Active material and lithium ion battery

A technology of active material and particle size, applied in the field of active materials and lithium-ion batteries, can solve the problems of battery safety hazards, performance degradation, SEI film instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

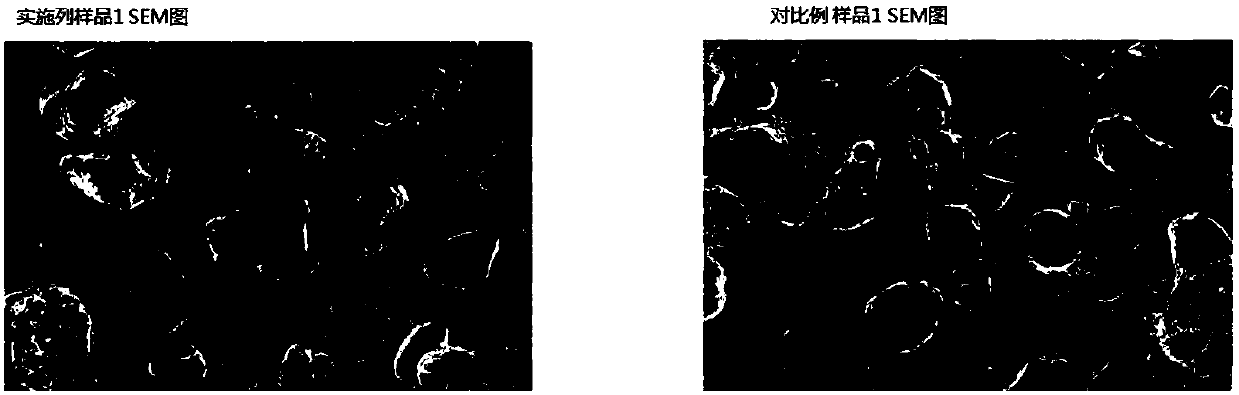

[0053] 1. Discharge the formed lithium ion battery sample 1 to 2.8V, disassemble the lithium ion battery, take out the pole piece, soak in DMC for 2 hours, dry it in a drying room, burn it in a muffle furnace at 600°C for 2 hours, and use 200 mesh Sieving to obtain active material sample 1. And using a scanning electron microscope (SEM) to observe the first particle and second particle distribution map of the active material sample 1, such as figure 1 Shown.

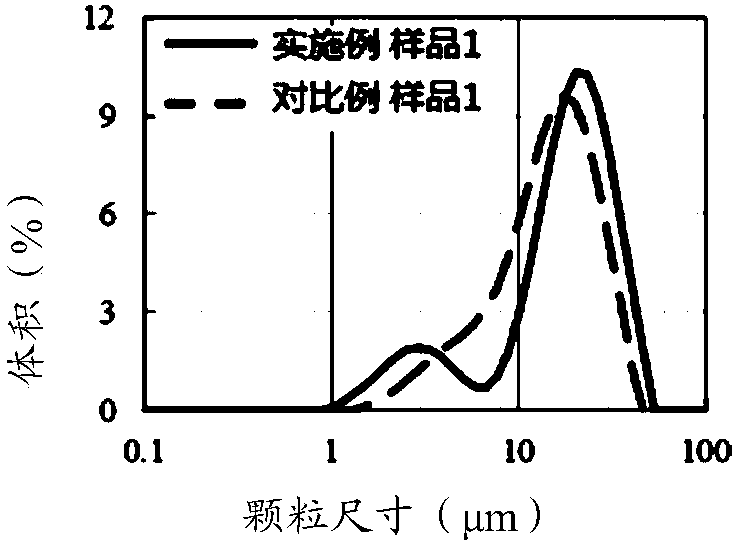

[0054] 2. Use a laser particle size tester (atersizer2000, Malvern, UK) to test the particle size of the active material sample 1 prepared in step 1, and draw the particle size versus volume distribution diagram based on the particle size test results, such as figure 2 Shown. Among them, the measured Dv10 is 1.9 μm, Dv50 is 11.5 μm, and Dv90 is 23.5 μm. According to the formula (Dv90-Dv50)-(Dv50-Dv10), the particle size distribution is calculated to be 2.4.

[0055] 3. Use an energy spectrometer (EDS, Oxford-X-max energy s...

Embodiment 2

[0058] The preparation method of the active material sample 2 is the same as in Example 1.

[0059] As in Example 1, the particle size of the prepared active material sample 2 was tested using a laser particle size tester. Among them, Dv10 is measured to be 2.7 μm, Dv50 is 17.2 μm, and Dv90 is 26.4 μm. According to the formula (Dv90-Dv50)-(Dv50-Dv10), the particle size distribution is calculated to be -5.3; the energy spectrometer is used to measure the types of doped elements in the first particle and the second particle in the active material sample 2, the test results and implementation Example 1 is the same; inductively coupled plasma mass spectrometry (ICP) is used to measure the content of doping elements in the first particle and the second particle in active material sample 2, and calculate the ratio according to the formula: (a / b) / (c / d) , The ratio of (a / b) / (c / d) is equal to that of Example 1.

Embodiment 3

[0061] The preparation method of the active material sample 3 is the same as in Example 1.

[0062] As in Example 1, the particle size of the prepared active material sample 3 was tested using a laser particle size tester. Among them, Dv10 is measured to be 2.5 μm, Dv50 is 14.7 μm, and Dv90 is 28.5 μm. According to the formula (Dv90-Dv50)-(Dv50-Dv10), the particle size distribution is calculated to be 1.6; the energy spectrometer is used to measure the types of doping elements in the first particle and the second particle in the active material sample 3. The test results and examples 1 Same; use inductively coupled plasma mass spectrometry (ICP) to measure the content of doping elements in the first particle and second particle in active material sample 3, and calculate the ratio according to the formula: (a / b) / (c / d), The ratio of (a / b) / (c / d) is equal to the ratio of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com