Patents

Literature

30results about How to "Orientation controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

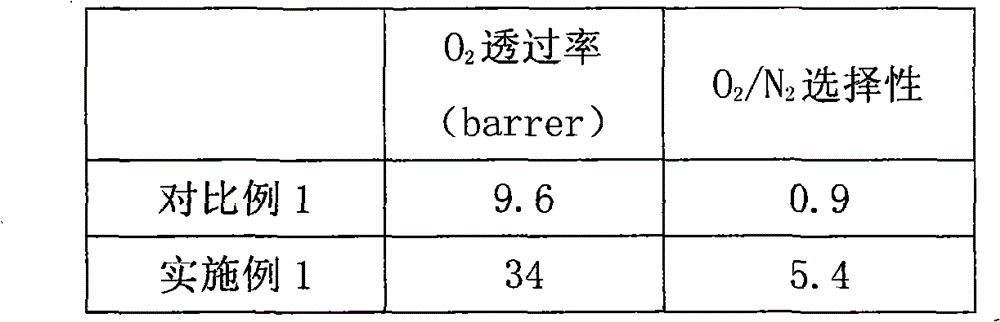

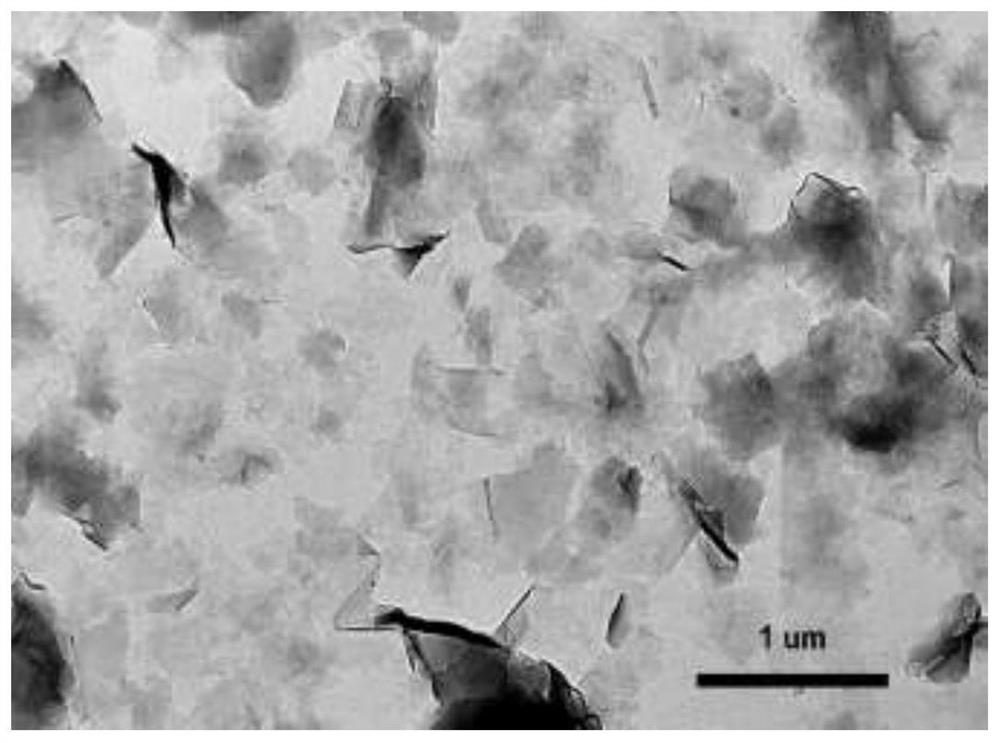

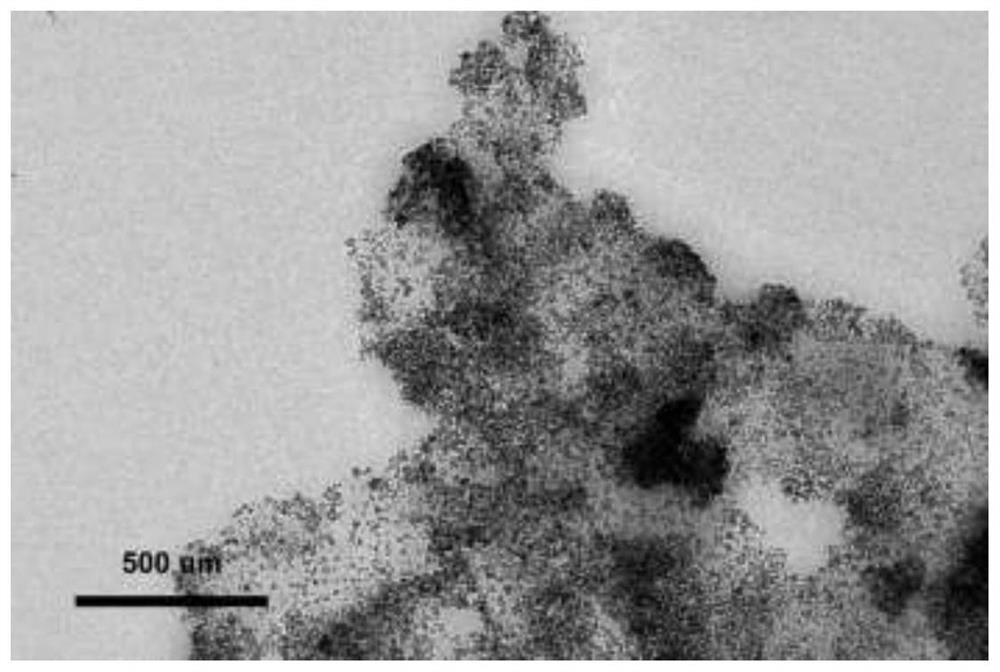

Polymer/inorganic nanometer composite separation membrane and preparation method thereof

InactiveCN101983758AImprove selectivity and transmittanceThe preparation process is simple to operateSemi-permeable membranesSmooth surfaceElectric field

