Trifluoroacetate induction based small-grain CsPbX3 perovskite thin film preparation method

A technology of trifluoroacetate and perovskite, which is applied in semiconductor/solid-state device manufacturing, chemical instruments and methods, lead compounds, etc., can solve problems such as limiting the performance of light-emitting devices, reducing device stability, and grain boundary defects. Achieve the effect of green and healthy preparation process, stable performance and less grain boundary defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In this example, see figure 1 with figure 2 , a small-grained CsPbBr based on trifluoroacetate-induced 3 The preparation method of perovskite thin film, comprises the steps:

[0020] a.CsPbBr 3 Preparation of perovskite precursor solution:

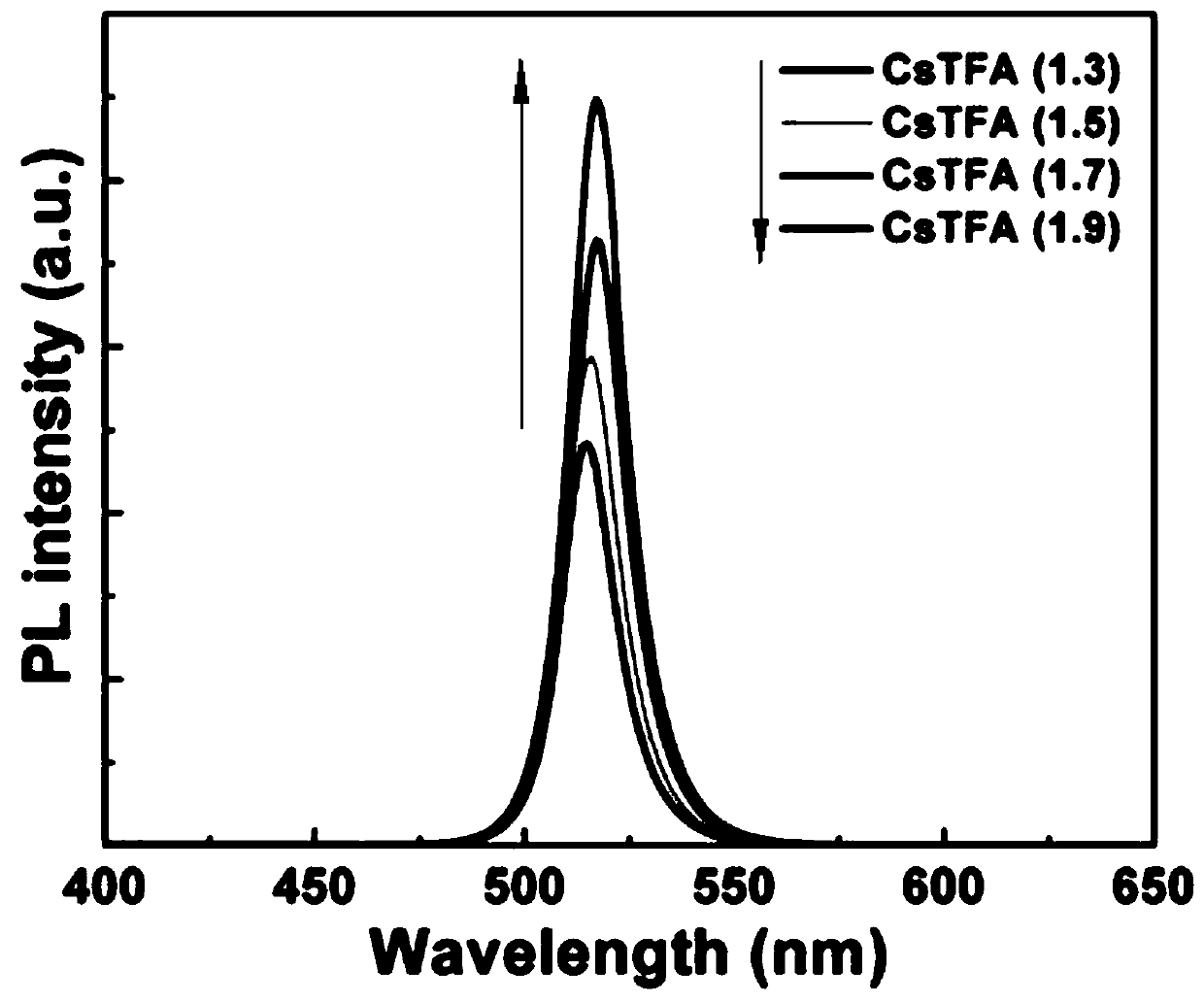

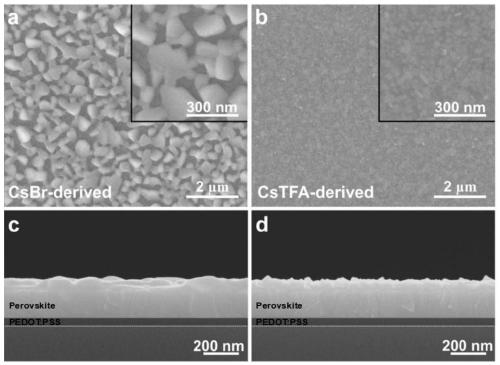

[0021] Cesium trifluoroacetate (CsTFA), lead bromide (PbBr 2 ) as raw material, according to CsTFA and PbBr 2 The molar ratios are respectively 1.3:1, 1.5:1, 1.7:1 and 1.9:1. Weigh the above-mentioned raw materials with different ratios respectively, and dissolve the raw materials in anhydrous dimethyl sulfoxide (DMSO) In , a series of raw material mixtures were obtained, and each raw material mixture was placed on a heating stirrer, heated at a temperature of 60°C, and stirred by the stirrer at the same time, so that the raw material mixture was stirred evenly overnight, and then the pore size The PTFE filter with a pore size of 0.45 μm is used to filter the raw material mixture to obtain uniform CsPbBr 3 Perovskite precurs...

Embodiment 2

[0028] This embodiment is basically the same as Embodiment 1, especially in that:

[0029] In this example, a trifluoroacetate-induced small-grain CsPbCl 3 The preparation method of perovskite thin film, comprises the steps:

