Laminated-oriented 3D printer nozzle mechanism

A technology of 3D printers and machine heads, applied in 3D object support structures, coating devices, additive manufacturing, etc., can solve the problems of performance index requirements, poor mechanical properties such as strength and stiffness, and cannot be used in engineering fields, and achieve orientation Controllable, improved comprehensive mechanical properties, and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

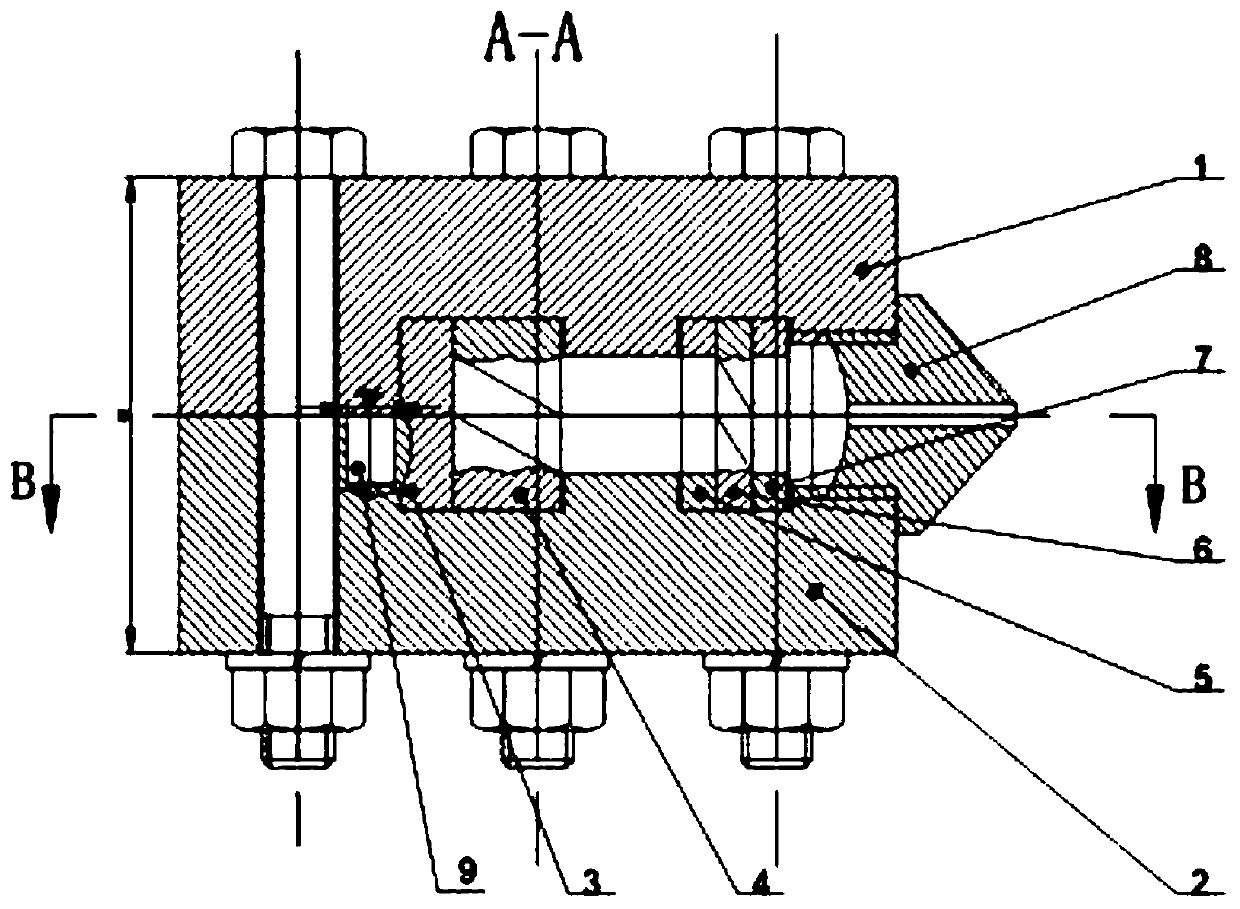

[0021] The present invention is a kind of stack orientation 3D printer spray head mechanism, such as figure 1 As shown, it includes an upper machine head 1 and a lower machine head 2, two positioning bosses 9 are arranged on the inner surface of the upper machine head 1, two positioning grooves are arranged on the inner surface of the lower machine head 2, and the positioning grooves and the positioning The bosses 9 cooperate, the upper machine head 1 and the lower machine head 2 are positioned through the positioning bosses 9, and connected by a plurality of evenly distributed bolts;

