A preparation method of perovskite photovoltaic thin film based on double-effect seed growth method

A photovoltaic thin film and perovskite technology, applied in the field of solar cells, can solve the problems of insolubility and limitation of perovskite photovoltaic thin films.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

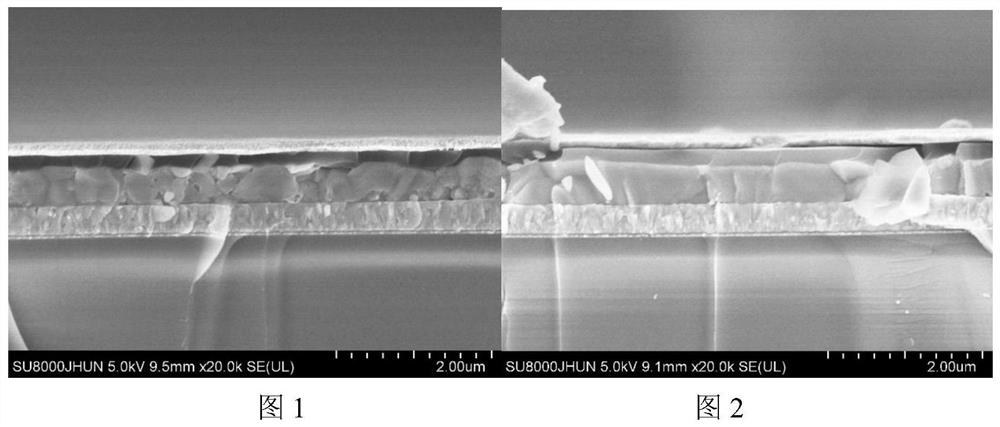

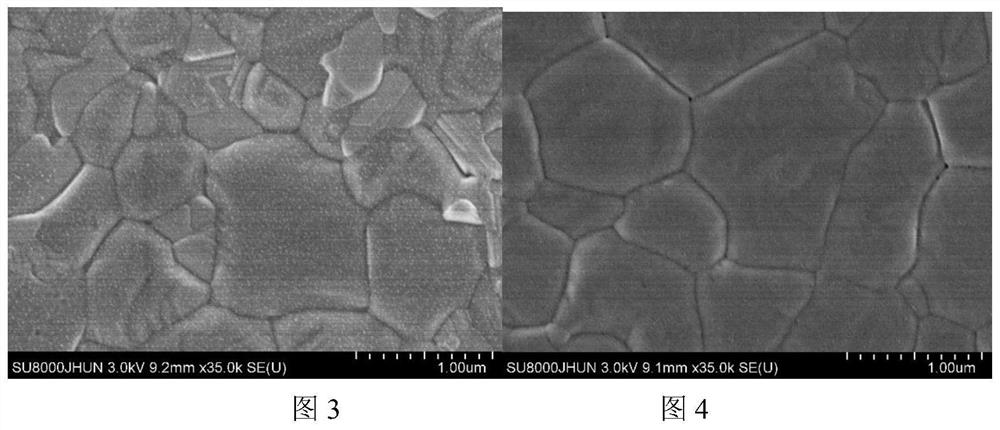

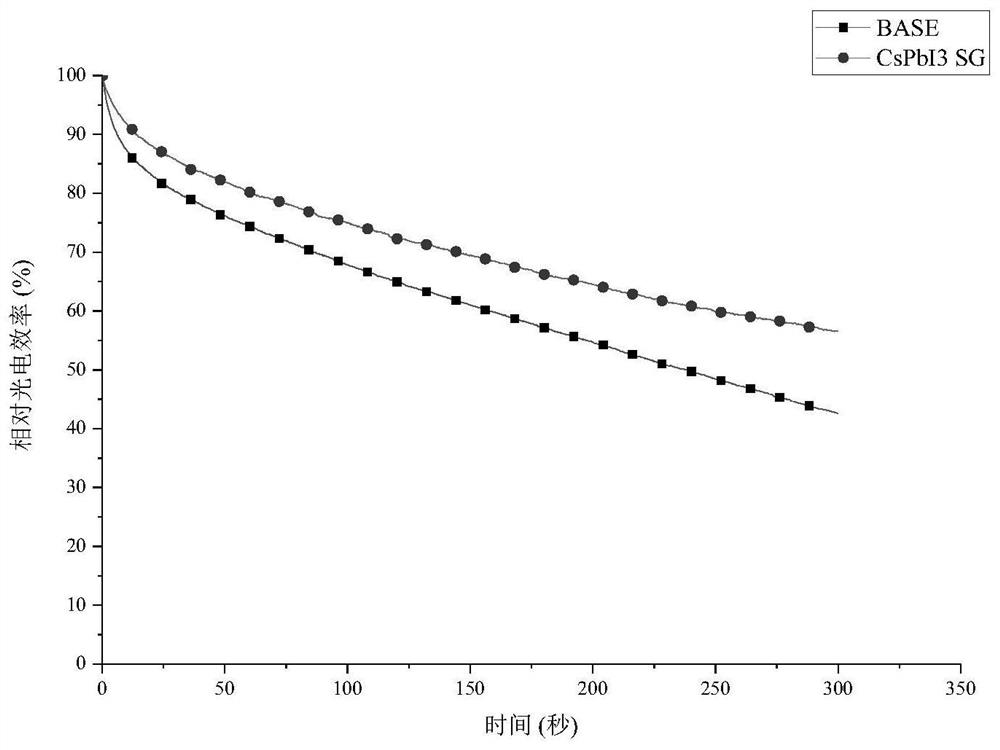

[0055] (1) Spin coating containing CsPbX on the substrate 3 PbI of seed solution 2 Precursor solution; where CsPbX 3 The components of the seed solution are, X=I, the concentration is 1M, the solvent is a DMF / DMSO mixed solvent, the DMF solvent volume ratio is 20%, CsPbX 3 Seed solution added to PbI 2 Accounting for the volume ratio of the whole mixed solution in the precursor solution is 5%; wherein PbI 2 The solvent of the precursor solution is a DMF / DMSO mixed solvent, the DMF solvent volume ratio is 80%, PbI 2 The concentration of the precursor solution was 1M.

[0056] (2) Heating and annealing at 50°C for 45s to obtain PbI 2 layer;

[0057] (3) Spin-coat FAI / MAI solution on PbI2 layer; Wherein FAI / MAI solution is the mixed solution of iodoformamidine (FAI) and iodomethylamine (MAI), wherein the mass ratio of FAI is 0%, FAI / MAI solution The total concentration of 50g / mL.

[0058] (4) Heating and annealing at 135° C. for 5 minutes to obtain a ternary mixed cation p...

Embodiment 2

[0060] (1) Spin coating containing CsPbX on the substrate 3 PbI of seed solution 2 Precursor solution; where CsPbX 3 The components of the seed solution are, X=I, the concentration is 2M, the solvent is a DMF / DMSO mixed solvent, the DMF solvent volume ratio is 80%, CsPbX 3 Seed solution