Dispersion liquid with adjustable optical properties and preparation method thereof

A technology of optical properties and dispersion liquid, applied in chemical instruments and methods, inorganic chemistry, oxides of ferrous iron, etc., can solve the problem of immature inorganic liquid crystal synthesis technology, difficult application of inorganic mineral liquid crystal, and optical properties of liquid crystal phase Uncontrollable and other problems, to achieve the effects of simple and controllable optical properties, short preparation cycle, and great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0039] According to one embodiment of the present invention, the anisotropic nanostructure is a two-dimensional non-(intrinsically) magnetically anisotropic nanostructure.

[0040] In a further preferred embodiment, the anisotropic nanostructure is selected from one or both of non-magnetic nanosheets or nanodisks.

[0041] In a further preferred embodiment, non-magnetic anisotropic nanostructures are non-magnetic nanosheets.

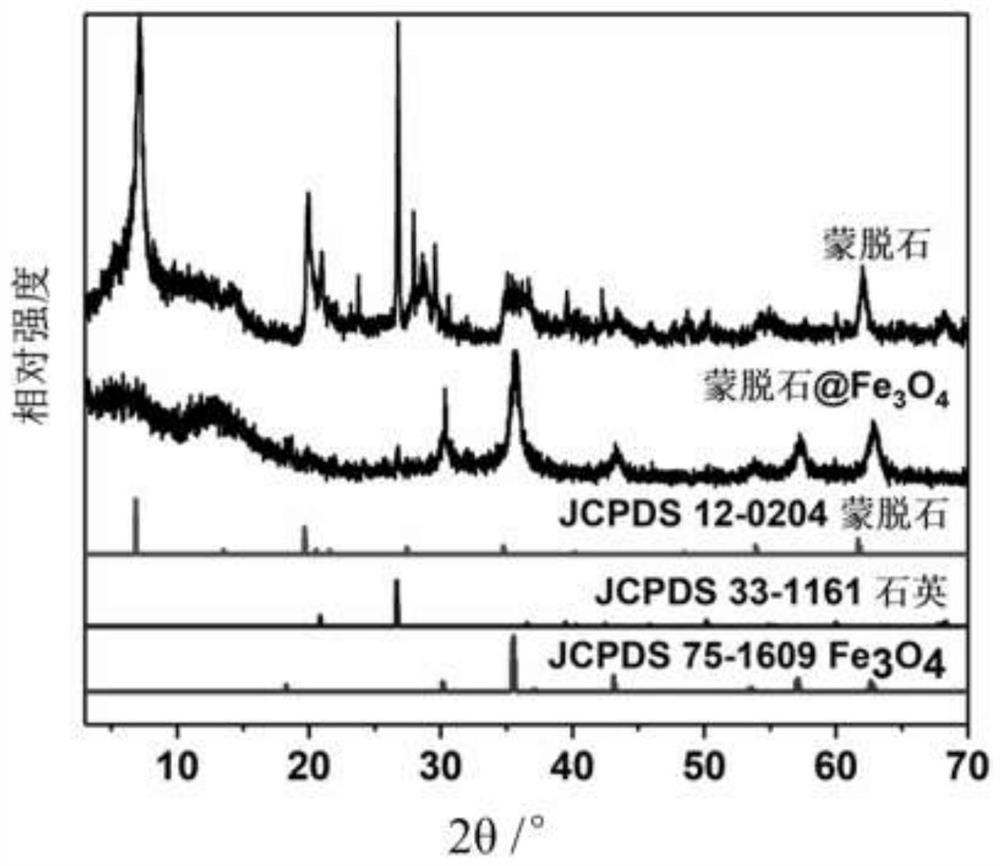

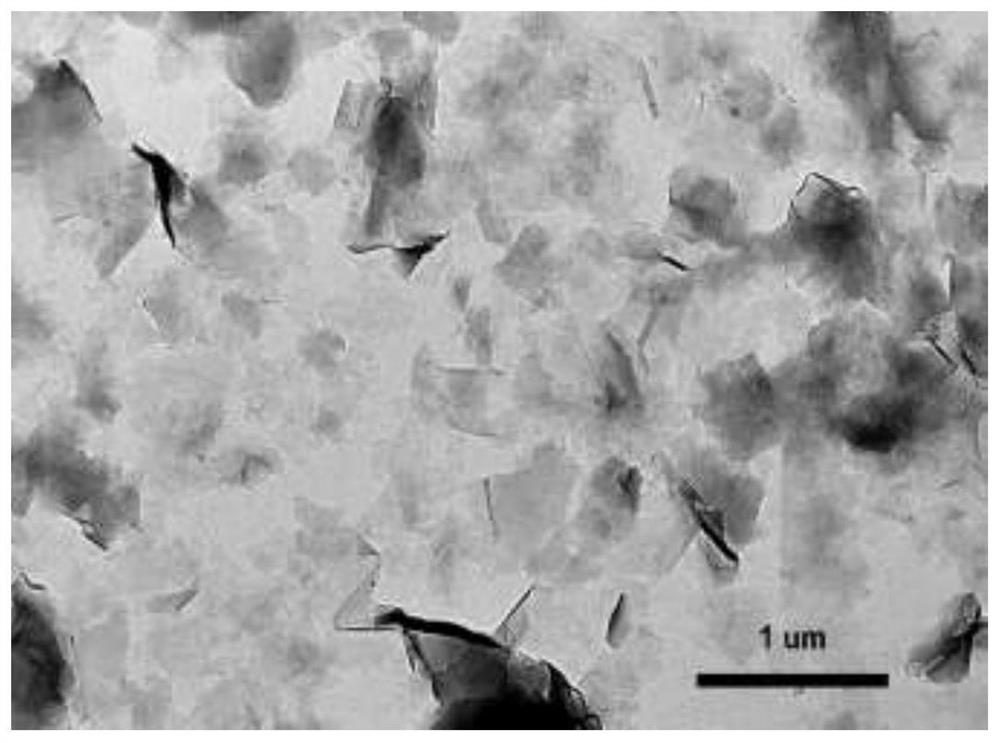

[0042] According to the present invention, the nonmagnetic anisotropic nanostructure is selected from inorganic materials, including one or more of mineral materials such as montmorillonite, gibbsite, laponite and vermiculite, preferably including montmorillonite, more It is preferably montmorillonite, for example, there are crystal plane diffraction peaks at 2θ of 7.10° and 19.7° in the XRD spectrum of the montmorillonite.

