A preparation method of cu-al-mn shape memory alloy single crystal with controllable orientation

A cu-al-mn, memory alloy technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., to achieve the effect of simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Using oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity of 99.99% as raw materials, the prefabricated alloy is prepared by electromagnetic induction vacuum melting. The alloy composition is A1: 17.5at.%, Mn: 11at.%, and the rest is Cu. Alloy melting The temperature is 1300°C, and after 20 minutes of heat preservation, it is air-cooled to room temperature to obtain a prefabricated alloy with uniform composition.

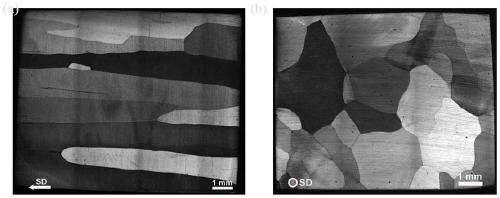

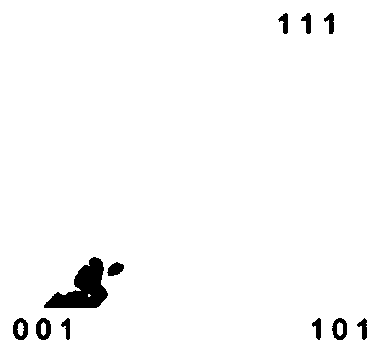

[0035] The directional solidification method is used to prepare columnar crystal structure alloy plates with wire texture along the solidification direction. The specific process is: re-melting the prefabricated alloy at 1150 ° C, holding it for 20 minutes, and pouring it to the bottom for cooling in a water-cooled copper mold. Into the graphite crystallizer with heat preservation (holding temperature 1100°C) (turn off the heat preservation and heating device after pouring), the alloy is directional solidified from bottom to top...

Embodiment 2

[0039] Using oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity of 99.99% as raw materials, the prefabricated alloy is prepared by electromagnetic induction vacuum melting. The alloy composition is A1: 17.5at%, Mn: 11at.%, and the rest is Cu. The alloy melting temperature 1200°C, keep warm for 20 minutes and then air-cool to room temperature to obtain a prefabricated alloy with uniform composition.

[0040] The directional solidification method is used to prepare columnar crystal structure alloy plates with wire texture along the solidification direction. The specific process is: re-melting the prefabricated alloy at 1150 ° C, holding it for 20 minutes, and pouring it to the bottom for cooling in a water-cooled copper mold. Into the graphite crystallizer with heat preservation (heat preservation temperature 1100°C) (turn off the heat preservation and heating device after pouring), the alloy is directional solidified from bottom to top to obtain ...

Embodiment 3

[0043] Using oxygen-free copper, electrolytic aluminum and electrolytic manganese with a purity of 99.99% as raw materials, the prefabricated alloy is prepared by electromagnetic induction vacuum melting. The alloy composition is A1: 17at%, Mn: 11at.%, and the rest is Cu. The alloy melting temperature is 1200°C, heat preservation for 20 minutes and then air-cool to room temperature to obtain a prefabricated alloy with uniform composition.

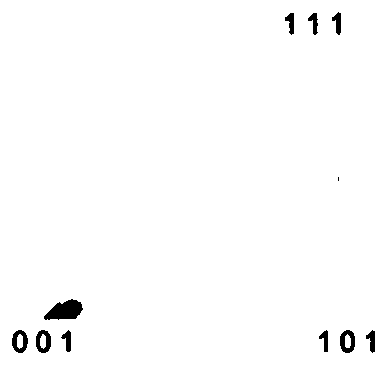

[0044] The continuous directional solidification method is used to prepare columnar grain structure alloy rods with silk texture along the solidification direction. The specific process is: using the pull-down continuous directional solidification equipment, first re-melting the prefabricated alloy at 1200 ° C, and controlling the graphite mold The temperature is 1100° C., and the casting speed is 20 mm / min. A rod with a diameter of 10 mm was prepared. Bars with a length of 100 mm were cut.

[0045] The columnar polycrystalline Cu-Al-Mn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com