain boundary defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

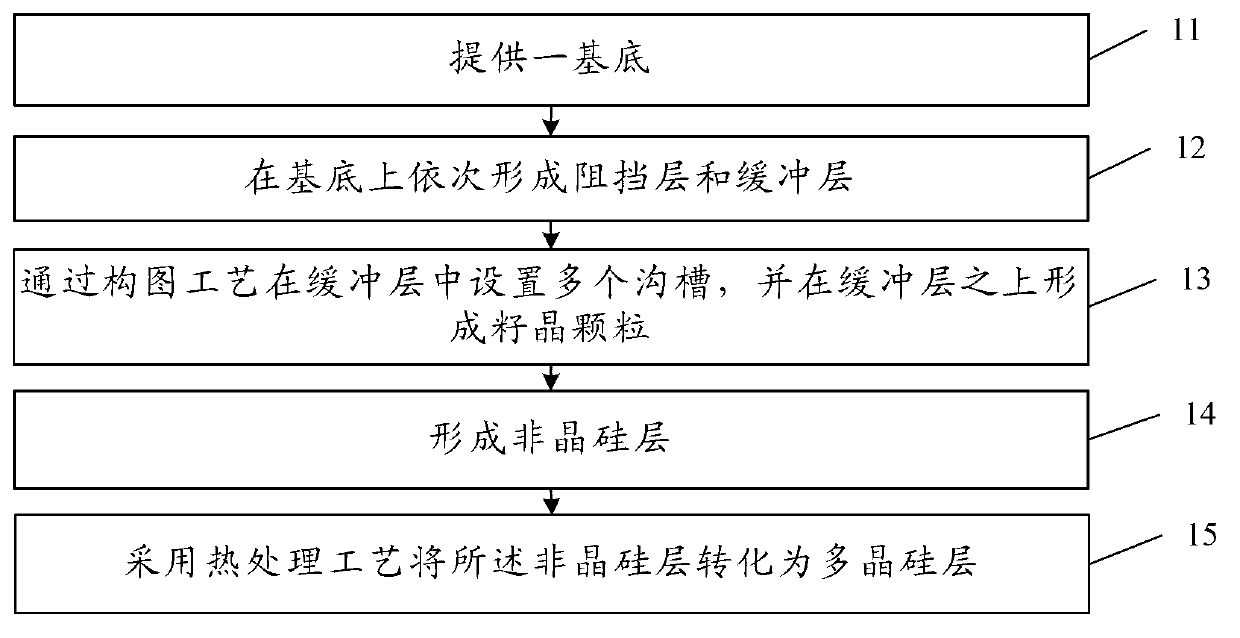

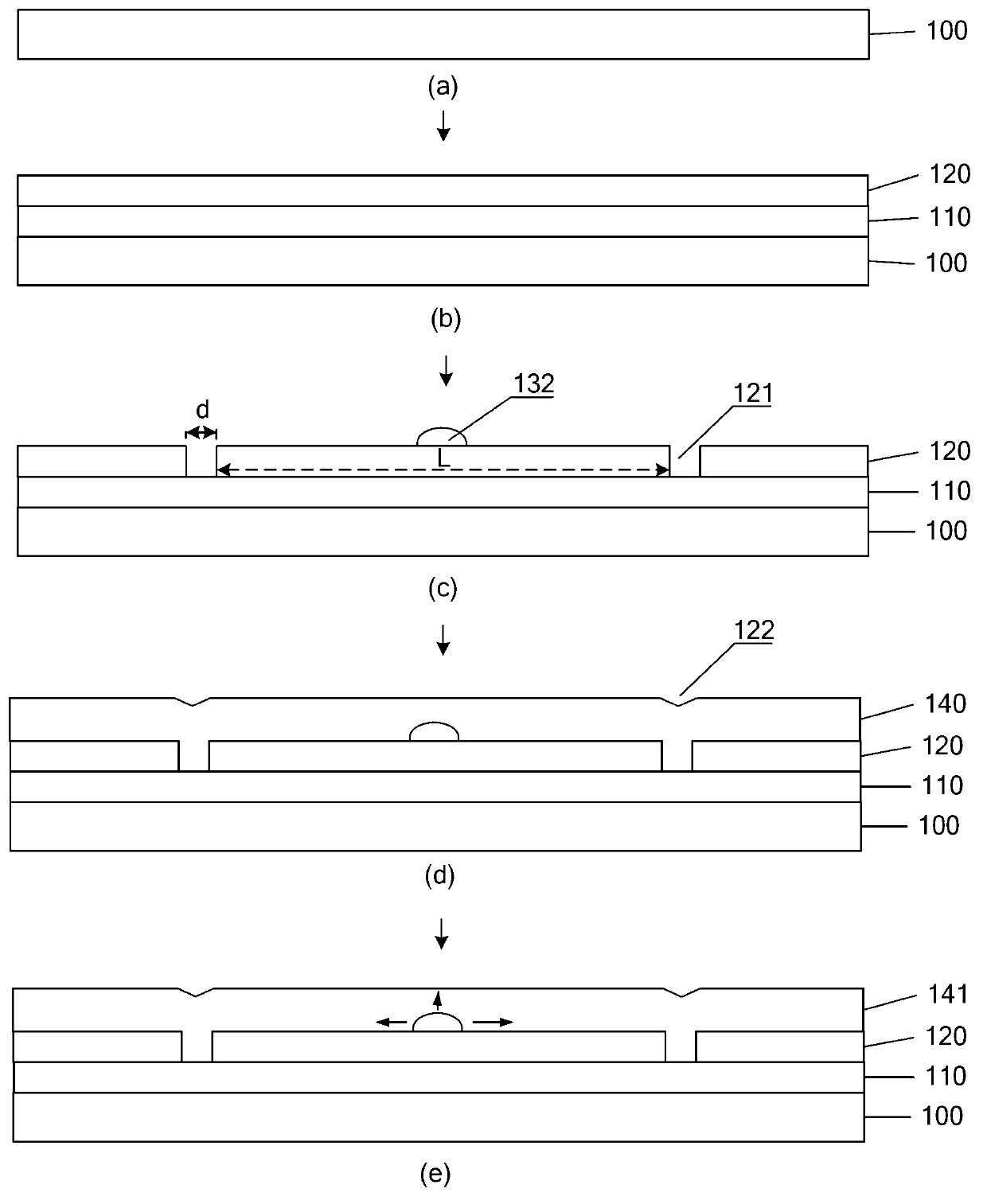

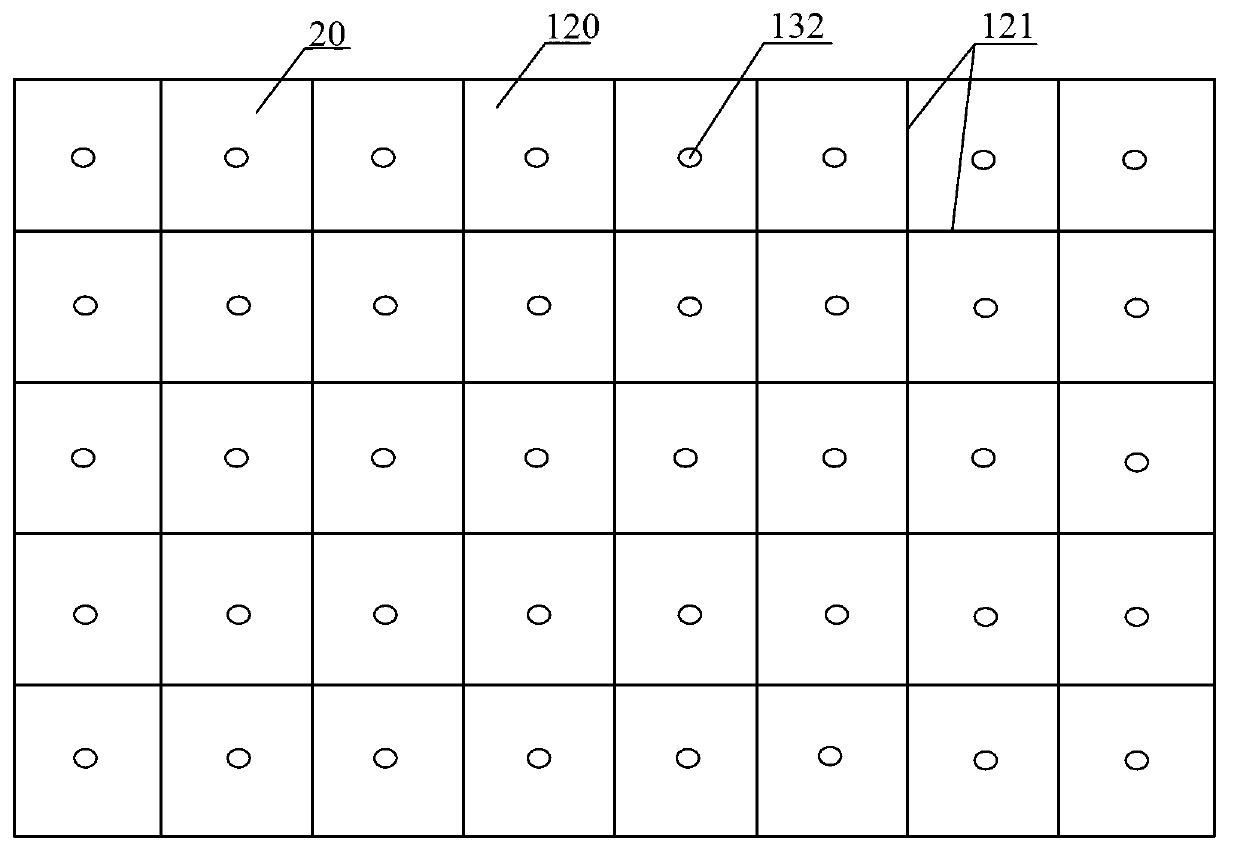

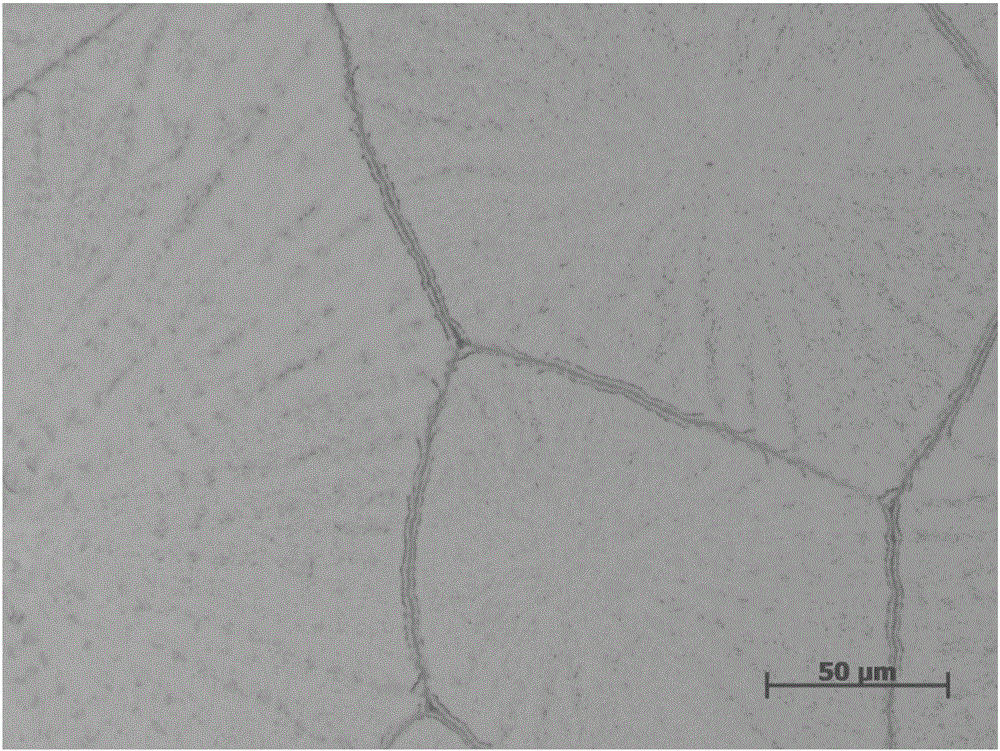

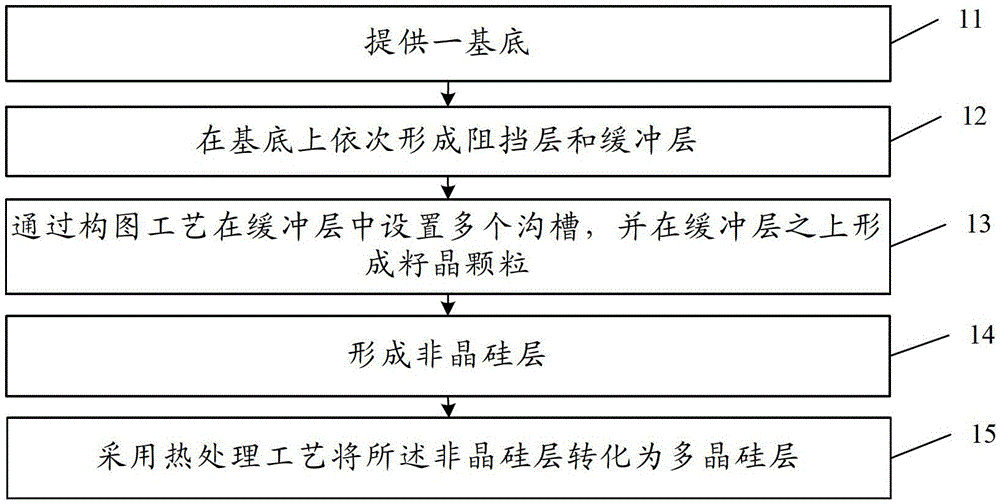

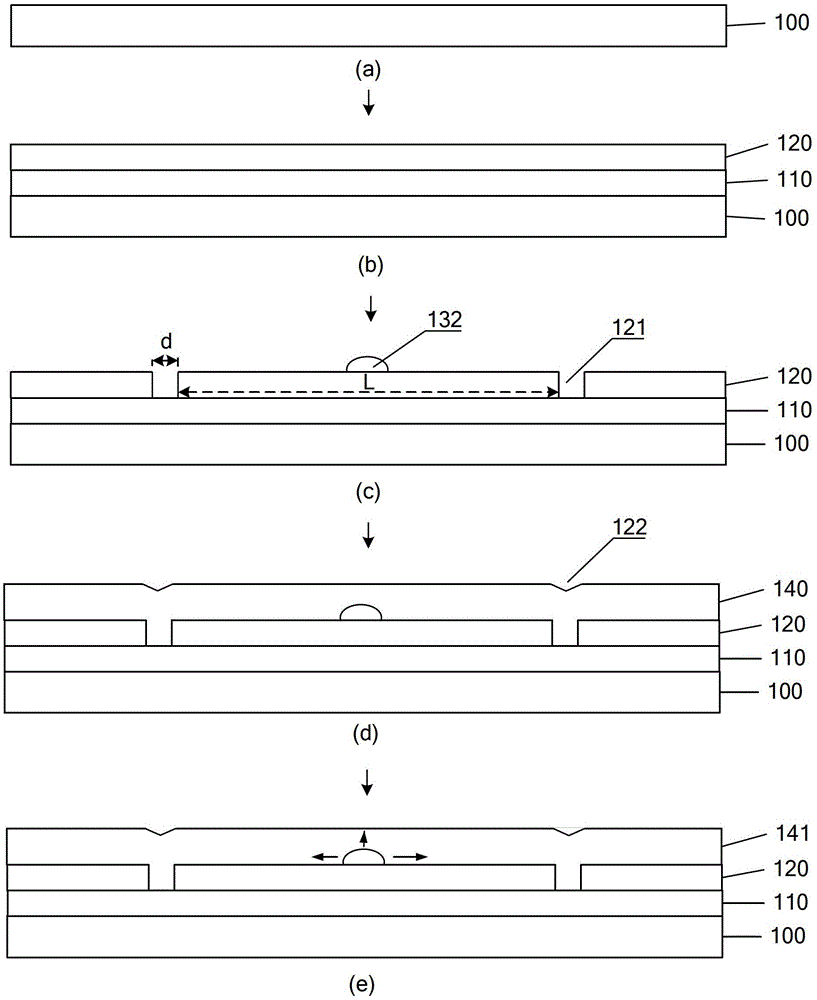

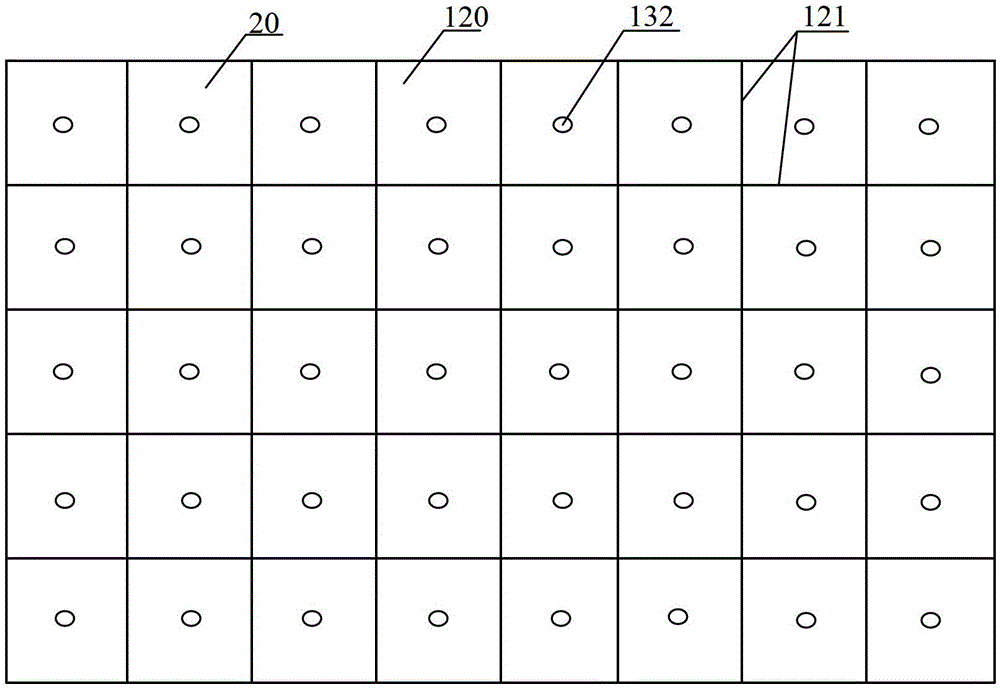

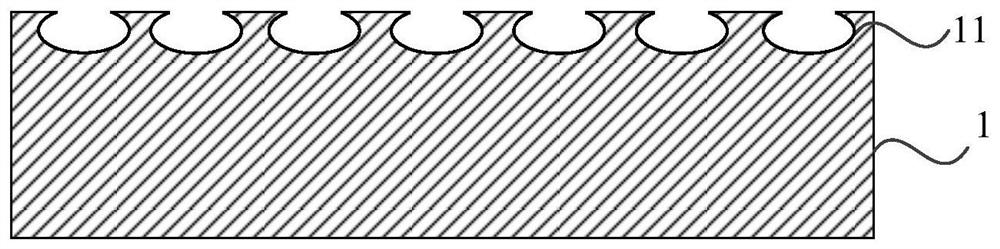

Manufacturing method of polycrystalline silicon layer and polycrystalline silicon thin film transistor and manufacturing method thereof

ActiveCN103219228AIncrease crystallization rateUniform grainTransistorSolid-state devicesAmorphous siliconComposition process

The invention discloses a manufacturing method of a polycrystalline silicon layer and a polycrystalline silicon thin film transistor and a manufacturing method thereof, and relates to the field of displaying. According to the manufacturing methods, a crystallization rate of a formed polycrystalline silicon layer is high, crystalline grains are uniform, crystal boundary defects are little, thus electrics properties of the polycrystalline silicon thin film transistor can be improved, and reliability of the polycrystalline silicon thin film transistor is improved. The manufacturing method of the polycrystalline silicon layer includes the steps that a substrate is provided; a barrier layer and a buffer layer are sequentially formed on the substrate; multiple groves are arranged in the buffer layer through a picture composition process, and seed crystals are formed on the buffer layer; an amorphous silicon layer is formed on the buffer layer provided with the grooves and the seed crystals; and the amorphous silicon layer is converted into the polycrystalline silicon layer through adoption of a heating processing process. The manufacturing method of the polycrystalline silicon layer and the polycrystalline silicon thin film transistor and the manufacturing method of the polycrystalline silicon thin film transistor are used for improving quality of polycrystalline silicon films.