added to PbI 2 Accounting for the volume ratio of the whole mixed solution in the precursor solution is 25%; wherein PbI 2 The solvent of the precursor solution is a mixed solvent of DMF / DMSO, the volume ratio of the DMF solvent is 100%, and the concentration is 2M.

[0061] (2) Heating and annealing at 120°C for 5 minutes to obtain PbI 2 layer;

[0062] (3) in PbI 2 Spin coating FAI / MAI solution on the layer; Wherein FAI / MAI solution is the mixed solution of iodoformamidine (FAI) and iodomethylamine (MAI), wherein the mass ratio of FAI is 100%, and the total concentration of FAI / MAI solution is 100g / mL.

[0063] (4) Heating and annealing at 180° C. for 60 minutes to obtain a ternary m...

Embodiment 3

[0065] (1) Spin coating containing CsPbX on the substrate 3 PbI of seed solution 2 Precursor solution; where CsPbX 3 The components of the seed solution are, X=I, the concentration is 1.5M, the solvent is a DMF / DMSO mixed solvent, the DMF solvent volume ratio is 50%, CsPbX 3 Seed solution added to PbI 2 Accounting for the volume ratio of the whole mixed solution in the precursor solution is 15%; wherein PbI 2 The solvent of the precursor solution is a DMF / DMSO mixed solvent, the DMF solvent volume ratio is 90%, PbI 2 The concentration of the precursor solution was 1.5M.

[0066] (2) Heating and annealing at 85°C for 3 minutes to obtain PbI 2 layer;

[0067] (3) in PbI 2 Spin coating FAI / MAI solution on the layer; Wherein FAI / MAI solution is the mixed solution of iodoformamidine (FAI) and iodomethylamine (MAI), wherein the mass ratio of FAI is 50%, and the total concentration of FAI / MAI solution is 75g / mL.

[0068] (4) Heating and annealing at 160° C. for 30 minutes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com