[0043] According to the present invention, it is particularly preferred to choose montmorillonite nanosheets as the non-magnetic ...

Embodiment 1

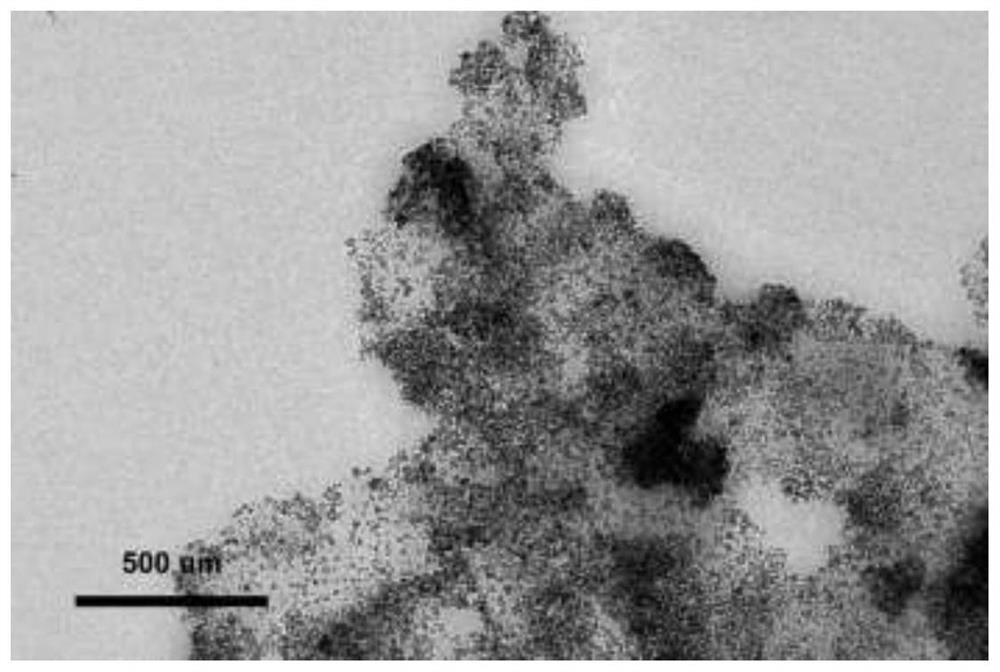

[0096] Prepare montmorillonite@ferric oxide two-dimensional magnetic nanocomposite, as follows: prepare 100 mL of 1 mg / mL montmorillonite aqueous suspension; pass nitrogen gas into the suspension, keep stirring, and add 1.0 mmol of ferric chloride React with 0.5mmol of ferrous sulfate at 60°C for 5 minutes; continue to add 5mL of ammonia water, react at 60°C for 30 minutes, centrifuge, wash and dry the above suspension to obtain montmorillonite@ferric oxide two-dimensional Magnetic nanocomposites;

[0097] The prepared montmorillonite@iron tetroxide two-dimensional magnetic nanocomposite material was added to 0.001mol / L hydrochloric acid to prepare a 0.125mg / mL dispersion, and stirred evenly to obtain a stable colloidal dispersion;

[0098] Place a magnet 2 cm away from the colloidal dispersion.

Embodiment 2

[0100] The experimental process of Example 1 was repeated, the only difference being that the prepared montmorillonite@ferric oxide two-dimensional magnetic nanocomposite material was added to 0.001mol / L hydrochloric acid to prepare a 0.25mg / mL dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com