Owner:BOE TECH GRP CO LTD +1

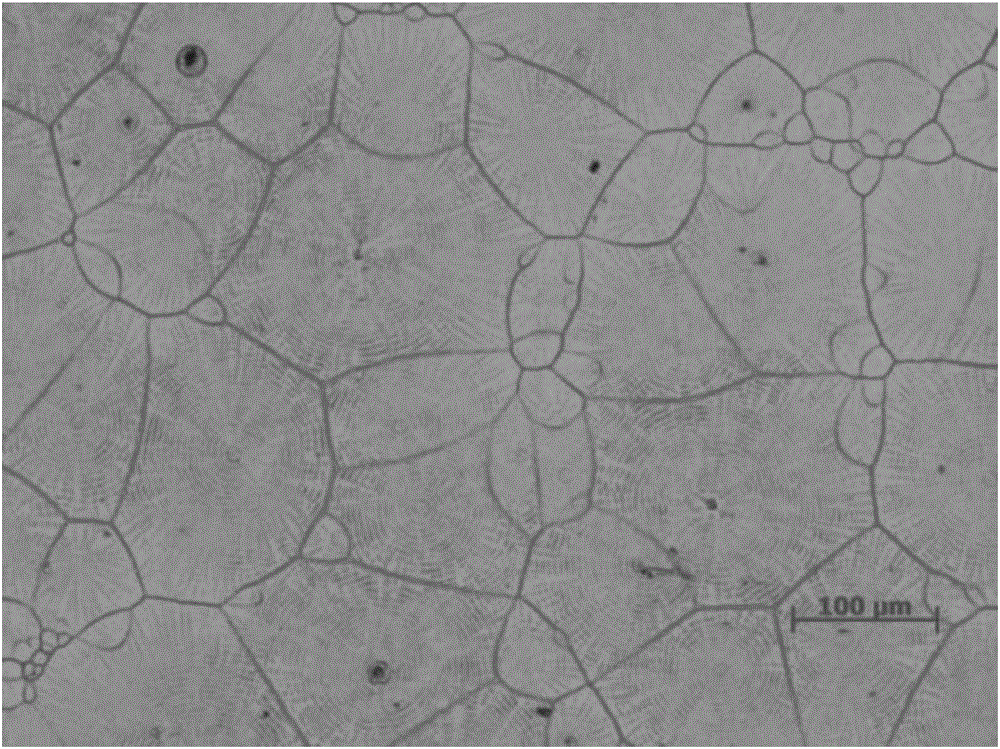

Large grain organic and inorganic hybrid perovskite film preparation method

ActiveCN106159088AEasy to controlEasy preparation of controlled substrate temperatureSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisSolar battery

The invention discloses a large grain organic and inorganic hybrid perovskite film preparation method, belonging to the perovskite type solar battery and correlated photoelectric semiconducting material field, and can prepare a uniform and compact large grain film through the steps of configuration of an organic and inorganic hybrid perovskite precursor solution, stirring and heating, spin coating, annealing, etc. The method requires no spin coating in a multistep approach, ca easily control the temperature of a room temperature substrate, has no strict requirements on an annealing and cooling rate, and can manufacture a film efficiently. The method realizes virtual grain film growth through adjusting the grain dimension of a perovskite light-absorption layer, thereby reducing grain inner defects, and increasing the carrier transport efficiency; in addition, the method controls grain boundary defects, greatly improves perovskite crystal film environment stability, and enhances perovskite thin-film device performances. A perovskite type virtual monocrystalline film prepared in the low temperature solution method can assemble hysteresis free, efficient and stable perovskite type solar batteries and correlated film transistor, electroluminescent and laser emission photoelectric semiconductor devices.

Owner:NANJING UNIV OF TECH

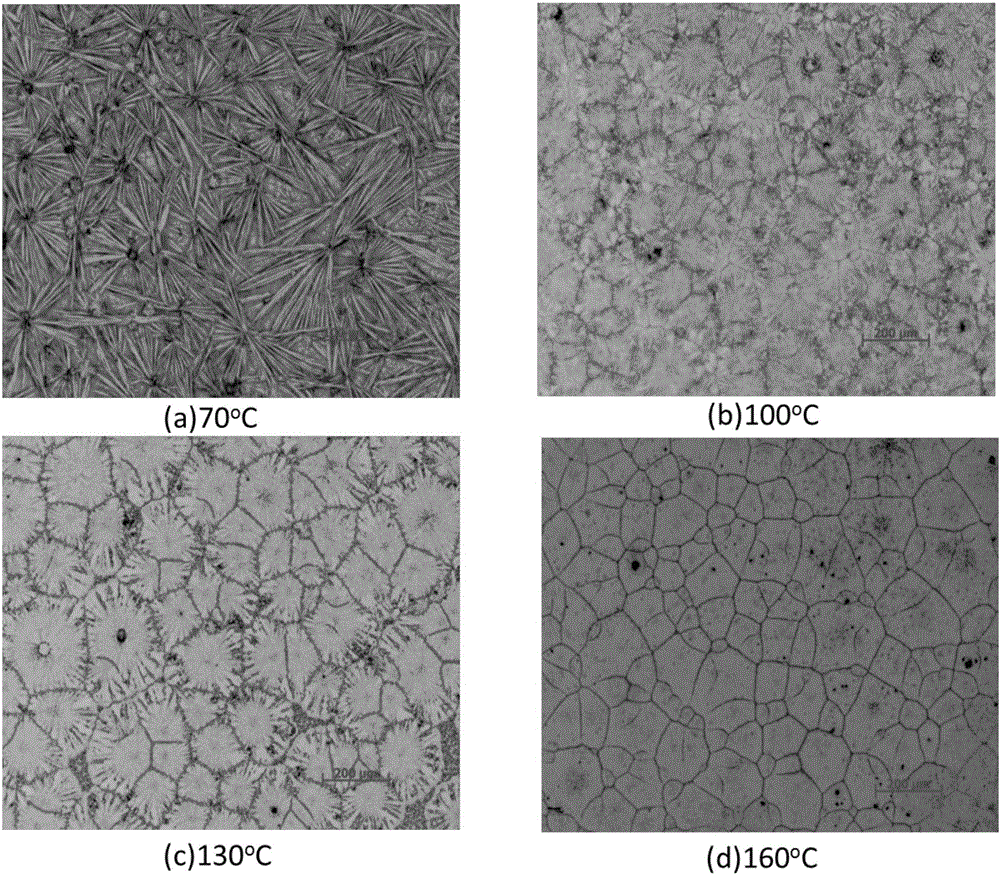

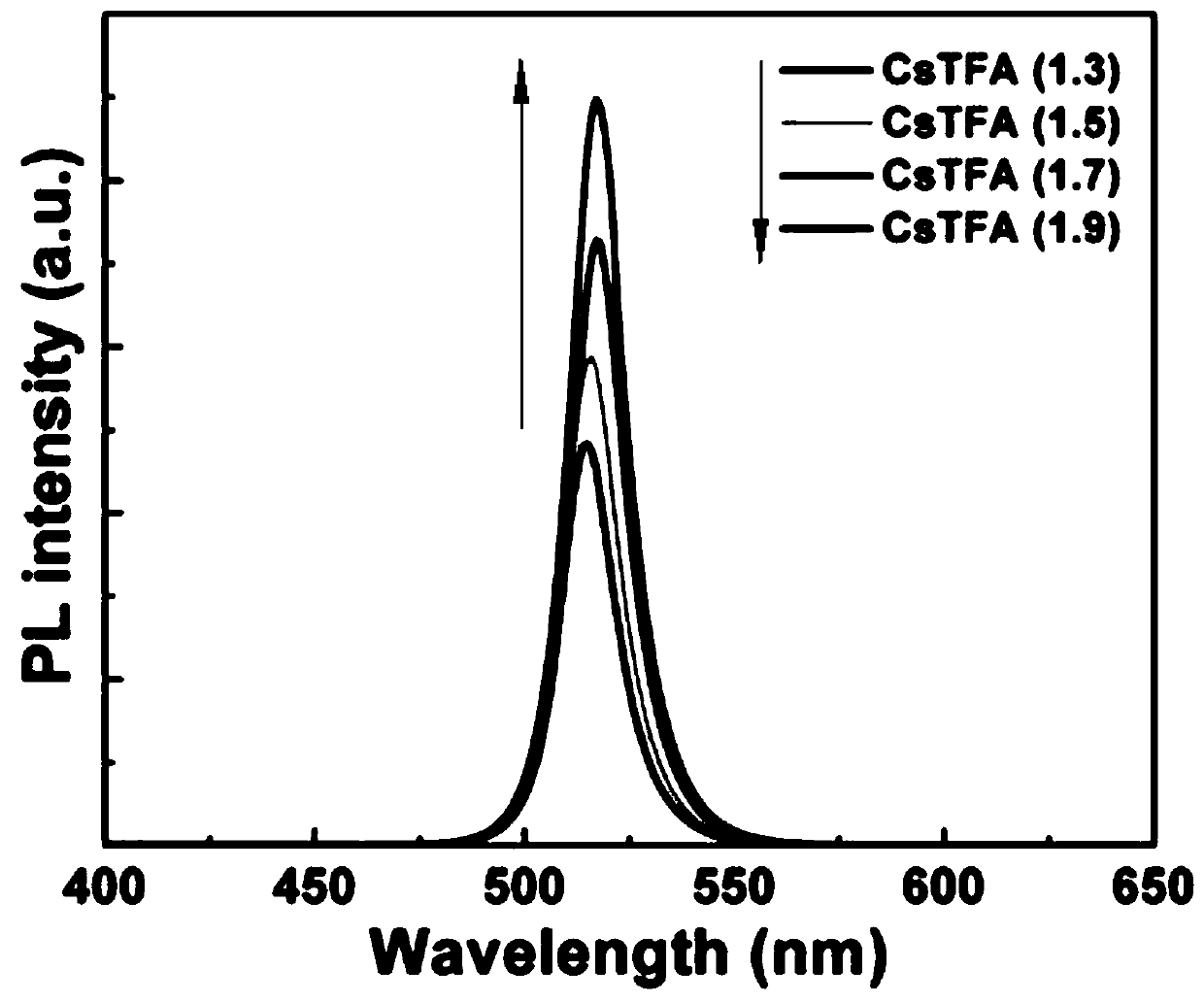

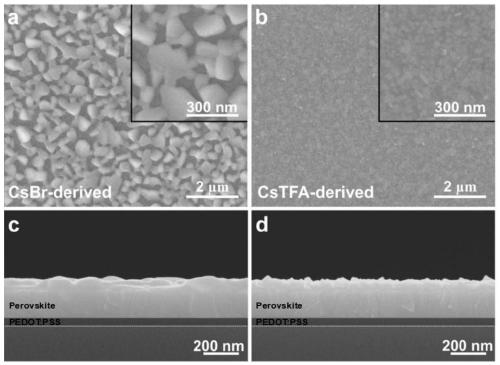

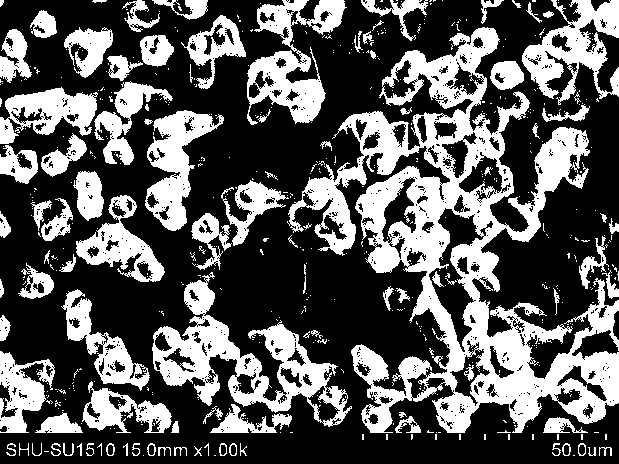

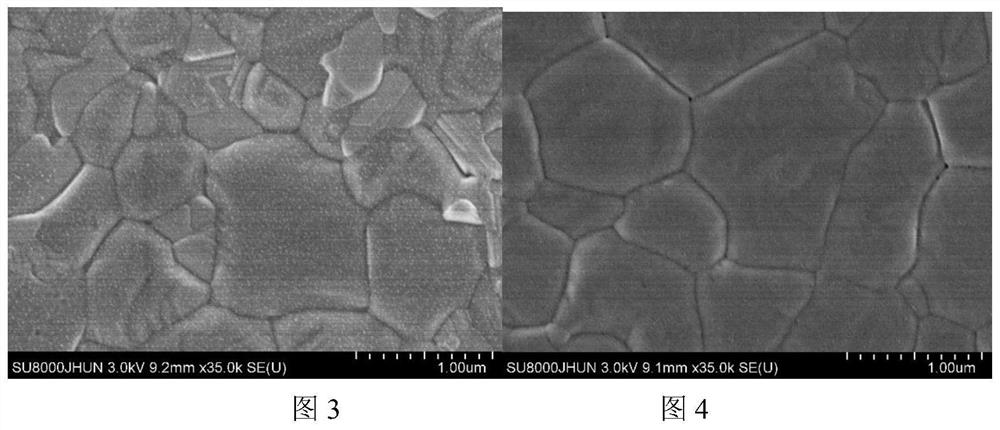

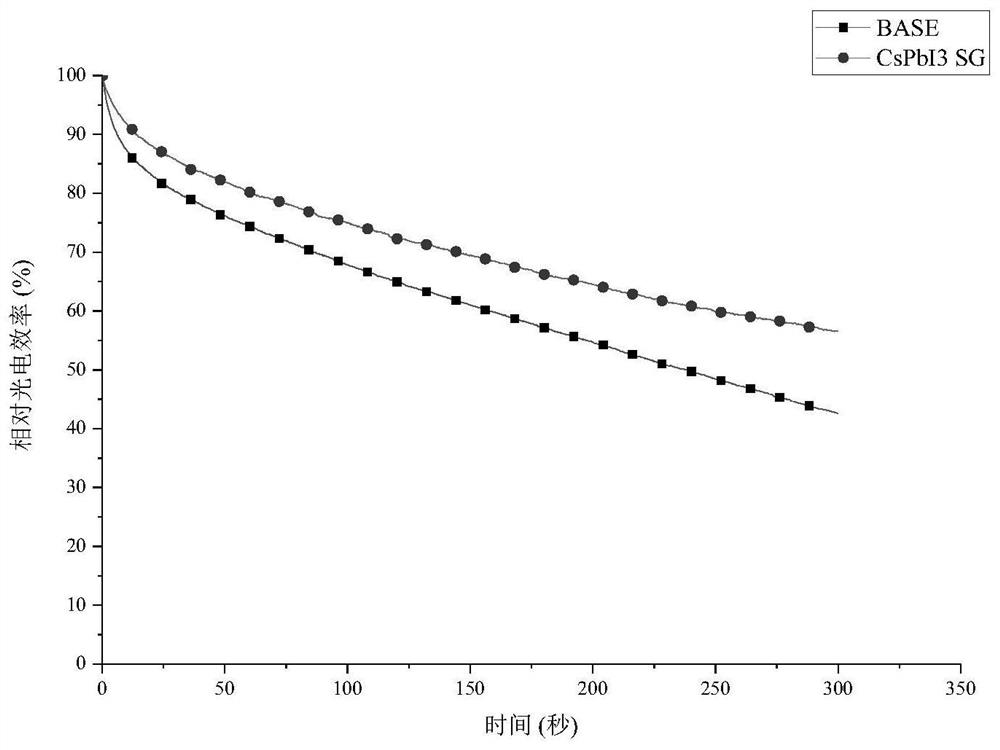

Trifluoroacetate induction based small-grain CsPbX3 perovskite thin film preparation method

InactiveCN110054214ALow costEasy to industrializeSemiconductor/solid-state device manufacturingLead compoundsHalogenTrifluoroacetic acid

The invention discloses a trifluoroacetate induction based small-grain CsPbX3 perovskite thin film preparation method. The method includes steps: firstly, preparing CsPbX3 perovskite precursor solution; secondly, setting the CsPbX3 perovskite precursor solution on a substrate, and performing curing and annealing to form a film. Under irradiation of an ultraviolet lamp, a CsPbX3 perovskite thin film varies in color according to different halogens. According to the method, cesium trifluoroacetate (CsTFA) is adopted as a new cesium source to take the place of cesium bromide (CsBr) which is a traditional cesium source for preparing the CsPbX3 perovskite thin film, and cost of the prepared perovskite thin film is evidently reduced. Compared with a CsPbX3 thin film prepared according to a traditional method, the CsPbX3 thin film prepared according to the method has advantages that stability is evidently improved, the perovskite grain size is evidently reduced, and the preparation process isenvironmentally friendly, green and healthy.

Owner:SHANGHAI UNIV

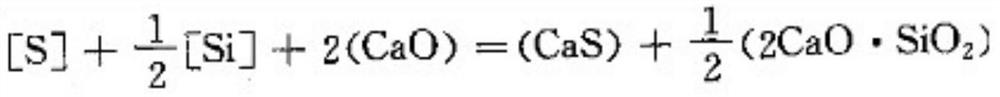

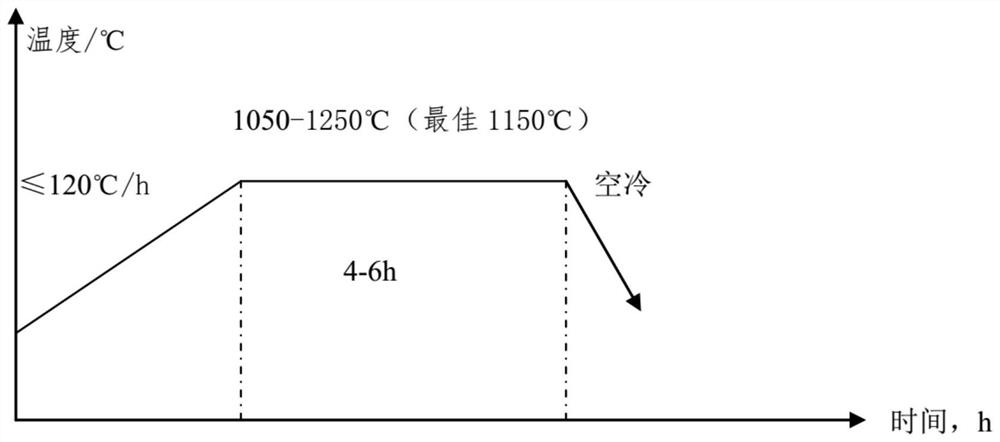

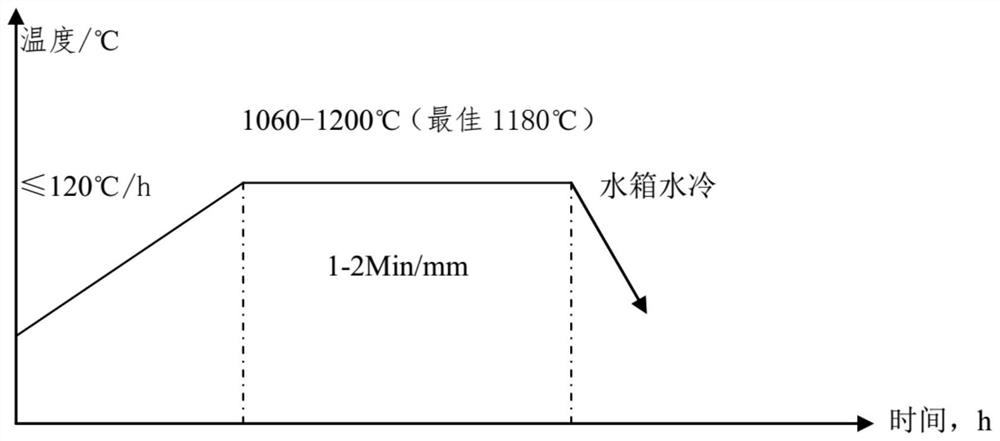

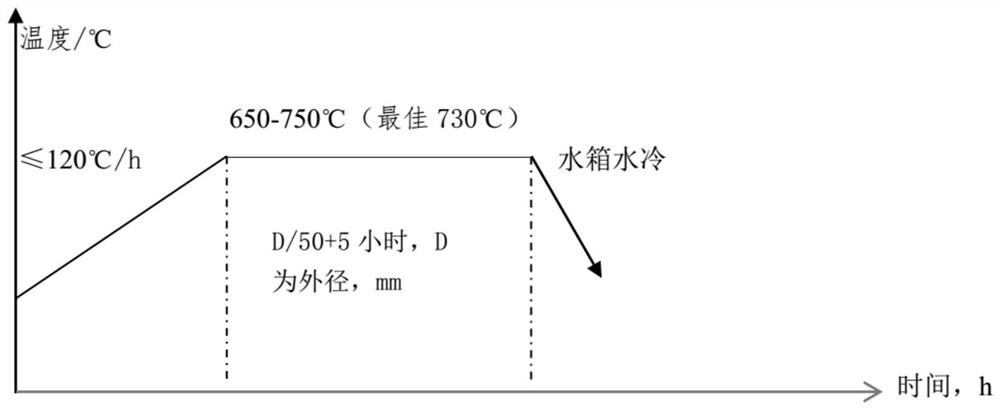

Hydrogen and hydrogen sulphide corrosion resistant steel forged piece and production process thereof

