High-breakdown-strength aramid diaphragm as well as preparation method and application thereof

A technology with high breakdown strength and breakdown strength, applied in hybrid capacitor separators, hybrid/electric double layer capacitor manufacturing, structural parts, etc., can solve the problem of less attention to the breakdown strength of the diaphragm, affecting the safety performance of the battery, and short circuit of the diaphragm High efficiency and other problems, to achieve the effect of reducing the internal short circuit of the battery core, high breakdown strength, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

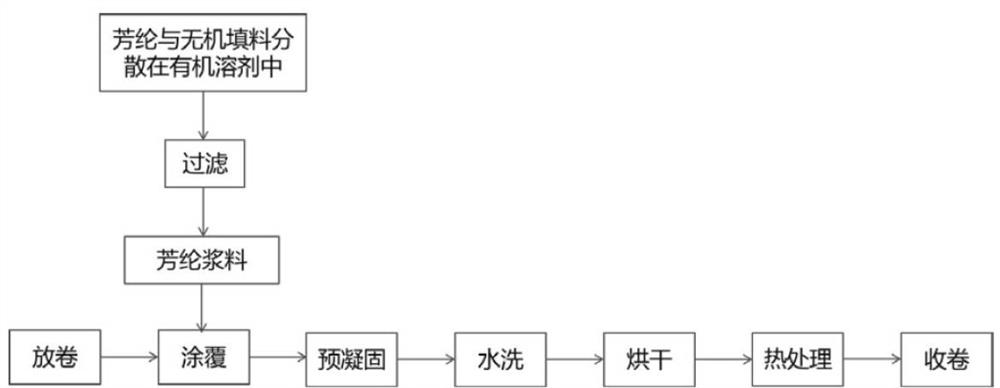

Method used

Image

Examples

Embodiment 1

[0087] The para-aramid stock solution with a mass fraction of 2% and an apparent viscosity of 20,000cp and alumina powder of 3 times the mass of the aramid polymer were stirred in NMP by a high-speed dispersing emulsifier for 60 minutes, and filtered through a 1,000-mesh filter to obtain a uniform Para-aramid size.

[0088] Select a wet-process synchronous biaxially oriented polyethylene film with a thickness of 12 μm, a porosity of 38%, an air permeability of 160s / 100cc, and a breakdown voltage of 1.3kv. Coated on one side of the base film.

[0089] The diaphragm coated with aramid slurry enters the coagulation tank for pre-coagulation. The mass concentration of the NMP aqueous solution in the coagulation bath in the first coagulation tank is 25%, and the mass concentration of the NMP aqueous solution in the coagulation bath in the second coagulation tank is 5%, and the longitudinal tension in the pre-solidification process is 350N / m.

[0090] The pre-solidified aramid fibe...

Embodiment 2

[0094] The difference between this embodiment and Example 1 is that the NMP mass concentration of the coagulation bath in the first coagulation tank is 45%, the NMP mass concentration of the coagulation bath in the second coagulation tank is 15%, and the longitudinal tension of the coagulation process is 320N / m.

[0095]The obtained aramid-coated separator had a thickness of 16.2 μm, an air permeability of 244 s / 100 cc, and a breakdown voltage of 2.31 kv. The coating thickness increase value is 4.2μm, the coating air permeability increase value is 20s / 100cc / μm, and the breakdown strength of the aramid coating is 0.24kv / μm.

Embodiment 3

[0097] The difference between this embodiment and Example 1 is that the NMP mass concentration of the coagulation bath in the first coagulation tank is 30%, the NMP mass concentration of the coagulation bath in the second coagulation tank is 12%, and the longitudinal tension of the coagulation process is not controlled. .

[0098] The obtained aramid-coated separator had a thickness of 16.4 μm, an air permeability of 252 s / 100 cc, and a breakdown voltage of 2.4 kv. The coating thickness increase value is 4.4μm, the coating air permeability increase value is 21s / 100cc / μm, and the breakdown strength of the aramid coating is 0.25kv / μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com