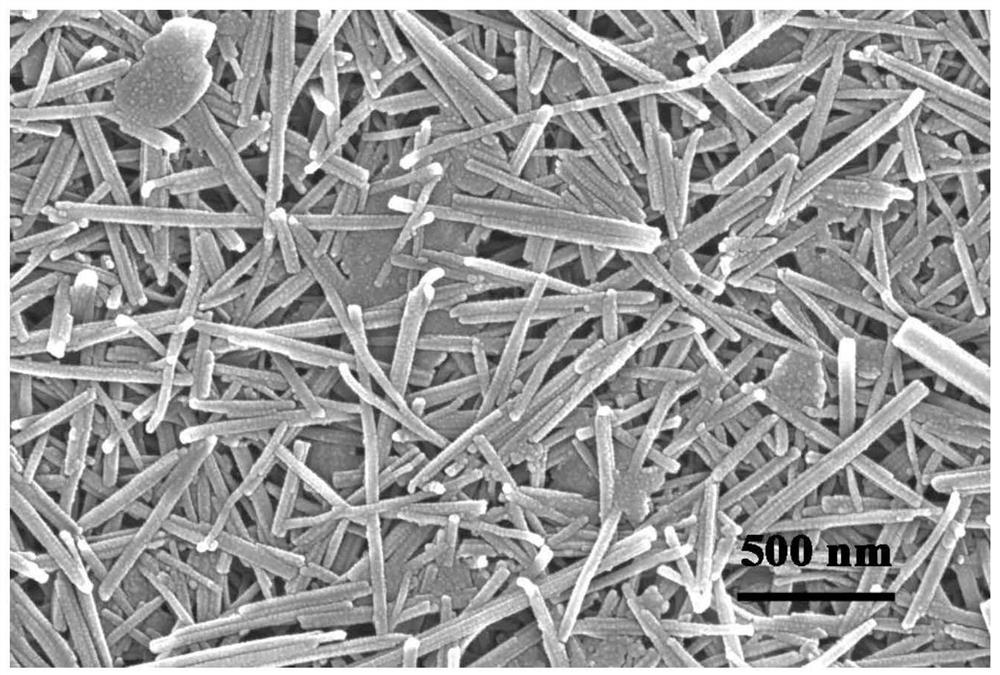

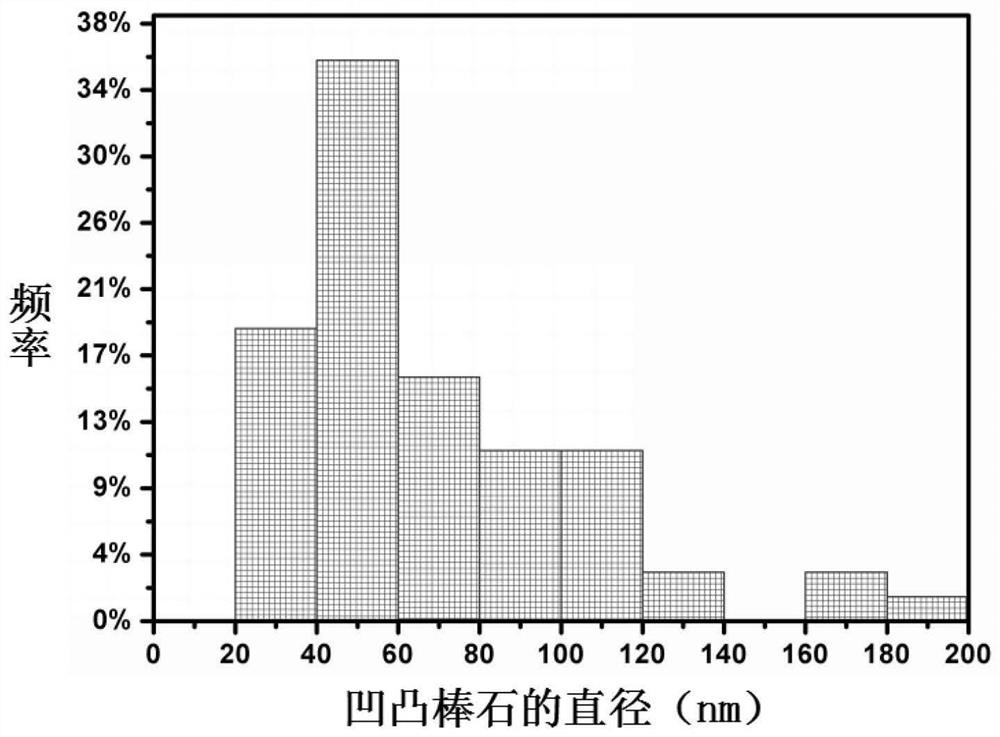

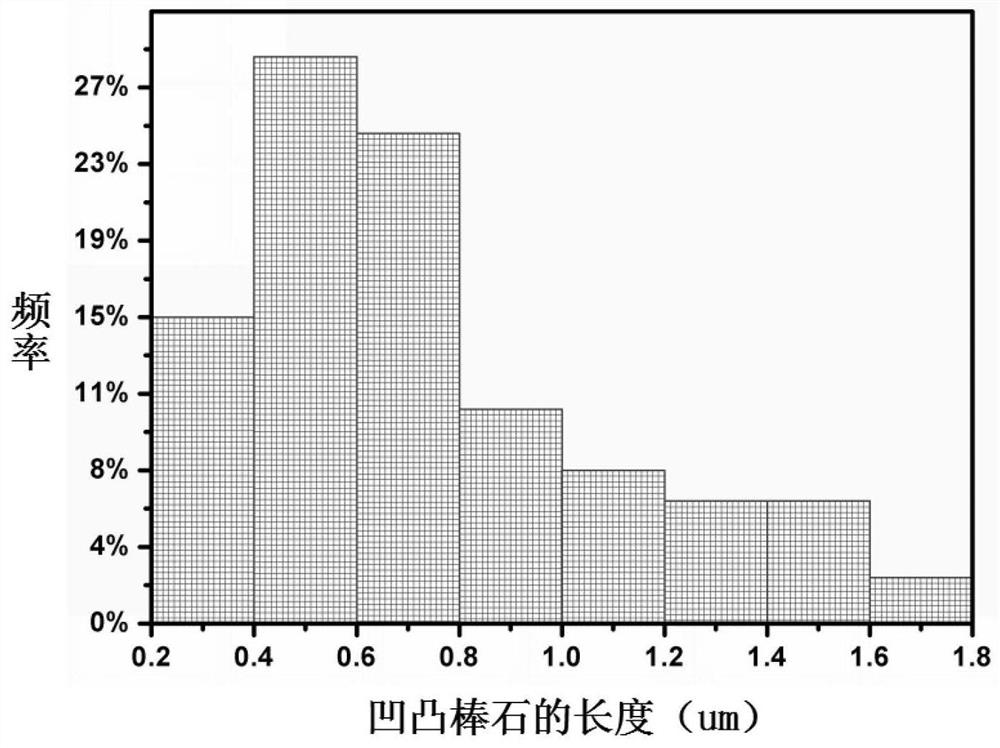

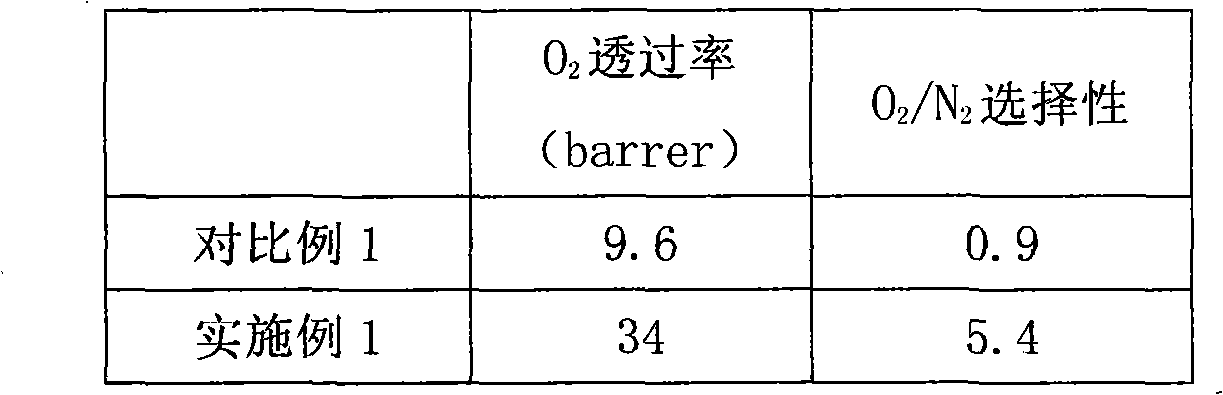

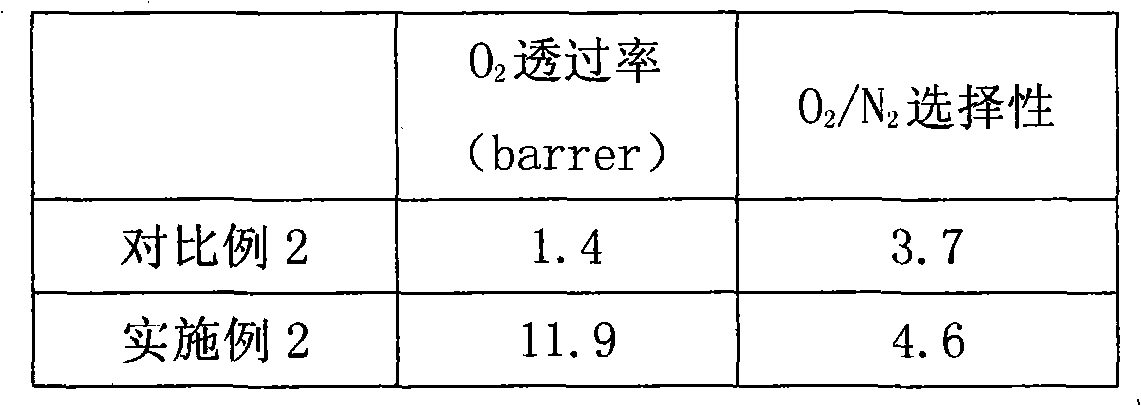

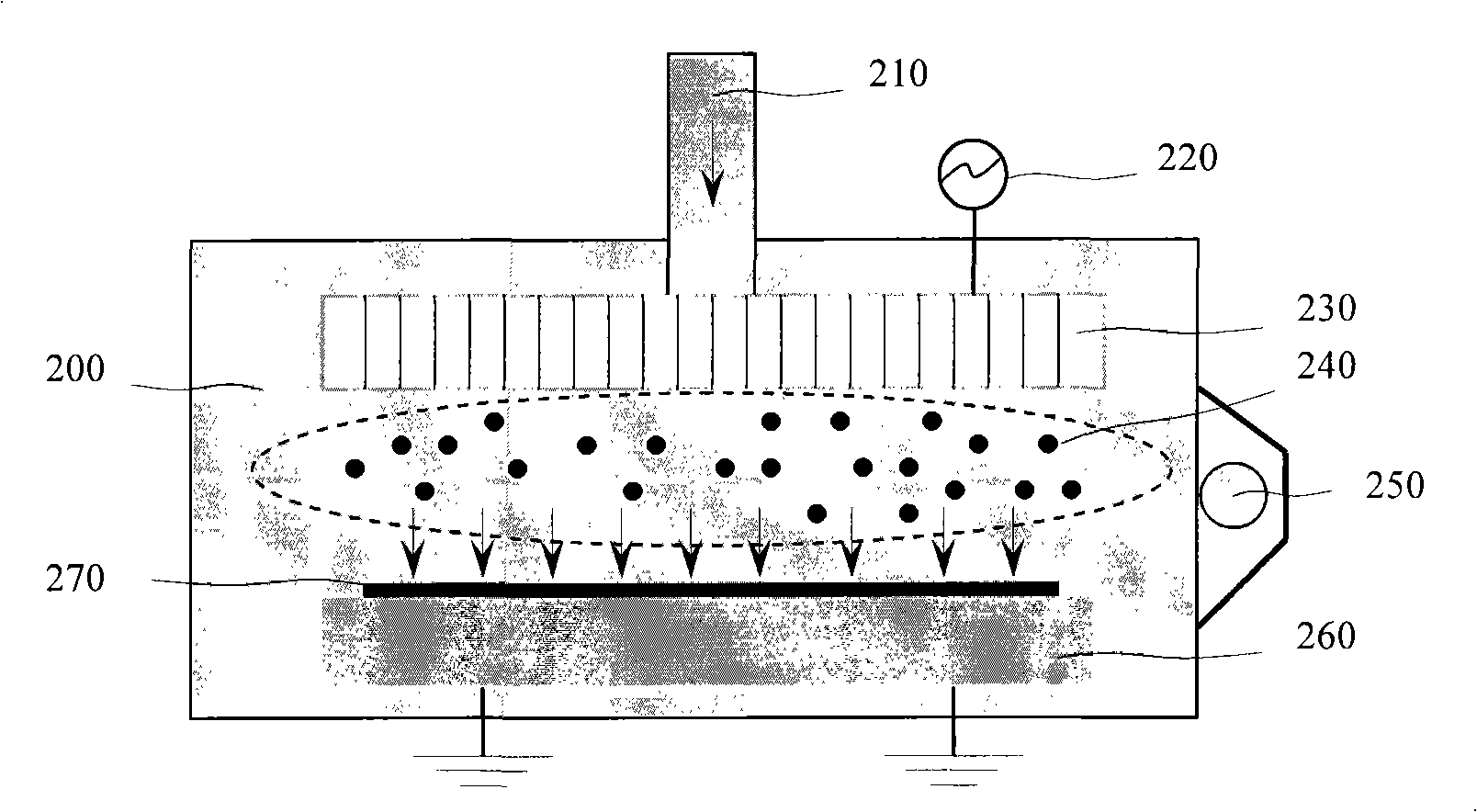

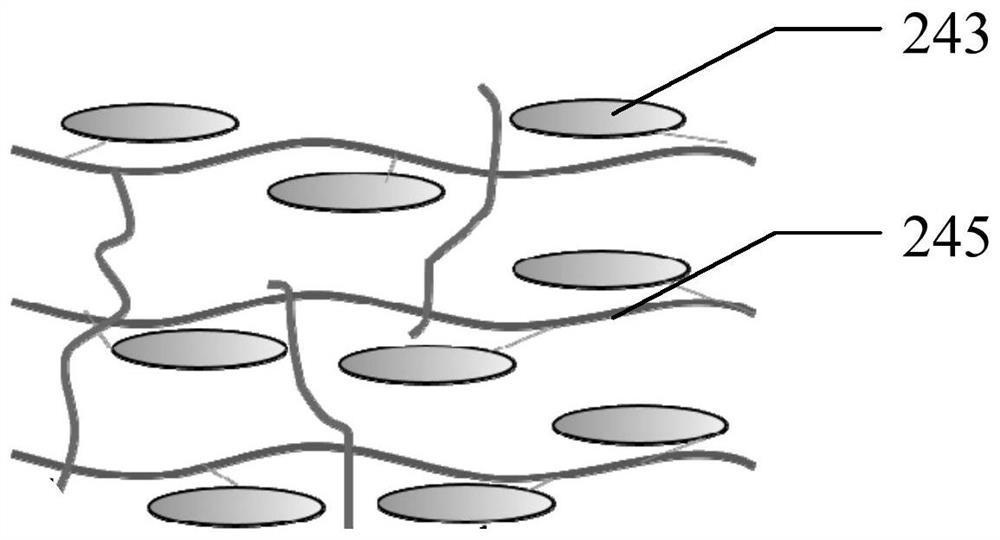

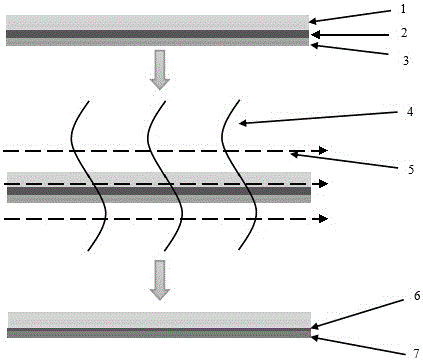

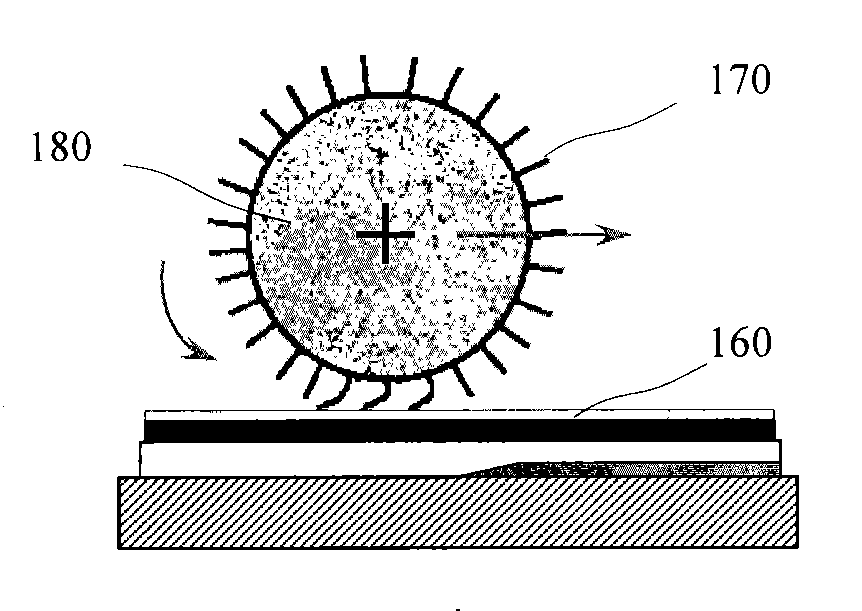

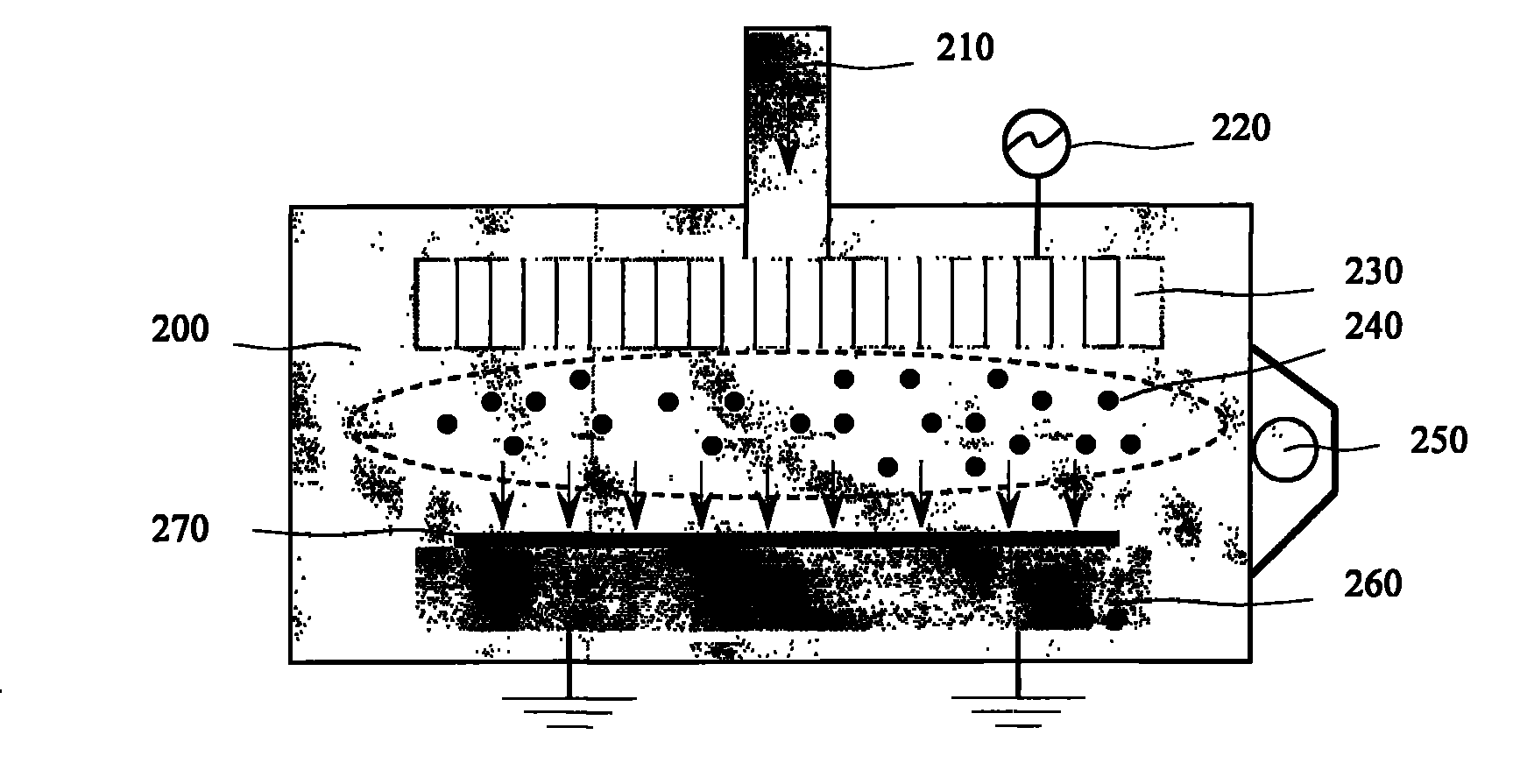

The invention relates to a polymer / inorganic nanometer composite separation membrane and a preparation method thereof. The composite separation membrane consists of a solid matrix of polymer materials and conductive nanomaterials uniformly distributed in the above matrix according to a certain orientation. In the preparation method, conductive nanomaterials which can be arrayed in a certain orientation are uniformly distributed in a film-forming macromolecular material solution. Then electric field is applied during the film-formation process of the mixed solution. The conductive nanomaterials are aligned to the direction of electric field in the film to form the polymer / inorganic nanometer composite separation membrane. The separation membrane has a greater area and smooth surface, controllable film thickness and strength, steerable nanomaterial density and orientation, good selectivity, high transmittance for selected gas and liquid molecules. The method of the invention has the characteristics of simple preparation, easy operation and low cost. The invention can be widely used in the fields of large-scale isolation and purification of gas and large-scale filtration and separation of liquid.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

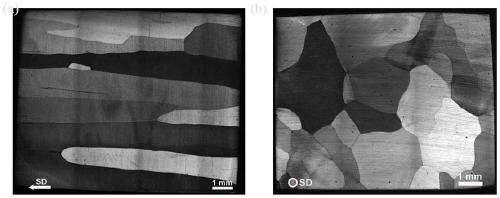

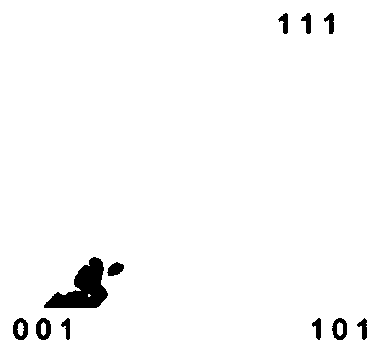

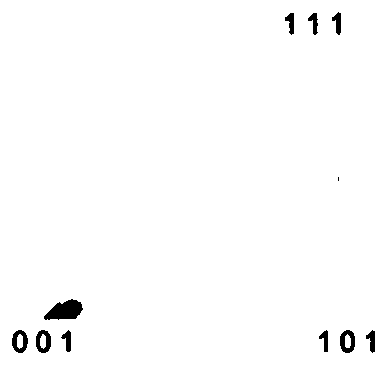

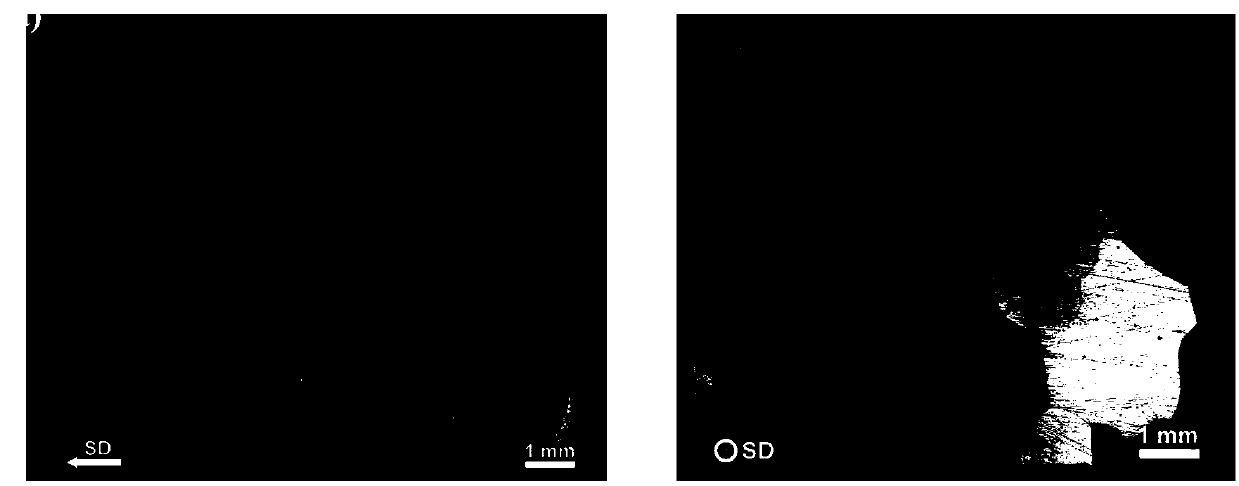

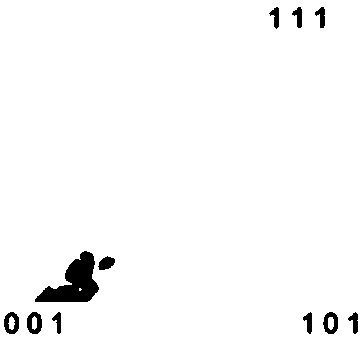

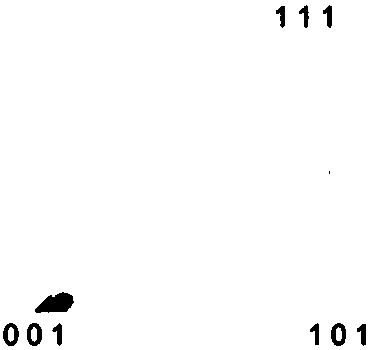

Preparation method of orientation-controllable Cu-Al-Mn shape memory alloy single crystals

ActiveCN107841790AOrientation controllableGuaranteed heredityPolycrystalline material growthAfter-treatment detailsSolid phasesDirectional solidification

The invention relates to a preparation method of orientation-controllable Cu-Al-Mn shape memory alloy single crystals, belonging to the field of preparation of metal materials. The preparation methodcomprises the steps of firstly, preparing columnar polycrystalline Cu-Al-Mn shape memory alloy blank with <100> fiber texture along the solidification direction by adopting a directional solidification method; then, adopting a cyclic heat treatment method to enable the alloy crystal grains to continuously grow abnormally until growing into single crystals; meanwhile, controlling the cycle heat treatment system and process parameters to ensure that the crystal grain orientation has no obvious change in a single crystal growth process so as to obtain the Cu-Al-Mn shape memory alloy single crystals having near <001> orientation along the initial solidification direction. The preparation method, provided by the invention, of the single crystals realizes the orientation control of the solid phase transformation method in the single crystal growth process, and has the advantages of capability of preparing the large-sized single crystals (the single crystal sizes can reach 50 mm or more), easy orientation control, simple process, and the like.

