Functional compositematerial and preparing method thereof

A functional composite material and functional technology, applied in the field of composite materials, can solve the problems that it is impossible to ensure the uniform distribution of each phase material, can not ensure that the powder is not chaotic, and the uniformity of composite functional materials is affected, and achieves good market prospects and stable performance. Reliable and uniform results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

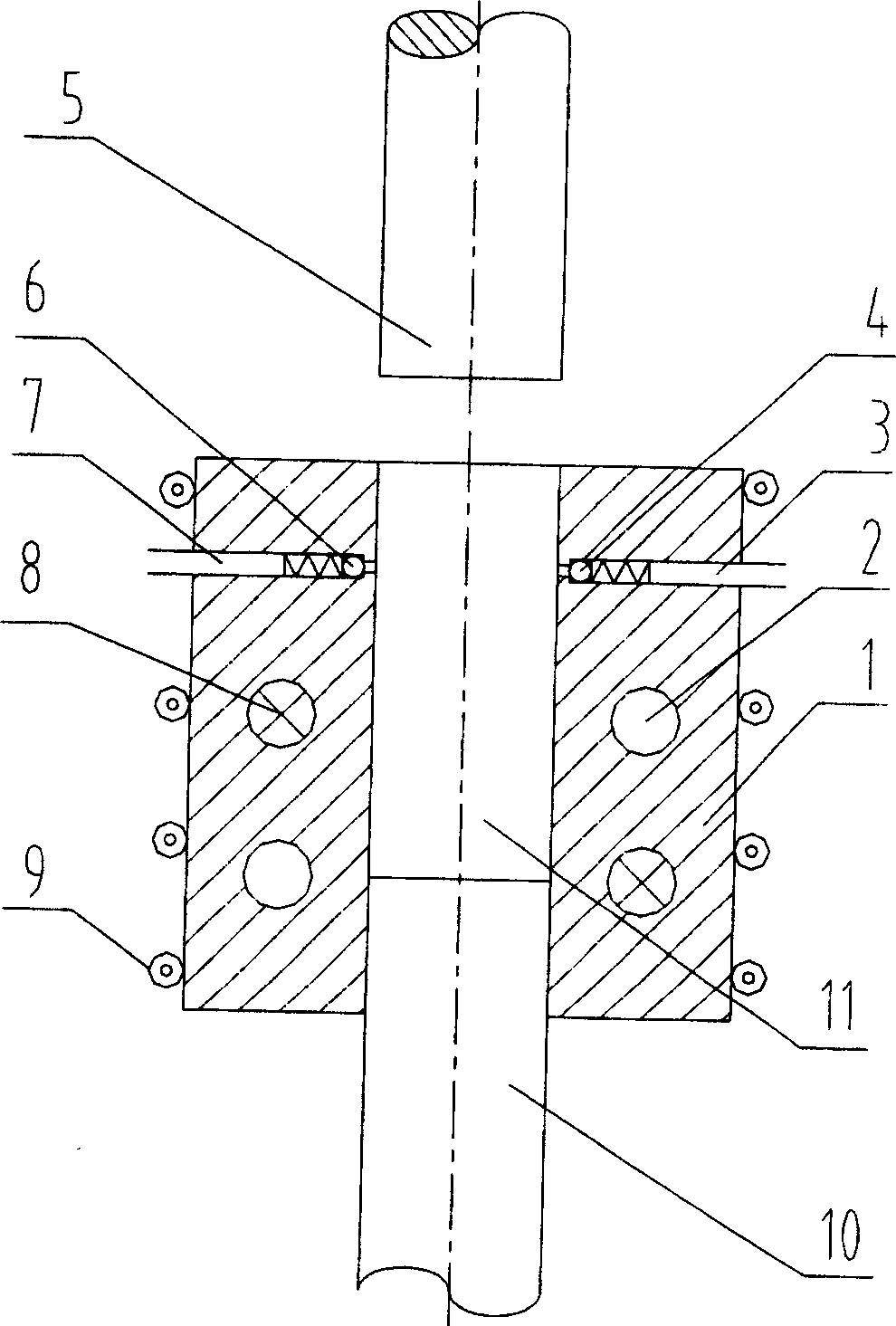

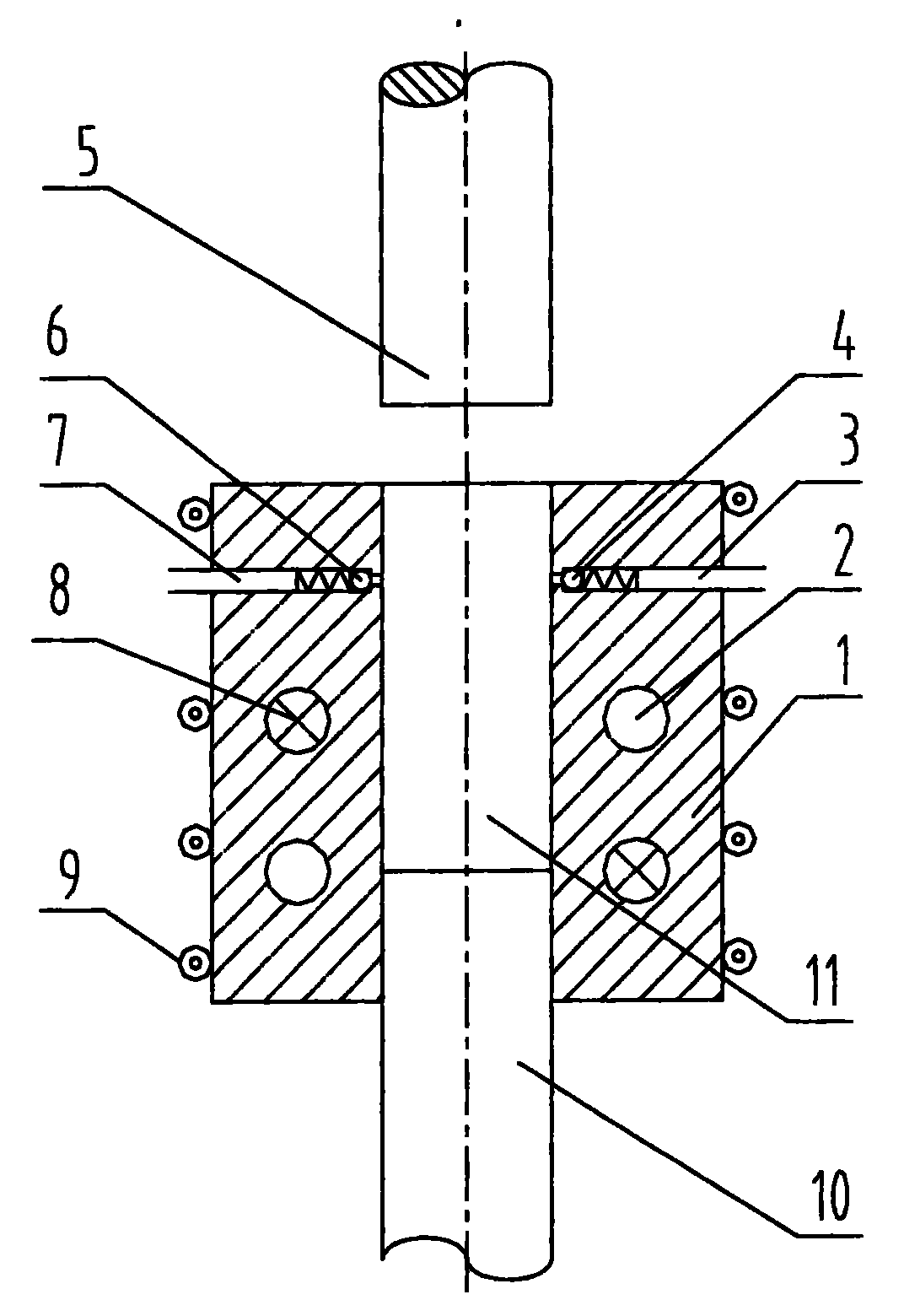

[0024] The method of the present invention adopts the mold shown in Figure 1 to prepare the functional composite material with magnetism, as can be seen from Figure 1, the mold includes a female mold 1, an upper male mold 5, a lower male mold 10, a heating wire 8, a coil 9, and a lower mold 1. The male mold 10 is inserted into the female mold 1 to form a mold cavity 11. The upper male mold 5 is set opposite to the mold cavity 11, and can be inserted into the mold cavity 11 to make the mold cavity 11 a closed space. The female mold 1 is provided with a heating wire 8 and cooling The channel 2 is surrounded by a coil 9 for forming a magnetic field outside the female mold 1. There are also through holes in the female mold 1. The through holes are respectively connected to the vacuum tube 3 and the liquid input tube 7. The through holes connected to the vacuum tube 3 are set There is a vacuum control valve 4, and a liquid input control valve 6 is arranged in the through hole connec...

Embodiment 2