The invention discloses a hydrogen and hydrogen sulphide corrosion resistant steel forged piece and a production process thereof. The hydrogen and hydrogen sulphide corrosion resistant steel forged piece comprises the following chemical components: 0.01-0.03% of C, 0.6-0.8 % of Si, 0.9-1.1% of Mn, less than 0.015% of P, less than 0.005% of S, 28.6-28.8% of Cr, 0.1-0.3% of Mo, 0.06-0.08% of Nb, 0.07-0.09% of V, 0.005-0.007% of Ti, 0.005-0.007% of B, 0.07-0.09% of Al, 0.03-0.05% of Cu, 0.014-0.016% of Co, 0.03-0.05% of N, 0.17-0.19% of composite rear earth and the balance of Fe. The forced piece provided by the invention can be used for obtaining fine and complete ferrite and austenite structures with high dislocation densities and has remarkable hydrogen and hydrogen sulphide corrosion resistant property.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

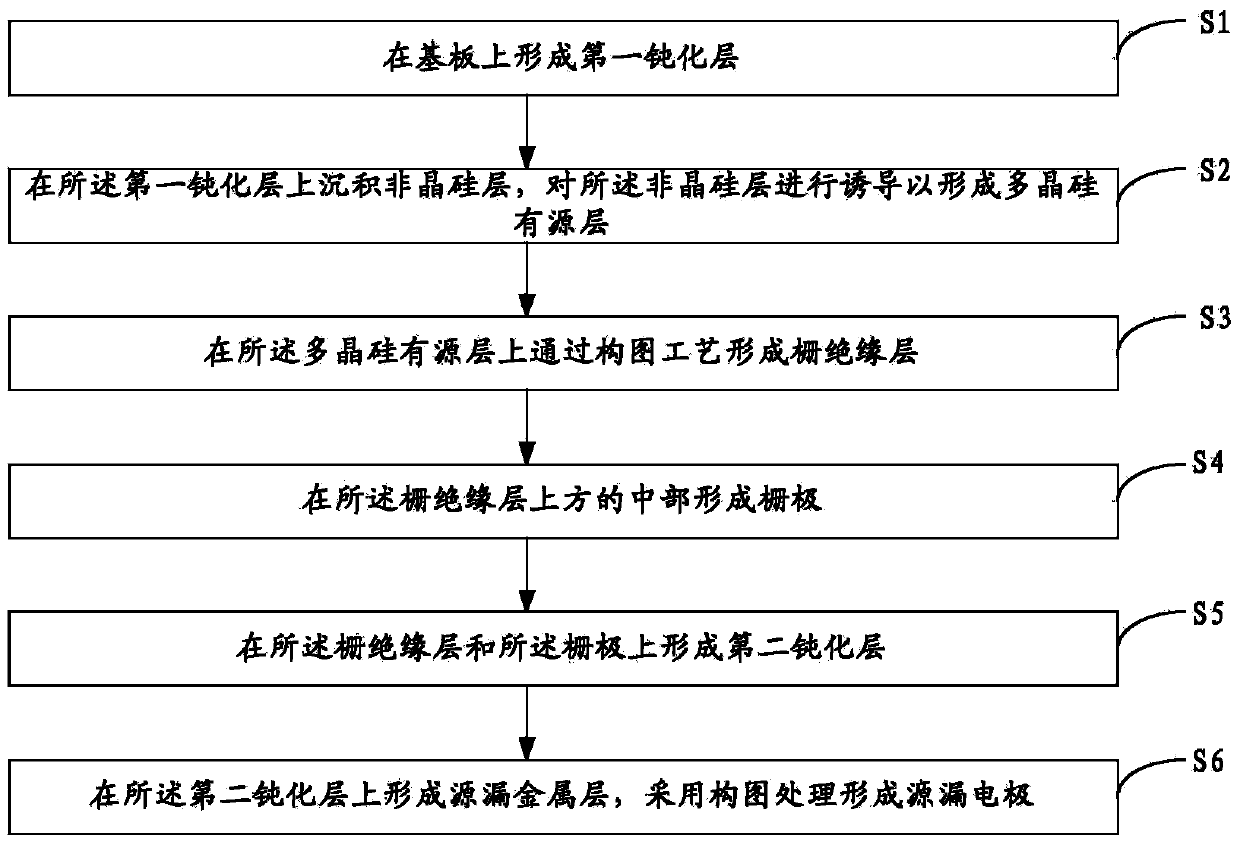

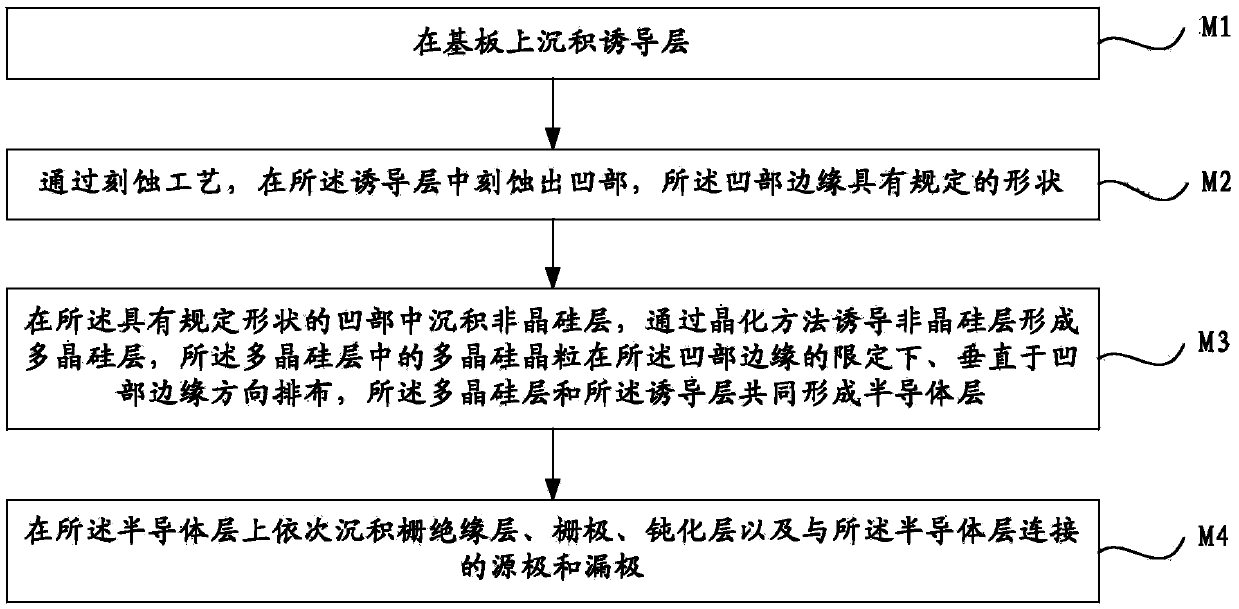

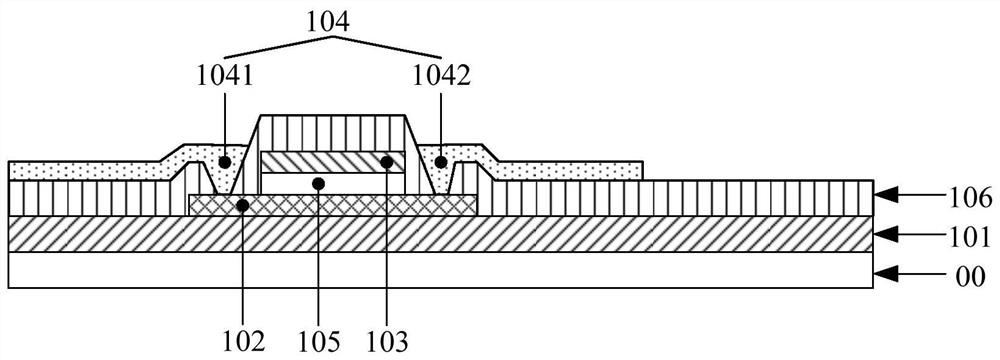

Preparation method of thin film transistor, thin film transistor and display panel

InactiveCN103700698AImprove stabilityImprove mobilityTransistorSolid-state devicesLiquid-crystal displayInsulation layer

The embodiment of the invention provides a preparation method of a thin film transistor, the thin film transistor and a display panel, and belongs to the field of liquid crystal display, which aims at improving the mobility of carriers in polycrystalline silicone. The preparation method of the thin film transistor comprises the following steps of M1, depositing an induction layer on a substrate; M2, etching a concave part in the induction layer through the etching process, wherein the edge of the concave part is in a specifical shape; M3, depositing a non-crystalline silicone layer in the specifically-shaped concave part, inducing the non-crystalline silicone layer to form a polycrystalline silicone layer through a crystallizing method, arranging the polycrystalline silicone particles in the polycrystalline silicone in the direction vertical to the edge of the concave part by the limitation of the edge of the concave part, and enabling the polycrystalline silicone layer and the induction layer to form a semiconductor layer; M4, respectively depositing a grid insulation layer, a grid, a passivating layer, a source and a drain on the semiconductor layer, wherein the source and the drain are connected with the semiconductor layer. The method can be used for manufacturing the thin film transistor.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

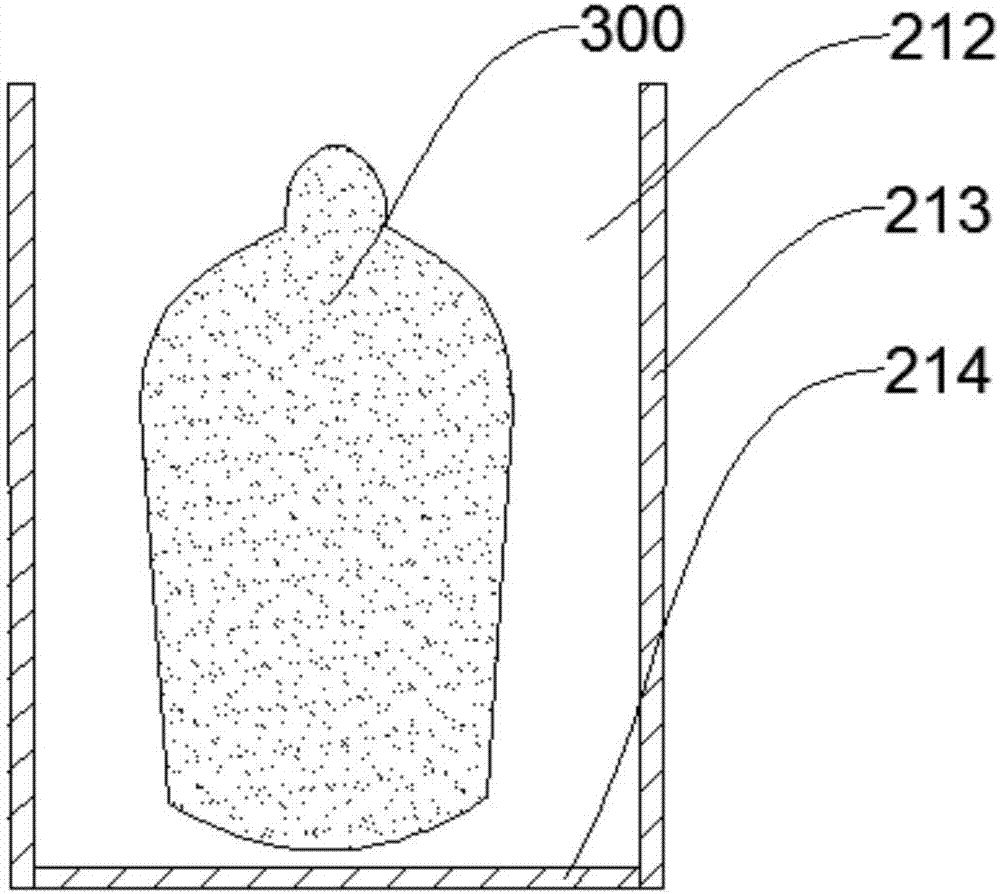

Preparation method for CdZnTe film with cylindrical structure

InactiveCN103343389ALow costHigh feasibility of batch growthPolycrystalline material growthSingle crystal growth detailsSingle crystalChemistry

The invention relates to a CdZnTe film with a cylindrical structure, and a preparation method for the same. The method comprises the following steps of: (a) preparing a CdZnTe monocrystal sublimation source; (b) pre-treating a substrate; (c) growing the CdZnTe film; and (d) polishing, corroding and annealing the CdZnTe film, wherein the thickness of the prepared CdZnTe film with the cylindrical structure is 100-500 mm. Compared with CdZnTe monocrystal growth, the method disclosed by the invention is simple in process, lower in cost, capable of preparing in a large scale, batched in growth, and high in feasibility. Compared with the conventional CdZnTe film, the cylindrical CdZnTe film prepared by the method disclosed by the invention is fewer in crystal boundary defects, and higher in electrical resistivity which is up to 6*10<9> Ohm.cm.