Owner:UNIV OF SCI & TECH BEIJING

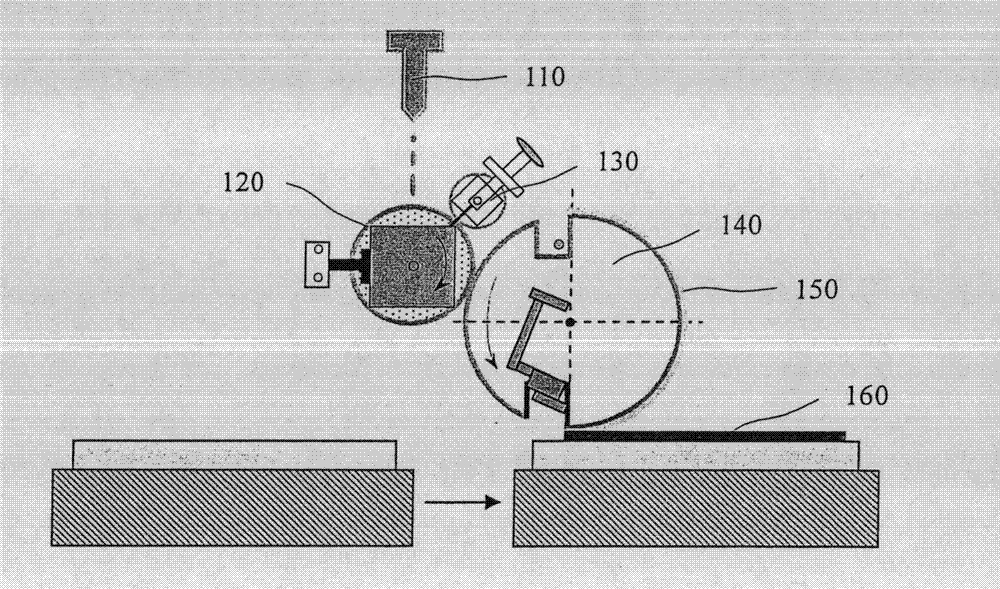

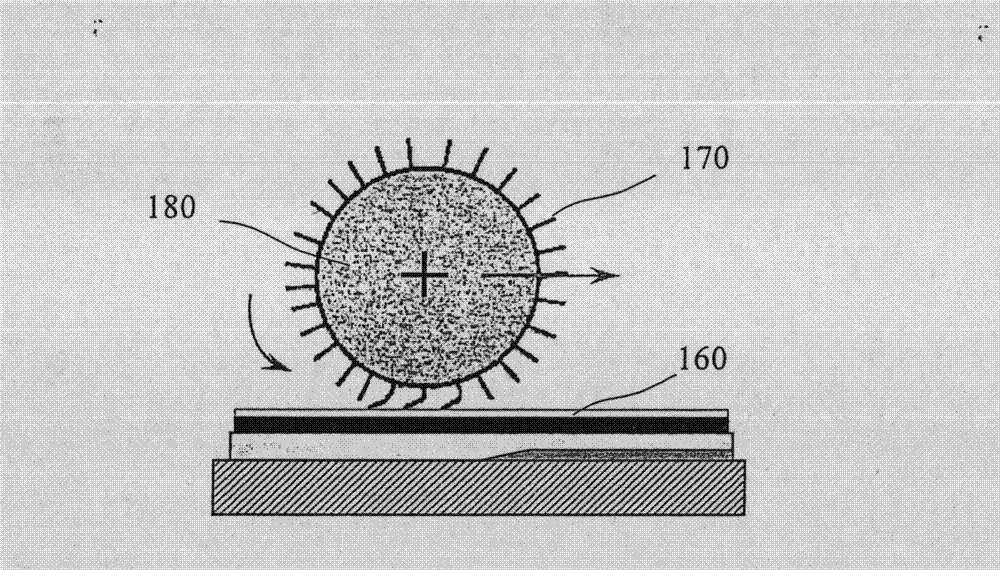

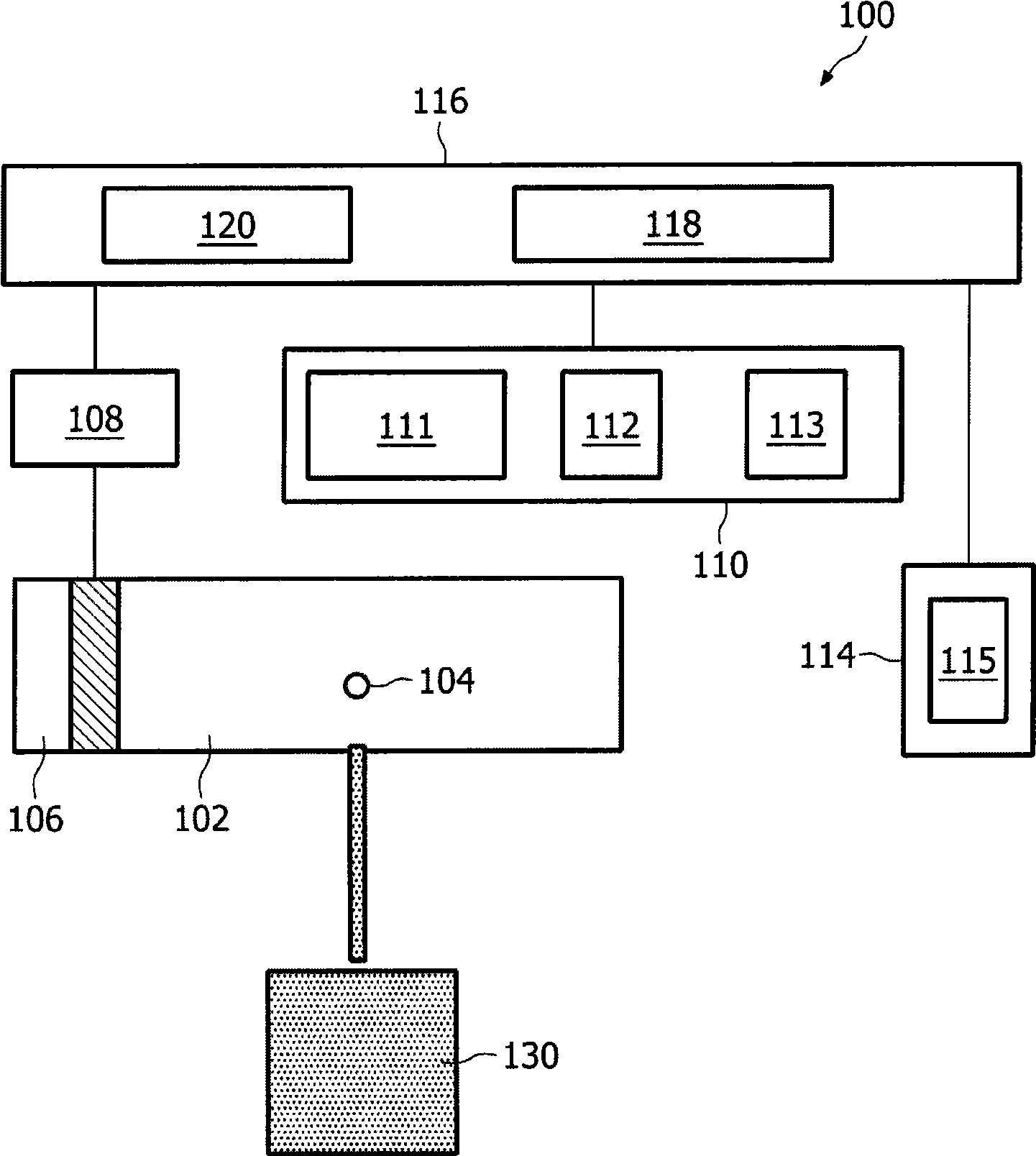

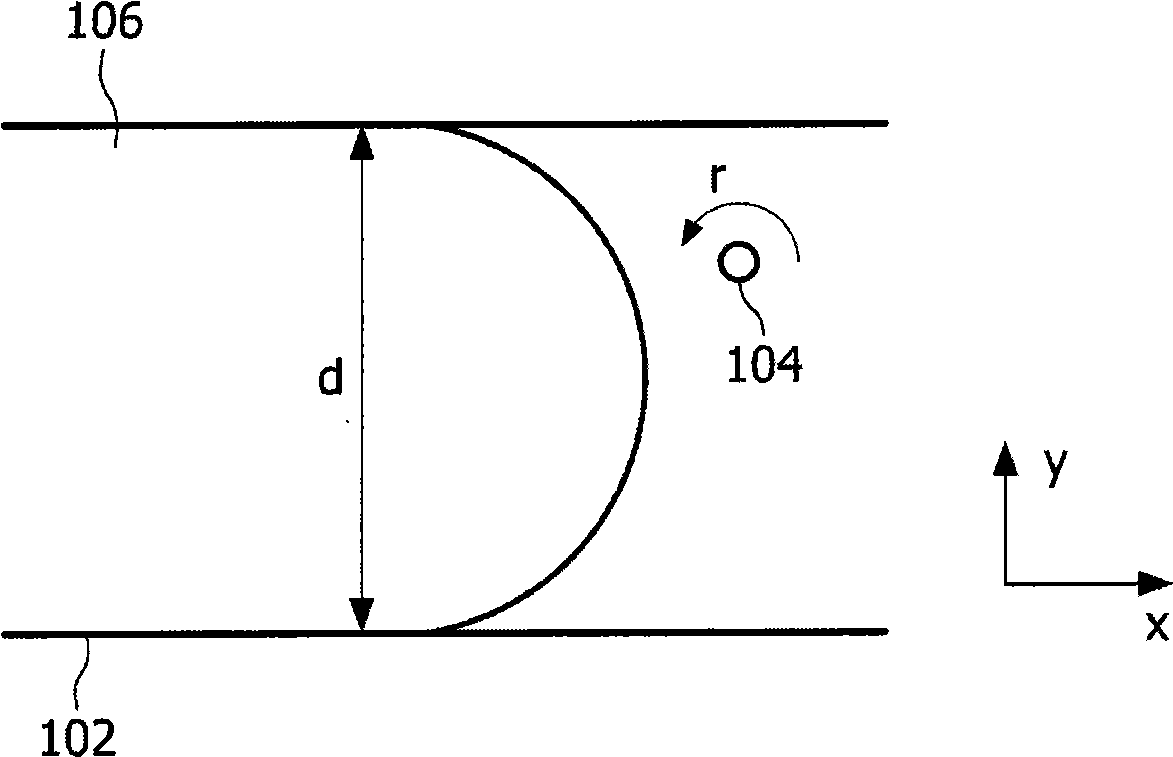

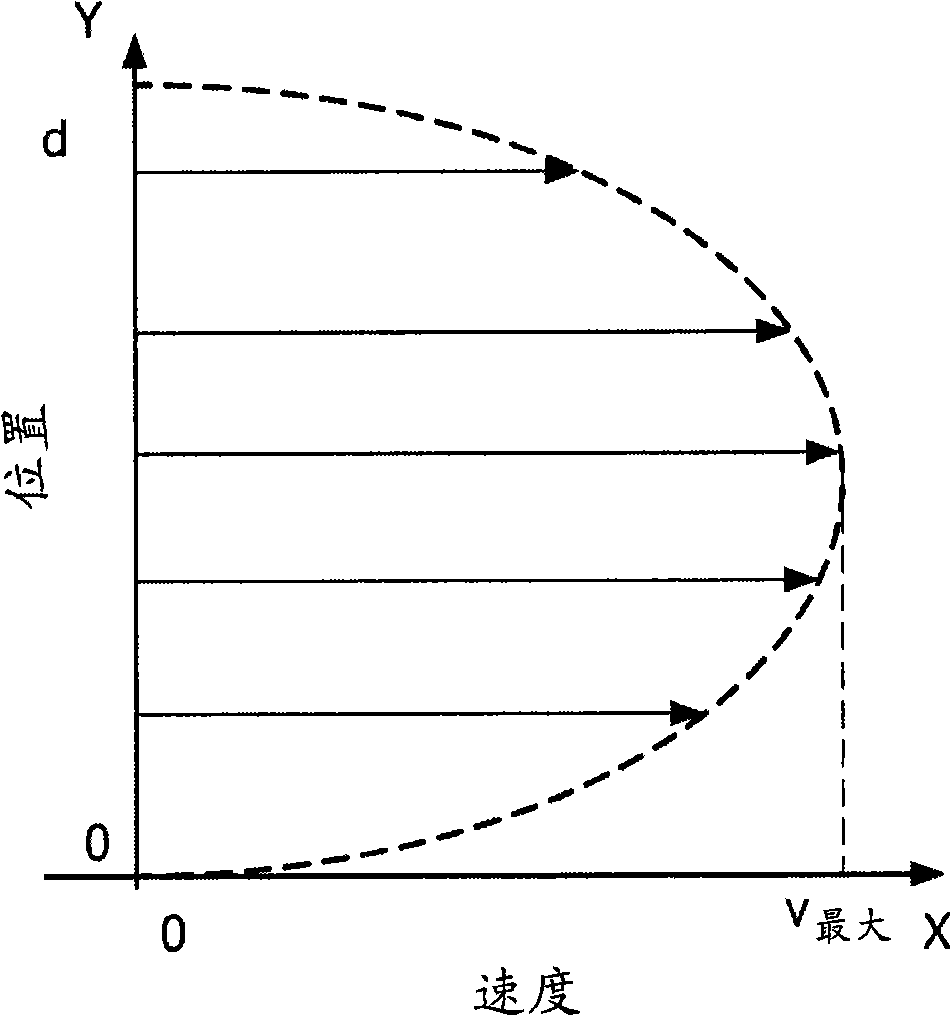

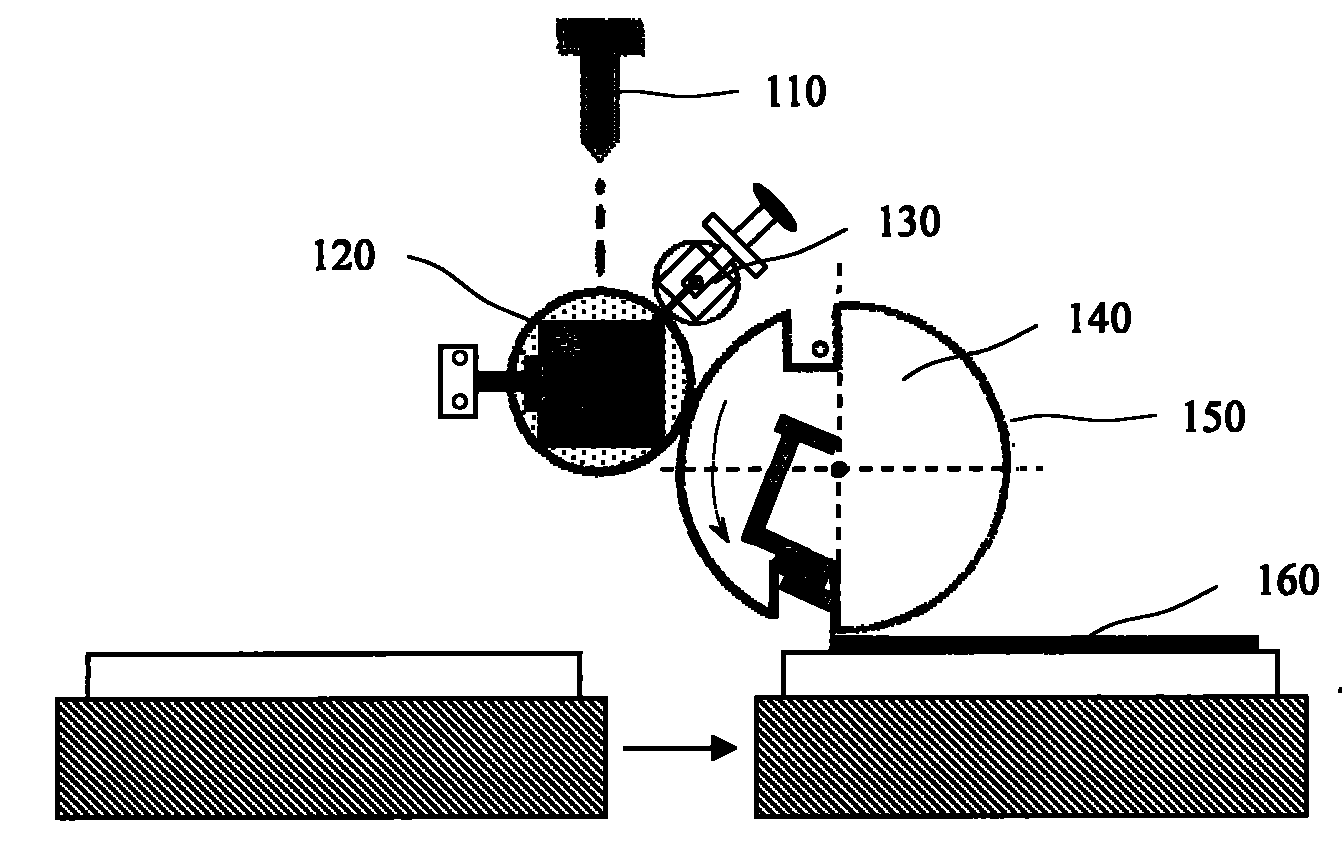

Fluidic cell manipulator

InactiveCN101548172AReduced strengthControl flow rateElectrostatic separationIndividual particle analysisParticle trappingEngineering

The present invention discloses a system (100) for individually manipulating, e.g. orienting, a particle (104) in a fluid (106). The manipulating system (100) comprises a particle trapping system (111) allowing trapping of the particle (111) in a fluid channel (102) and a controller for controlling shear force gradients on the particle. Shear force gradients on the particle are 5 controlled by positioning a particle off center in the fluid channel (102) in a laminar flow or by controlling the laminar flow itself. The laminar flow thereby is generated using a flow generator (108). The system (100) for manipulating may be used in a particle characterization system or may be used for performing actions on the particle (104) under predetermined orientations.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

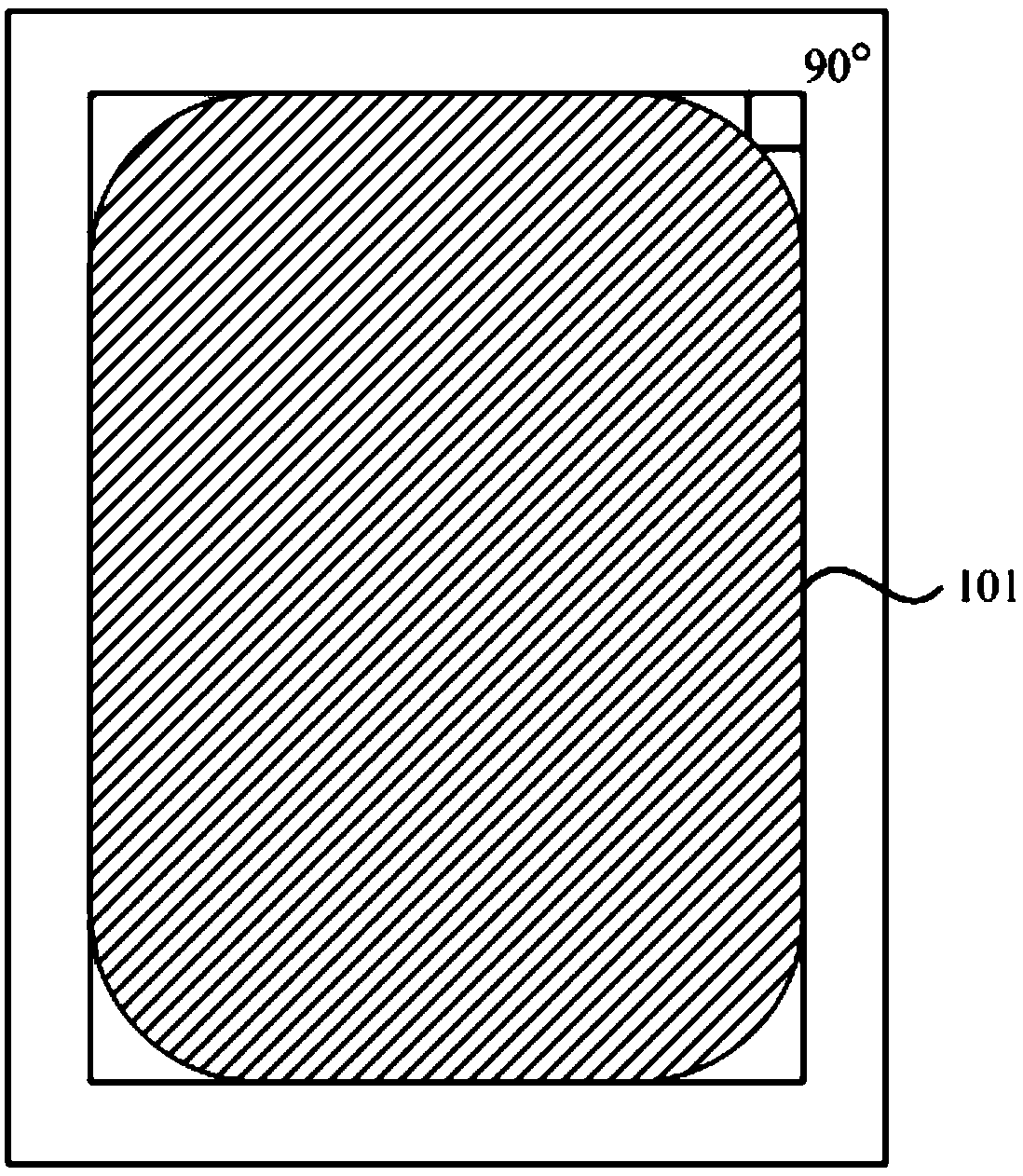

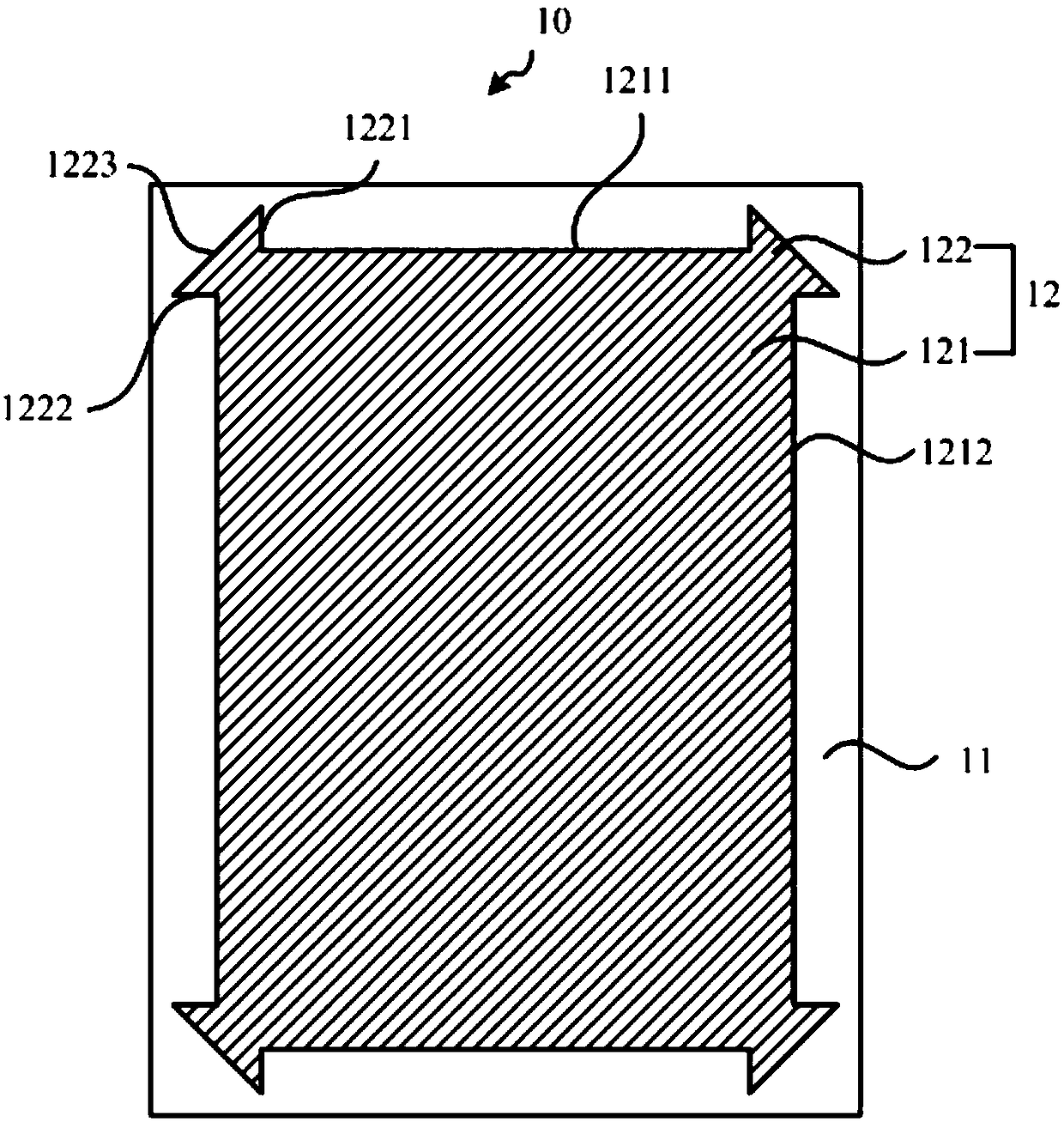

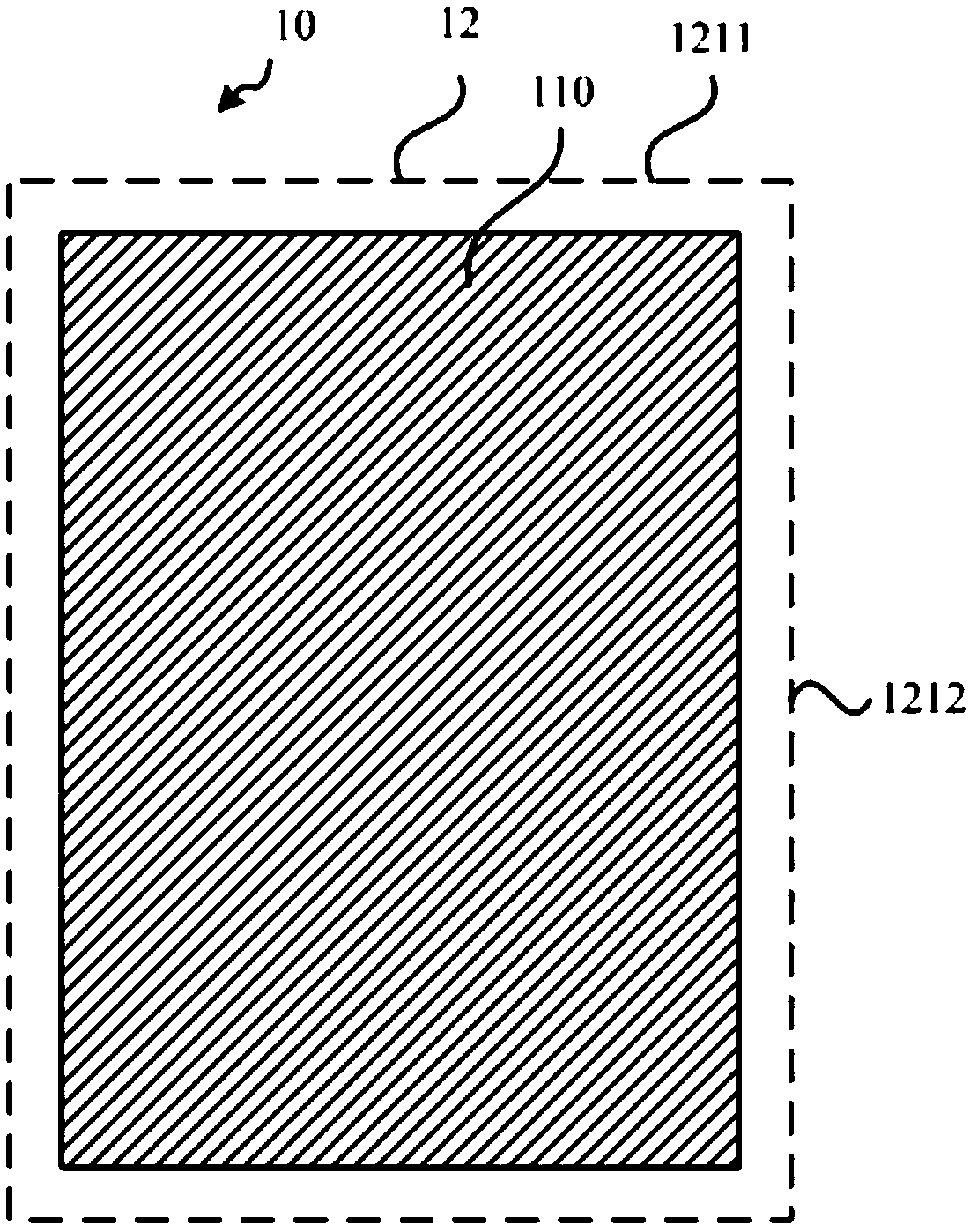

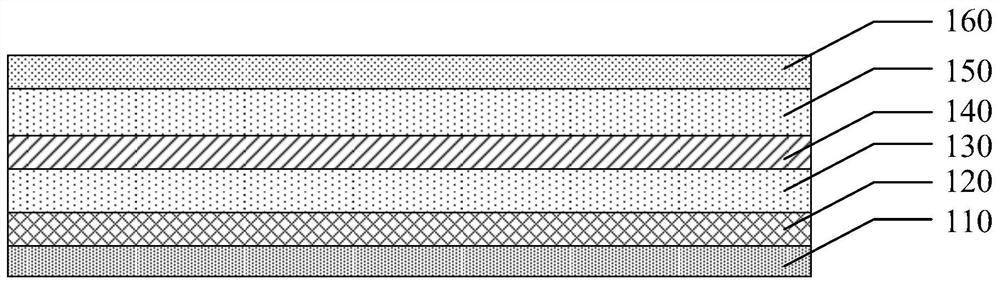

Liquid crystal display substrate, preparation method thereof, display panel and display device

PendingCN108983503AOrientation controllableAvoid light leakageNon-linear opticsLiquid-crystal displayDisplay device

An embodiment of the present invention provides a liquid crystal display substrate, a preparation method thereof, a display panel and a display device. By setting an alignment film formed on the substrate to have a body alignment region and an extension region at a corner of the body alignment region, the extension region is a special-shaped pattern different from that of the body alignment region, the body alignment region at least covers a display region of the liquid crystal display substrate such that an alignment material at the corner of an alignment film body alignment region further diffuses and extends to the extension region and the alignment film coating the substrate can completely cover the display region of the liquid crystal display substrate, therefore, the orientation ofliquid crystal molecules injected into the display region can be controlled after the liquid crystal display substrate is subjected to cell formation, and a light leakage phenomenon can be prevented.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

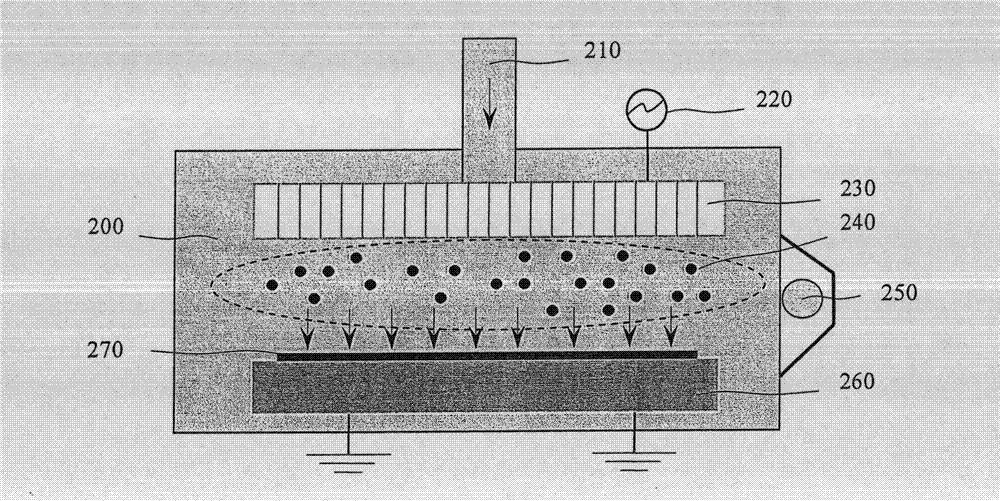

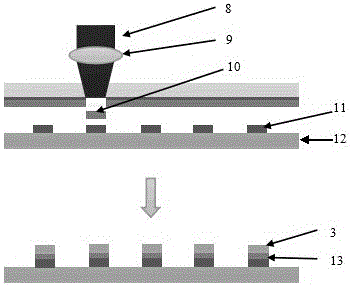

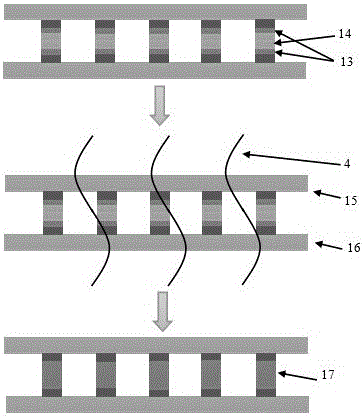

Manufacturing method of liquid crystal alignment layer

InactiveCN101539686AOrientation controllableSame orientationVacuum evaporation coatingSputtering coatingManufacturing cost reductionDistributor

The invention discloses a manufacturing method of a liquid crystal alignment layer. The method comprises the following steps: (1) a deposition bin is arranged, and a glass substrate and a gas distributor are respectively arranged at both sides of the deposition bin; (2) the deposition bin is vacuumized; (3) the glass substrate is heated to the required temperature; (4) the deposition bin is filled with hydrocarbon gas and inert gas; (5) high frequency voltage is applied to the glass substrate and the gas distributor, the gas reacts under the action of the electric field and under the condition of gas pressure, and an alignment film is formed on the surface of the glass substrate; and (6) the bombarding is performed to the alignment film through an ion gun to form an alignment groove, so that a liquid crystal alignment layer is formed. The invention also discloses a manufacturing method of the other kind of liquid crystal alignment layer, and the alignment film is formed by a sputtering method and then is bombarded through the ion gun to form an alignment groove, so that a liquid crystal alignment layer is formed. The invention enables the alignment of the liquid crystal alignment layers to be more consistent to further improve the display quality of the liquid crystal display; and in addition, the manufacturing cost can be also reduced.

Owner:BOE TECH GRP CO LTD +1

Functional compositematerial and preparing method thereof

The present invention provides a method for preparing functional composite material, which includes the following steps: firstly, placing the powder with functional action in a container cavity, applying field action to said powder, impregnating the powder with liquid material, finally solidifying the liquid material or firstly, placing the liquid material in the container cavity, then adding the powder with functional action into the container cavity in whith the liquid material is held, and applying field action to the power in the container cavity, and finally solidifying the liquid material. Said functional composite material can have the functions of electric conductivity, semi-conduction, superconductance, magnetism, piezoelectricity, damping, sound-absorbing, light sensation and thermal sensation, etc.

