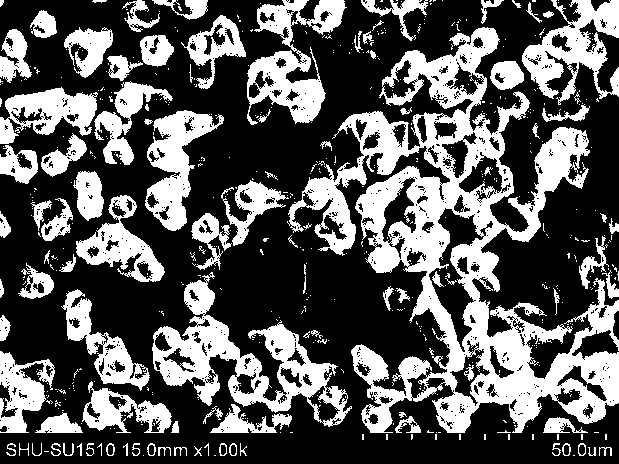

Preparation method for CdZnTe film with cylindrical structure

A columnar structure and thin film technology, applied in the field of columnar structure CdZnTe thin film and its preparation, can solve the problems of application influence, disordered thin film, difficult to achieve high resistance, low defects, etc., and achieve fewer grain boundary defects, high feasibility of batch growth, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The preparation process and steps of this embodiment are as follows:

[0020] (a) Preparation of CdZnTe single crystal sublimation source: According to the known prior art, put high-purity Cd, Zn, Te into a quartz tube, and use moving heating method to grow under high vacuum. Uniform CdZnTe single crystal, wherein the molar content of zinc is 5%, and the grown crystal slice is used as the sublimation source;

[0021] (b) Substrate pretreatment: use glass coated with a transparent conductive layer FTO as the substrate, and ultrasonically clean the substrate with deionized water, acetone and ethanol for 15 minutes respectively to remove impurities and organic substances on the surface, dry and put Into the close space sublimation reaction chamber;

[0022] (c) CdZnTe thin film growth process: turn on the mechanical pump to evacuate the sublimation chamber to below 3Pa, then turn off the mechanical pump, feed argon gas to adjust the pressure to 200Pa, and close the gas cy...

Embodiment 2

[0025] The preparation process and steps of this embodiment are as follows:

[0026] (a) Preparation of CdZnTe single crystal sublimation source: According to the known prior art, put high-purity Cd, Zn, Te into a quartz tube, and use moving heating method to grow under high vacuum. Uniform CdZnTe single crystal, wherein the molar content of zinc is 5%, and the grown crystal slice is used as the sublimation source;

[0027] (b) Substrate pretreatment: ordinary soda-lime glass is used as the substrate, and the substrate is ultrasonically cleaned with deionized water, acetone and ethanol for 15 minutes to remove impurities and organic matter on the surface, and then placed in the near space after drying sublimation reaction chamber.

[0028] (c) CdZnTe film growth process: turn on the mechanical pump to evacuate, pump the air pressure in the sublimation chamber to below 3Pa, then turn off the mechanical pump, feed argon gas to adjust the air pressure to 250Pa, and close the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com