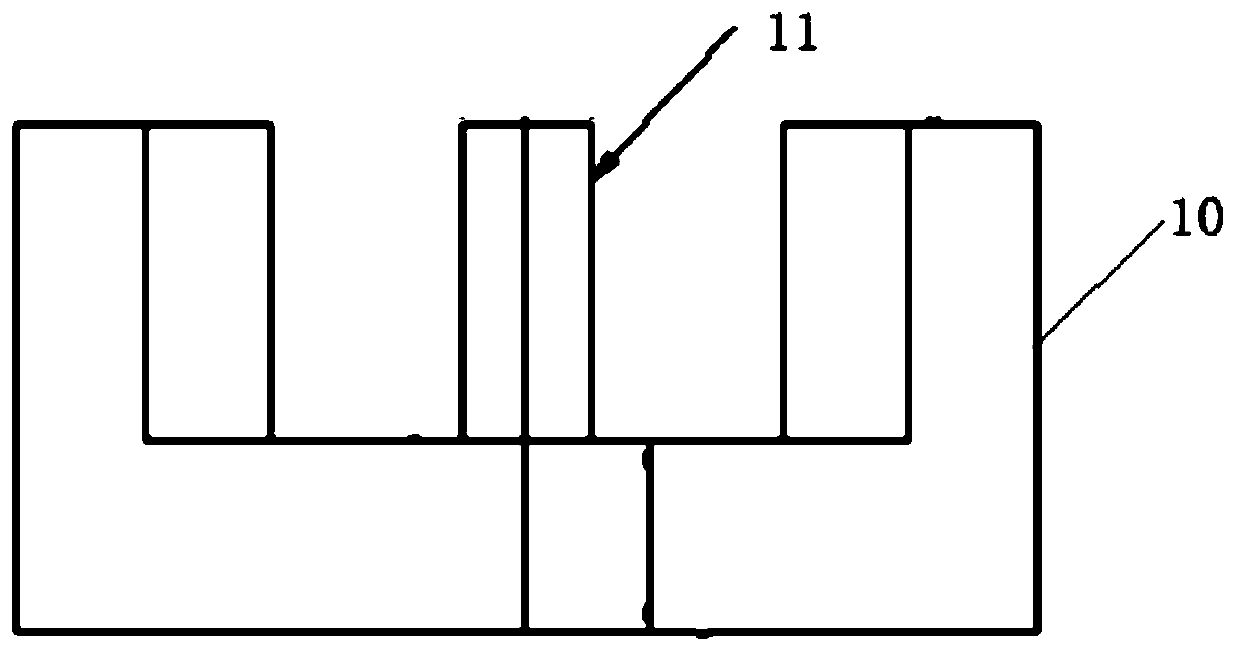

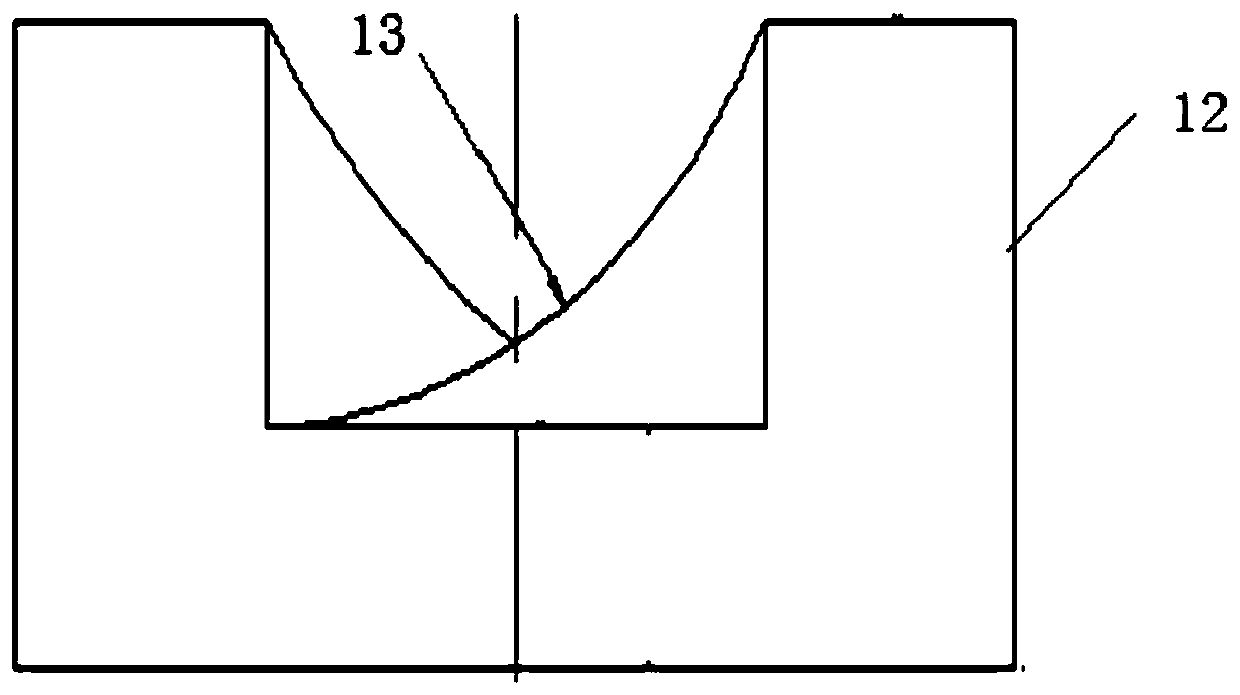

[0022] The inside of the upper machine head 1 and the lower machine head 2 are provided with a first internal thread segment, a groove and a second internal thread segment sequentially along the radial direction, and both ends of the groove are connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com