Owner:周照耀

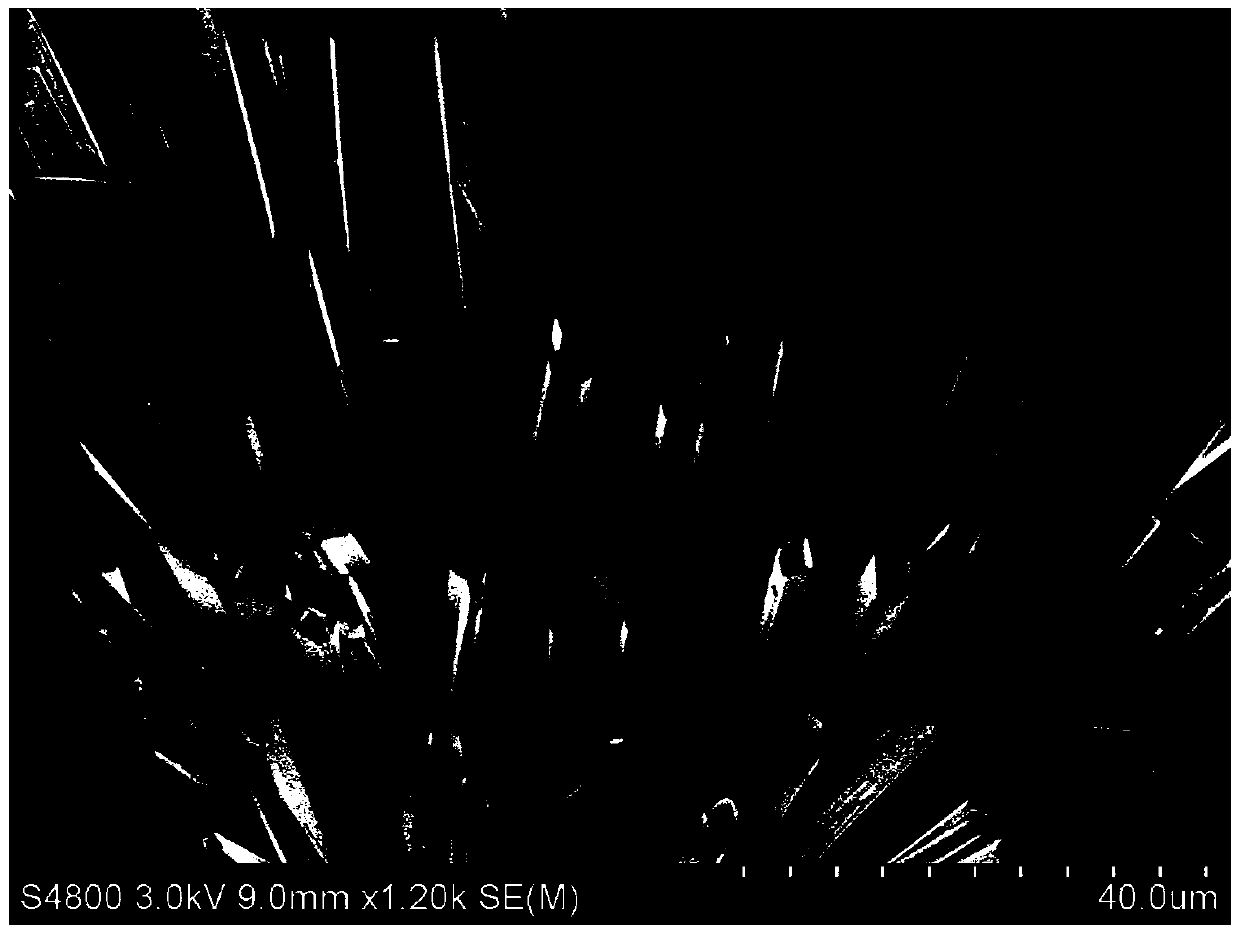

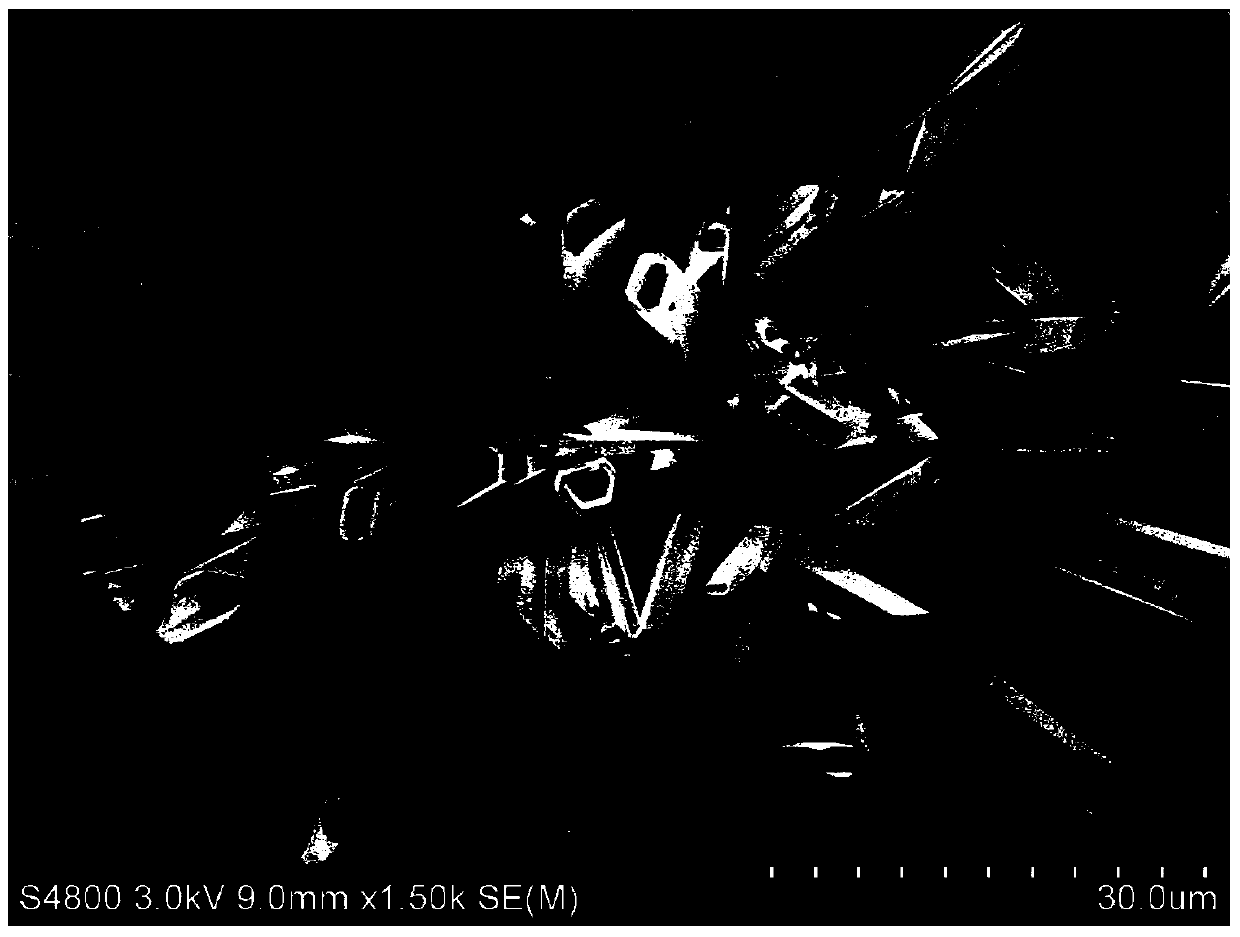

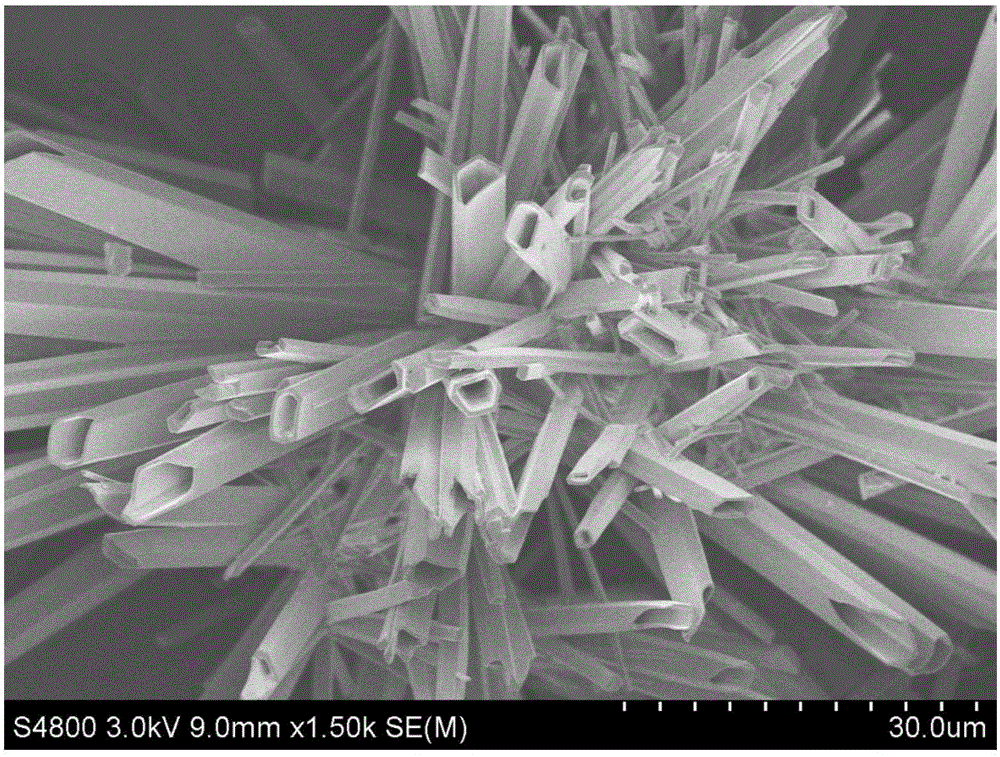

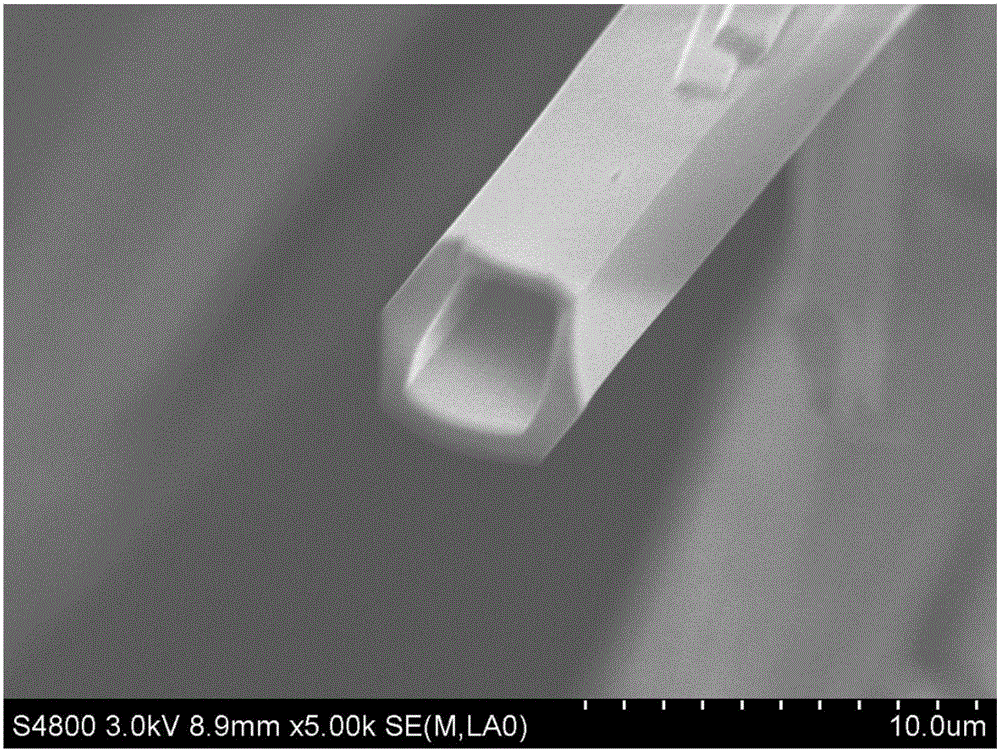

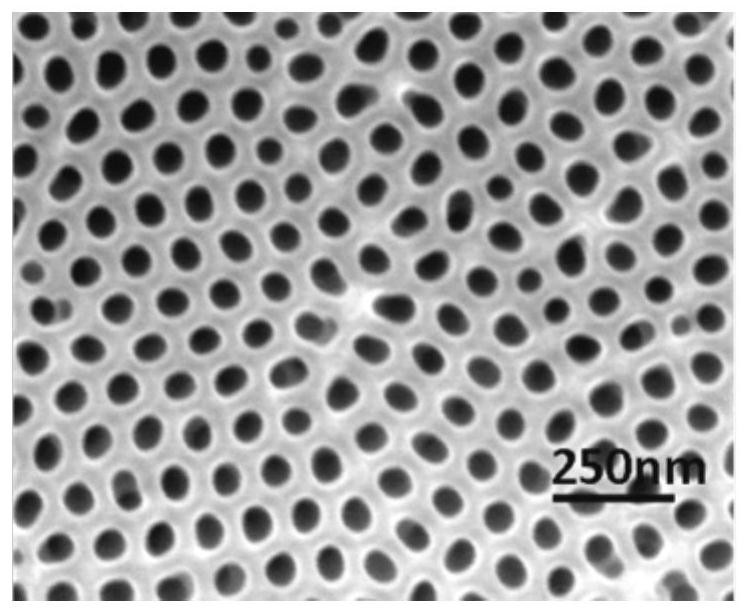

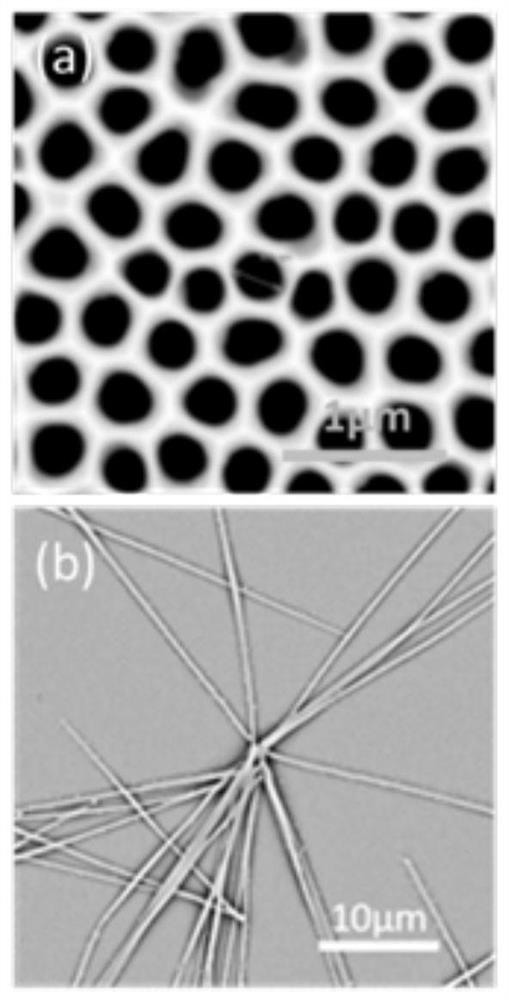

8-hydroxyquinoline metal compound micrometer/nanometer tube and preparation method thereof

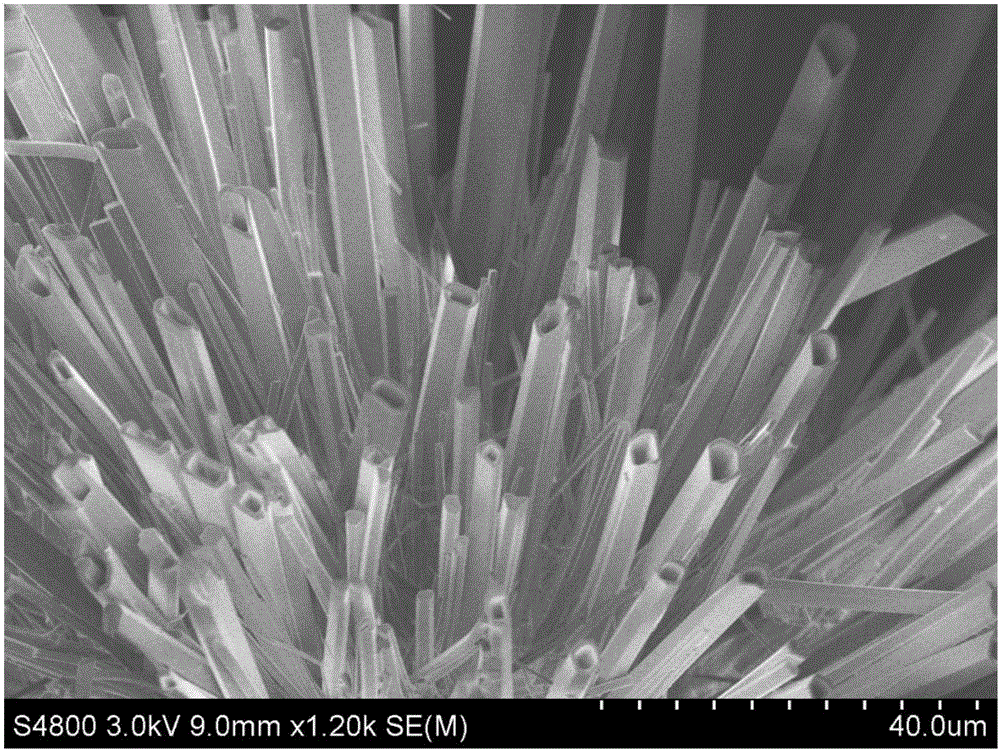

InactiveCN105200524AIncrease profitSimple and fast operationMaterial nanotechnologyPolycrystalline material growthChemical compoundMicrometer

The invention relates to an 8-hydroxyquinoline metal compound micrometer / nanometer tube and a preparation method thereof. A chemical compound of the micrometer / nanometer tube is 8-hydroxyquinoline gallium (Gaq3) or 8-hydroxyquinoline aluminum (Alq3); the cross section of the micrometer / nanometer tube is in a hexagonal shape or square shape, an orifice of the micrometer / nanometer tube is in a square shape or a circular shape, the length of the micrometer / nanometer tube is 200nm to 60 micrometers, the wall thickness of the micrometer / nanometer tube is 20nm to 1 micrometer, and the radius of the micrometer / nanometer tube is 20nm to 3 micrometers. The invention also provides a preparation method of the micrometer / nanometer tube. The 8-hydroxyquinoline gallium (Gaq3) and 8-hydroxyquinoline aluminum (Alq3) micrometer / nanometer tube is controllable in size and direction and good in crystallization quality. The 8-hydroxyquinoline metal compound micrometer / nanometer tube can be used as an anticancer drug and also has a drug transport characteristic, other medicine components can fill the micrometer / nanometer tube to be carried and transported, and the biological application is excellent.

Owner:SHANDONG UNIV

Polarizing material, preparation method thereof, polaroid and display panel

PendingCN112592420AReduce manufacturing costOrientation controllableLiquid crystal compositionsSolid-state devicesLiquid crystallineOptical polarization

The invention discloses a polarizing material, a preparation method thereof, a polaroid and a display panel. The polarizing material comprises iodine bond liquid crystal, the iodine bond liquid crystal contains iodine molecules, and the orientation of the iodine bond liquid crystal can absorb light vibrating in a specific direction to realize a polarization function. Orientation of the iodine bondliquid crystal is easy to control, single-axis stretching treatment is not needed, an upper TAC plate and a lower TAC plate do not need to be used, and therefore the polaroid made of the polarizing material can simplify the process and the polaroid film layer structure, and the manufacturing cost of the display panel is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Growth of ferroelectric thick films with films as seeds by liquid phase epitaxy

InactiveCN1585150AEpitaxial growth is fastQuality improvementPiezoelectric/electrostrictive device manufacture/assemblyLiquid-phase epitaxial-layer growthNiobiumCrystal growth

In this method, the component of the plumbum magnesium acid-plumbum titanic acide (PMNT) or plumbum zincic niobium acid-plumbum titanic acid (PZNT) crystal growth is applied to process the blending of the oxide. Grinding and calcinating the confected powder material in the agate ball milling pot; mixing the calcinated powder material with the fluxing agent, plumbum oxide under the high temperature, dunking the material after a period of time, on the base plate with the germ film, the PZNT or PMNT thick film being produced. The simple technology, convenient operation extend the application of liquid phase epitaxy.

Owner:SHANGHAI JIAO TONG UNIV

Method for preparing electric ferroelectric thick film by liquid phase epitaxy

InactiveCN1472782AImprove performanceSimple processPolycrystalline material growthPiezoelectric/electrostrictive device manufacture/assemblyZincateLead titanate

In the method, oxide raw material is prepared according to composition used normally in crystal growth of lead magnesate niobium-lead titanate or lead zincate niobium-lead titanate first. Then the prepared power material is put into agate mortar for ball grinding and to carry on roasting at temperature of 900 degreeC. At last, PZNT (PMNT) thick film is prepared by epitaxial growth on substrate of strontium titanate after the roasted powder material is mixed uniformly with flux of lead oxide and to soak it under high temperature for a period of time.

Owner:SHANGHAI JIAO TONG UNIV

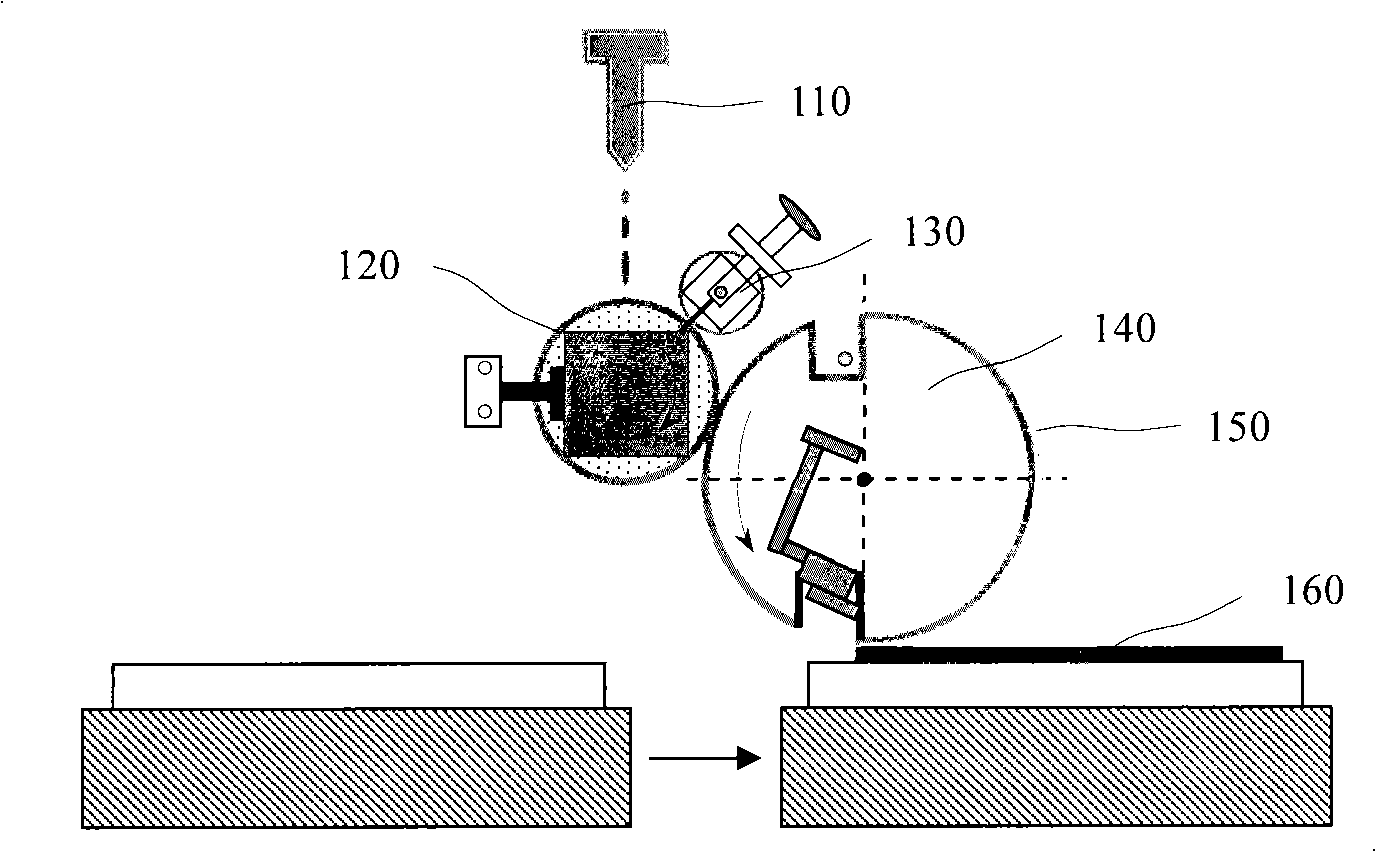

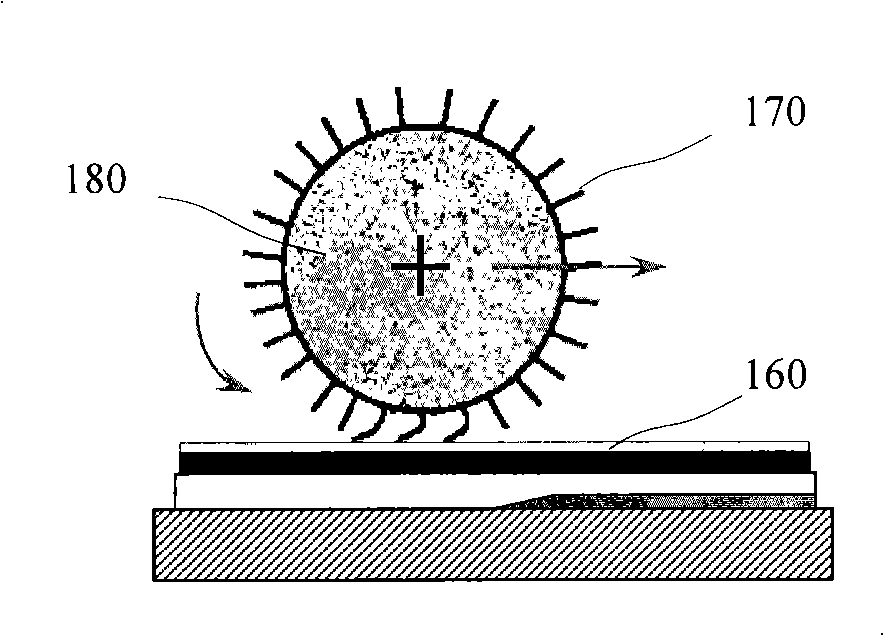

A Method for Induced Intermetallic Growth of Thin Films with Specific Grain Orientation and Quantity Using Laser Forward Transfer