Owner:SHANGHAI UNIV

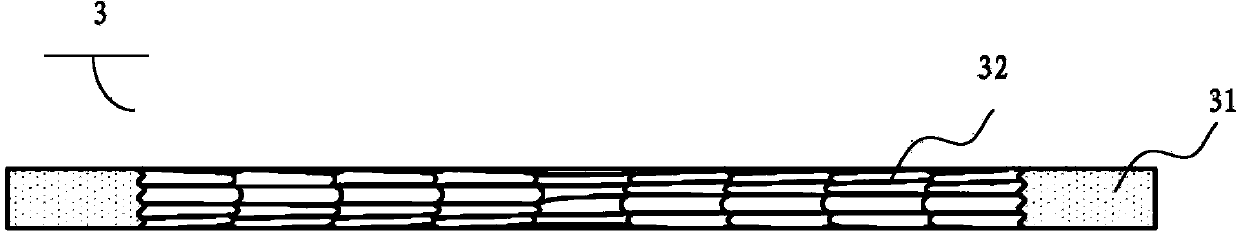

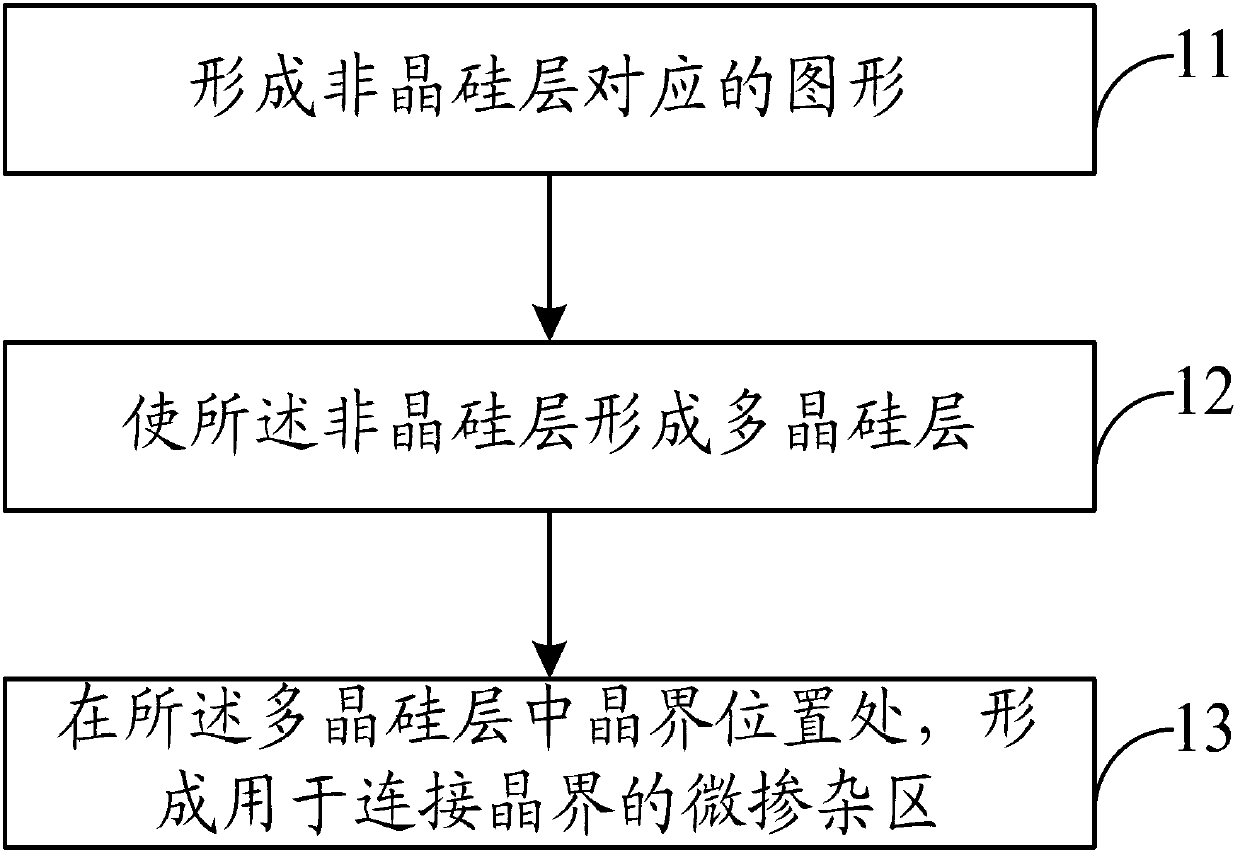

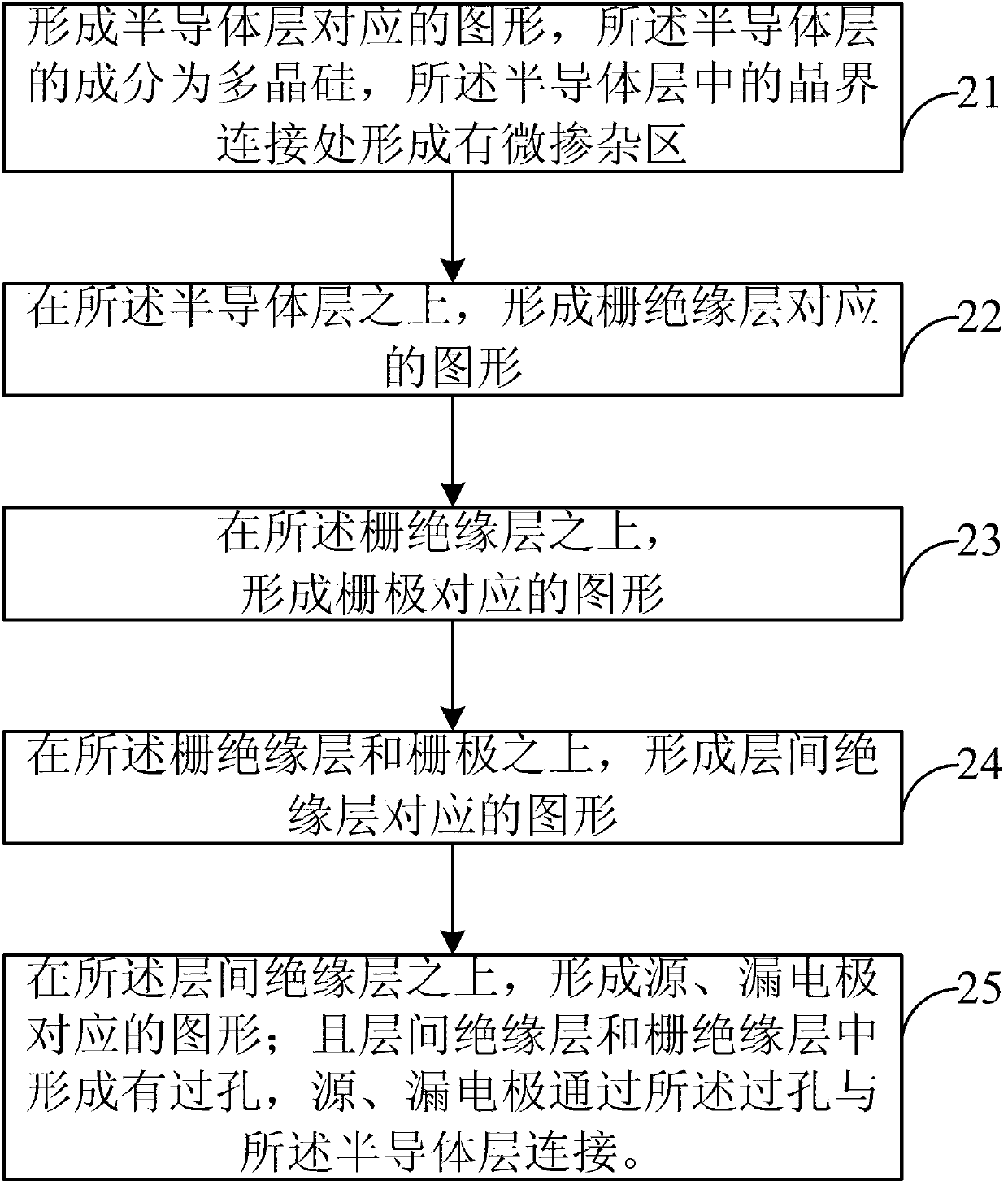

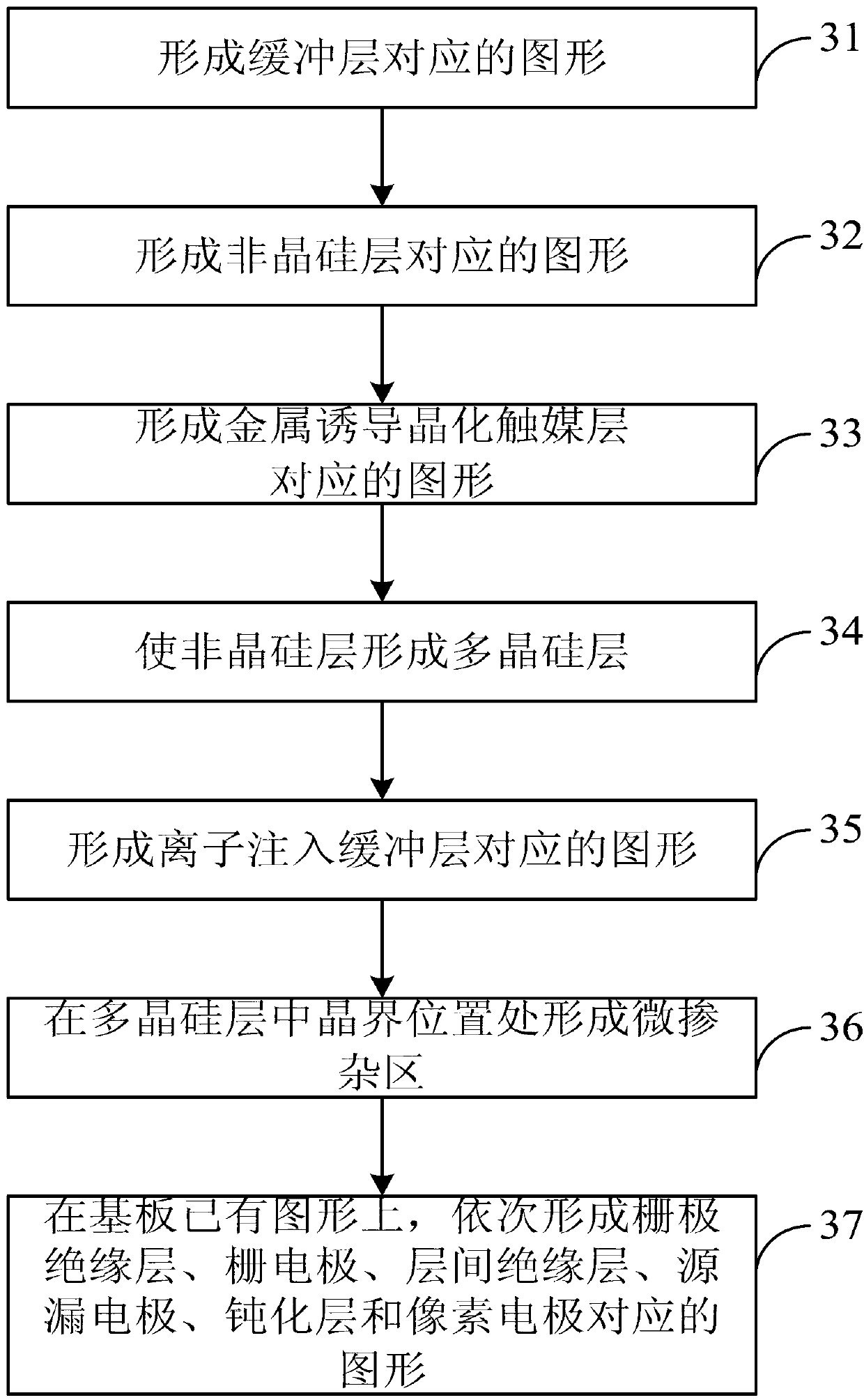

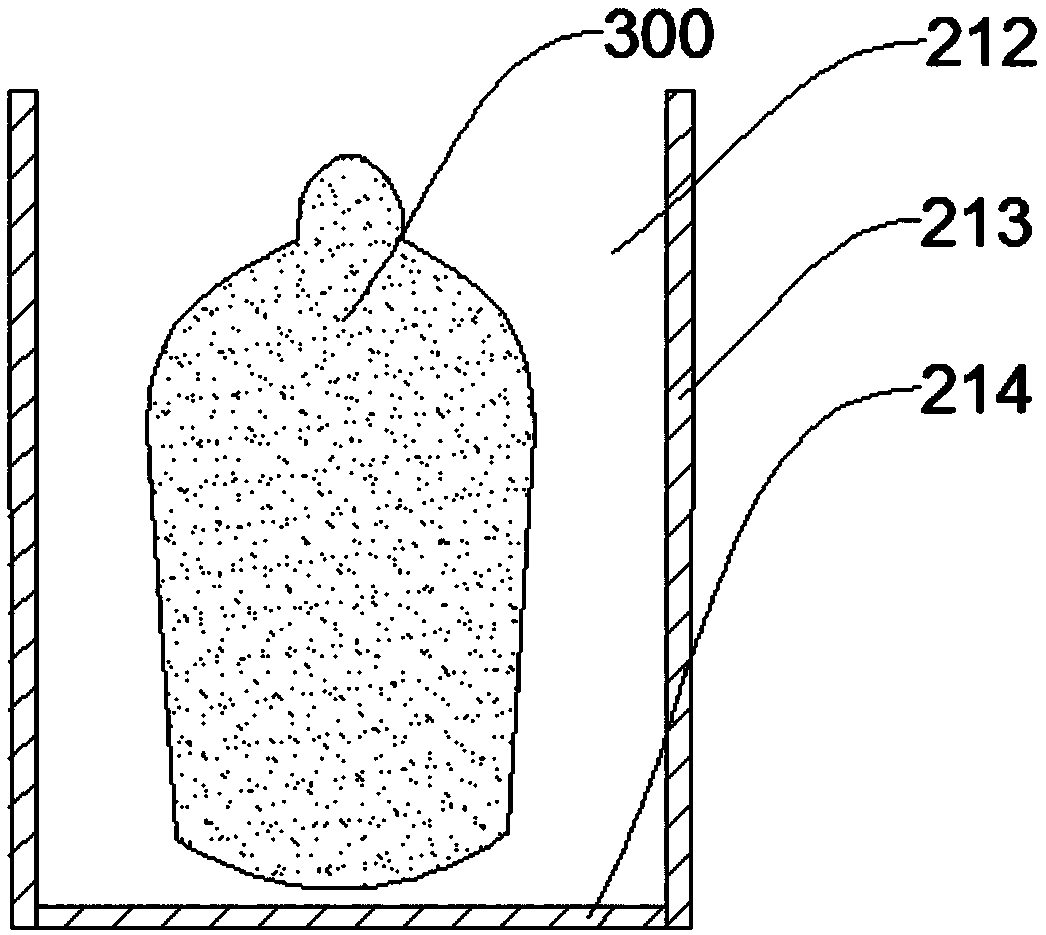

Semiconductor layer structure, polysilicon thin film transistor, manufacturing method and display device

InactiveCN103123902AReduce grain boundary defectsImprove electrical performanceTransistorSemiconductor/solid-state device manufacturingDisplay deviceElectrical performance

The invention provides a semiconductor layer structure, a polysilicon thin film transistor, a manufacturing method and a display device. By adopting the grain boundary connecting line technology, namely micro doping area used for connecting a grain boundary is formed at the grain boundary in a semiconductor layer made of polysilicon, grain boundary defects of polysilicon can be reduced, grain uniformity is improved, and electrical performance of a thin film transistor is improved.

Owner:BOE TECH GRP CO LTD +1

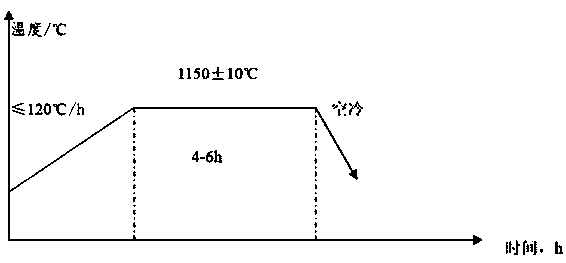

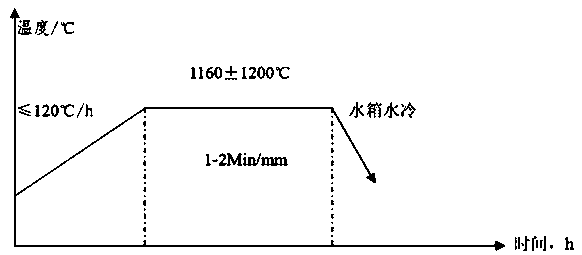

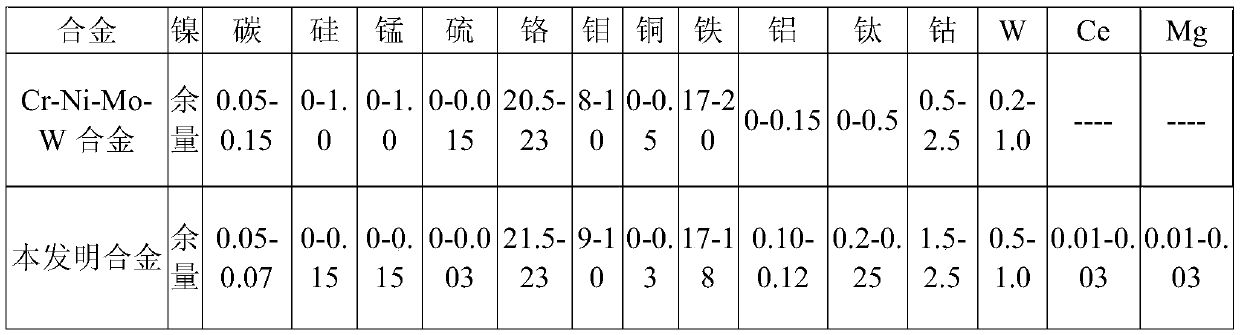

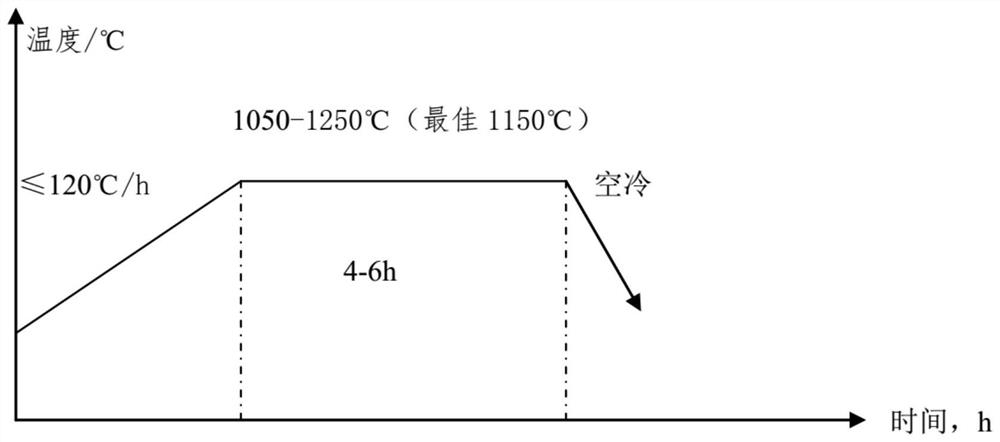

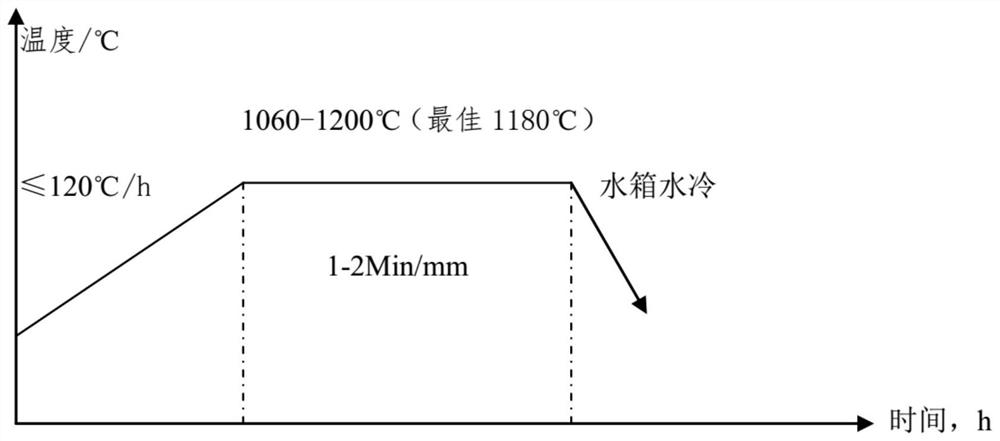

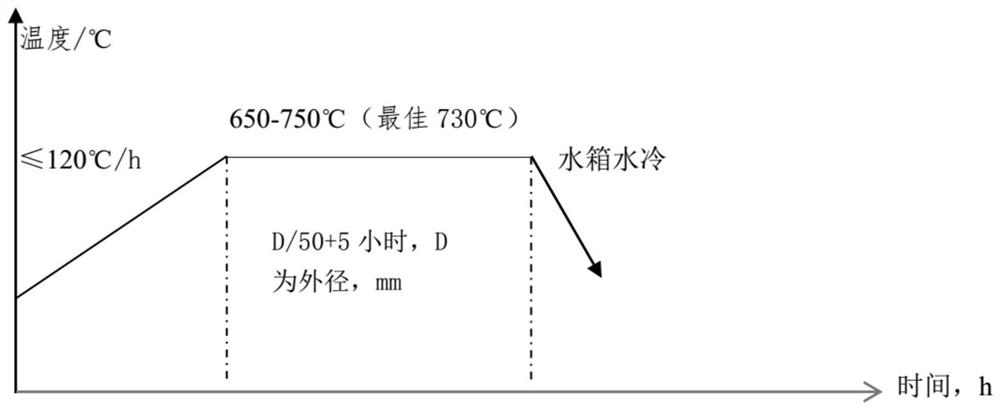

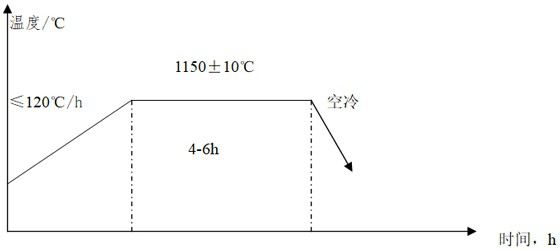

Manufacturing method for alloys with excellent durability performance under high temperature and high pressure conditions

ActiveCN109988927AManufacturing method of alloy with excellent durabilityImprove high temperature strengthAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesRare earthHigh pressure

The invention provides a manufacturing method for alloys with excellent durability performance under high temperature and high pressure conditions. The manufacturing method for the alloys with the excellent durability performance under the high temperature and high pressure conditions comprises the following steps of (1) raw material preparation, (2) vacuum smelting, (3) electroslag remelting, (4)forging, (5) heat treatment, and (6) durability performance testing, sampling, peeling, inspection, packaging and storage, wherein the step 2 comprises the steps of (2.1) charging, (2.2) melting, (2.3) refining, (2.4) pouring, and the manufacture of the alloys with the excellent durability performance under the high temperature and high pressure conditions is completed. On the one hand, the manufacturing method optimizes the design of alloy elements, moreover, the traditional vacuum degassing and desulphurization technology is combined, and the desulphurization and degassing effect of using Ni-Mg and rare earth is especially increased; and on the other hand, the heat treatment process of a Cr-Ni-Mo-W alloy is optimized, and high end Cr-Ni-Mo-W alloy steel with a lasting life of more than500 hours is successfully manufactured under the conditions of 815 DEG C high temperature and 110 MPa high pressure.

