Ultrahigh-strength corrosion-resistant alloy and manufacturing method thereof

A corrosion-resistant alloy and ultra-high-strength technology, applied in the field of alloy manufacturing, can solve problems such as short service life, insufficient strength index, and insufficient stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

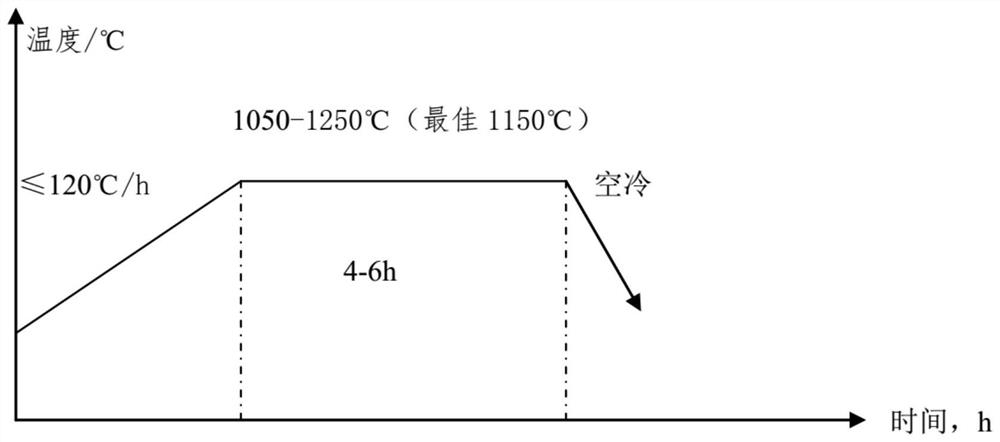

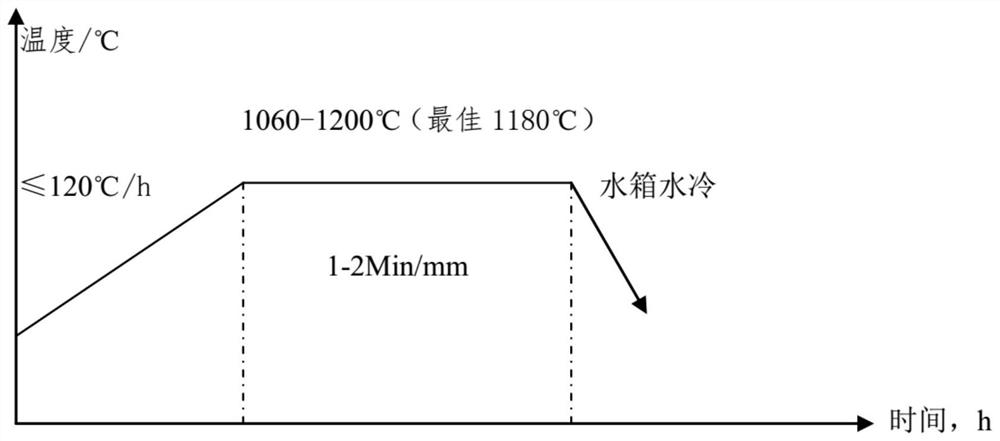

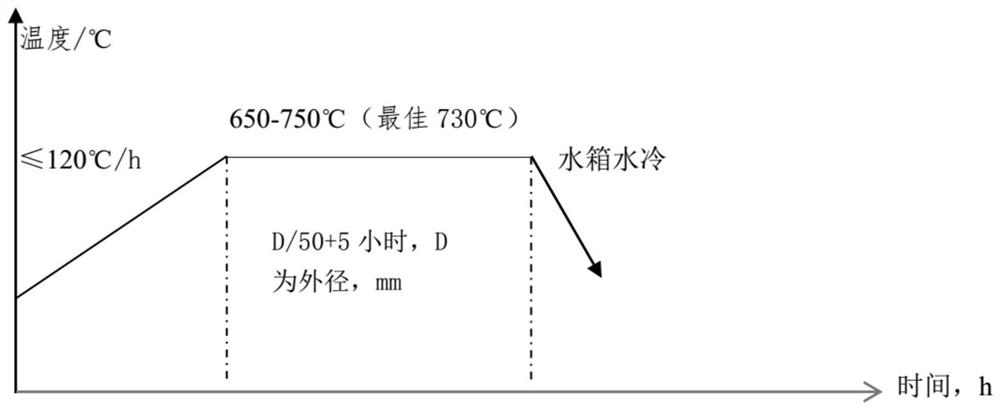

[0092] The invention develops the HQ9725 alloy including the optimization design of the chemical composition and the optimization design of the production process route.

[0093] 1. Chemical composition design of HQ9725 alloy

[0094] Compared with the traditional GH4169 and Inconel 625 alloys, the HQ9725 alloy produced by the present invention has more optimized components, and the design Ti / Al ratio ranges from 4.0 to 6.0, the best being 5.0, which further improves the strength of the alloy; boldly innovative design, adding Zr, and the control range is 0.01 -0.08%, best 0.02%, add Y, control range 0.01-0.08%, best 0.02%, see Table 2 for details.

[0095] Table 2 Composition design comparison (percentage, %)

[0096]

[0097] In the following, the preferred scheme of HQ9725 alloy is taken as an example to illustrate its specific manufacturing process, and based on this, the comprehensive performance comparison with traditional GH4169 and Inconel 625 alloys is carried out....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com