ActiveCN105081500BFast preparationShort manufacturing timeLamination ancillary operationsSoldering apparatusButt jointInterconnection

Owner:HARBIN INST OF TECH

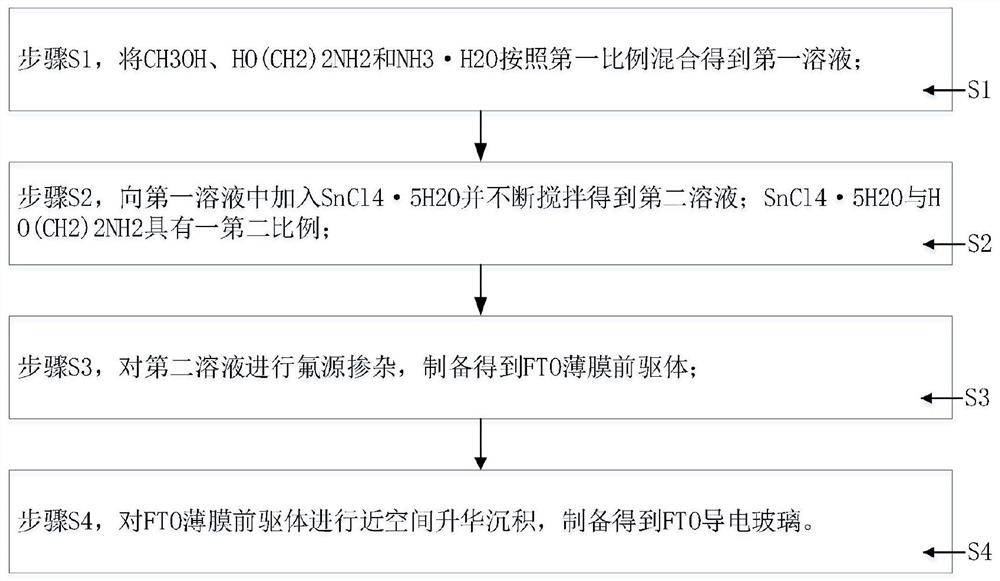

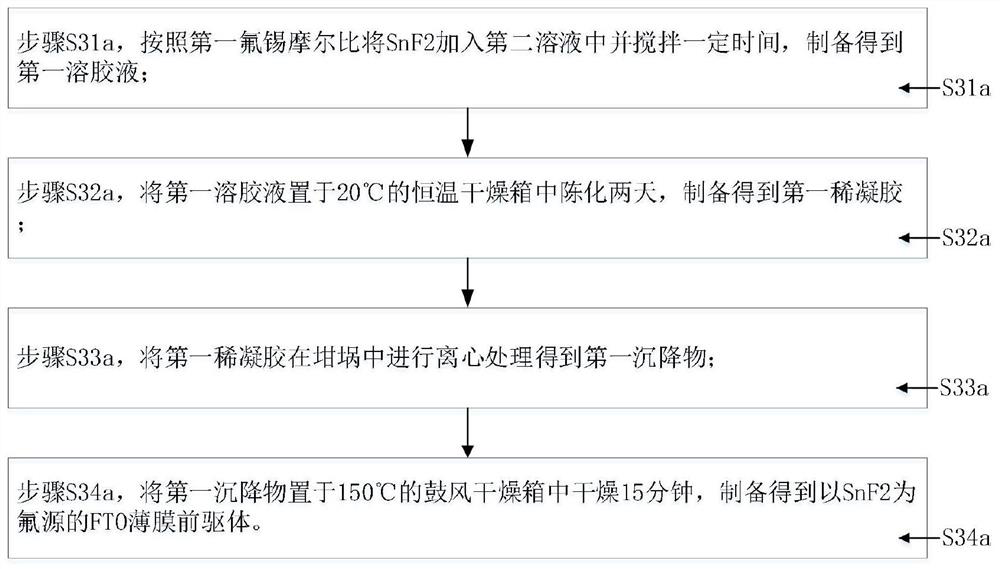

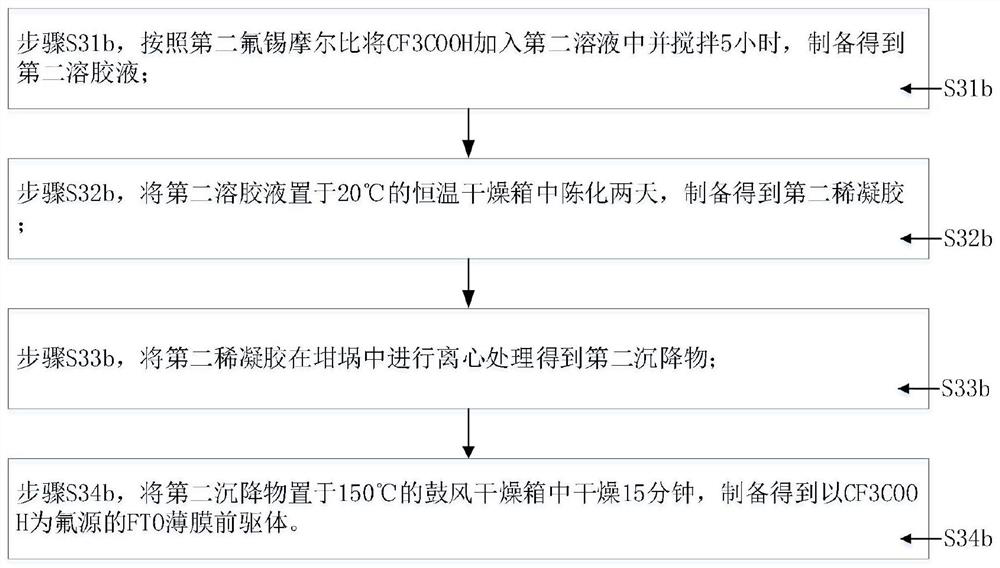

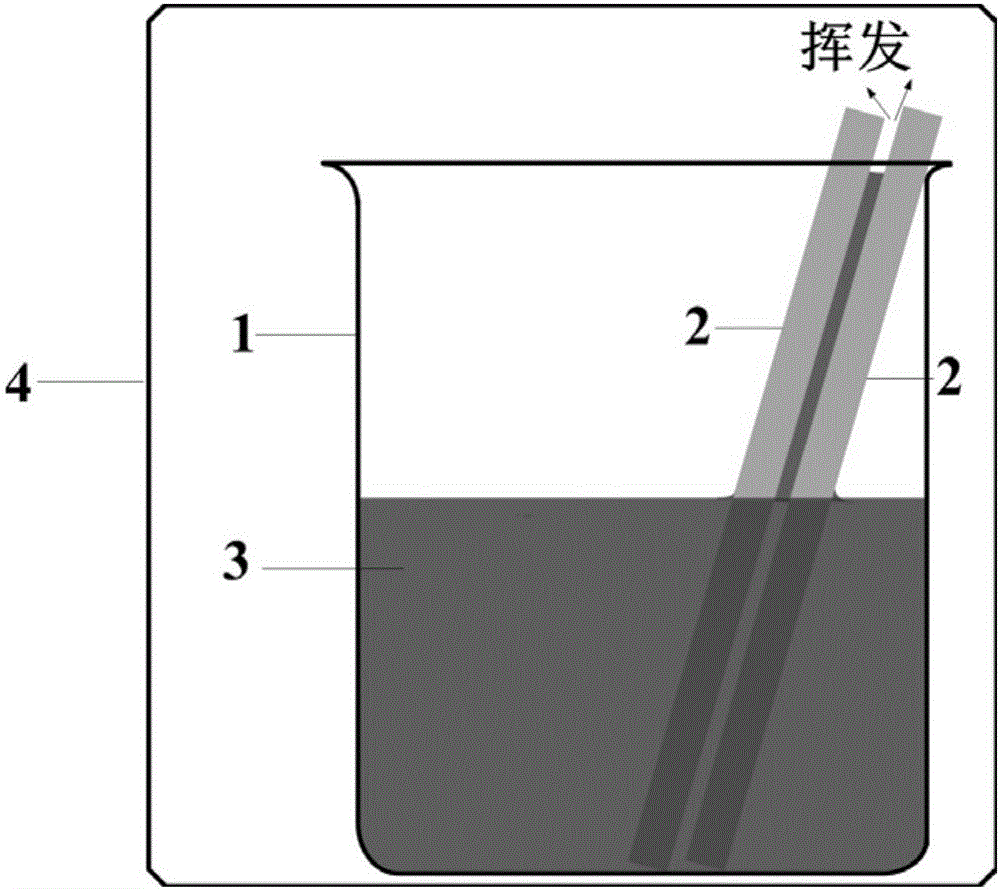

A method for preparing fto conductive glass by near space sublimation technology

The invention provides a method for preparing FTO conductive glass by using near space sublimation technology, and relates to the technical field of FTO conductive glass preparation, comprising: mixing CH3OH, HO(CH2)2NH2 and NH3·H2O according to a first ratio to obtain a first solution; Adding SnCl4·5H2O to the first solution and stirring continuously to obtain a second solution; the SnCl4·5H2O and the HO(CH2)2NH2 have a second ratio; doping the second solution with a fluorine source to prepare An FTO thin film precursor is obtained; the FTO thin film precursor is subjected to near-space sublimation deposition to prepare an FTO conductive glass. The invention has simple process and low cost, can use FTO precursor to control the composition of the FTO film layer, and is prepared in combination with the mature industrialized CSS process, and can obtain the FTO conductive glass with specific structure, morphology and photoelectric performance.