Owner:江苏汉青特种合金有限公司

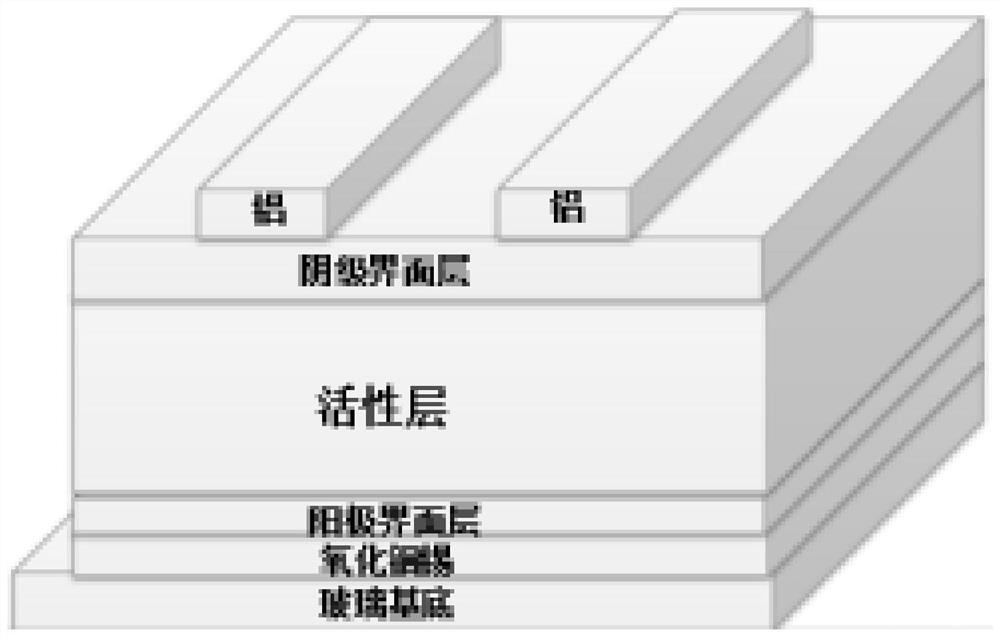

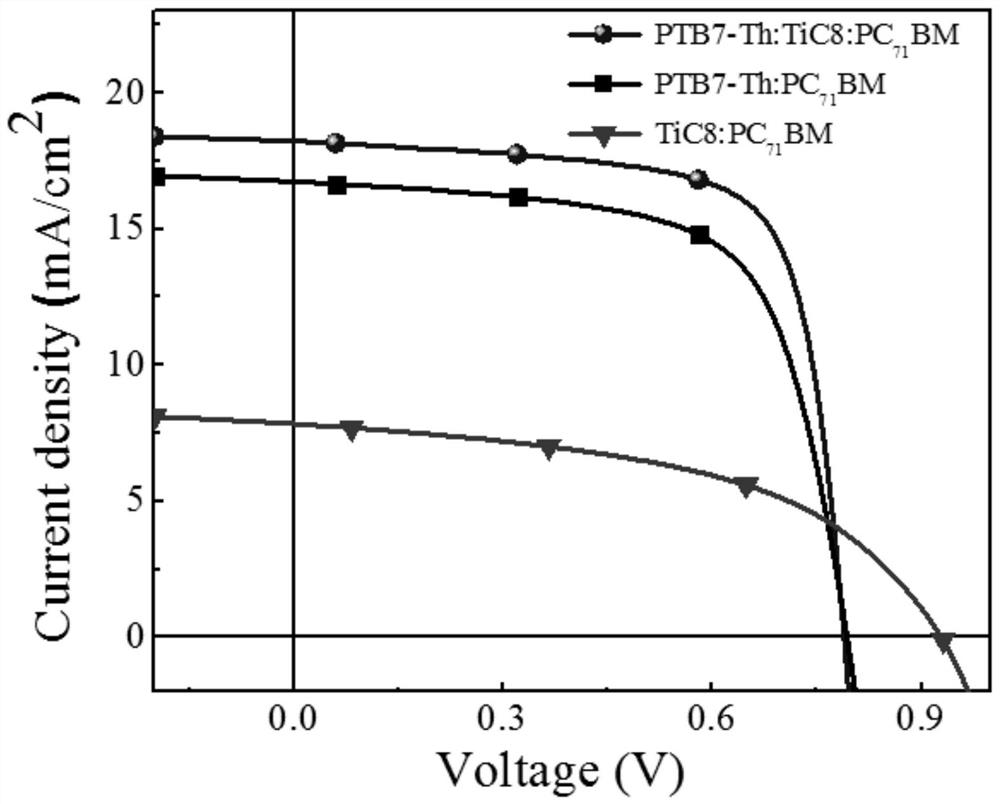

Ternary fullerene organic solar cell

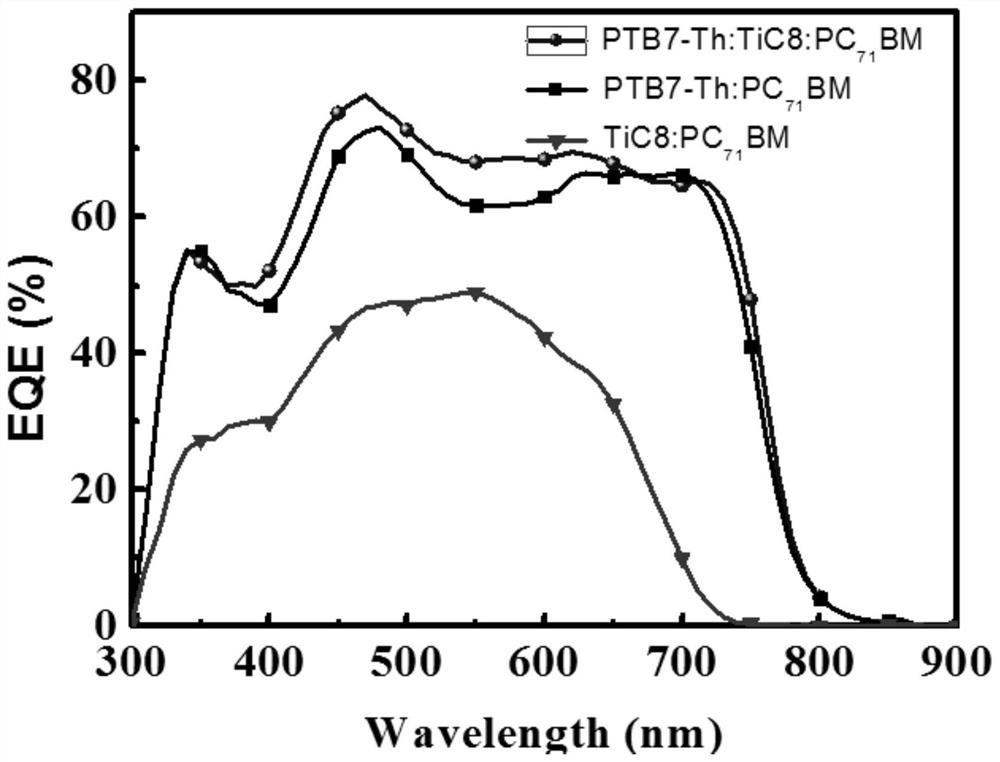

InactiveCN112259687ABroad spectrum absorptionReduce grain boundary defectsSolid-state devicesSemiconductor/solid-state device manufacturingPolymer chemistryEnergy conversion efficiency

The invention discloses a ternary fullerene organic solar cell, and belongs to the technical field of photovoltaics. According to the invention, in an active layer of a binary fullerene bulk heterojunction organic solar cell composed of a polymer donor material (PTB7-Th) and a fullerene acceptor material (PC71BM), an asymmetric thieno isobenzopyran-based (A'-D) 2A type small molecular donor material (TiC8) is added to construct an efficient and stable ternary fullerene organic solar cell with a PTB7-Th:TiC8:PC71BM active layer, wherein the energy conversion efficiency of the device reaches 10.40%, and the energy conversion efficiency of the device is still maintained at 81% of the original energy conversion efficiency after the device is placed in a nitrogen atmosphere for 4500 h; and compared with a binary fullerene organic solar cell, the ternary fullerene organic solar cell of the invention has the advantages that the energy conversion efficiency is improved by 18.3%, and the stability is also remarkably improved.

Owner:CHANGZHOU UNIV

Steel for high-strength high-tenacity storage rack stand column and production technology of steel

InactiveCN104711478AComplete organizationReduce grain boundary defectsChemical compositionLanthanide

The invention discloses steel for a high-strength high-tenacity storage rack stand column. The steel comprises the following chemical components in percent by weight: 0.20-0.50% of C, 0.8-2.0% of Si, 1.5-3.0% of Mn, 0.02-0.08% of Al, 0.005-0.015% of Ti, 0.5-2.0% of Ni, 0.021-0.033% of lanthanide series rare earth, and the balance of Fe and unavoidable impurities, wherein the sum of Mn and Ni is 3.2-3.6%; the microstructures comprise lath martensite and retained austenite; the volume percentage composition of the retained austenite is 7.5-15.0%; the ballistic work of the steel at -20 DEG C is 38-48 J, the yield strength is 1,450-1,480 MPa, the tensile strength is greater than 1,300 MPa, and the ductility is 12-12.5%. The steel disclosed by the invention is good in corrosion resistance, cold workability and tenacity, meanwhile higher in tensile strength, and high in yield strength.

Owner:SUZHOU KESHENG STORAGE & LOGISTICS EQUIP

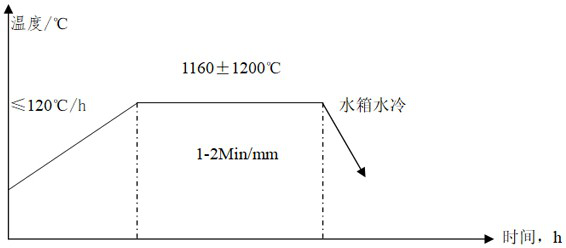

Ultrahigh-strength corrosion-resistant alloy and manufacturing method thereof

The invention belongs to the technical field of alloy manufacturing, and particularly relates to an ultrahigh-strength corrosion-resistant alloy and a manufacturing method thereof, in particular to a Cr-Ni-Mo-Nb corrosion-resistant alloy with ultrahigh strength and excellent stress corrosion resistance and a production technology of the alloy. The alloy comprises the elements of nickel, carbon, silicon, manganese, sulfur, chromium, molybdenum, iron, aluminum, titanium, niobium, zirconium and yttrium. The alloy prepared by the invention has very high strength and excellent stress corrosion resistance in the environments of high-pressure H2S, high-pressure CO2 and chloride ions, can be used for manufacturing key parts of oil field drilling and production equipment, and is long in service life.

Owner:江苏汉青特种合金有限公司

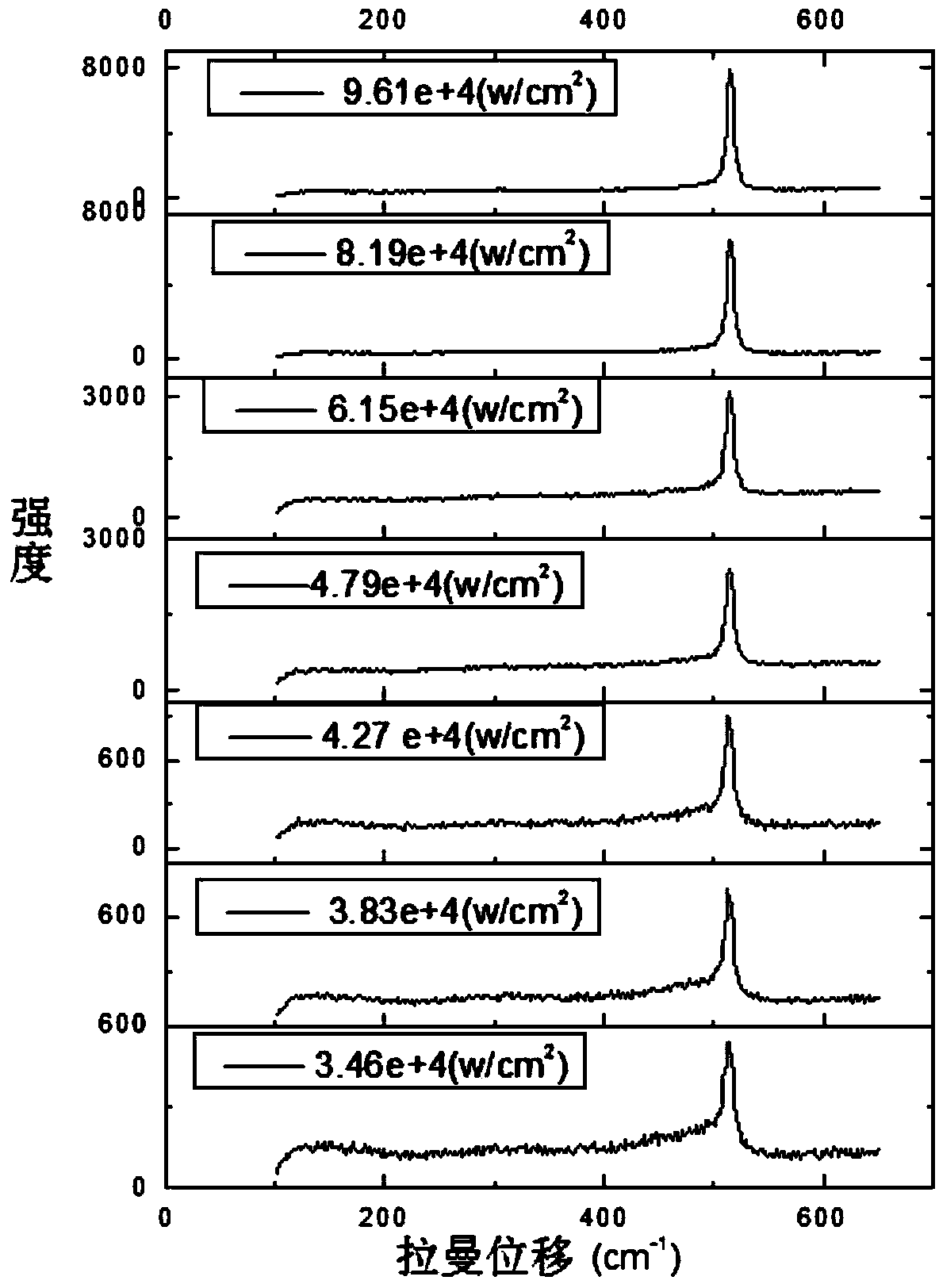

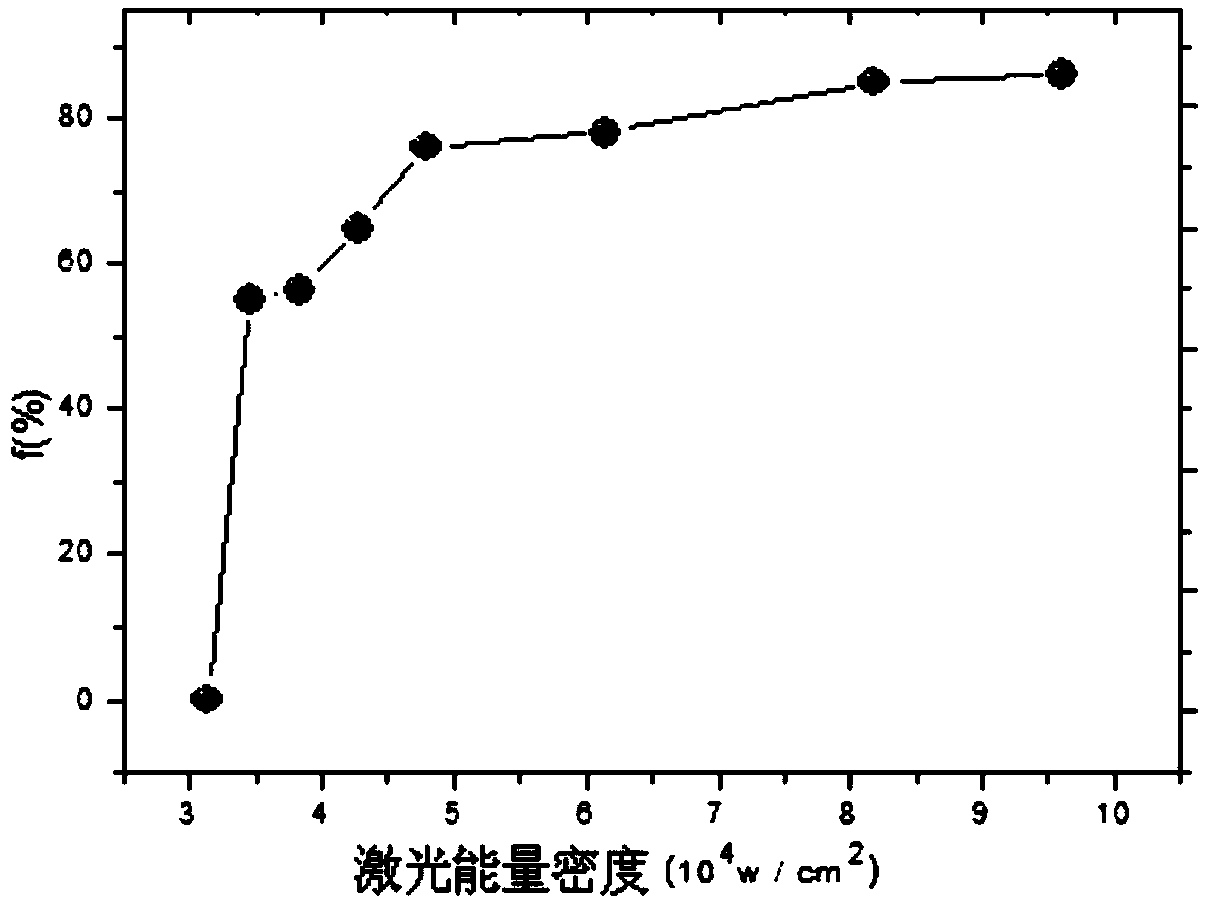

Preparation method of polysilicon thin film material

InactiveCN104392908AReduce the temperatureReduce energy consumptionSemiconductor/solid-state device manufacturingComposite filmSilanes

The invention relates to the field of preparation of a polysilicon thin film material, especially to a preparation method of a polysilicon thin film material. The method comprises the following steps: depositing an amorphous silicon film and a metal aluminum film successively on a glass substrate by using a magnetron sputtering technology so as to obtain a composite thin film; and carrying out laser irradiation on the composite thin film and carrying out crystallization on the amorphous silicon film, thereby obtaining a polysilicon thin film material. When the amorphous silicon film and the metal aluminum film are successively deposited by using the magnetron sputtering technology, the temperature is not higher than 150 DEG C. According to the provided preparation method, the amorphous silicon film and the metal aluminum film are obtained by using the magnetron sputtering technology and no dangerous gas like silane is required; the highest temperature does not exceed 150 DEG C during the process of successive deposition of the amorphous silicon film and the metal aluminum film with the magnetron sputtering technology, so that the cheap glass substrate can be used; and the temperature of the polysilicon thin film preparation process is low, thereby substantially reducing the energy consumption.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Preparation method for directional growth of tellurium-zinc-cadmium film on graphene substrate

ActiveCN108546995AReduce grain boundary defectsHigh resistivityPolycrystalline material growthAfter-treatment detailsCvd grapheneCopper foil

The invention discloses a preparation method for directional growth of a tellurium-zinc-cadmium film on a graphene substrate. The preparation method comprises: preparing a single layer of graphene ona copper foil by using a CVD method, and preparing a layer of a directional tellurium-zinc-cadmium film by using the graphene as a substrate through a close-space sublimation method. According to thepresent invention, through the scheme for close-space sublimation preparation of the film by setting the distance between the substrate and the sublimation source, the graphene material is used as thesubstrate structure, and has the high lattice matching degree with the target CdZnTe film so as to prepare the CdZnTe film with good orientation; a purpose of the invention is to prepare the directional CdZnTe film on the graphene substrate by using the close-space sublimation method, such that the loss of the carrier transmission between the upper pole and the lower pole during the device preparation is low, the carrier transmission speed is improved, and the device transmission speed is improved; and compared to the CdZnTe single crystal growth process, the method of the invention has advantages of simplenes, lower cost, large area preparation, batch growth and high feasibility.

Owner:SHANGHAI UNIV

A kind of film drying method and its application

ActiveCN111933809BImprove performanceQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellPhysical chemistry

The invention involves a thin film drying method, including the following steps: coating the wet film on the basis surface, add a layer of covering film or cover plate containing nano -grade holes on the surface of the wet film., Heat the wet film covering the covered film or cover plate, wait for the wet film to change from the state of the solvent to solid state, and unveil the coverage of the covering film or cover plate to complete the dryness of the wet film.The present invention also disclosed that the method is applied to the solar cells of perovskite.The invention can control the drying rate of the film, increase the growth time of the crystal in the film, increase the grain size, reduce the crystal defect, and improve the quality of the film.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

A kind of low-temperature rapid sintering soft ferrite and its preparation method

ActiveCN107200571BGuaranteed initial permeabilityReduce manufacturing costInorganic material magnetismInductances/transformers/magnets manufactureAir atmospherePolyvinyl alcohol

The invention discloses low-temperature rapidly sintered soft magnetic ferrite and a preparation method thereof. The preparation method comprises the following steps: S1, weighing the following components in parts by mole: 60-80 parts of ferric oxide, 40-60 parts of zinc oxide, 30-50 parts of copper oxide and 15-20 parts of manganese carbonate, and performing mixing ball-milling till the average particle size is 5-30 [mu]m so as to obtain mixed powder; S2, pre-sintering the mixed powder at 900-1000 DEG C so as to obtain a pre-sintered material; S3, weighing yttrium oxide, aluminum oxide and lithium carbonate as doping materials; S4, adding the doping materials weighed in the step S3 into the pre-sintered material, performing secondary ball-milling for 6-8 hours, drying, adding polyvinyl alcohol, and performing pelletizing so as to obtain a granular material; S5, heating the granular material to sintering temperature in the presence of an air atmosphere, and performing warm-keeping sintering, thereby obtaining the low-temperature rapidly sintered soft magnetic ferrite, wherein the sintering temperature meets the equation that T=1454 / [1g(X+2Y+Z)+t]. Due to mutual cooperation of the main material and the doping materials, a preparation process is optimized, the sintering temperature is reduced, and meanwhile the electromagnetic properties of the ferrite are ensured.

