A preparation method of tib whisker reinforced titanium matrix composite with controllable orientation

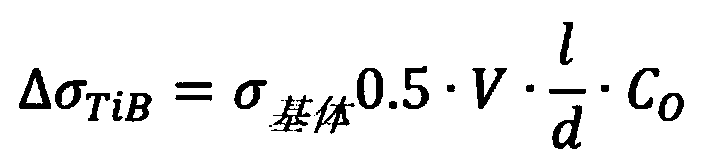

A technology of titanium-based composite materials and composite material blocks, which is applied in the field of metal-based composite materials, can solve the problems of reducing the mechanical properties of composite materials, impact, and the reduction of length-to-diameter ratio, and achieve controllable sintering atmosphere, high efficiency, and reduced matrix crystallization. The effect of grain coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

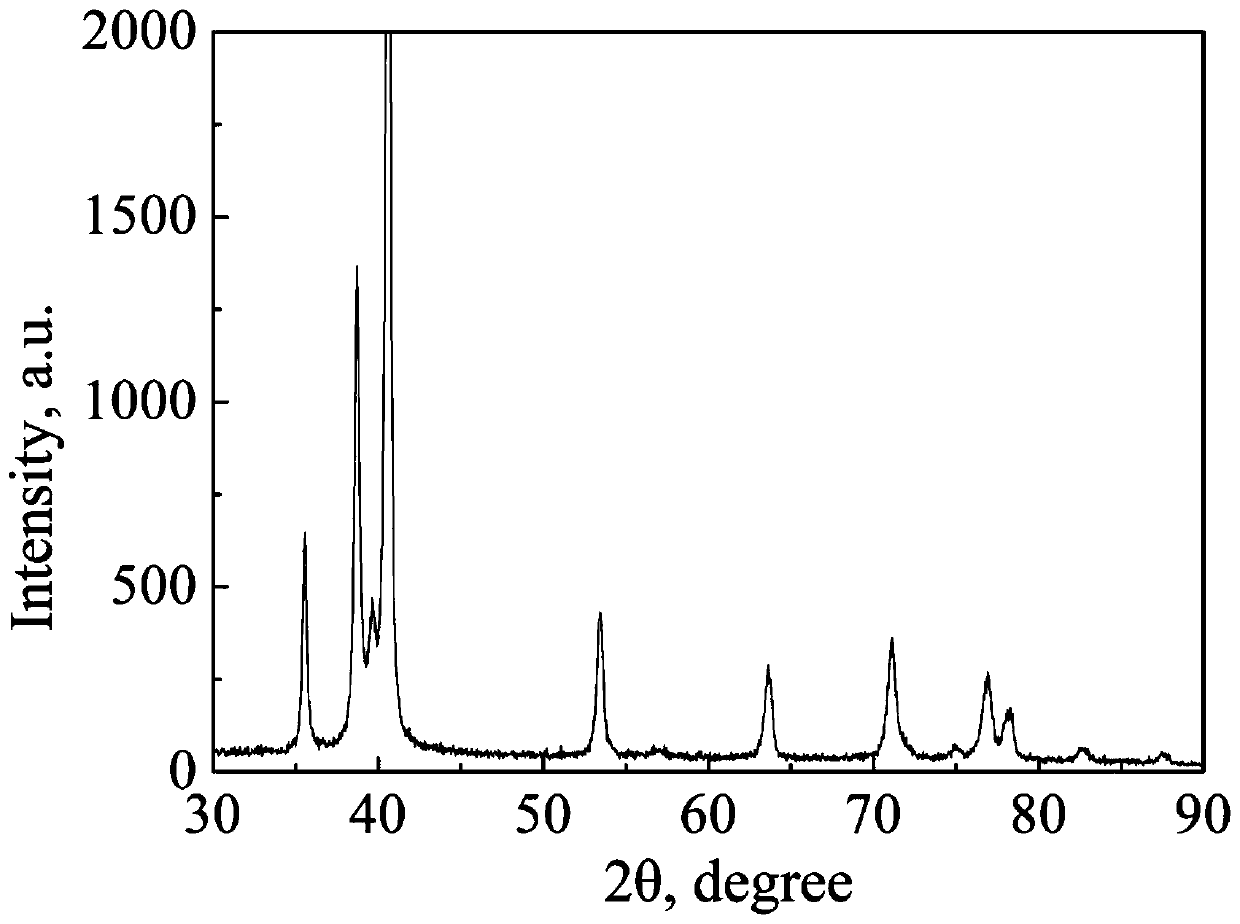

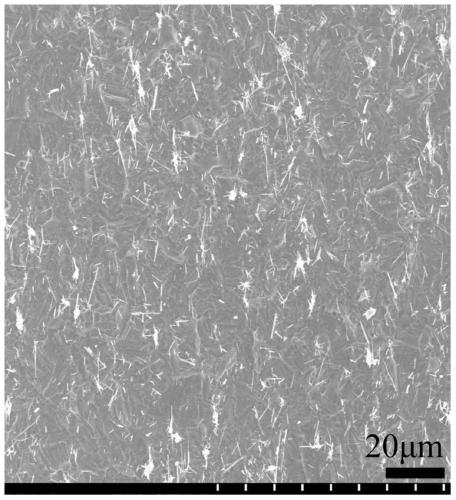

[0062] A method for preparing a TiB whisker-reinforced titanium-based composite material with controllable orientation, the steps of the method are as follows:

[0063] (1) Add 0.02g TiB 2 Powder and 39.98g TC4 powder were added to the ball mill tank of SM-QB planetary ball mill, and balls and excess absolute ethanol were added according to the ball-to-material ratio of 2:1; at a speed of 600r / min, ball milled for 0.5h and mixed evenly Obtain the mixed slurry; pour the mixed slurry into a vacuum rotary evaporator, and steam it for 0.2h under the conditions of a rotating speed of 100r / min and a water bath temperature of 80°C, and obtain a mixed powder precursor after the ball milling medium is volatilized; the mixed The powder precursor was placed in an electrothermal constant temperature blast drying oven, and dried at 60° C. for 1 h to obtain a mixed powder.

[0064] Wherein, the grinding ball is composed of a large agate ball and a small agate ball with a mass ratio of 0.1:...

Embodiment 2

[0094] A method for preparing a TiB whisker-reinforced titanium-based composite material with controllable orientation, the steps of the method are as follows:

