Micro-gravure coating machine

A coating machine, gravure coating technology, applied in the direction of coatings, devices that apply liquid to surfaces, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

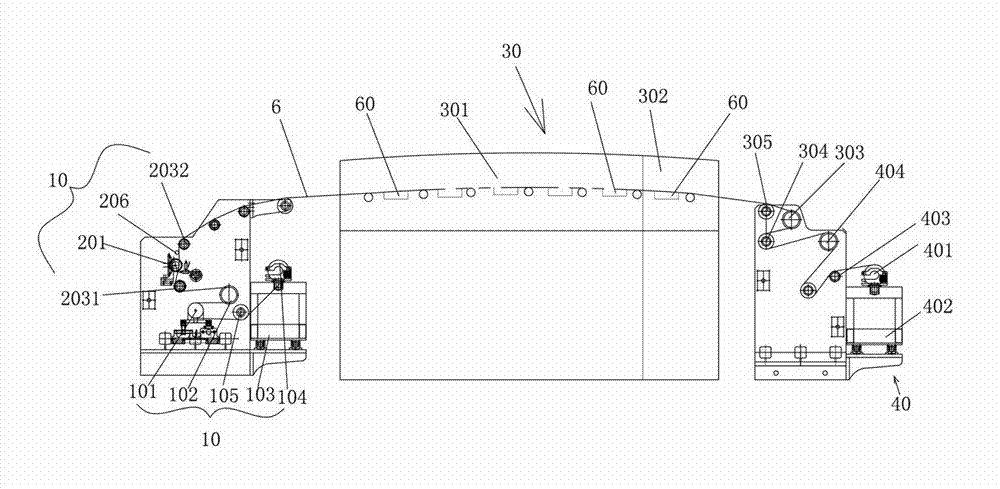

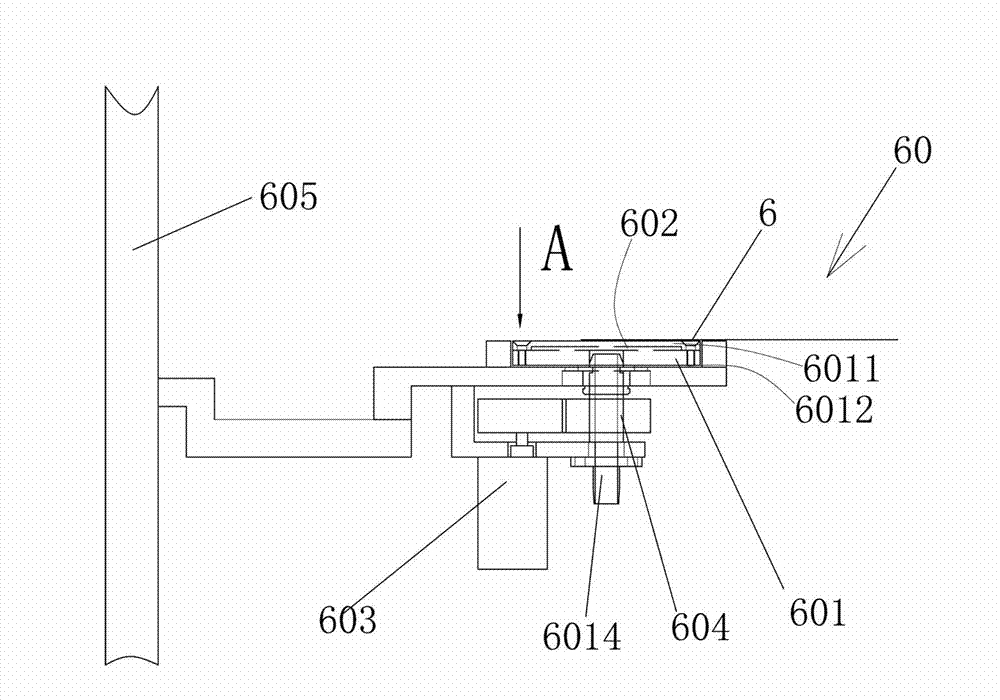

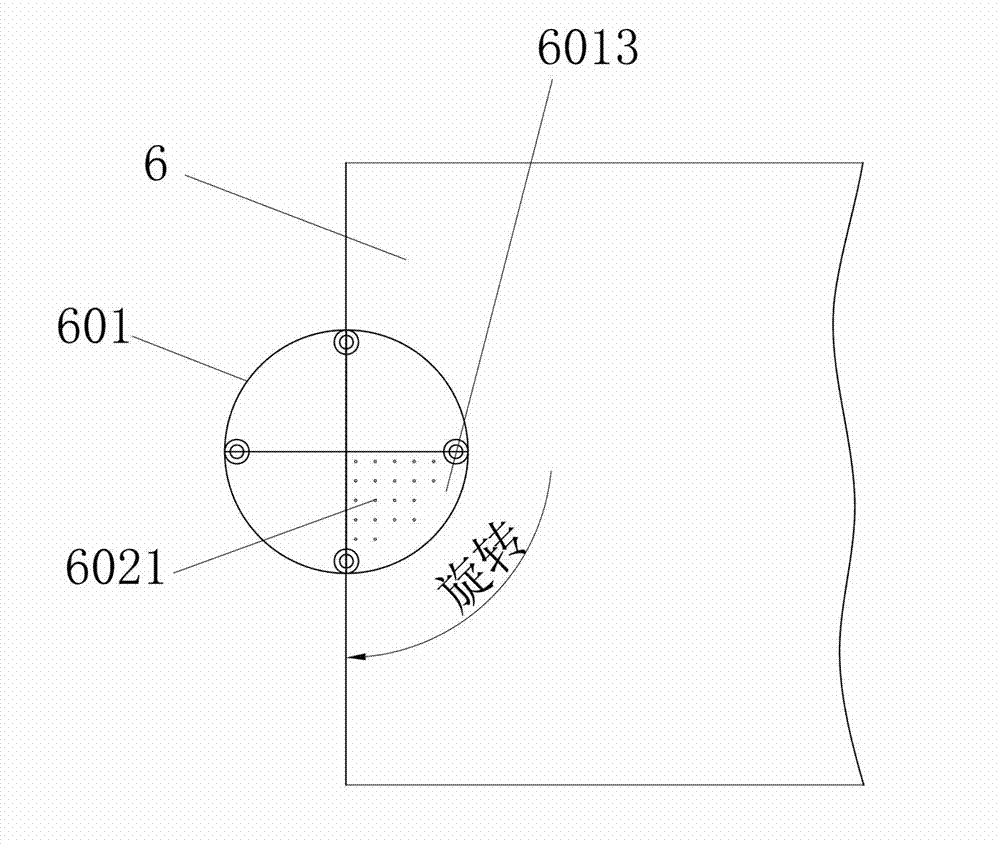

[0032] See figure 1 , figure 1What is disclosed is a dimple coating machine, including an unwinding device 10, a dimple coating head 20, a baking and cooling box 30, and a rewinding device 40. The diaphragm 6 comes out of the unwinding device 10 and is coated with dimples The cloth head 20 is coated with slurry, then baked and cooled, and enters the winding device 40 for winding. The flattening system of the dimple coating machine includes two dimple ceramic anilox rollers located at the dimple coating head 20. The first flattening roller 2031 and the second flattening roller 2032 on the side, and more than one vacuum flattening device 60 close to the lower bottom surface on both sides of the diaphragm 6 in the baking and cooling box 30, the vacuum flattening The device 60 includes a negative pressure source device 601 connected to a negative pressure source and an adsorption member 602 provided with many adsorption holes 6021. The adsorption member 602 moves relative to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com