Owner:ZHONGDE ELECTRONICS

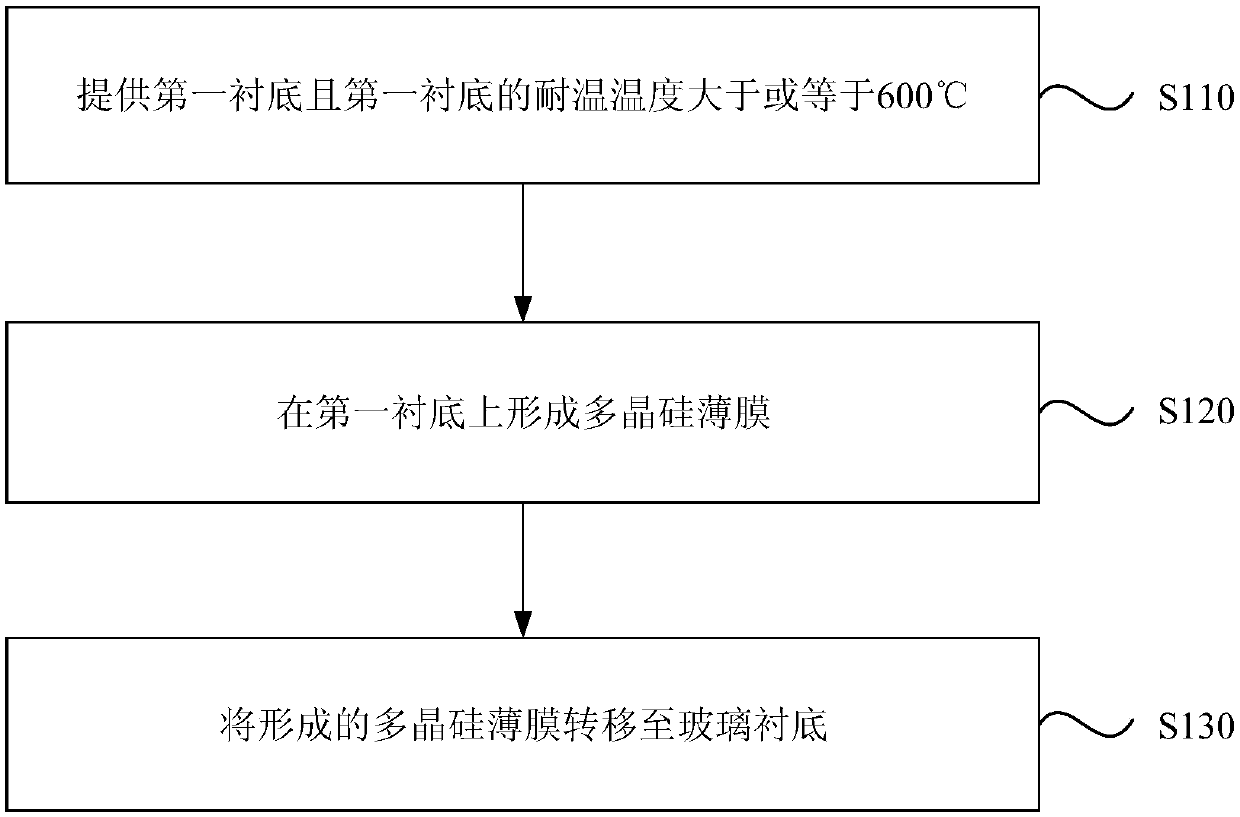

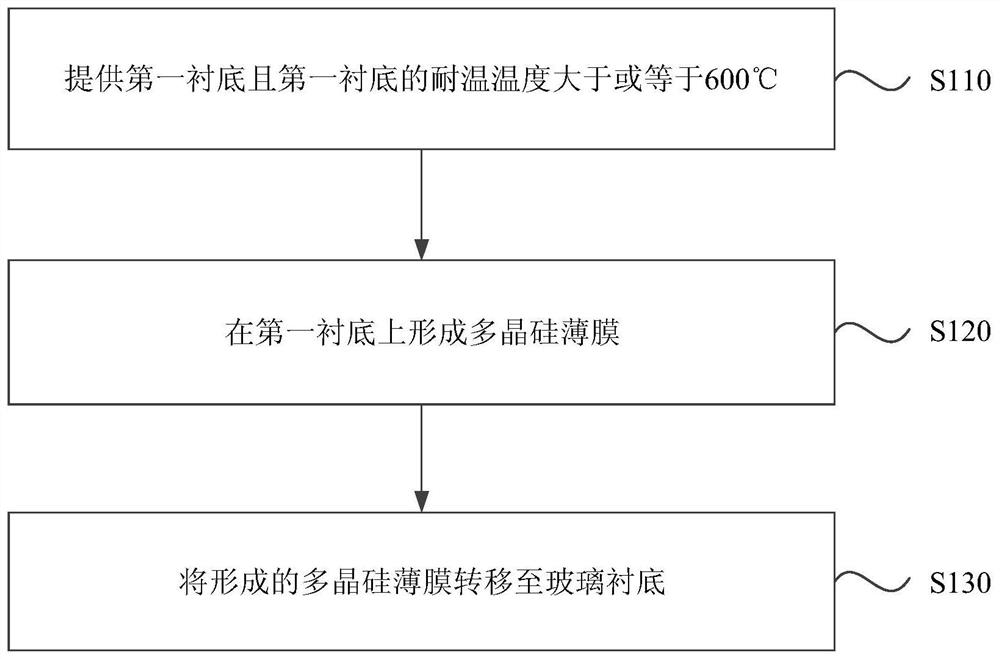

Polycrystalline silicon thin film manufacturing method

ActiveCN110581058AAvoid the problem of limited production processReduce grain boundary defectsSemiconductor/solid-state device manufacturingOptoelectronicsTemperature resistance

An embodiment of the invention discloses a polycrystalline silicon thin film manufacturing method. The polycrystalline silicon thin film manufacturing method comprises the steps: providing a first substrate, wherein the temperature resistance temperature of the first substrate is larger than or equal to 600 DEG C; forming a polycrystalline silicon thin film on the first substrate; and transferringthe formed polycrystalline silicon thin film to a glass substrate. According to the technical scheme provided by the invention, by forming the polycrystalline silicon thin film on the first substratewith higher temperature resistance, and then, transferring the formed polycrystalline silicon thin film onto the glass substrate, the problem that the manufacturing process of the polycrystalline silicon thin film is limited due to the temperature resistance of the glass substrate is avoided; and compared with a laser process adopted in the prior art, the method can allow crystal grains of the polycrystalline silicon thin film to reach a larger size, wherein crystal boundary defects of the polycrystalline silicon thin film with larger crystal grain size are fewer, so that the film forming quality of the formed polycrystalline silicon thin film and the electrical reliability of the polycrystalline silicon thin film are improved.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

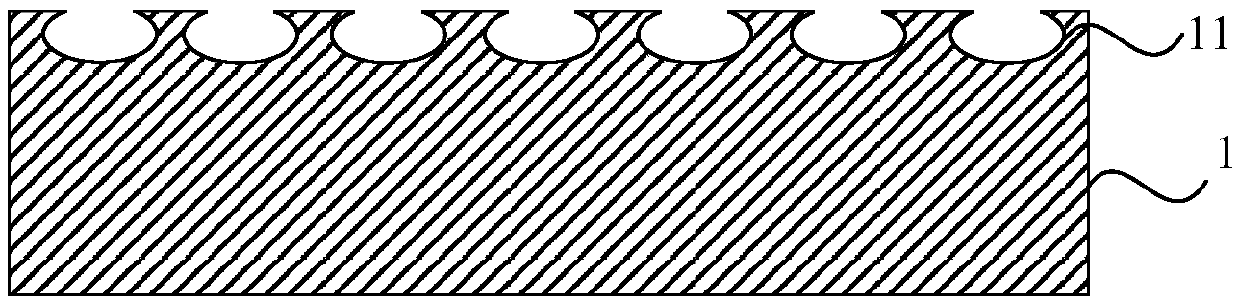

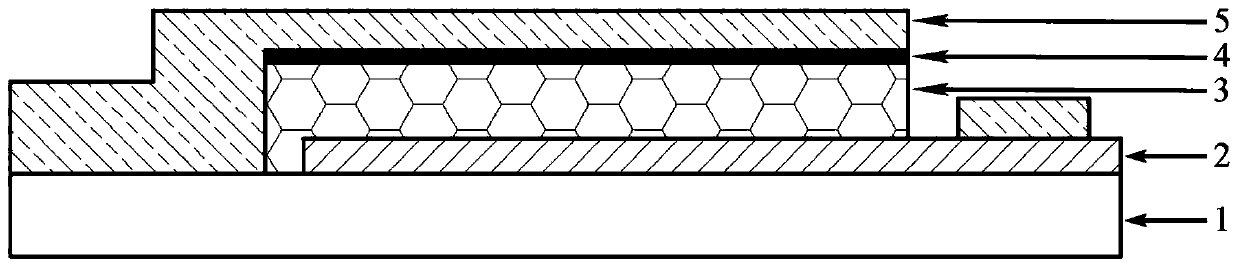

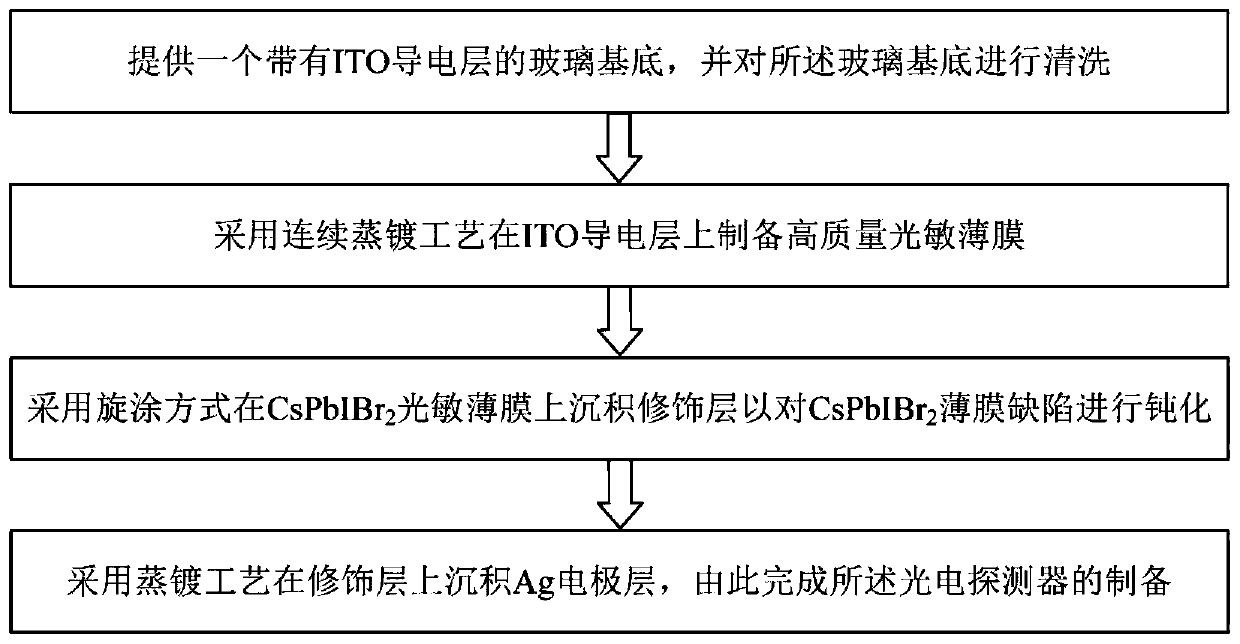

Self-powered perovskite photoelectric detector and preparation method thereof

InactiveCN111403605AHigh phase purityReduce grain boundary defectsSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsElectrically conductive

The invention belongs to the related technical field of micro-nano manufacturing. The invention discloses a self-powered perovskite photoelectric detector and a preparation method thereof. The photoelectric detector comprises a glass substrate, a CsPbIBr2 photosensitive film, a PMMA modification layer and an Ag electrode layer. The glass substrate comprises a substrate body and an ITO conductive layer arranged on the substrate body; the CsPbIBr2 photosensitive film is arranged on the ITO conductive layer; the PMMA modification layer is arranged on the surface, far away from the ITO conductivelayer, of the CsPbIBr2 photosensitive film; and the Ag electrode layer is arranged on the surface, far away from the CsPbIBr2 photosensitive film, of the PMMA modification layer. Compared with other perovskite photoelectric detectors, the perovskite photoelectric detector is lower in production cost and process complexity; and the introduction of the PMMA modification layer is beneficial to further passivating the defects of the CsPbIBr2 photosensitive film, improving the carrier transmission rate and reducing the adverse non-radiative recombination loss, thereby improving the sensitivity andresponse rate of the photoelectric detector.

Owner:HUAZHONG UNIV OF SCI & TECH

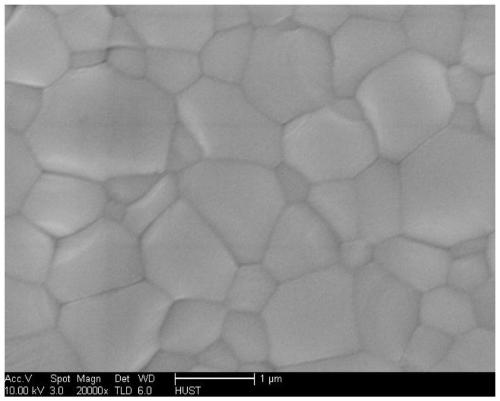

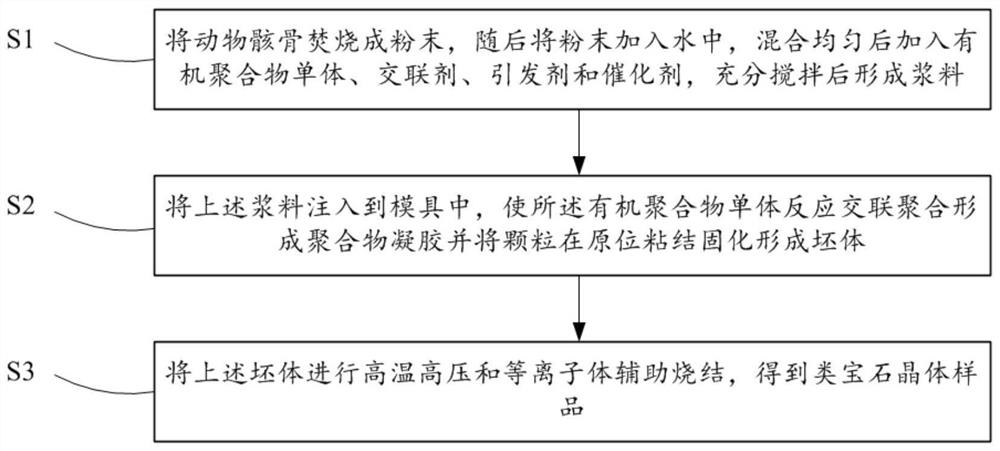

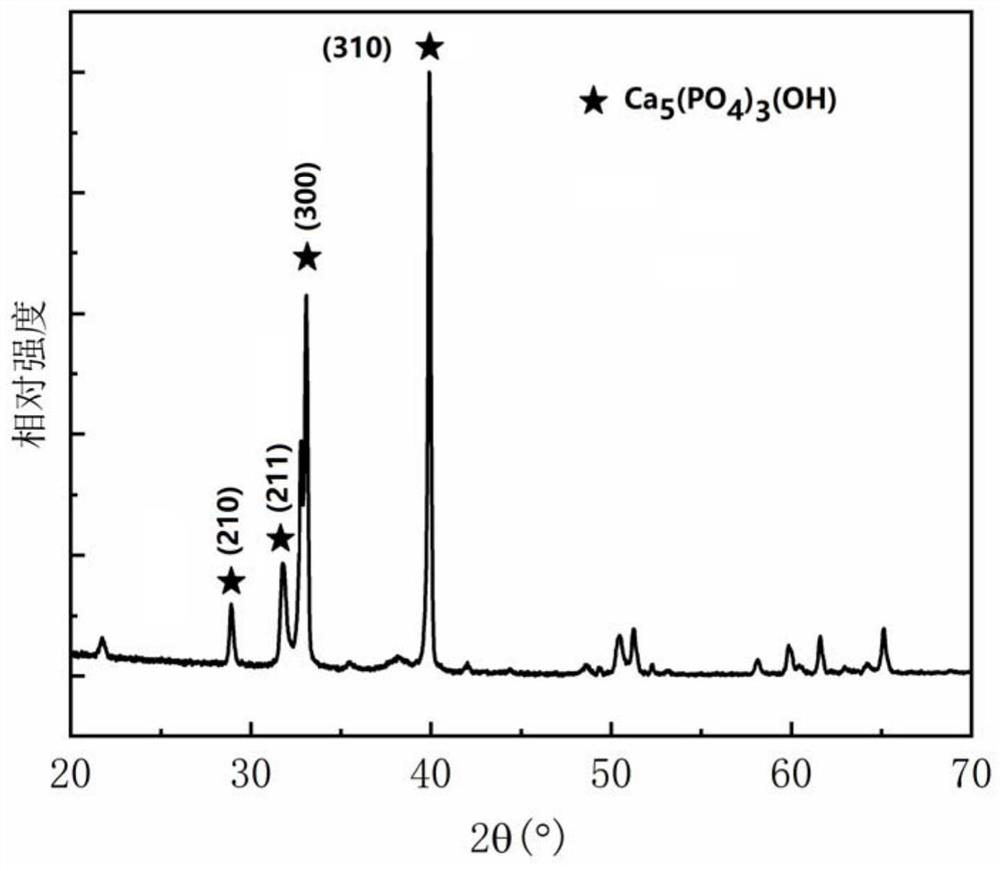

Jewel-like crystal based on animal skeletons and preparation method of jewel-like crystal

The invention relates to a jewel-like crystal based on animal skeletons and a preparation method of the jewel-like crystal. The preparation method comprises the following steps of burning animal skeletons into powder, then adding the powder into water, uniformly mixing, then adding an organic polymer monomer, a cross-linking agent, an initiator and a catalyst, and fully stirring to form slurry, injecting the slurry into a mold, enabling the organic polymer monomer to react, crosslink and polymerize to form polymer gel, and bonding and curing the particles in situ to form a green body, and carrying out high-temperature and high-pressure plasma-assisted sintering on the green body to obtain the jewel-like crystal. The technical means of material synthesis and crystal reconstruction are adopted, and the natural dead pet skeletons are subjected to atom recombination to form jewel-like crystals containing elements such as carbon, calcium, phosphorus, magnesium and oxygen; on the basis of the traditional hot pressing sintering technology, the plasma auxiliary sintering technology is combined, multi-field coupling of a thermal field, a force field and an electric field is achieved, energy needed by reaction is reduced, and the reaction rate and the production efficiency are improved.