Owner:CHINA TRIUMPH INT ENG

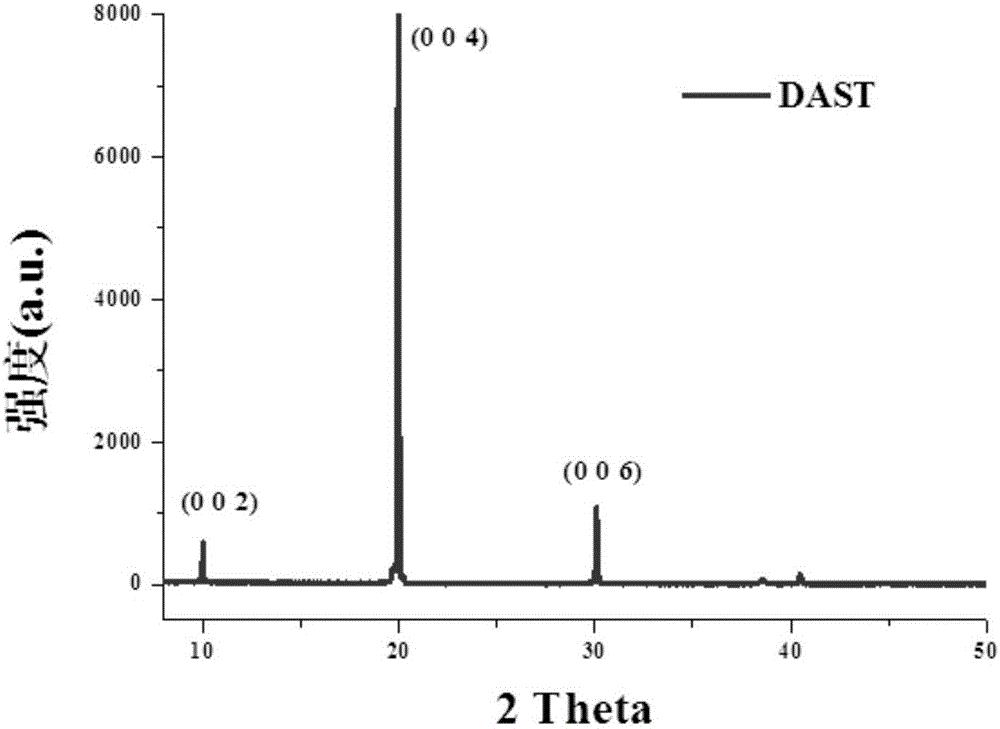

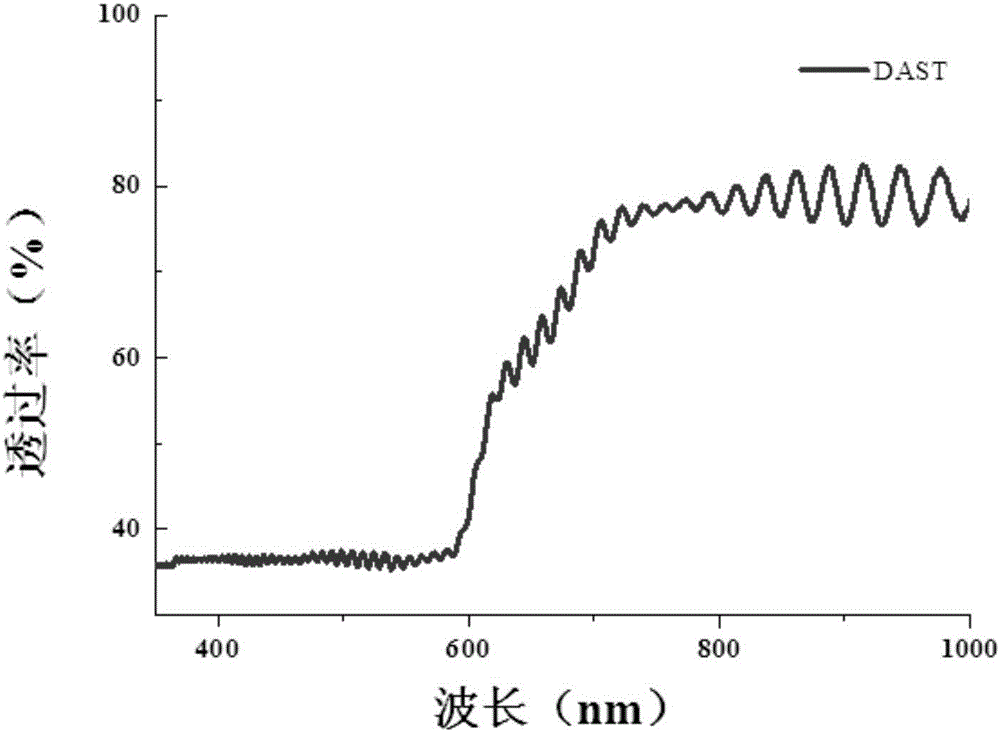

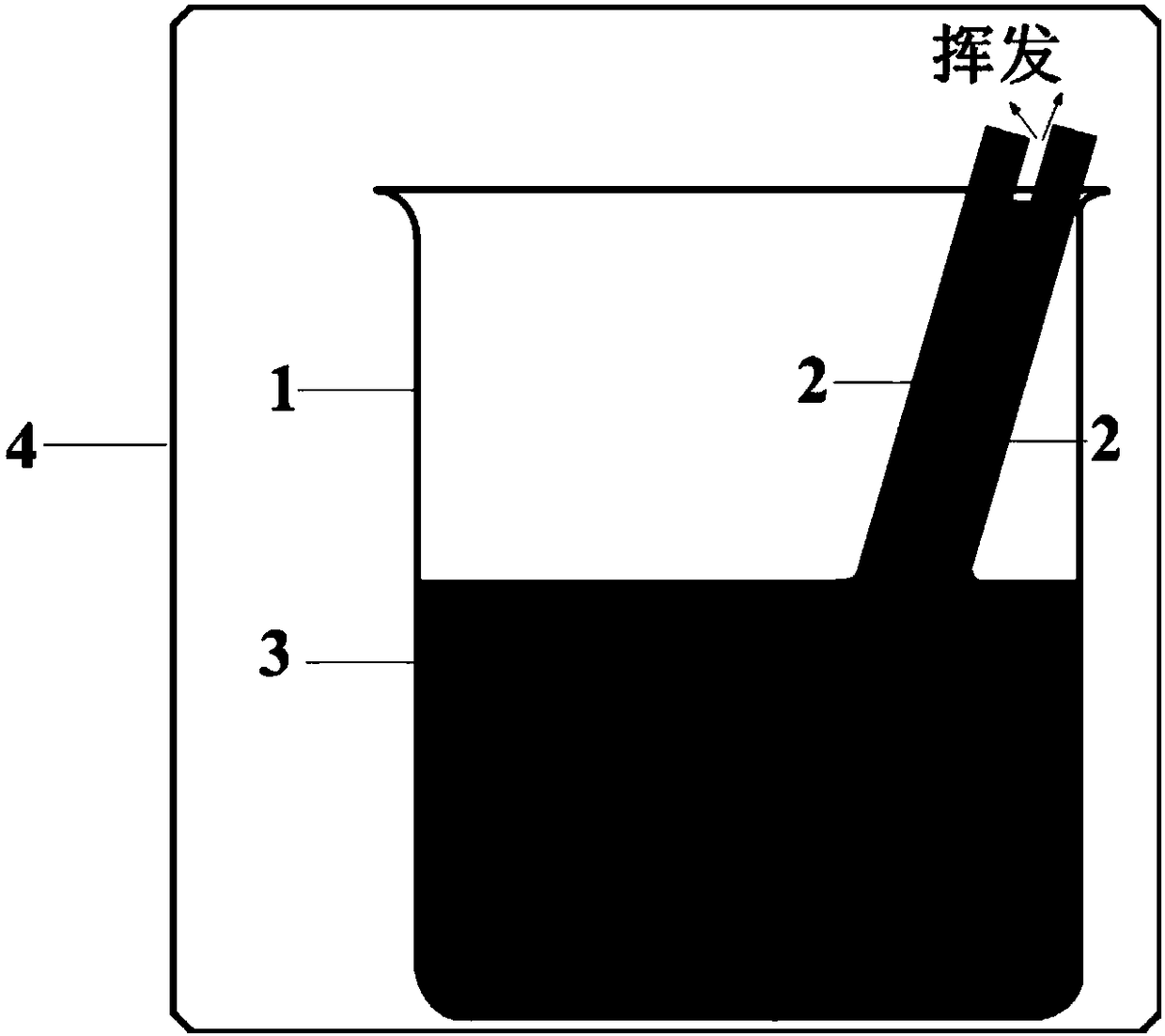

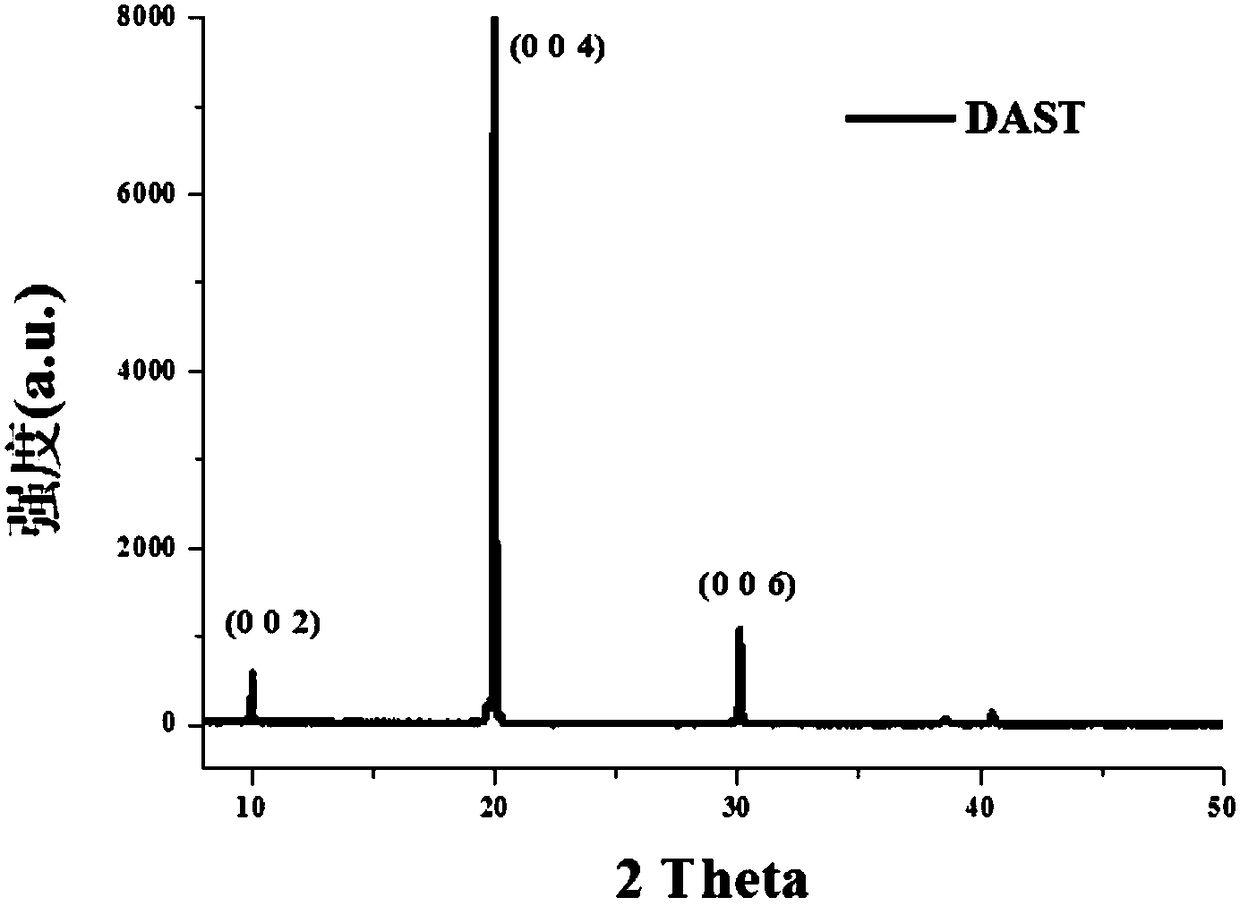

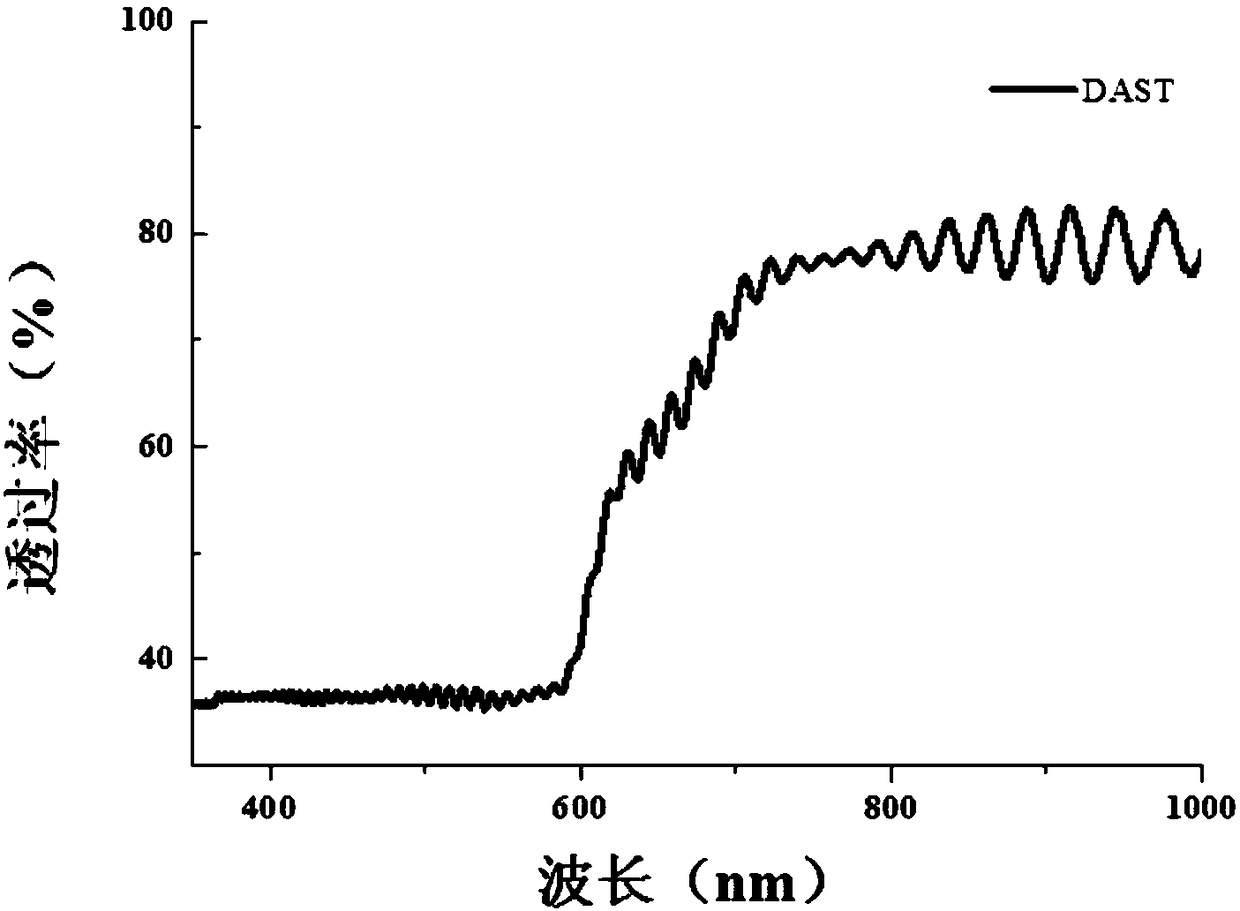

Method for induced growth of DAST and derivative single-crystal film thereof by using self-assembly monomolecular film

InactiveCN106149044AEasy to controlControl thicknessPolycrystalline material growthFrom normal temperature solutionsOrganic filmCrystal twinning

The invention discloses a method for induced growth of DAST and a derivative single-crystal film thereof by using a self-assembly monomolecular film. The method comprises the following steps: performing self-assembly of a layer of monomolecular film containing one or more functional groups of -SO3-, -OH, -Cl-, -NH2-, -F- and -COOH on the surface of a substrate to realize functionalization of the substrate; clinging two functionalized substrates in parallel and inserting to DAST or DAST derivative solution; and growing DAST or DAST derivative single crystal between the two substrates by adopting a slow solvent evaporation process. The method disclosed by the invention can effectively overcome the problems such as poor thickness and orientation controllability of crystal, easy formation of twin crystal and water vapor interference with crystal growth in the growth process of organic film single crystal, and can effectively control the thickness and growth direction of the DAST or DAST derivative crystal to avoid twin crystal.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for preparing electric ferroelectric thick film by liquid phase epitaxy

InactiveCN100437949CControlled Orientation GrowthEasy accessPiezoelectric/electrostrictive device manufacture/assemblyPolycrystalline material growthStrontium titanateZincate

In the method, oxide raw material is prepared according to composition used normally in crystal growth of lead magnesate niobium-lead titanate or lead zincate niobium-lead titanate first. Then the prepared power material is put into agate mortar for ball grinding and to carry on roasting at temperature of 900 degreeC. At last, PZNT (PMNT) thick film is prepared by epitaxial growth on substrate of strontium titanate after the roasted powder material is mixed uniformly with flux of lead oxide and to soak it under high temperature for a period of time.