[0030] a.CsPbCl 3 Preparation of perovskite precursor solution:

[0031] Cesium trifluoroacetate (CsTFA), lead chloride (PbCl 2 ) as raw material, according to CsTFA and PbCl 2 The molar ratios are respectively 1.3:1, 1.5:1, 1.7:1 and 1.9:1. Weigh the above-mentioned raw materials with different ratios respectively, and dissolve the raw materials in anhydrous dimethyl sulfoxide (DMSO) In , a series of raw material mixtures were obtained, and each raw material mixture was placed on a heating stirrer, heated at a temperature of 60°C, and stirred by the stirrer at the same time, so that the raw material mixture was stirred evenly overnight, and then the pore size Filter the raw material mixture with a polytetrafluoroethylene filter with a pore size of ...

Embodiment 3

[0038] This embodiment is basically the same as the previous embodiment, and the special features are:

[0039] In this example, a trifluoroacetate-induced small-grain CsPbI 3 The preparation method of perovskite thin film, comprises the steps:

[0040] a.CsPbI 3 Preparation of perovskite precursor solution:

[0041] Cesium trifluoroacetate (CsTFA), lead iodide (PbI 2 ) as raw material, according to CsTFA and PbI 2 The molar ratios are respectively 1.3:1, 1.5:1, 1.7:1 and 1.9:1. Weigh the above-mentioned raw materials with different ratios respectively, and dissolve the raw materials in anhydrous dimethyl sulfoxide (DMSO) In , a series of raw material mixtures were obtained, and each raw material mixture was placed on a heating stirrer, heated at a temperature of 60°C, and stirred by the stirrer at the same time, so that the raw material mixture was stirred evenly overnight, and then the pore size Filter the raw material mixture with a polytetrafluoroethylene filter with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com