Owner:福建省泉州市半岛建材有限公司

A preparation method of perovskite photovoltaic thin film based on double-effect seed growth method

InactiveCN110120455BQuality improvementReduce grain boundary defectsSolid-state devicesSemiconductor/solid-state device manufacturingFilm baseSeed crystal

Owner:WUHAN UNIV

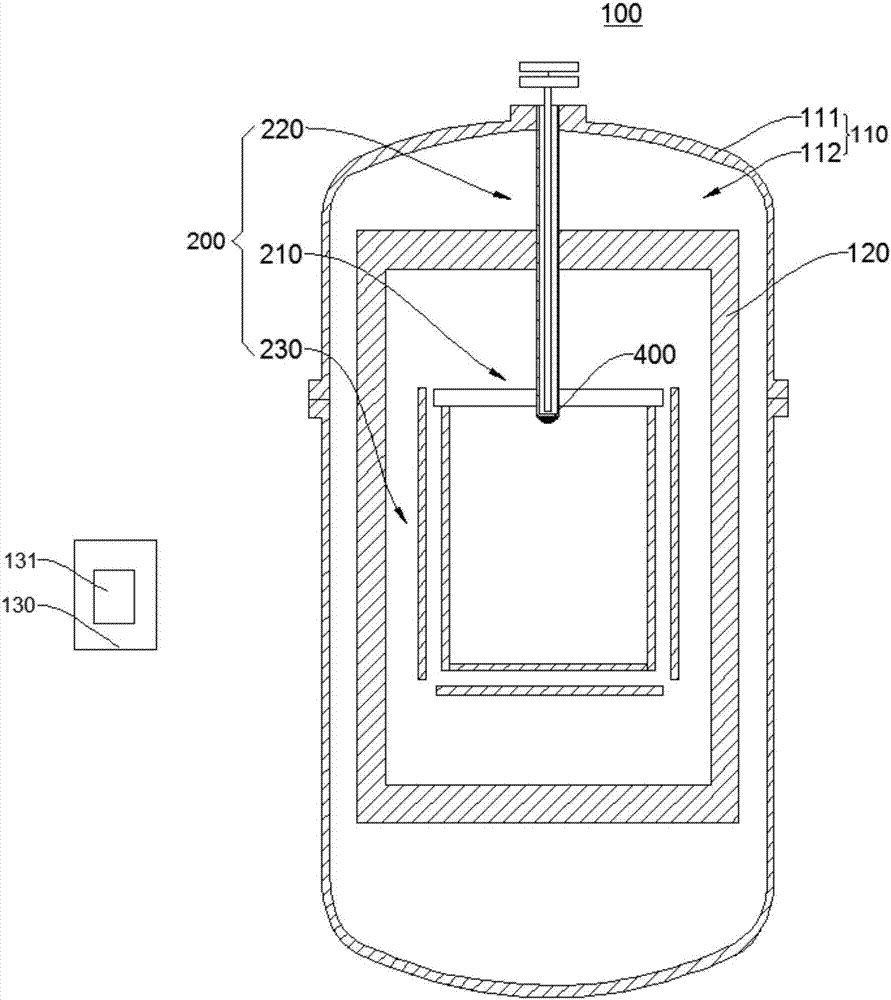

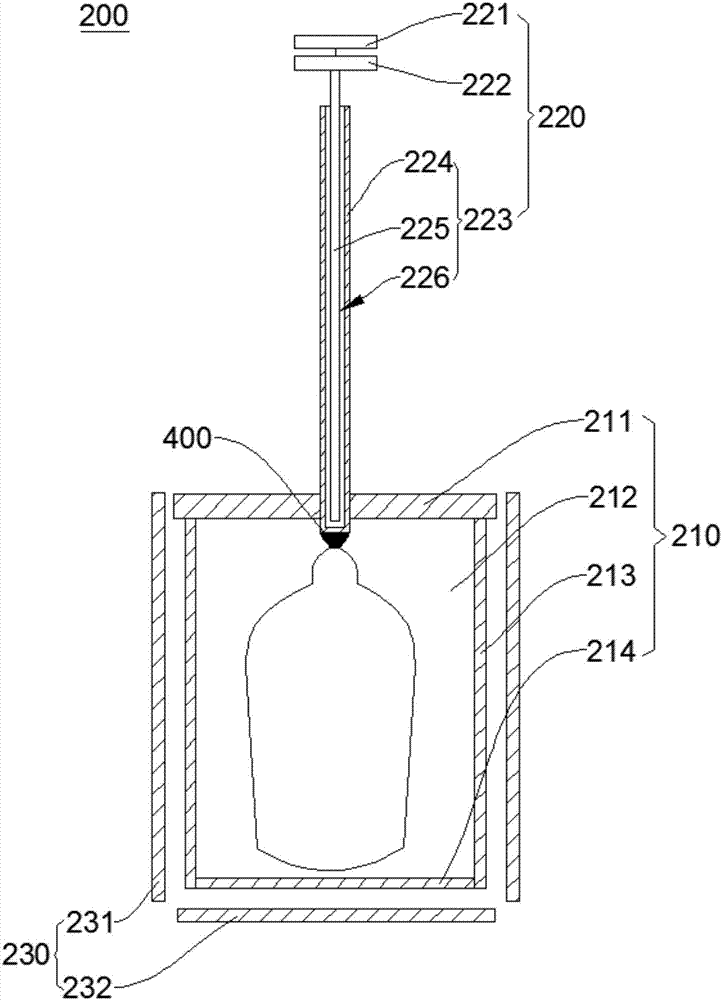

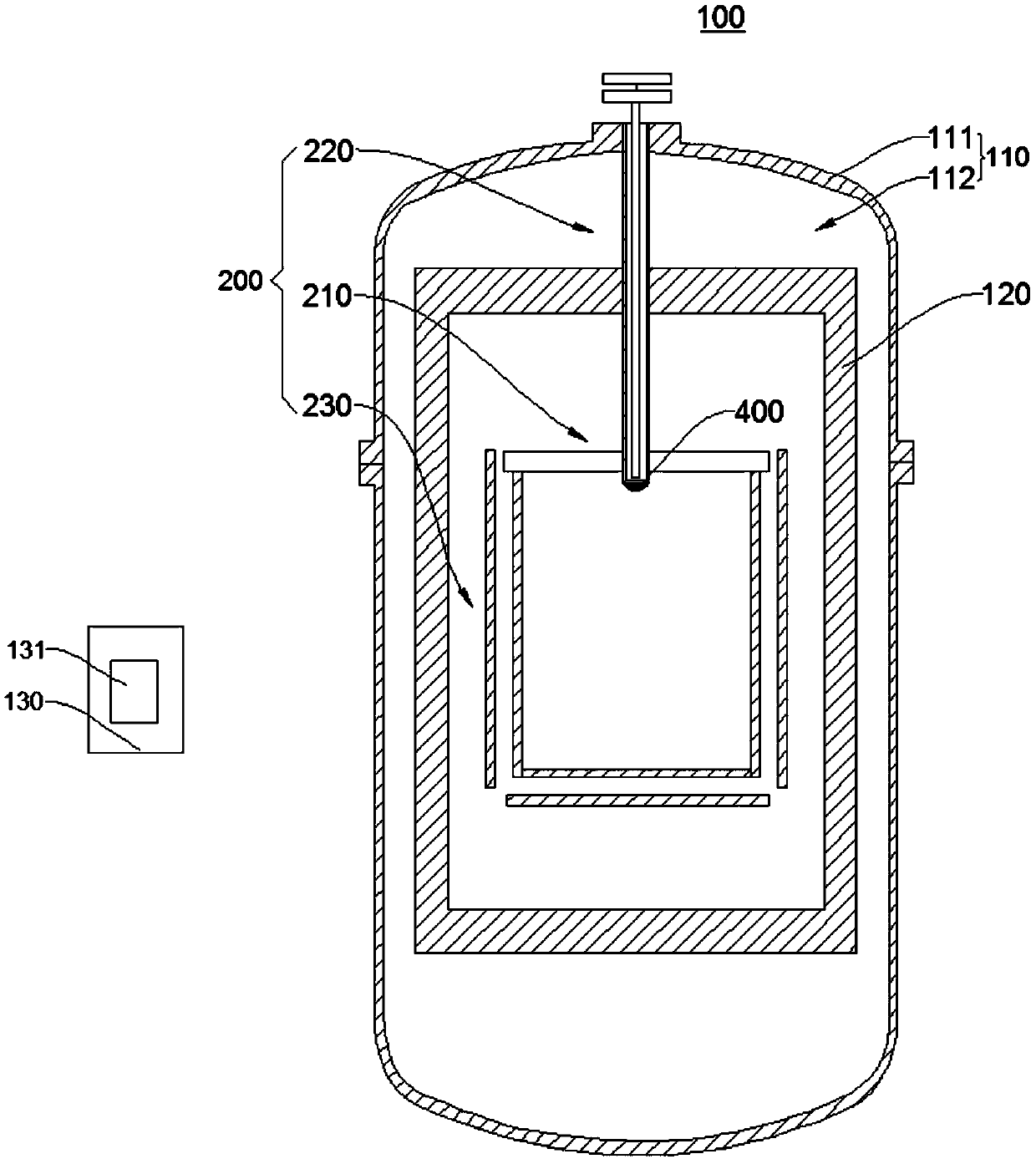

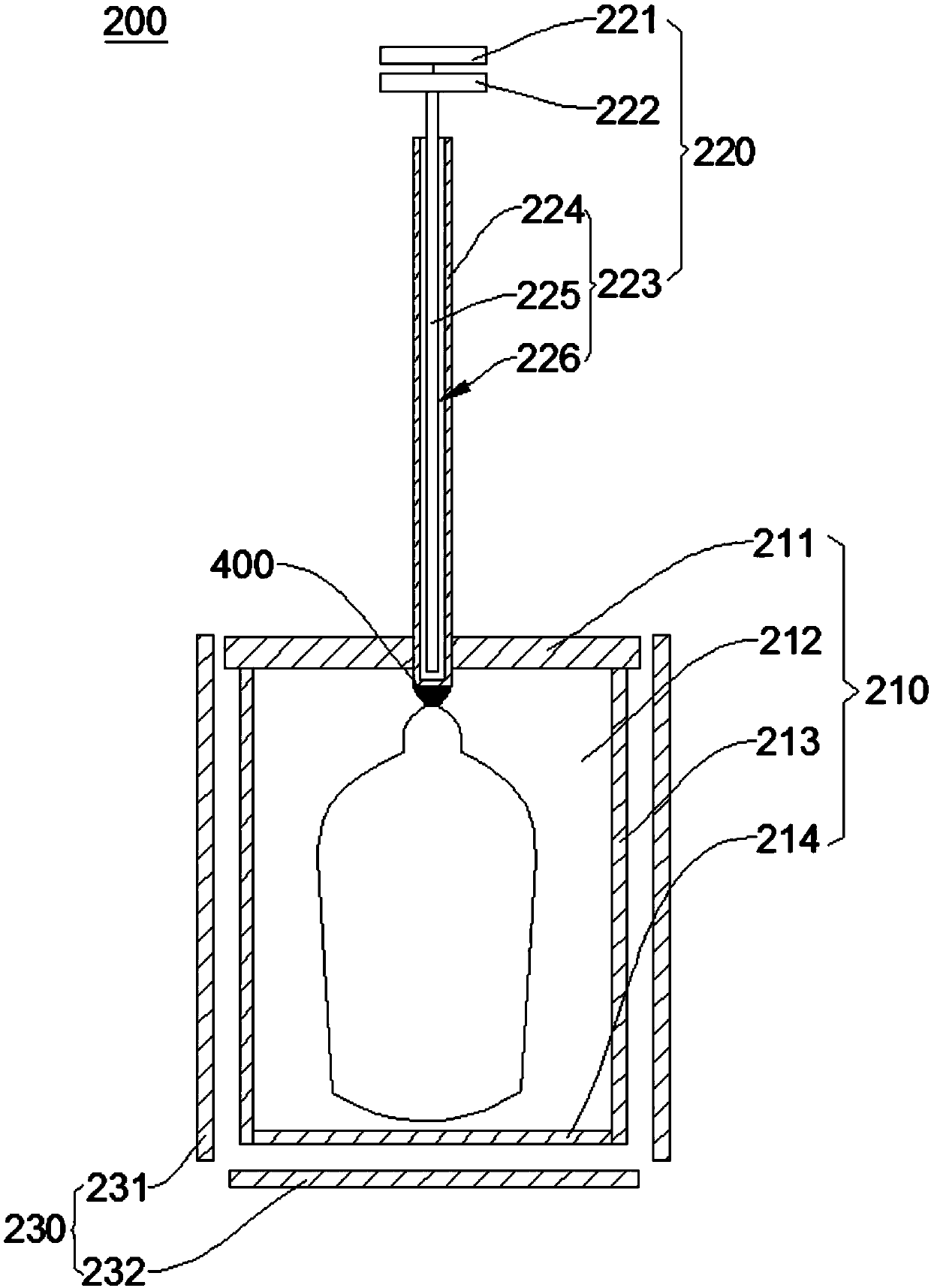

Crystal growth crucible, crystal growth device and crystal growth method

ActiveCN106854773AAvoid crackingEasy to realize release treatmentBy pulling from meltFrom frozen solutionsCrucibleCzochralski method

The invention belongs to the technical field of crystal growth, and concretely relates to a crystal growth crucible, a crystal growth device and a crystal growth method. The crystal growth crucible comprises a crucible body and a heat exchanger. The crucible body comprises a sidewall, a bottom wall and a crucible cover, and the sidewall, the bottom wall and the crucible cover form a crucible chamber providing a place for the growth of crystals. The heat exchanger traverses through the crucible cover and stretches into the crucible chamber, and one end, stretching into the crucible, of the heat exchanger is provided with seed crystals. Heaters are arranged around the crucible body. A heat exchange method, a Kyropoulos method and a Czochralski method are combined to provide the optimized crystal growth method, so the internal defects of the crystals are reduced, the cracking probability of the crystals is reduced, and the yield of the crystals is increased.

Owner:通辽精工蓝宝石有限公司

Manufacturing method of polysilicon layer and polysilicon thin film transistor and manufacturing method thereof

ActiveCN103219228BIncrease crystallization rateUniform grainTransistorSolid-state devicesAmorphous siliconComposition process

Owner:BOE TECH GRP CO LTD +1

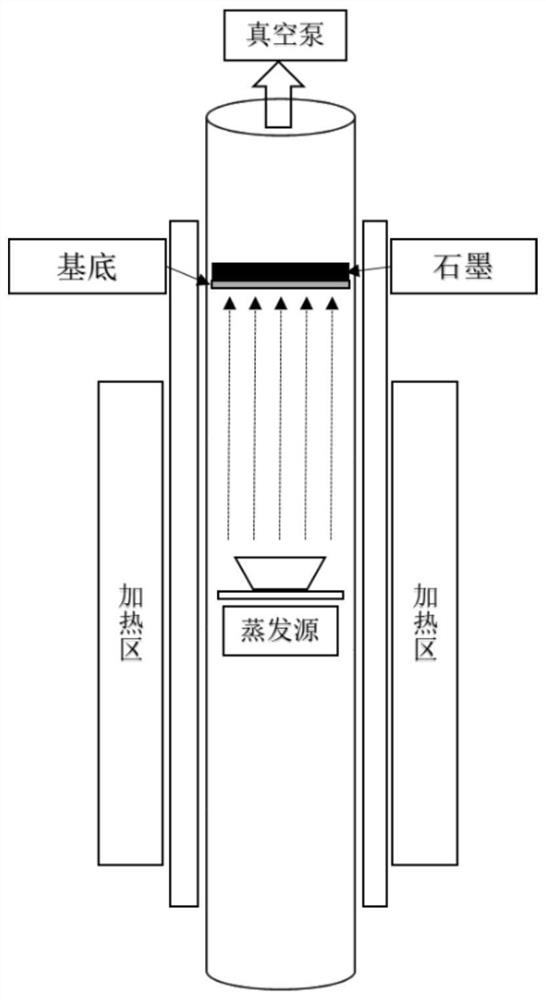

A thin film preparation method of a quasi-one-dimensional structure material with controllable orientation

ActiveCN111020487BOrientation is well controllableOrientation controllableFinal product manufactureVacuum evaporation coatingEvaporation (deposition)Tube furnace

The invention discloses a method for preparing a thin film of a quasi-one-dimensional structural material with controllable orientation. The method is based on a vertical evaporation tube furnace, and specifically includes the following steps: (1) placing the evaporation source material and the substrate to be deposited on the In the vertical evaporation tube furnace; (2) vacuum treatment, so that the vacuum degree of the vertical evaporation tube furnace remains at the preset vacuum degree and the fluctuation does not exceed ± 1Pa; (3) heat treatment in the heating zone, so that The evaporation source material is evaporated and deposited on the substrate to form a thin film; during the preparation process, the orientation of the formed quasi-one-dimensional material film can be controlled by controlling the parameters of the evaporation process. The present invention improves the key process parameters of the preparation method, adopts a vertical evaporation tube furnace with a specific structure for deposition, realizes the deposition and orientation control of a quasi-one-dimensional material film, and obtains a semiconductor film with a controllable orientation independent of the substrate , compared with the prior art, it can effectively solve the problem that the orientation of quasi-one-dimensional materials cannot be controlled.