Owner:SHANGHAI JIAO TONG UNIV

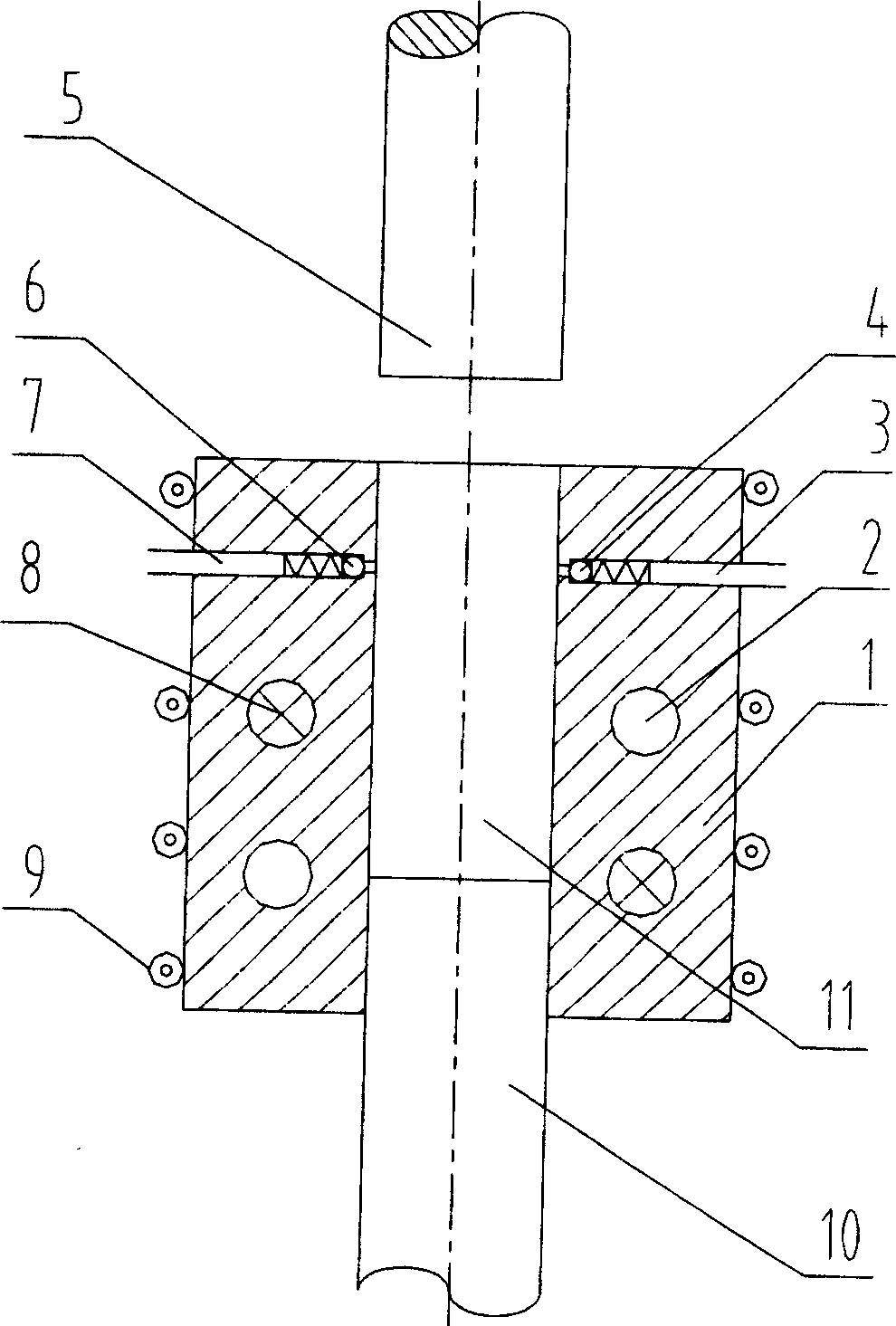

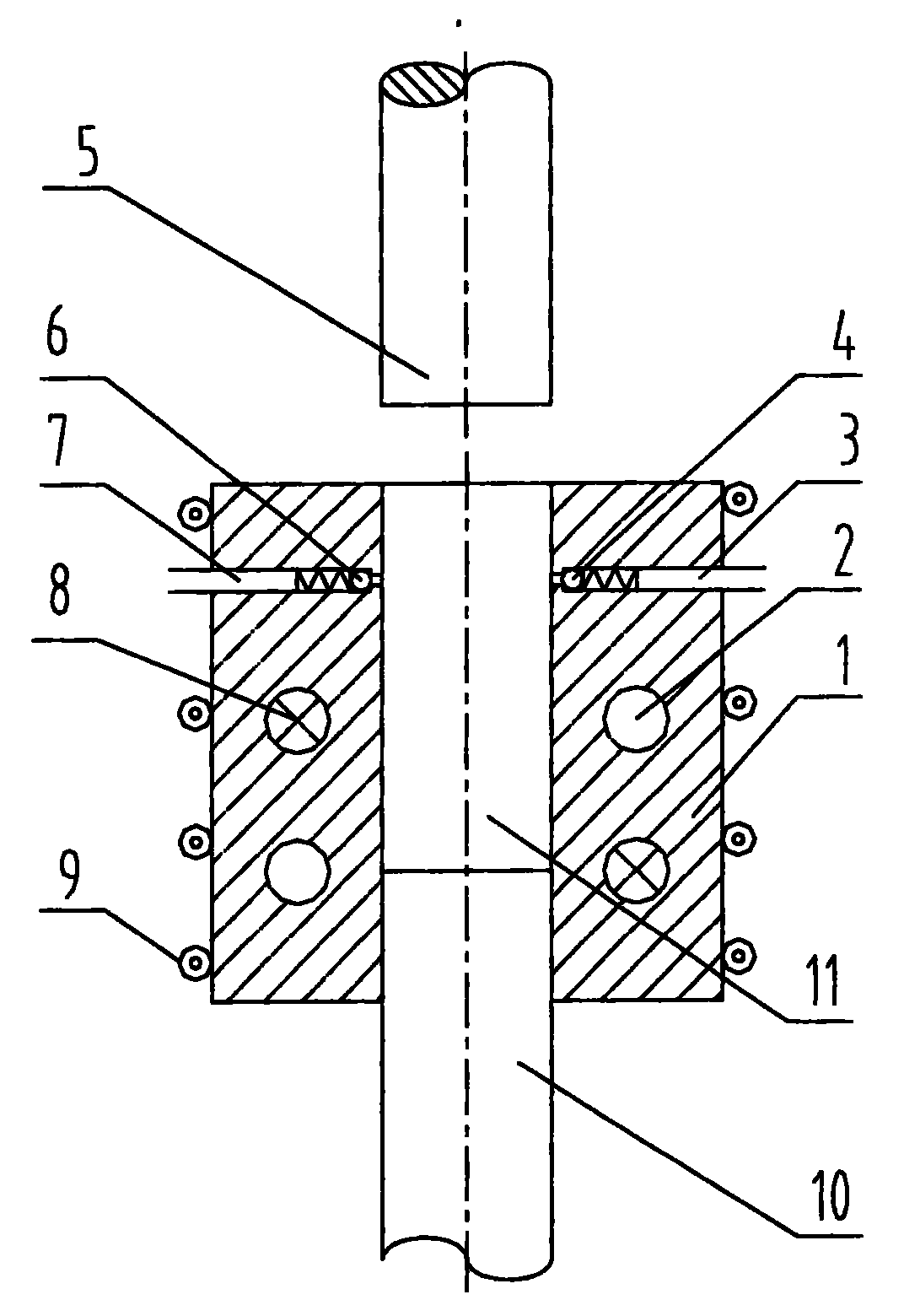

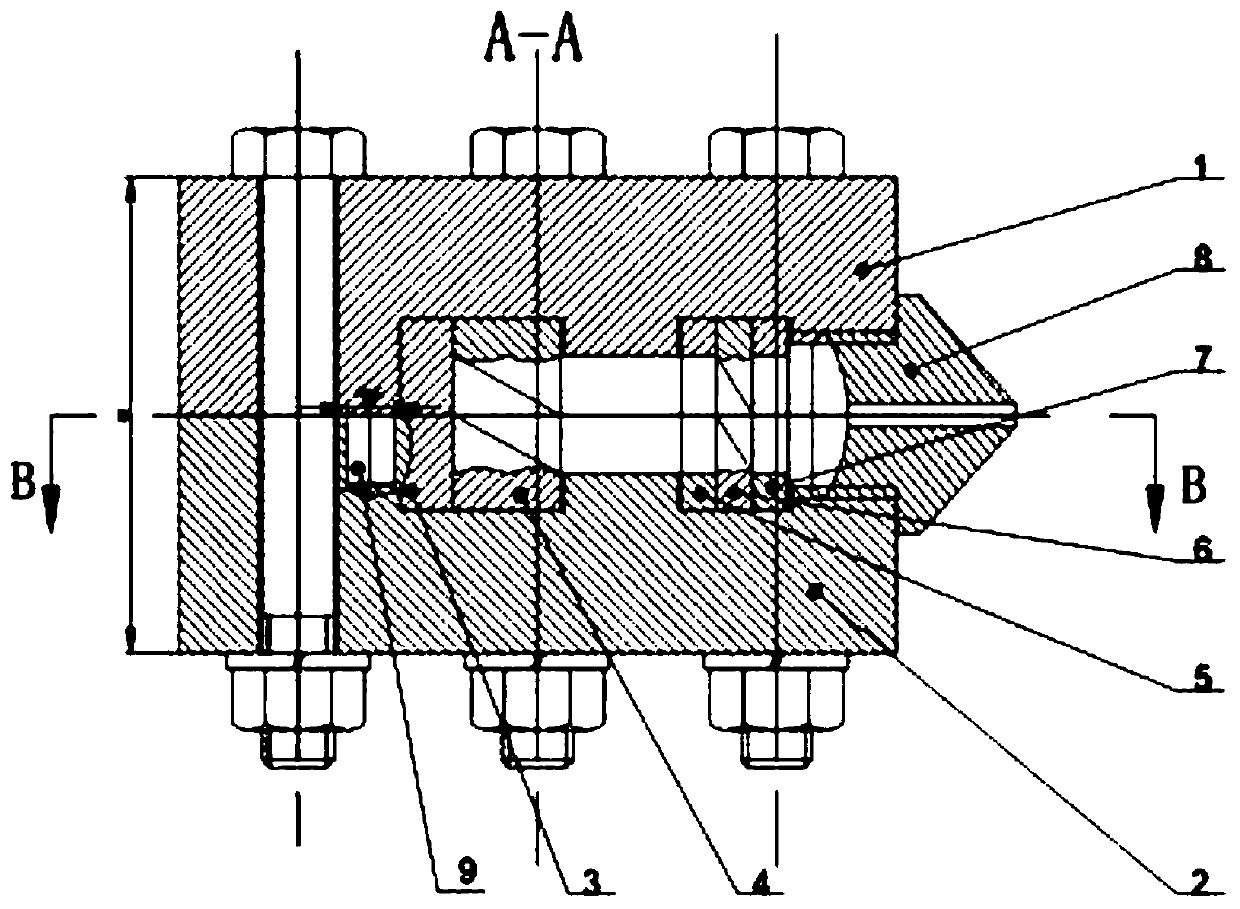

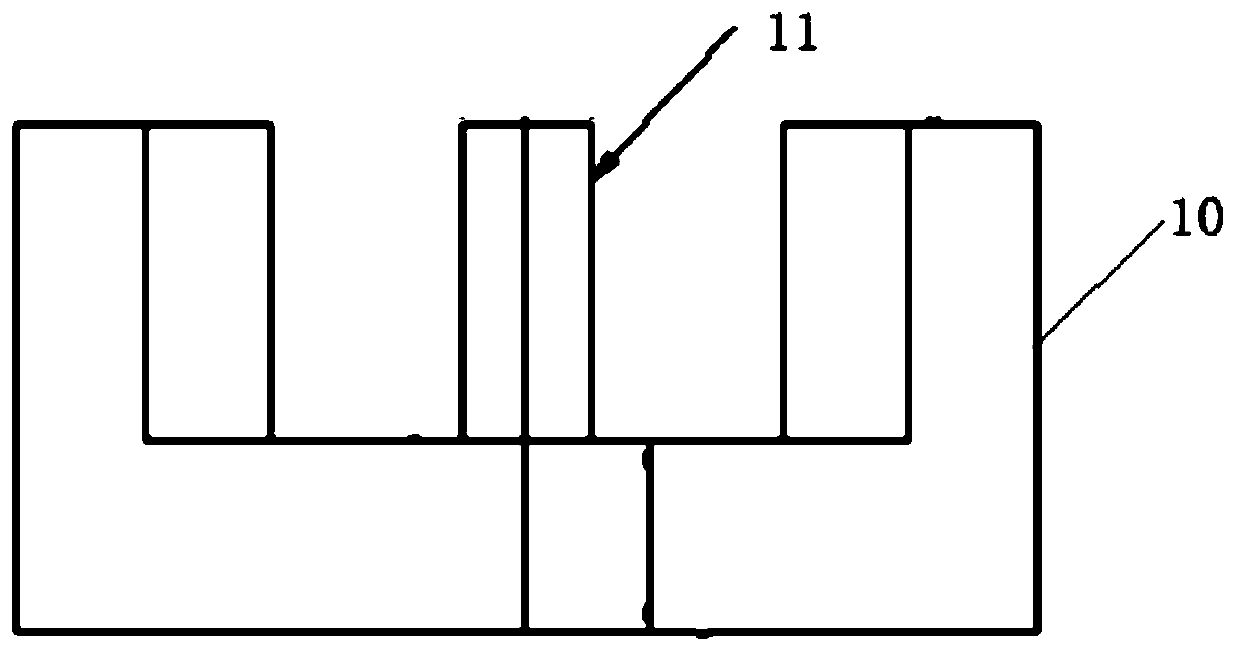

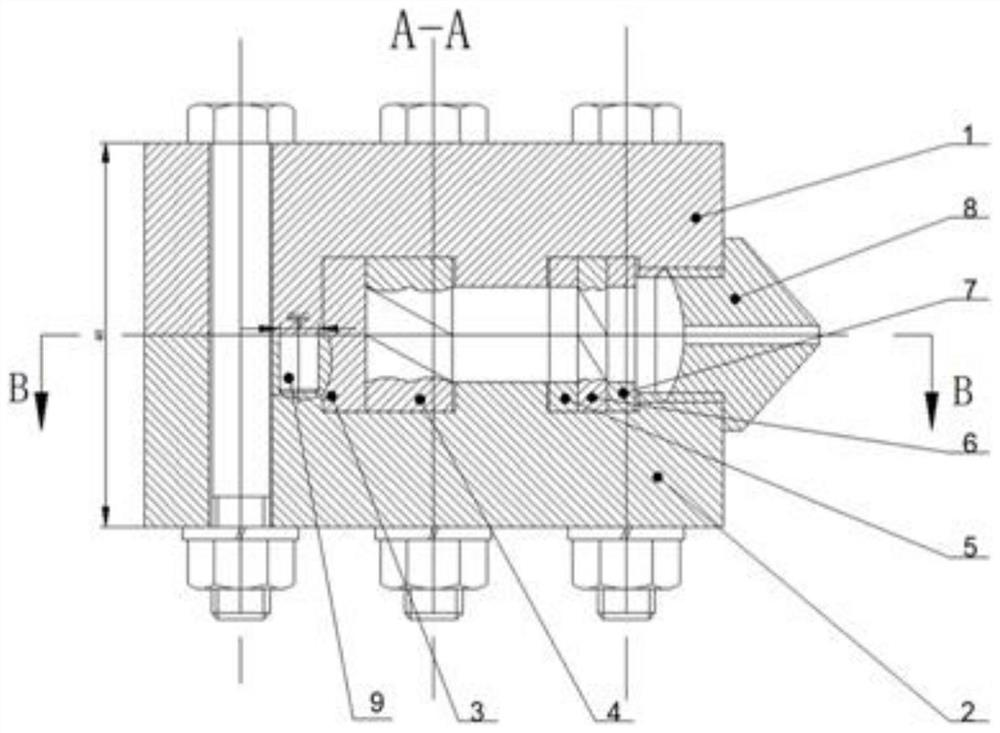

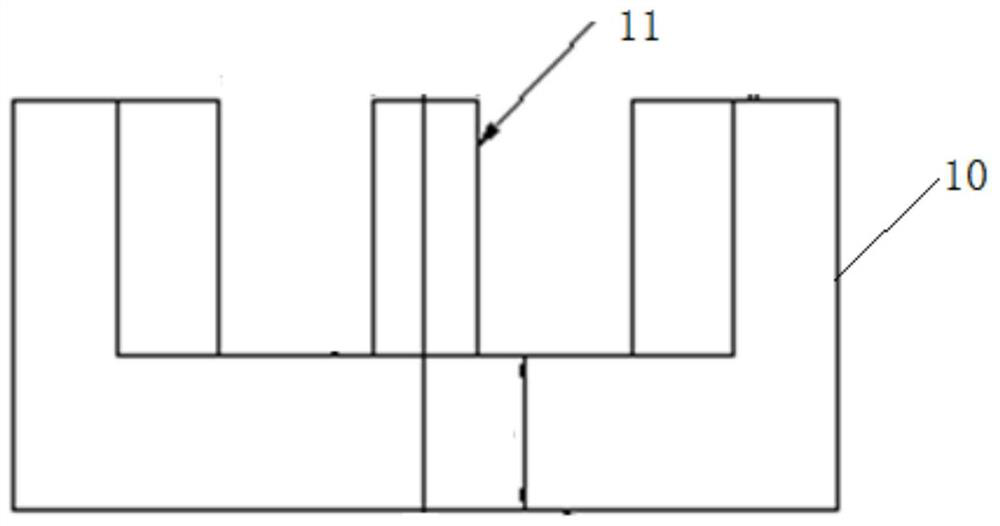

Laminated-oriented 3D printer nozzle mechanism

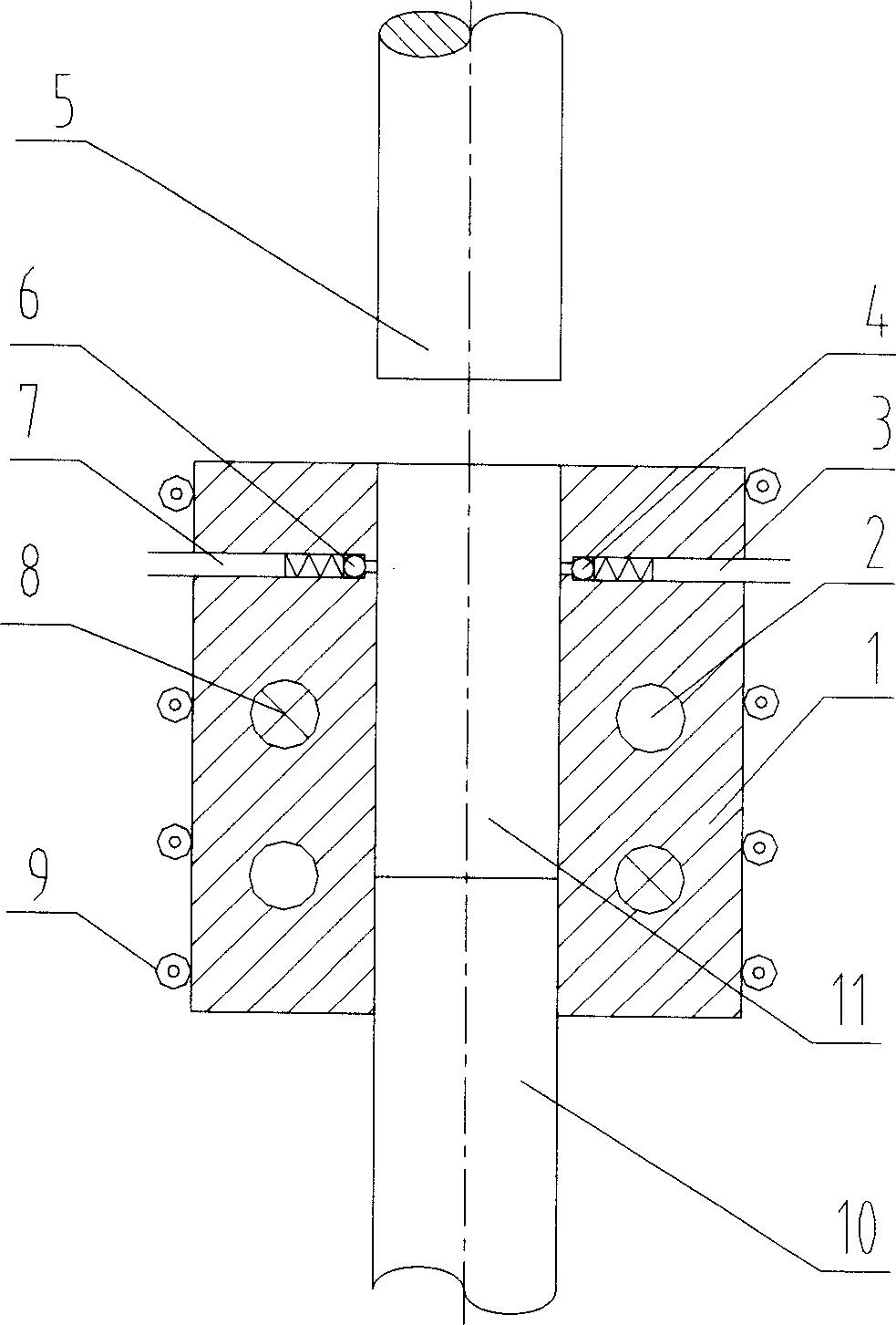

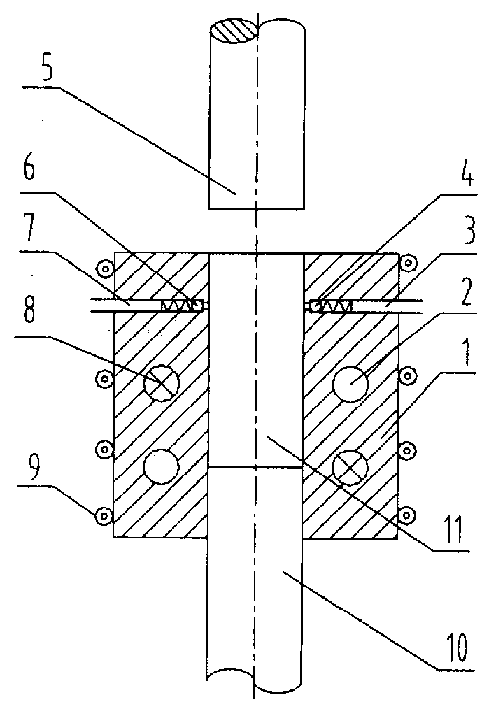

ActiveCN110076988AEasy to operateEvenly dispersed3D object support structuresApplying layer meansEngineeringScrew thread

The invention discloses a laminated-oriented 3D printer nozzle mechanism. The mechanism involves an upper machine head and a lower machine head, wherein the upper machine head and the lower machine head are positioned through positioning bosses, a first inner thread section, grooves and a second inner thread section are sequentially arranged in the upper machine head and the lower machine head along the radial direction, the second inner thread section located at the ends of the upper machine head and the end of the lower machine head is connected with an outer thread of a nozzle, a first layering section, a first torsion section, a second layering section, a second torsion section and a confluence section are sequentially arranged in a cavity formed by connecting the grooves of the uppermachine head and the lower machine head in the radial direction. The fused printing wire material flows into a laminated-oriented 3D printer nozzle, then is subjected to the process of layering, twisting, re-layering, re-twisting and confluence, so that the melt can be continuously subjected to strong shearing action, the material can be more uniformly mixed; and meanwhile, the orientation state of the high polymer is more obvious, so that the mechanical property of the material is improved.

Owner:SHAANXI UNIV OF SCI & TECH

A self-assembled monomolecular film induced growth method of dast and its derivative single crystal thin film

InactiveCN106149044BEasy to controlControl thicknessPolycrystalline material growthOrganic chemistryOrganic filmCrystal twinning

The invention discloses a method for inducing the growth of a self-assembled monomolecular film of DAST and its derivative monocrystalline film. First, self-assembled on the surface of a substrate containing -SO3-, -OH, -Cl-, -NH2, -F-F One layer of monomolecular film of one or several functional groups in ‑COOH, functionalize the substrate, and then insert the functionalized two substrates side by side into the DAST or DAST derivative solution, and slowly evaporate the solvent In this method, single crystals of DAST or DAST derivatives are grown between two substrates. The invention can effectively overcome the problems of poor controllability of crystal thickness and orientation, easy formation of twins, interference of crystal growth by water vapor and the like during the growth process of organic thin film single crystals, and can effectively control the thickness and growth direction of DAST or DAST derivative crystals, Avoid twinning.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

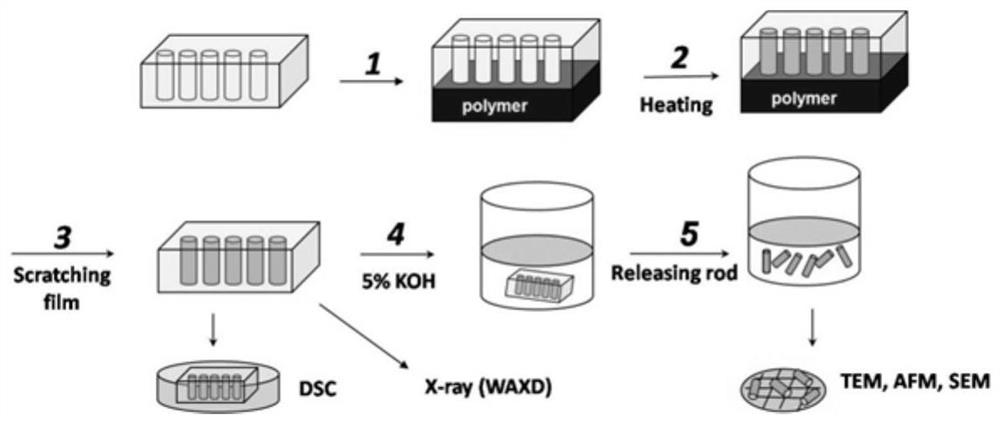

A method for preparing polymer nanowires with controllable molecular orientation

ActiveCN109594142BHigh degree of crystallinityOrientation controllableMaterial nanotechnologyMonocomponent copolyamides artificial filamentPolymer scienceNanowire

Owner:SHENZHEN UNIV

Manufacturing method of liquid crystal alignment layer

InactiveCN101539686BOrientation controllableSame orientationVacuum evaporation coatingSputtering coatingManufacturing cost reductionDistributor

The invention discloses a manufacturing method of a liquid crystal alignment layer. The method comprises the following steps: (1) a deposition bin is arranged, and a glass substrate and a gas distributor are respectively arranged at both sides of the deposition bin; (2) the deposition bin is vacuumized; (3) the glass substrate is heated to the required temperature; (4) the deposition bin is filled with hydrocarbon gas and inert gas; (5) high frequency voltage is applied to the glass substrate and the gas distributor, the gas reacts under the action of the electric field and under the condition of gas pressure, and an alignment film is formed on the surface of the glass substrate; and (6) the bombarding is performed to the alignment film through an ion gun to form an alignment groove, so that a liquid crystal alignment layer is formed. The invention also discloses a manufacturing method of the other kind of liquid crystal alignment layer, and the alignment film is formed by a sputtering method and then is bombarded through the ion gun to form an alignment groove, so that a liquid crystal alignment layer is formed. The invention enables the alignment of the liquid crystal alignment layers to be more consistent to further improve the display quality of the liquid crystal display; and in addition, the manufacturing cost can be also reduced.

Owner:BOE TECH GRP CO LTD +1

A stack-oriented 3D printer nozzle mechanism

ActiveCN110076988BEasy to operateEvenly dispersed3D object support structuresApplying layer meansComputer printingEngineering

The invention discloses a layer-oriented 3D printer nozzle mechanism, comprising an upper machine head and a lower machine head, the upper machine head and the lower machine head are positioned by a positioning boss, and the upper machine head and the lower machine head are arranged radially in sequence inside There are a first internal thread segment, a groove and a second internal thread segment, the second internal thread segment located at the end of the upper head and the lower head is connected to the external thread of the nozzle, and the grooves of the upper head and the lower head are connected A first layered section, a first torsion section, a second layered section, a second torsion section and a converging section are arranged radially in the cavity formed afterward. The molten printing filament flows into the 3D printer nozzle of the stack orientation, and goes through the process of layering-twisting-re-layering-re-twisting-convergence, so that the melt is continuously subjected to strong shearing action to make the material more uniformly mixed, At the same time, the orientation state of the polymer is more obvious, thereby increasing the mechanical properties of the material.

Owner:SHAANXI UNIV OF SCI & TECH

Polymer/inorganic nanometer composite separation membrane and preparation method thereof

InactiveCN101983758BOvercoming the problem of disorderly arrangementHigh selectivitySemi-permeable membranesFiltrationPolymer

The invention relates to a polymer / inorganic nanometer composite separation membrane and a preparation method thereof. The composite separation membrane consists of a solid matrix of polymer materials and conductive nanomaterials uniformly distributed in the above matrix according to a certain orientation. In the preparation method, conductive nanomaterials which can be arrayed in a certain orientation are uniformly distributed in a film-forming macromolecular material solution. Then electric field is applied during the film-formation process of the mixed solution. The conductive nanomaterials are aligned to the direction of electric field in the film to form the polymer / inorganic nanometer composite separation membrane. The separation membrane has a greater area and smooth surface, controllable film thickness and strength, steerable nanomaterial density and orientation, good selectivity, high transmittance for selected gas and liquid molecules. The method of the invention has the characteristics of simple preparation, easy operation and low cost. The invention can be widely used in the fields of large-scale isolation and purification of gas and large-scale filtration and separation of liquid.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

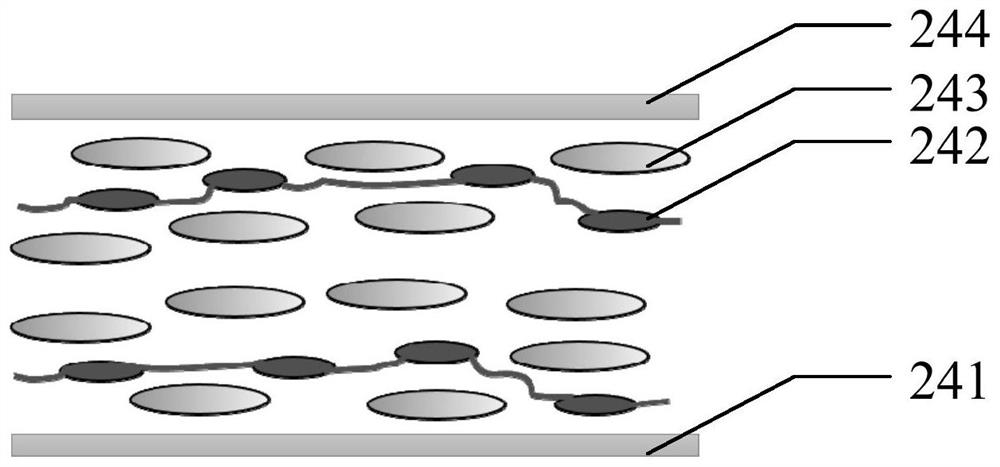

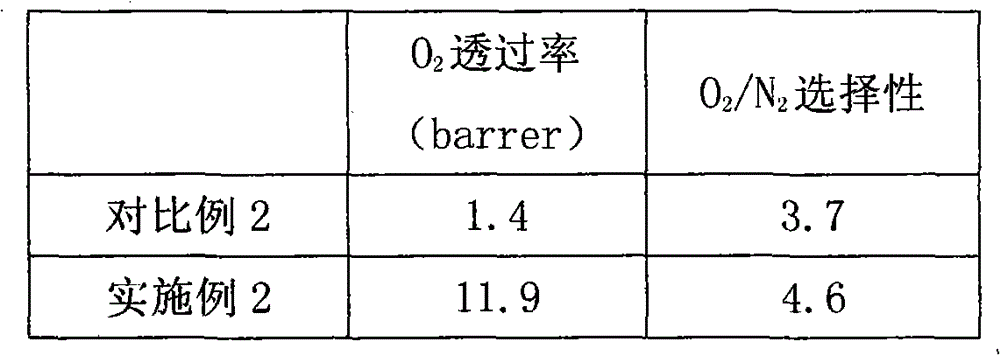

Dispersion liquid with adjustable optical properties and preparation method thereof

ActiveCN110655089BOptical properties are tunableOrientation controllableFerroso-ferric oxidesSilicon compoundsPolymer scienceOptical property

The invention discloses a magnetic nanocomposite material and a preparation method thereof, as well as a dispersion liquid with adjustable optical properties and a preparation method thereof. The magnetic nanocomposite material includes a magnetically coated anisotropic nanostructure, preferably a magnetically coated coated anisotropic nanostructures. The dispersion with tunable optical properties includes a magnetic nanocomposite. Wherein, the preparation method of the dispersion comprises the following steps: preparing a two-dimensional magnetic nanocomposite material; dispersing the two-dimensional magnetic nanocomposite material in a solution to prepare a colloidal dispersion; applying an external magnetic field to the colloidal dispersion to obtain a Composite dispersions. The preparation method of the invention has simple conditions, short preparation period, low cost, and is easy to realize. The prepared dispersion liquid with adjustable optical properties has high magnetic response and adjustable optical properties, and has great application potential in the field of display devices.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

A kind of 5-hydrogen-benzo[b]carbazole and related derivatives and synthesis method thereof

ActiveCN109851549BOrientation controllableEasy to separate and purifyOrganic chemistryTetraloneCarbazole

The invention discloses a 5-hydro-benzo[b]carbazole and related derivatives and a synthesis method thereof. Step 1) 2-tetralone is activated by alpha carbon by using sodium hydride, wherein sodium hydride and 2-naphthalene The molar ratio of fullone is 0.8~1.2:1, and bromine is dripped into the reaction solution to generate substitution reaction to generate 1-bromo-2 tetralone, wherein the molar ratio of 2-tetralone to bromine is 1:1~ 1:1.5; Step 2) Use the 1-bromo-2 tetralone generated in step 1) to undergo Fisher indole ring closure reaction with phenylhydrazine salt to generate 6-bromo-6,11-dihydro-5-hydrobenzene [b] carbazole and related derivatives, wherein the molar ratio of 1-bromo-2 tetralone to phenylhydrazine salt is 1:1~1:1.3; 6-bromo-formed in step 2) in step 3) 6,11-Dihydro-5-hydrobenzo[b]carbazole and related derivatives are aromatized to 5-hydro-benzo[b]carbazole and related derivatives.

