High-oxygen index thermoplastic low-smoke halogen-free polyolefin cable material and preparation method thereof

A polyolefin cable material, high oxygen index technology, used in plastic/resin/wax insulators, circuits, electrical components, etc., can solve the problems of slow extrusion speed, high hardness, mechanical properties decline, etc., to improve flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Five groups of formulas in Table 1 are prepared in parts by weight. The matrix resin, flame retardant, antioxidant, etc. were mixed in a high-speed mixer at 80° C. for 10 minutes. Then the mixture is extruded and granulated in a two-stage granulator, the temperature range of the upper stage barrel is 145~165°C, and the screw speed is about 130 rpm. The temperature range of the lower barrel is 125~145°C, and the screw speed is about 70 rpm.

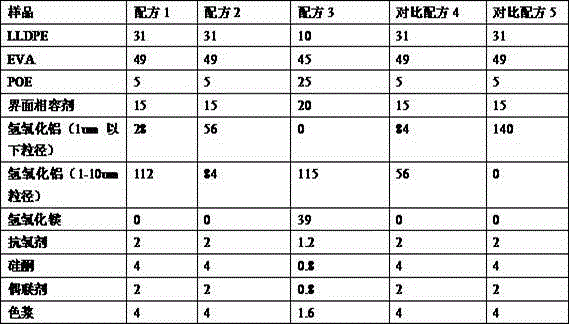

[0029] The main performance test of the embodiment formula is shown in Table 2. It can be seen from the comparison of formulas 4 and 5 that the mechanical strength and oxygen index of the added components not in accordance with the claims are obviously lower.

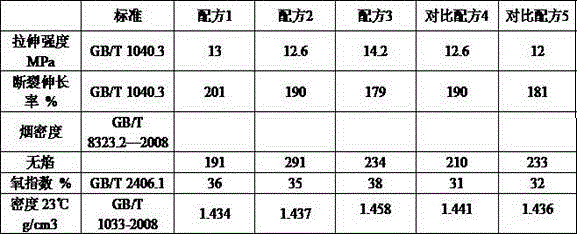

[0030] Table 1, embodiment formula table

[0031]

[0032] Table 2, embodiment formula performance test table

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com