Owner:HUAZHONG UNIV OF SCI & TECH +1

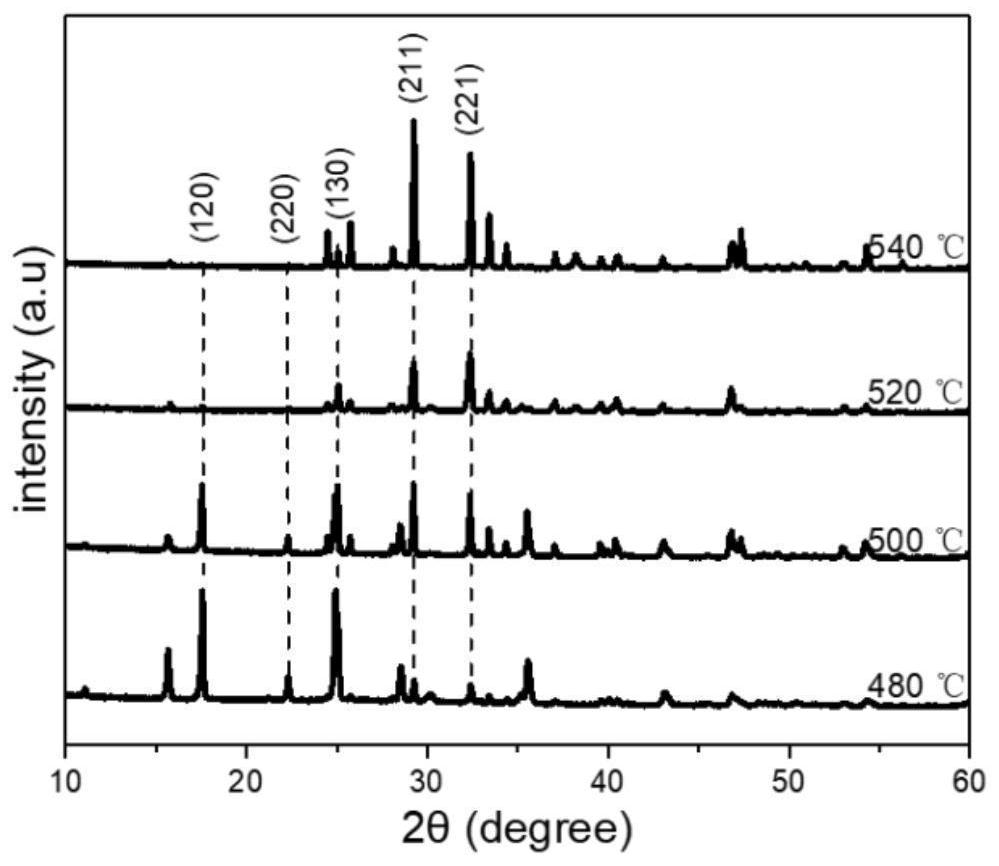

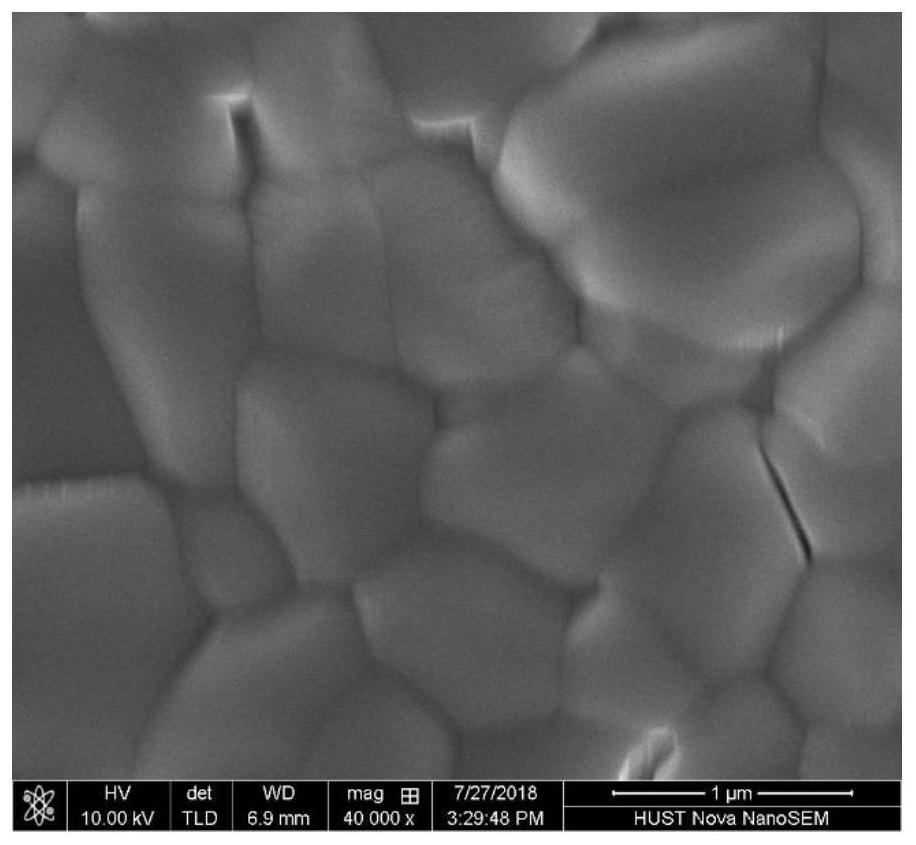

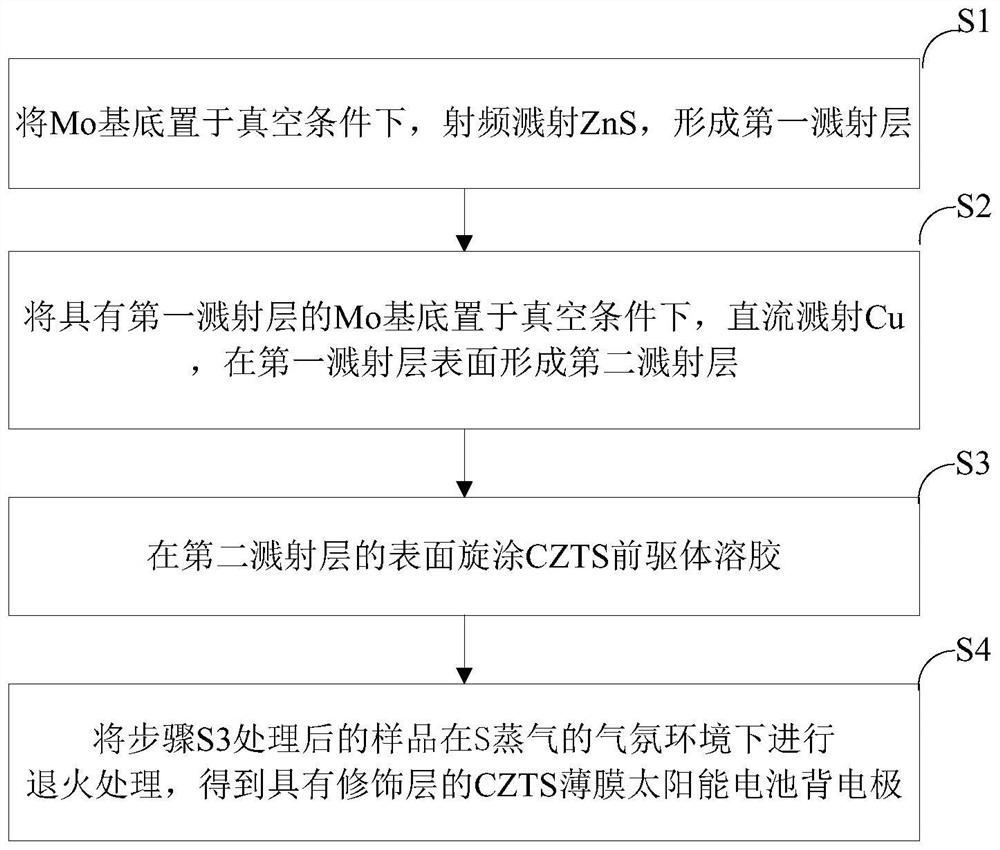

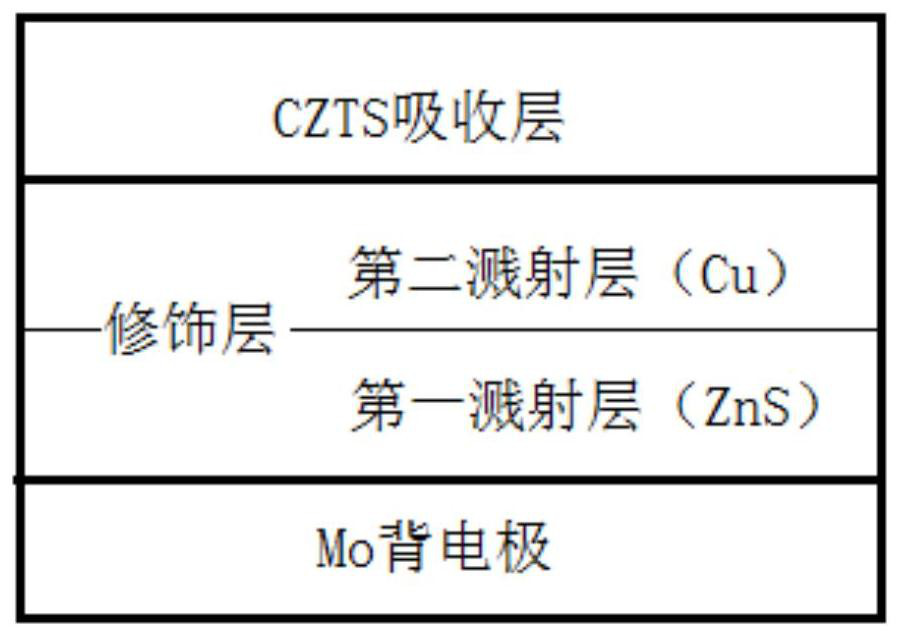

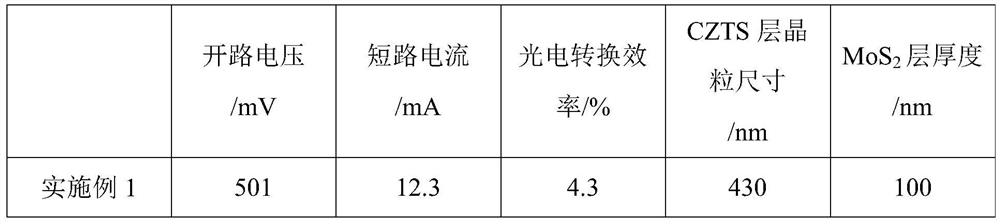

Preparation method of CZTS thin-film solar cell back electrode with modification layer

PendingCN114171637AReduce grain boundary defectsReduce or eliminate growthFinal product manufactureVacuum evaporation coatingEngineeringElectrode Contact

The invention provides a preparation method of a CZTS thin-film solar cell back electrode with a modification layer, and the method comprises the following steps: firstly, placing a Mo substrate under a vacuum condition, and carrying out the radio-frequency sputtering of ZnS, so as to form a first sputtering layer; secondly, under the vacuum condition, Cu is subjected to direct current sputtering, and a second sputtering layer is formed on the surface of the first sputtering layer; thirdly, spin-coating CZTS precursor sol on the surface of the second sputtering layer; and finally, carrying out annealing treatment under S steam. Wherein the first sputtering layer of the modification layer can be used as an S vapor barrier layer to inhibit vulcanization of the Mo layer and reduce the thickness of MoS2; and the second sputtering layer of the modification layer takes Cu as a raw material for direct current sputtering, so that the crystallization of an upper-layer CZTS precursor is facilitated, and the grain boundary defect of the CZTS is reduced. Besides, the modification layer can form a heavy p + type layer between the CZTS thin film on the upper layer and the Mo electrode on the lower layer, the carrier transmission performance of the contact side of the CZTS layer and the Mo back electrode is improved, and the photoelectric conversion efficiency of the solar cell device is further improved.

Owner:HUBEI UNIV OF TECH

A kind of polysilicon film production method

ActiveCN110581058BAvoid the problem of limited production processReduce grain boundary defectsSemiconductor/solid-state device manufacturingThin membraneEngineering

The embodiment of the present invention discloses a polysilicon thin film manufacturing method. The polysilicon thin film manufacturing method includes providing a first substrate and the temperature resistance of the first substrate is greater than or equal to 600° C.; forming a polysilicon thin film on the first substrate ; Transferring the formed polysilicon film to a glass substrate. In the technical solution of the present invention, a polysilicon film is first formed on the first substrate with a high temperature resistance temperature, and then the formed polysilicon film is transferred to a glass substrate, which avoids the temperature resistance of the glass substrate from making the production process of the polysilicon film subject to difficulties. Compared with the laser laser process adopted in the prior art, the crystal grains of the polysilicon film can reach a larger size, and the polysilicon film with a large grain size has fewer grain boundary defects, which improves the film quality of the formed polysilicon film And the electrical reliability of the polysilicon thin film.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

A kind of preparation method of rare earth cobalt-based material

ActiveCN105489331BShorten the timeReduce lossInorganic material magnetismHydrogen pressureRare earth

The invention relates to a preparation method for a rare earth cobalt-based material, and specifically a preparation method for a 2:17 type rare earth cobalt-based material, comprising the steps of (1) smelting and preparing an alloy ingot based on the proportion of elements, wherein the chemical atom stoichiometric equation of the alloy ingot is Sm1-xRx(Co1-a-b-cFeaCubZrc)z; R is any one or more of Ce, Pr, Nd, Gd, Tb, Dy, Ho or Er; x is greater than or equal to 0 and less than or equal to 0.5; a is greater than or equal to 0 and less than or equal to 0.5; b is greater than or equal to 0 and less than or equal to 0.15; c is greater than or equal to 0 and less than or equal to 0.04; and z is greater than or equal to 6.5 and less than or equal to 8.5; (2) performing hydrogen absorption on the alloy ingot at a hydrogen absorption temperature of 10-180 DEG C and at hydrogen pressure of 0.2-0.5MPa for 2-5h to obtain smashed hydrogen powder; (3) continuing to smash the smashed hydrogen powder by an airflow mill to obtain magnetic powder; and (4) performing orientation moulding, isostatic cool pressing, sintering and solid solution treatment and aging treatment on the magnetic powder in sequence to obtain the rare earth cobalt-based material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A method for manufacturing an alloy with excellent durability under high temperature and high pressure conditions

ActiveCN109988927BManufacturing method of alloy with excellent durabilityImprove high temperature strengthAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesElectro-slag remeltingMaterials science

The invention provides a method for manufacturing an alloy with excellent durability under high temperature and high pressure conditions, comprising the following steps: 1) raw material preparation; 2) vacuum smelting, including: 2.1) charging; 2.2) melting; 2.3) refining; 2.4) pouring ; 3) electroslag remelting; 4) forging; 5) heat treatment; 6) durability performance testing, sampling, peeling, inspection, packaging, storage, and completing the manufacture of alloys with excellent durability under high temperature and high pressure conditions. On the one hand, the manufacturing method optimizes the design of alloying elements; moreover, in combination with the above-mentioned traditional vacuum degassing and desulfurization technologies, the desulfurization and degassing effects of Ni-Mg and rare earth are especially increased; on the other hand, Cr-Ni-Mo is optimized. The heat treatment process of ‑W alloy successfully produced a high-end Cr‑Ni‑Mo‑W alloy steel with a durable life of more than 500 hours under the conditions of high temperature 815 °C and high pressure 110 MPa.

Owner:江苏汉青特种合金有限公司

A ultra -high -strength corrosion resistance alloy and manufacturing method

The invention belongs to the technical field of alloy manufacturing, and in particular relates to an ultra-high-strength corrosion-resistant alloy and a manufacturing method, in particular to a Cr-Ni-Mo-Nb corrosion-resistant alloy having both ultra-high strength and excellent stress corrosion properties and the Alloy production technology. The alloys of the present invention include the elements nickel, carbon, silicon, manganese, sulfur, chromium, molybdenum, iron, aluminum, titanium, niobium, zirconium, yttrium. The alloy prepared by the present invention is in high pressure H 2 S. High pressure CO 2 And in the chloride ion environment, it not only has very high strength, but also has excellent stress corrosion resistance, can be used to manufacture key components of oilfield drilling and production equipment, and has a long service life.

Owner:江苏汉青特种合金有限公司

A kind of anti-hydrogen and anti-hydrogen sulfide corrosion steel forging and its production process

Owner:WUXI PAIKE HEAVY CASTING & FORGING

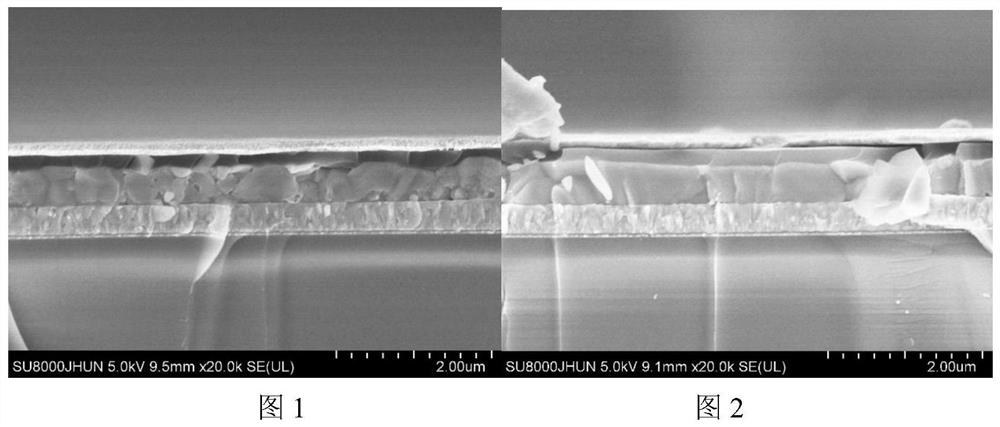

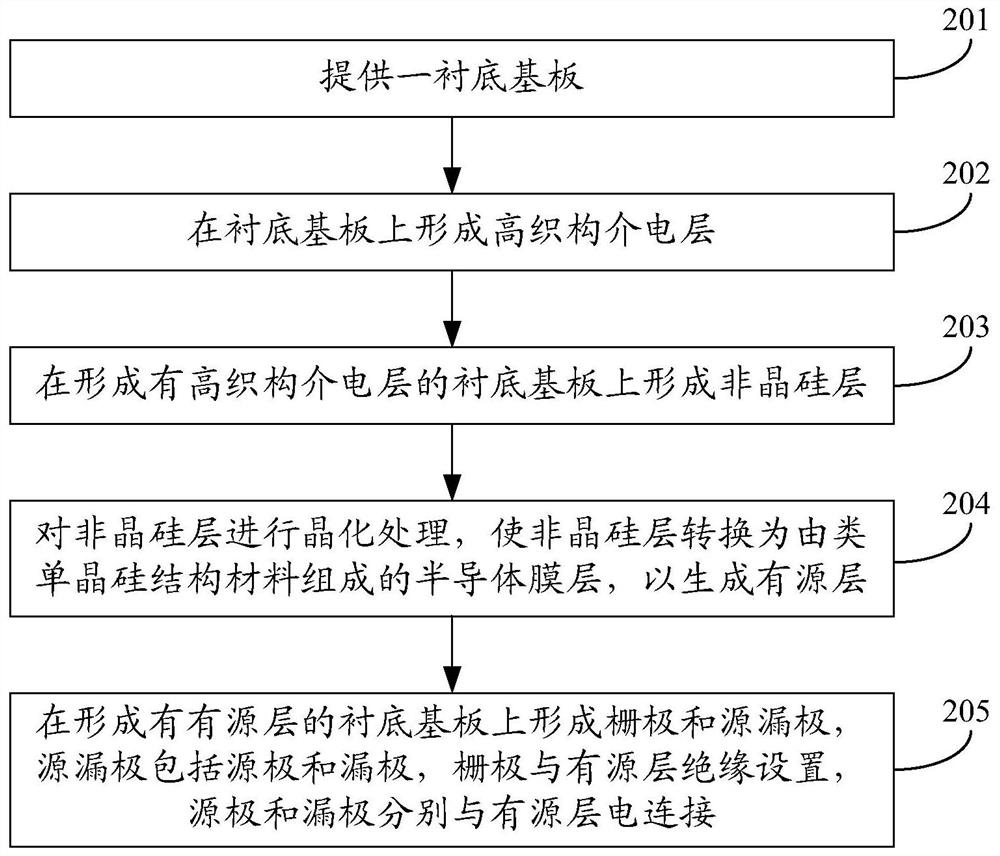

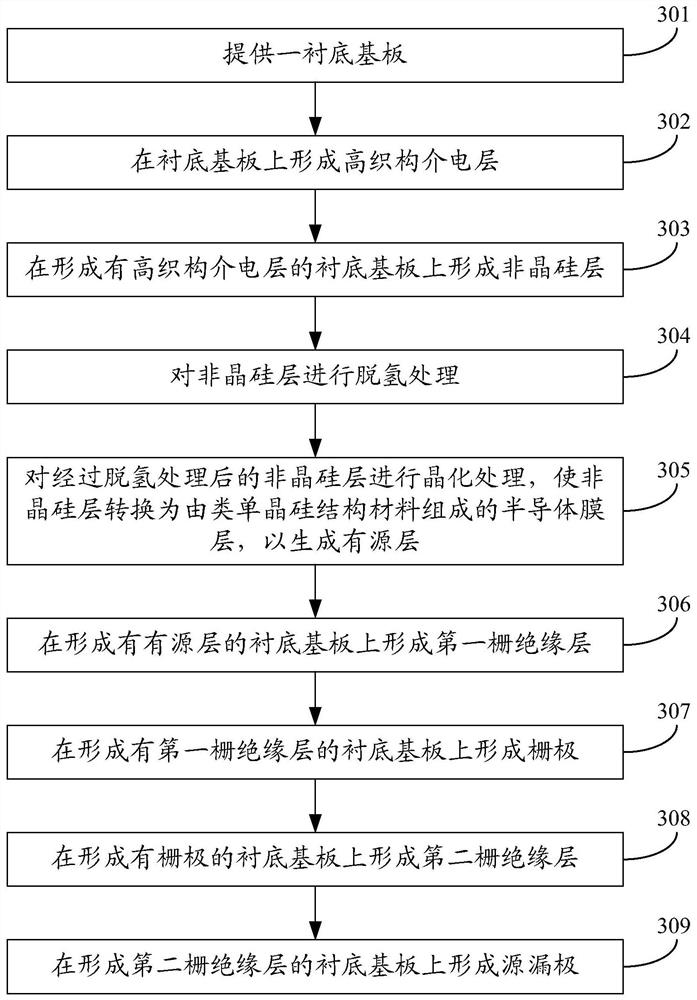

Thin film transistor and its manufacturing method, array substrate and display device

ActiveCN109801973BHigh carrier mobilityImprove performanceTransistorSolid-state devicesDisplay deviceElectrical connection

The invention discloses a thin film transistor, a manufacturing method thereof, an array substrate and a display device, and belongs to the field of display technology. It includes: a highly textured dielectric layer stacked on the base substrate, an active layer, a gate and a source and drain, the source and drain include a source and a drain, and the gate and the active layer Insulated, the source and the drain are electrically connected to the active layer respectively; wherein, the constituent particles of the active layer are single-crystal silicon-like structures. The invention replaces the original buffer layer with a highly textured dielectric layer to induce the active layer to grow into a single-crystal silicon-like structure, thereby improving the performance of the thin film transistor.

Owner:BOE TECH GRP CO LTD +1

A kind of crystal growth crucible, device and growth method thereof

ActiveCN106854773BAvoid crackingEasy to realize release treatmentBy pulling from meltFrom frozen solutionsCzochralski methodCrucible

The invention belongs to the technical field of crystal growth, and concretely relates to a crystal growth crucible, a crystal growth device and a crystal growth method. The crystal growth crucible comprises a crucible body and a heat exchanger. The crucible body comprises a sidewall, a bottom wall and a crucible cover, and the sidewall, the bottom wall and the crucible cover form a crucible chamber providing a place for the growth of crystals. The heat exchanger traverses through the crucible cover and stretches into the crucible chamber, and one end, stretching into the crucible, of the heat exchanger is provided with seed crystals. Heaters are arranged around the crucible body. A heat exchange method, a Kyropoulos method and a Czochralski method are combined to provide the optimized crystal growth method, so the internal defects of the crystals are reduced, the cracking probability of the crystals is reduced, and the yield of the crystals is increased.

Owner:通辽精工蓝宝石有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com