[0095] (1) Add 0.40g TiB 2 Powder and 39.60g TC4 powder were added to the ball mill tank of SM-QB planetary ball mill, and balls and excess absolute ethanol were added according to the ball-to-material ratio of 10:1; at a speed of 150r / min, ball milled for 5.0h and mixed evenly Obtain the mixed slurry; pour the mixed slurry into a vacuum rotary evaporator, turn the steam at a speed of 40r / min and a water bath temperature of 70°C for 2 hours, and obtain a mixed powder precursor after the ball milling medium is volatilized; the mixed powder The precursor was put into an electrothermal constant temperature blast drying oven, and dried at 30°C for 0.5h to obtain a mixed powder.

[0096] Wherein, the grinding ball is composed of a large agate ball and a small agate ball with a mass ratio of 10:1, the diameter of the large...

Embodiment 3

[0126] A method for preparing a TiB whisker-reinforced titanium-based composite material with controllable orientation, the steps of the method are as follows:

[0127] (1) Add 16.00g TiB 2 Add Ti powder and 24.00g Ti powder into the ball mill tank of SM-QB planetary ball mill, and add grinding balls and excess absolute ethanol according to the ball-to-material ratio of 10:1; at a speed of 150r / min, ball mill for 5.0h, and mix well Obtain the mixed slurry; pour the mixed slurry into a vacuum rotary evaporator, turn the steam at a speed of 40r / min and a water bath temperature of 70°C for 2 hours, and obtain a mixed powder precursor after the ball milling medium is volatilized; the mixed powder The precursor was put into an electrothermal constant temperature blast drying oven, and dried at 30°C for 0.5h to obtain a mixed powder.

[0128] Wherein, the grinding ball is composed of a large agate ball and a small agate ball with a mass ratio of 10:1, the diameter of the large agat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com