A method for preparing polymer nanowires with controllable molecular orientation

A molecular orientation and polymer technology, applied in the field of materials, can solve the problems affecting actual use, many defects in molecular chain arrangement, and imperfect molecular orientation, and achieve the effects of uniform orientation, high crystallinity, and controllable orientation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

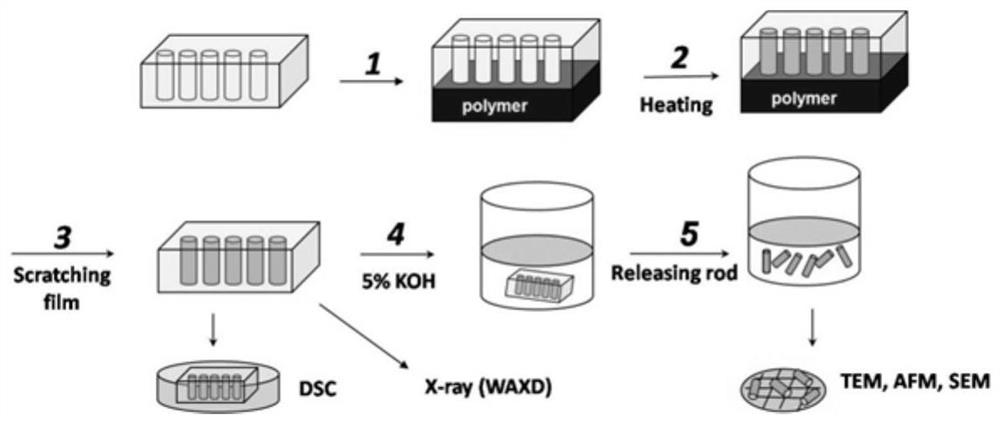

[0043]The preparation and characterization of polymer nanowires with controllable molecular orientation mainly include the following five steps, such as figure 2 shown.

[0044] Step S1, preparing a nanoporous alumina template, wherein the template has nanocylindrical holes in a hexagonal arrangement, and the diameter of the nanoholes is 10-1000 nanometers;

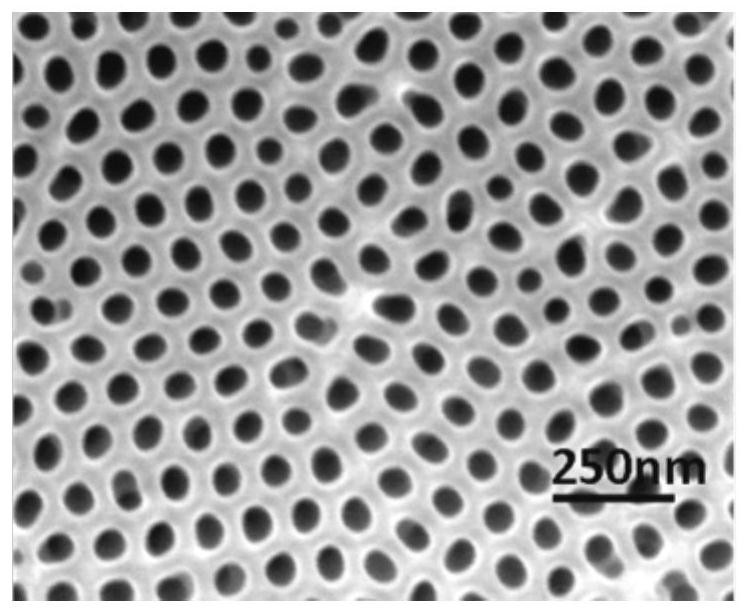

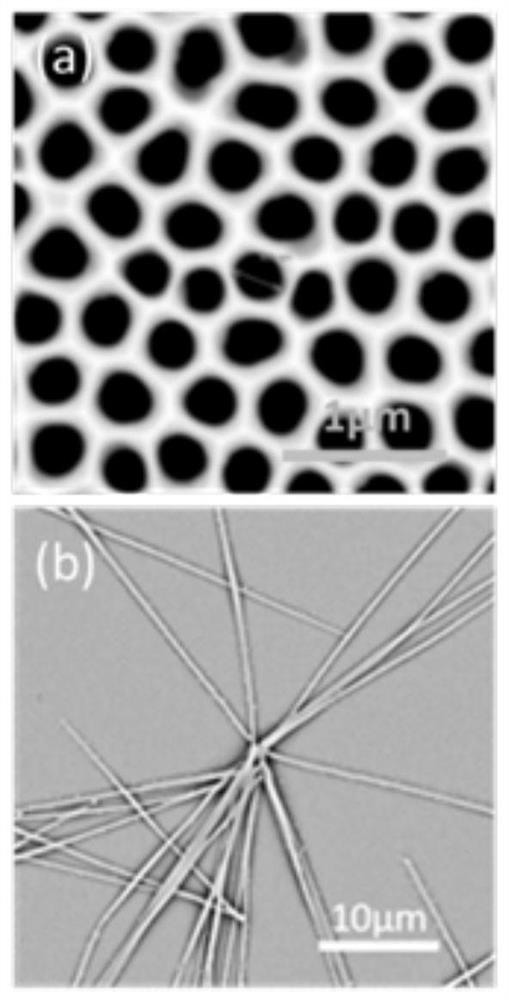

[0045] The anodized aluminum template is an inorganic metal oxide template with nano-cylindrical holes. The nano-cylindrical holes in the template are arranged in a hexagonal manner, and its scanning electron microscope image is shown in figure 1 shown.

[0046] Anodized aluminum templates are prepared by a two-step anodization method. The diameter of the nanopores in the inorganic alumina template can be adjusted by selecting different electrolytes and voltages. The inorganic alumina template component is alumina, and its surface tension is much greater than that of the polymer. Therefore, the semiconducting polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com