Owner:西安欧得光电材料有限公司

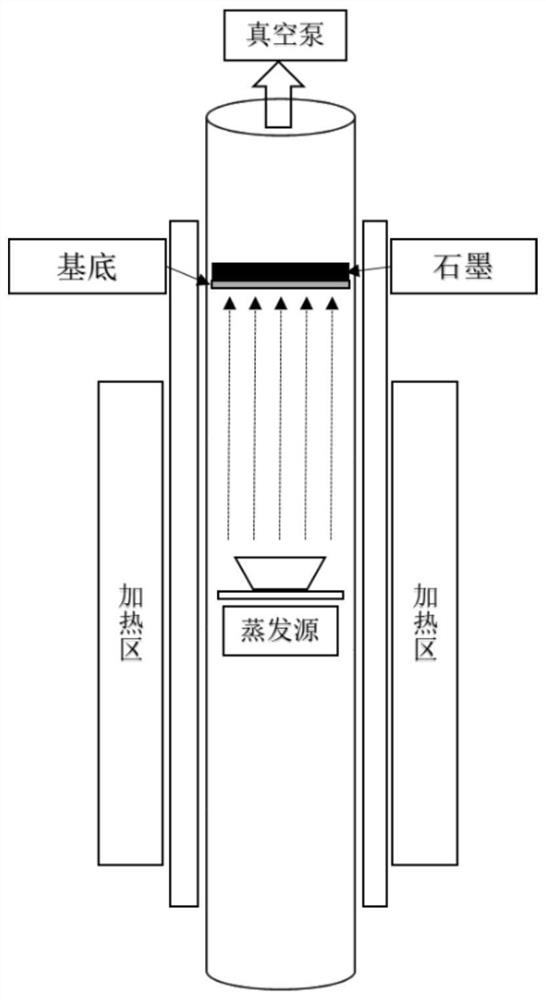

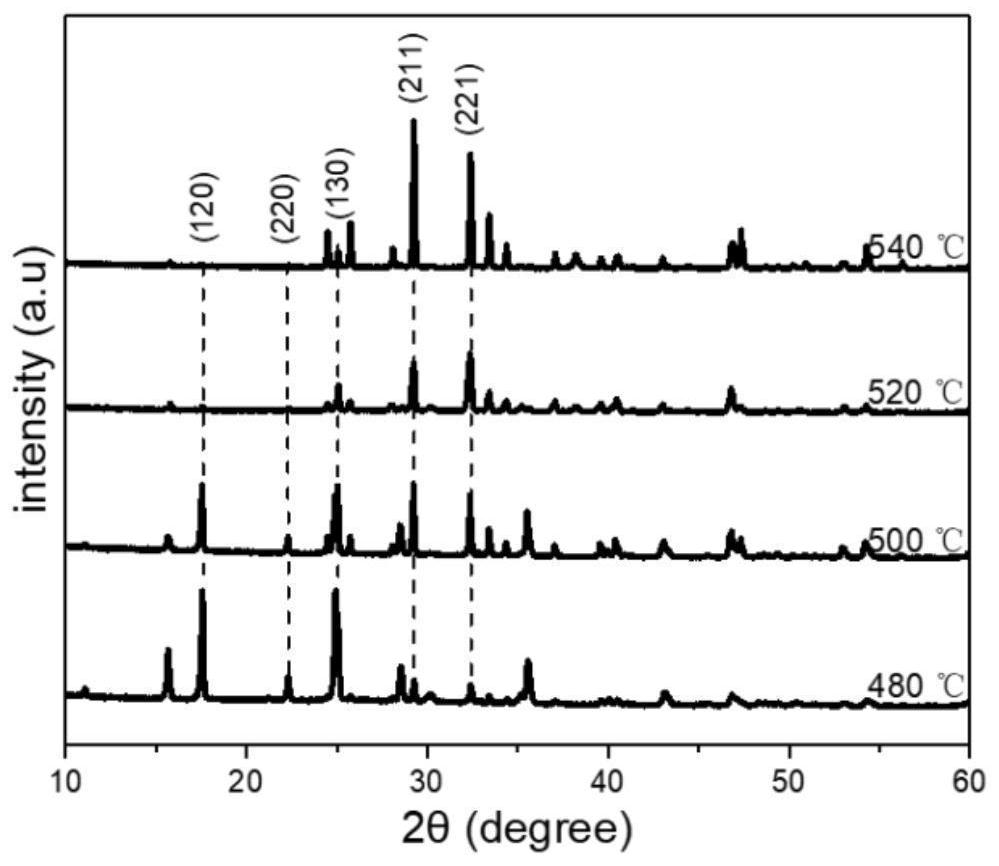

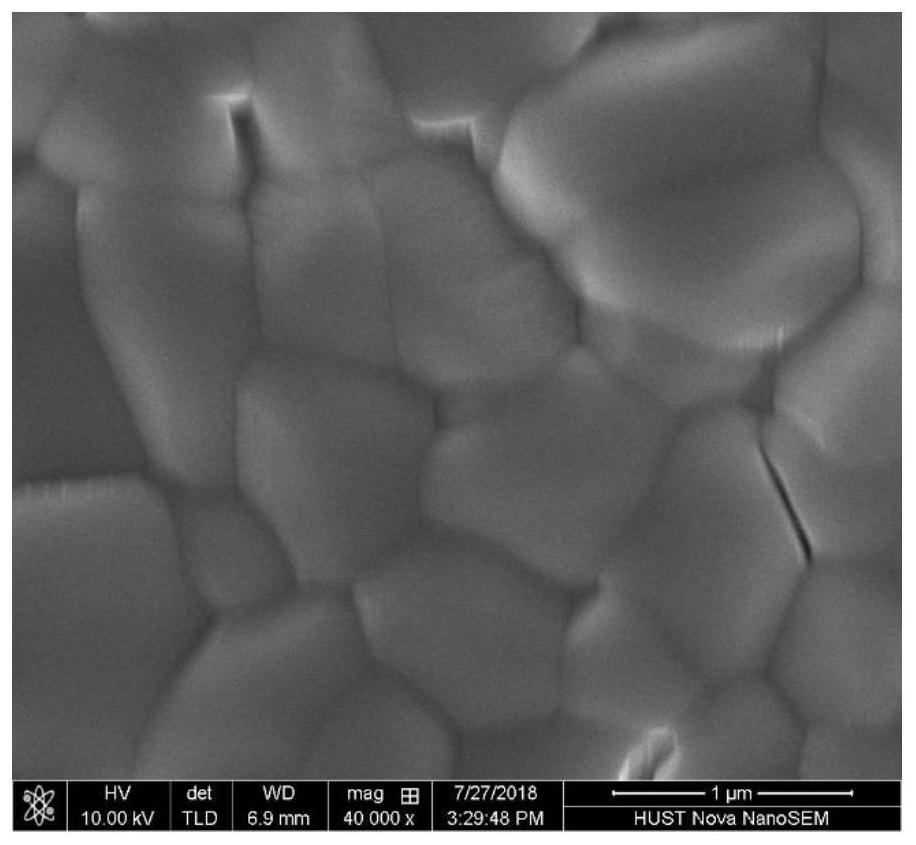

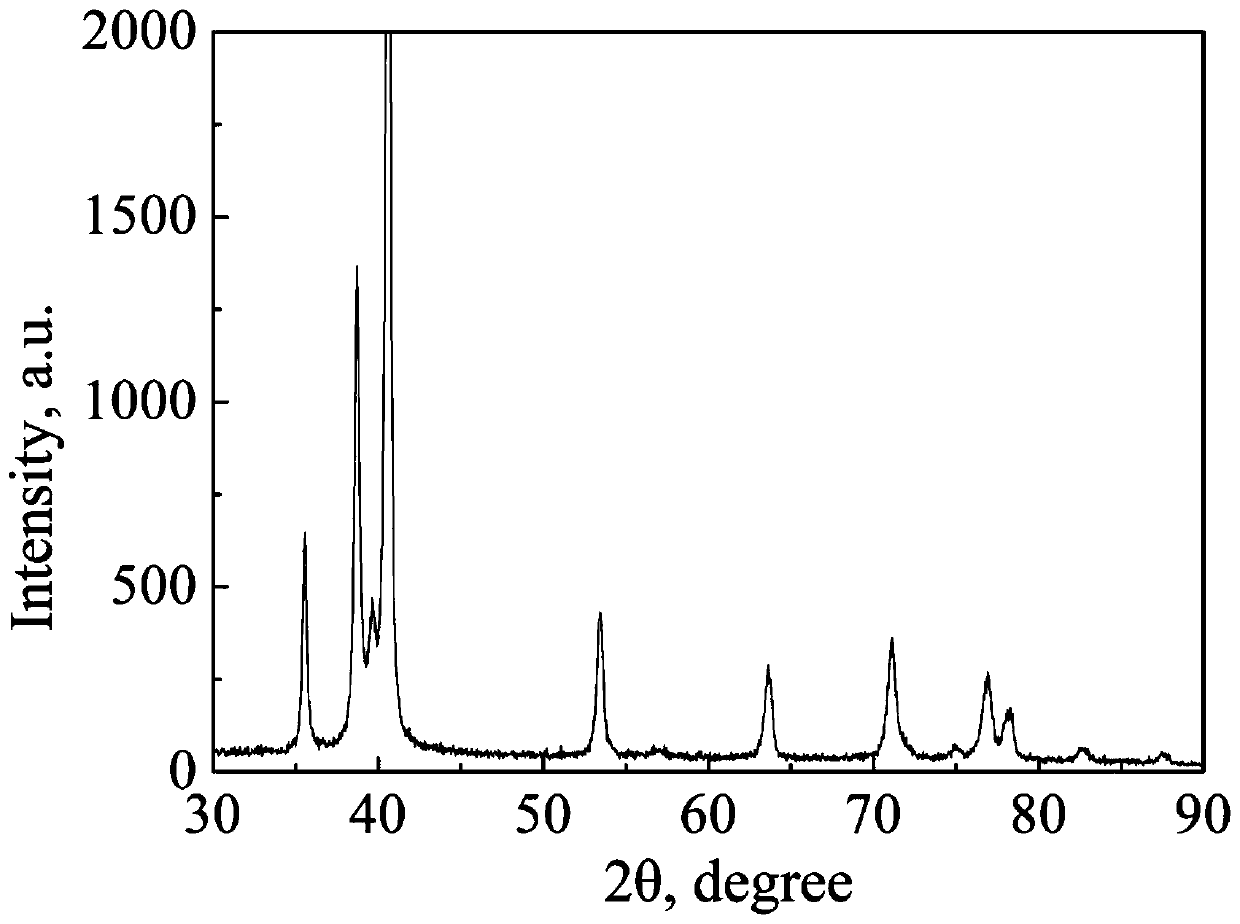

A thin film preparation method of a quasi-one-dimensional structure material with controllable orientation

ActiveCN111020487BOrientation is well controllableOrientation controllableFinal product manufactureVacuum evaporation coatingEvaporation (deposition)Tube furnace

The invention discloses a method for preparing a thin film of a quasi-one-dimensional structural material with controllable orientation. The method is based on a vertical evaporation tube furnace, and specifically includes the following steps: (1) placing the evaporation source material and the substrate to be deposited on the In the vertical evaporation tube furnace; (2) vacuum treatment, so that the vacuum degree of the vertical evaporation tube furnace remains at the preset vacuum degree and the fluctuation does not exceed ± 1Pa; (3) heat treatment in the heating zone, so that The evaporation source material is evaporated and deposited on the substrate to form a thin film; during the preparation process, the orientation of the formed quasi-one-dimensional material film can be controlled by controlling the parameters of the evaporation process. The present invention improves the key process parameters of the preparation method, adopts a vertical evaporation tube furnace with a specific structure for deposition, realizes the deposition and orientation control of a quasi-one-dimensional material film, and obtains a semiconductor film with a controllable orientation independent of the substrate , compared with the prior art, it can effectively solve the problem that the orientation of quasi-one-dimensional materials cannot be controlled.

Owner:HUAZHONG UNIV OF SCI & TECH +1

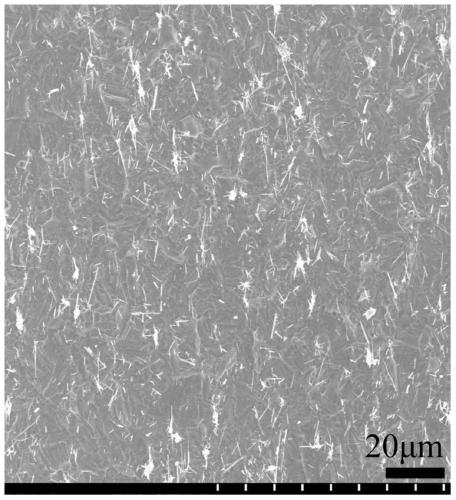

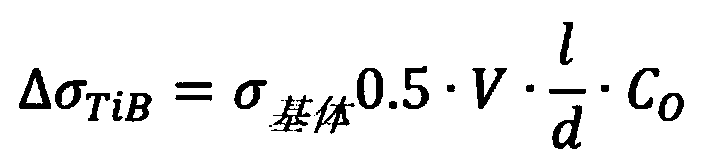

A preparation method of tib whisker reinforced titanium matrix composite with controllable orientation

ActiveCN109136608BOrientation controllableEffective regulation of orientationTitanium matrix compositesThermal deformation

The invention relates to a preparation method of an orientation controllable TiB whisker reinforcement titanium-based composite material, and belongs to the field of metal-based composite materials. By combining the technologies of ball milling, discharge plasma low-temperature forming and discharge plasma thermal deformation, the optimal morphology of TiB whiskers reaching consistent orientationin the titanium-based composite material is effectively regulated. According to the method, deformation temperature and atmosphere can be controlled, the influence of adverse factors such as oxidationis omitted, deformation rate can be indirectly regulated by pressurization rate, the obtained TiB whiskers are high in length-diameter ratio and good in integrity, the TiB whiskers and titanium substrates have good interface bonding and coherency relationship, the substrates can be enhanced according to orientation factors and length-diameter ratio optimization in a load transfer mechanism, and the integrated mechanical performance of the composite material is remarkably improved. The preparation method sufficiently solves the problems that TiB whisker orientation is not easily regulated, means is single, the length-diameter ratio of the whiskers is low, additional thermal deformation equipment is needed, technology difficulty and cost are accordingly increased and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

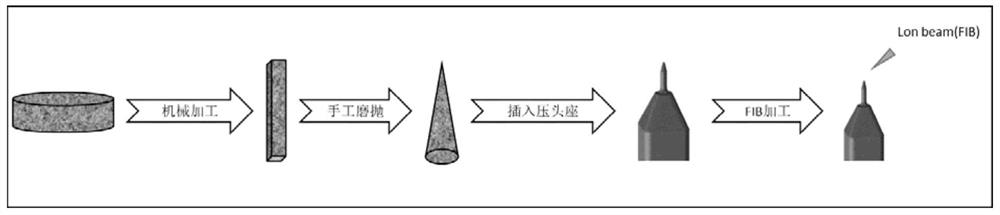

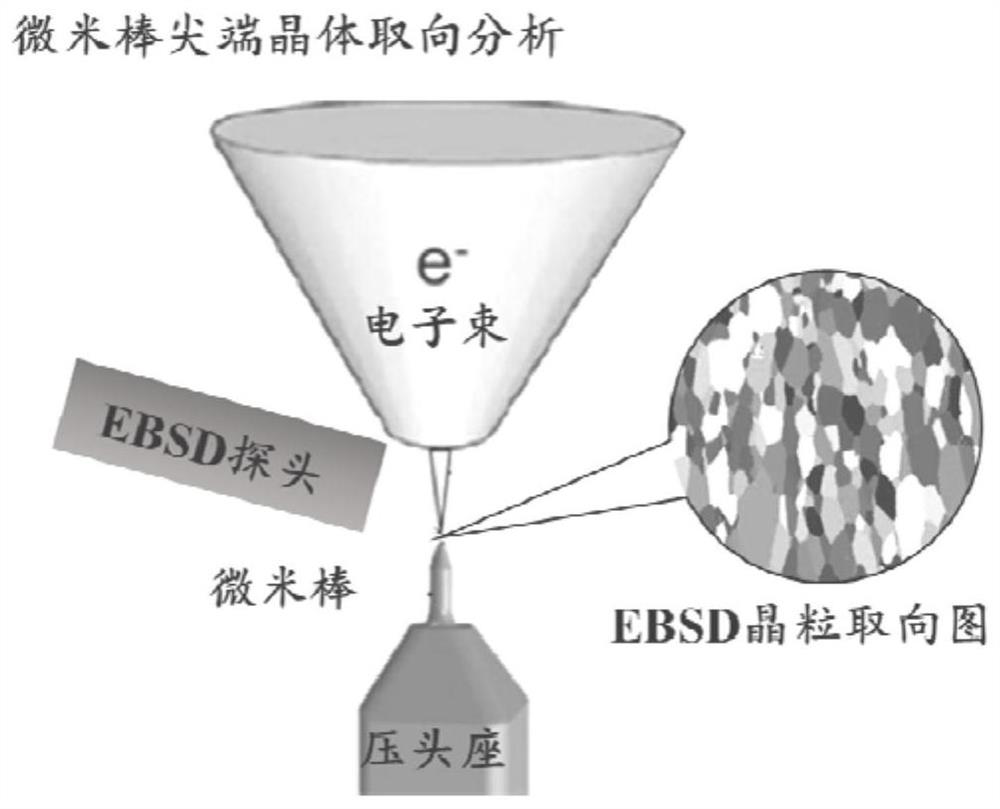

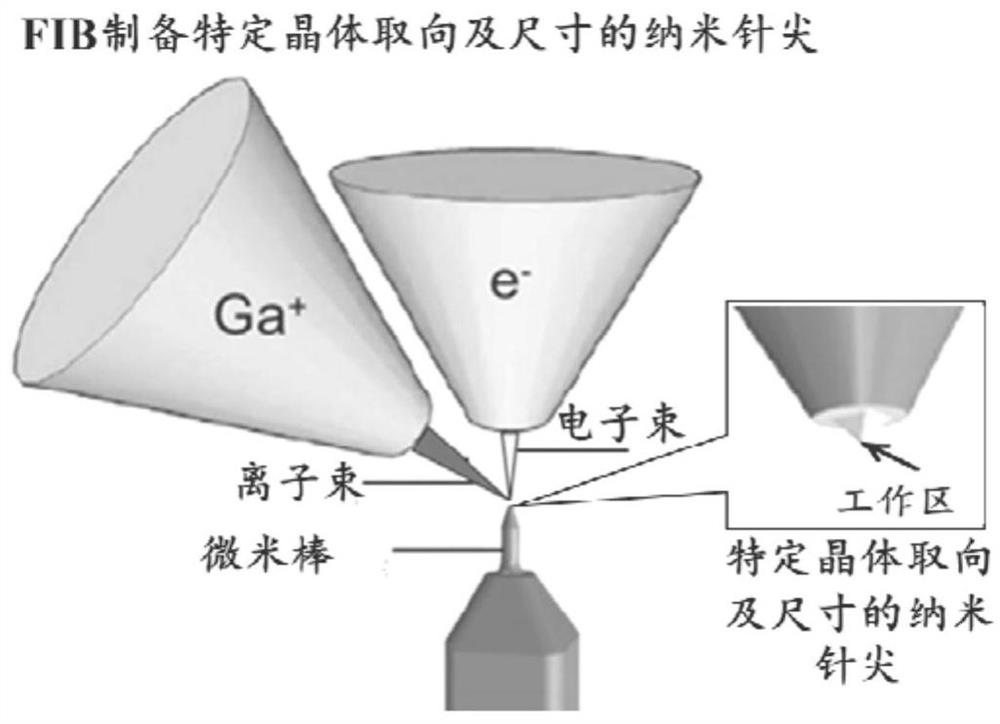

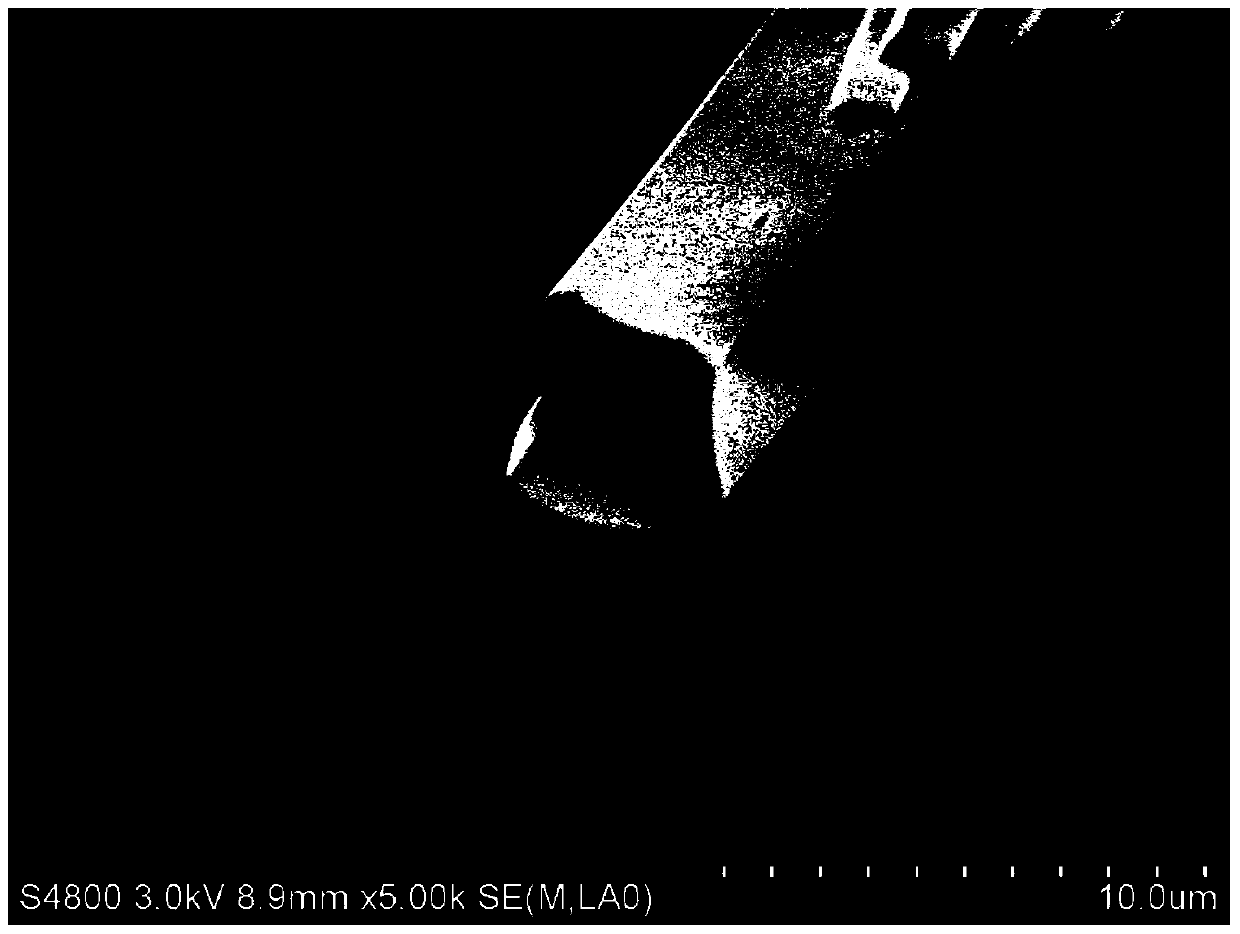

A preparation method of nano needle tip with controllable crystal orientation and size

The invention discloses a method for preparing a nano needle tip with controllable crystal orientation and size, and belongs to the field of nano material preparation. The method includes the steps of: 1) processing the bulk material to be processed into a microrod with a needle point at one end and reaching the micron level; 2) analyzing the crystal orientation of the needle point part of the microrod, and selecting a Grains suitable for processing, and then using gallium ion beams to process the suitable crystal grains into nano needle tips with controllable crystal orientation and size. This method solves the current problem of controllable crystal orientation and size in the process of simulating single nano-particles with the help of nano-tips, and further establishes a more reasonable physical model for the contact between single nano-particles and the surface of materials, which can be widely used in the microscopic process between nanoparticles and the surface of substrate materials in the research.

Owner:SHAANXI UNIV OF SCI & TECH

A preparation method of cu-al-mn shape memory alloy single crystal with controllable orientation

ActiveCN107841790BOrientation controllableGuaranteed heredityPolycrystalline material growthAfter-treatment detailsShape-memory alloyMetallic materials

The invention relates to a preparation method of orientation-controllable Cu-Al-Mn shape memory alloy single crystals, belonging to the field of preparation of metal materials. The preparation methodcomprises the steps of firstly, preparing columnar polycrystalline Cu-Al-Mn shape memory alloy blank with <100> fiber texture along the solidification direction by adopting a directional solidification method; then, adopting a cyclic heat treatment method to enable the alloy crystal grains to continuously grow abnormally until growing into single crystals; meanwhile, controlling the cycle heat treatment system and process parameters to ensure that the crystal grain orientation has no obvious change in a single crystal growth process so as to obtain the Cu-Al-Mn shape memory alloy single crystals having near <001> orientation along the initial solidification direction. The preparation method, provided by the invention, of the single crystals realizes the orientation control of the solid phase transformation method in the single crystal growth process, and has the advantages of capability of preparing the large-sized single crystals (the single crystal sizes can reach 50 mm or more), easy orientation control, simple process, and the like.

Owner:UNIV OF SCI & TECH BEIJING

Functional compositematerial and preparing method thereof

The present invention provides a method for preparing functional composite material, which includes the following steps: firstly, placing the powder with functional action in a container cavity, applying field action to said powder, impregnating the powder with liquid material, finally solidifying the liquid material or firstly, placing the liquid material in the container cavity, then adding the powder with functional action into the container cavity in whith the liquid material is held, and applying field action to the power in the container cavity, and finally solidifying the liquid material. Said functional composite material can have the functions of electric conductivity, semi-conduction, superconductance, magnetism, piezoelectricity, damping, sound-absorbing, light sensation and thermal sensation, etc.

Owner:周照耀

A kind of 8-hydroxyquinoline metal complex micro/nanotube and preparation method thereof

InactiveCN105200524BIncrease profitSimple and fast operationMaterial nanotechnologyPolycrystalline material growthControllability8-Hydroxyquinoline

The present invention relates to a kind of 8-hydroxyquinoline metal complex micro / nanotube and preparation method thereof, the chemical composition of this micro / nanotube is 8-hydroxyquinoline gallium (Gaq3) or 8-hydroxyquinoline aluminum (Alq3) ; The cross-section of the micro / nanotube is hexagonal or square, the mouth of the micro / nanotube is square or circular, the length of the micro / nanotube is 200nm-60μm, and the wall thickness of the micro / nanotube is 20nm-1μm , the radius of the micro / nanotubes is 20nm‑3μm. The present invention also provides a method for preparing the above-mentioned micro / nanotubes. The 8-hydroxyquinolate gallium (Gaq3) and 8-hydroxyquinolate aluminum (Alq3) micro / nanotubes of the invention have controllable size and orientation and good crystal quality. In addition to being an anticancer drug itself, it also has drug delivery properties, and other drug components can be filled in micro / nanotubes for drug loading and delivery, which is more advantageous in biological applications.

Owner:SHANDONG UNIV

Manufacture method of liquid crystal orientation layer

InactiveCN102033361BOrientation controllableSame orientationVacuum evaporation coatingSputtering coatingManufacturing cost reductionLiquid-crystal display

The invention discloses a manufacture method of a liquid crystal orientation layer, comprising the following steps: (1) arranging a deposition cabin, arranging targets on the cathode side of the deposition cabin, and arranging a glass substrate on the anode side of the deposition cabin; (2) vacuumizing the deposition cabin; (3) filling inert gas into the deposition cabin; (4) applying direct-current high voltage on the glass substrate and the target, ensuring that the target sputters target atoms under the action of electric field and under certain gas pressure, and depositing on the glass substrate to form an orientation film, wherein the pressure of inert gas is 50-6000Pa; and (5) adopting an ion gun with a certain relative angle and an inclined angle with the glass substrate, carrying out ion bombardment on the orientation film arranged on the surface of the glass substrate, and forming an orientation slot on the orientation film so as to form the liquid crystal orientation layer. The invention can bring more consistent orientation of the liquid crystal orientation layer so as to improve the display quality of the liquid crystal display; in addition, the invention can lower the manufacture cost.

Owner:BOE TECH GRP CO LTD +1

A kind of magnetron liquid crystal and preparation method thereof

ActiveCN110127770BOrientation controllableInstantly controllable magnetic fieldLiquid crystal compositionsFerroso-ferric oxidesLiquid crystallineOptical property

The invention relates to a magnetic control liquid crystal and a preparation method thereof. The preparation method comprises: preparing a one-dimensional magnetic nanometer composite material; dispersing the one-dimensional magnetic nanometer composite material in a solution to prepare a colloidal dispersion liquid; and applying an external magnetic field to the colloidal dispersion liquid to obtain the magnetic field regulated liquid crystal. According to the present invention, the preparation method has characteristics of simple conditions, short preparation period and low cost; the obtained colloidal dispersion liquid has high stability; and the prepared magnetic control liquid crystal has characteristics of high magnetic responsiveness and short relaxation time, and has great application potential in the field of display devices, wherein the light transmittance of the liquid crystal can be controlled at any time by controlling the strength and the direction of the magnetic field so as to control the optical properties of the liquid crystal.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![A kind of 5-hydrogen-benzo[b]carbazole and related derivatives and synthesis method thereof A kind of 5-hydrogen-benzo[b]carbazole and related derivatives and synthesis method thereof](https://images-eureka.patsnap.com/patent_img/8c19d237-a142-48a3-98ba-47a19d522056/BDA0002023904480000062.png)

![A kind of 5-hydrogen-benzo[b]carbazole and related derivatives and synthesis method thereof A kind of 5-hydrogen-benzo[b]carbazole and related derivatives and synthesis method thereof](https://images-eureka.patsnap.com/patent_img/8c19d237-a142-48a3-98ba-47a19d522056/BDA0002023904480000081.png)

![A kind of 5-hydrogen-benzo[b]carbazole and related derivatives and synthesis method thereof A kind of 5-hydrogen-benzo[b]carbazole and related derivatives and synthesis method thereof](https://images-eureka.patsnap.com/patent_img/8c19d237-a142-48a3-98ba-47a19d522056/BDA0002023904480000082.png)