[0027]This embodiment is still realized by using the mold described in Embodiment 1, and what is to be prepared is a functional composite material of polymer semiconductor. When the functional composite material is stressed, the resistivity of the material can change. The specific steps of realizing the method of the present invention are as follows: open the liquid input control valve 6 on the female mold 1, input the N-200 type resin liquid in the mold cavity 11 through the liquid input pipe 7, and then transport the copper powder with an average particle diameter of 100 nm into In the mold cavity 11, the copper powder is located on the N-200 type resin liquid, and then the upper male mold 5 descends, so that the lower surface of the upper male mold 5 forms a closed space with the inner wall of the female mold 1 and the upper surface of the lower male mold 10, and then the female mold is opened. Vacuum the control valve 4 on the mold 1, and evacuate the mold cavity 11 through...

Embodiment 3

[0029] What is to be prepared in this embodiment is a semiconductor functional composite material. The specific steps for realizing the method of the present invention are as follows: put the sulfur powder in a glass test tube, place it in a heating furnace and heat it to 130°C to liquefy the sulfur, then add the iron powder preheated to 100°C with an average particle size of 80 μm In the test tube with liquid sulfur, since the specific gravity of iron is greater than that of sulfur, the iron powder is deposited in the liquid sulfur in the test tube under the action of gravity field, and the iron powder in the liquid sulfur is stirred slowly with a glass test rod to make the iron powder adsorb The gas is discharged, and the stirring is stopped after the gas is released. The deposition time is determined according to the needs, and then the test tube is taken out of the furnace to cool. After the sulfur in the test tube is solidified, the iron powder is in contact with each othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com