A Method for Induced Intermetallic Growth of Thin Films with Specific Grain Orientation and Quantity Using Laser Forward Transfer

A technology of intermetallic compounds and grain orientation, applied in chemical instruments and methods, metal layered products, metal processing equipment, etc., can solve the problems of high manufacturing cost, device damage, long time, etc. in tens of minutes or even hours. problems, to achieve the effect of improving thermal conductivity and mechanical properties, optimizing and improving microstructure, and improving high temperature service ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

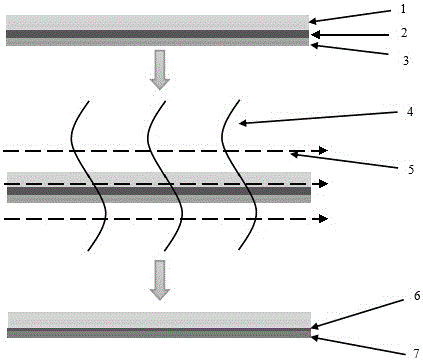

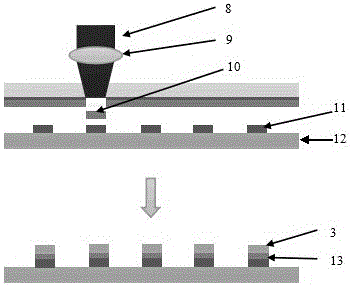

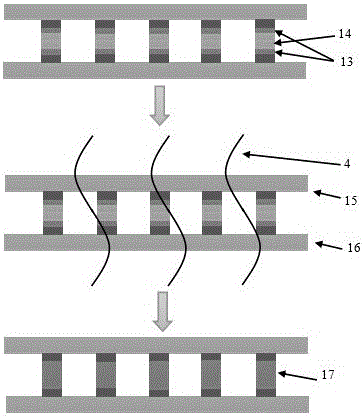

[0024] Such as Figure 1-3 As shown, the laser forward transfer Cu 3 Sn Single Crystal Thin Film Induced Preparation of Single Cu 3 The Sn interconnect solder joint method comprises the following steps:

[0025] Step 1: Prepare a Cu thin film as a seed layer on the surface of a transparent quartz substrate by magnetron sputtering, and the thickness of the seed layer is 50 nm.

[0026] Step 2: continue to prepare a Cu thin film with a thickness of 500 nm by electroplating.

[0027] Step 3: preparing a Sn film with a thickness of 400 nm on the surface of the Cu film by electroplating.

[0028] Step 4: Heating with a hot plate placed under the glass substrate for directional heating of the Cu / Sn double-layer film. The temperature of the hot plate is set at 360° C., the heating time is 200 h, and the heating environment is in a nitrogen environment. The direction of the applied magnetic field is parallel to the glass substrate. After heating, single crystal Cu 3 Sn.

[0029...

Embodiment 2

[0033] Such as Figure 1-3 As shown, the laser forward transfer Ag 3 Single Ag Induced by Sn Thin Film 3The Sn interconnect solder joint method comprises the following steps:

[0034] Step 1: Prepare an Ag thin film on the surface of the quartz substrate by evaporation, with a thickness of 300 nm.

[0035] Step 2: preparing a Sn film with a thickness of 100 nm on the surface of the Ag film by vapor deposition or other methods.

[0036] Step 3: heating the above-mentioned Ag / Sn double-layer film through a constant temperature furnace, the furnace temperature is set to 400° C., the heating time is 300 h, and the heating environment is in a nitrogen environment. Applied electric field, its direction is perpendicular to the quartz substrate. After heating, a single crystal of Ag is formed 3 Sn.

[0037] Step 4: using laser forward transfer technology to transfer the intermetallic compound film to the surface of the chip and the pad of the substrate respectively, the metal on...

Embodiment 3

[0041] Such as Figure 1-3 As shown, laser forward transfer Ni 3 sn 4 Thin film induced single Ni 3 sn 4 The method of interconnecting solder joints includes the following steps:

[0042] Step 1: preparing a Ni thin film on the surface of the quartz substrate by evaporation, with a thickness of 400 nm.

[0043] Step 2: preparing a Sn film with a thickness of 250 nm on the surface of the Ni metal film by vapor deposition or other methods.

[0044] Step 3: heating the above-mentioned Ni / Sn double-layer film through a constant temperature furnace, the temperature of the furnace is set at 350° C., the heating time is 500 h, and the heating environment is nitrogen environment. The direction of the applied magnetic field is perpendicular to the quartz substrate. Single crystal Ni formed after heating 3 sn 4 .

[0045] Step 4: Use laser forward transfer technology to transfer the intermetallic compound thin film to the surface of the chip and the substrate pad respectively. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com