Preparation of silicon composite material and negative plate containing silicon composite material

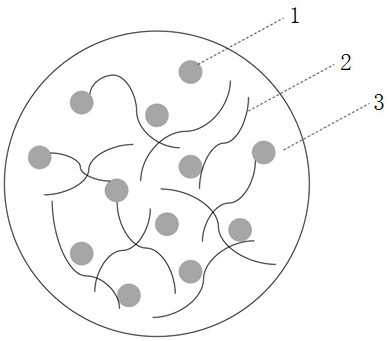

A silicon composite material, negative electrode sheet technology, applied in negative electrodes, nanotechnology for materials and surface science, battery electrodes, etc., can solve the problems of low initial efficiency and consumption of batteries, and achieve small volume expansion and cycle stability. Good, high gram capacity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

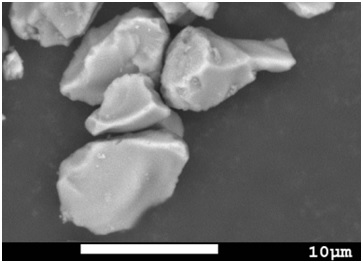

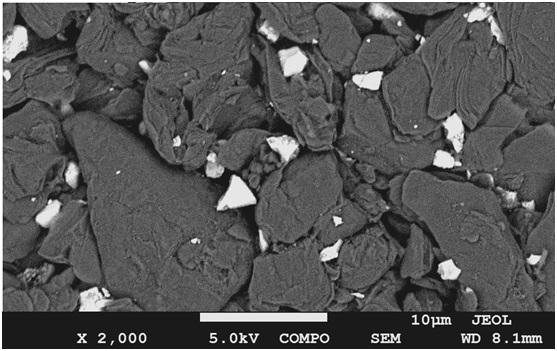

[0056] (1) Preparation of nano-silicon / carbon nanotubes / silicon-oxygen complex:

[0057] Add 1g of nano silicon, 0.05g of carbon nanotubes, 1g of alkyleneiminoalkenyl dimethylsilane, and 0.1g of polyethylene glycol with a molecular weight of 900 to 100g of organic solvent N-methylpyrrolidone in sequence, and stir and mix evenly. Spray-dried to obtain a mixed powder, carbonized the mixed powder at a high temperature of 600° C. for 5 hours, and ball-milled to obtain a nano-silicon / carbon nanotube / silicon-oxygen composite.

[0058] (2) Lithium supplementation of silicon / carbon nanotube / silicon-oxygen complex:

[0059] Mix the activator (a mixture of 0.15M HCl, 0.05M HF and 0.05M sodium nitrate) and nano-silicon / carbon nanotubes / silicon-oxygen complex at room temperature for 10 hours, then dry at 90°C for 8 hours , heat-treated at 550°C for 6h, and finally cooled to room temperature under the protection of Ar gas. The obtained powder was cooled and lithium source (50wt.% lithium...

Embodiment 2

[0063] (1) Preparation of nano-silicon / carbon nanotubes / silicon-oxygen complex:

[0064] Add 1.5g of nano-silicon, 0.03g of carbon nanotubes, 1.5g of alkyleneiminoalkenyldimethylsilane, and 0.2g of polyethylene glycol with a molecular weight of 900 to 100g of organic solvent acetone in sequence, stir and mix evenly, and spray dry A mixed powder was obtained, which was carbonized at a high temperature of 500° C. for 6 hours, and ball milled to obtain a nano-silicon / carbon nanotube / silicon-oxygen composite.

[0065] (2) Lithium supplementation of silicon / carbon nanotube / silicon oxygen complex:

[0066] The activator (a mixture of 0.25M HCl, 0.02M HF and 0.02M sodium nitrate) was uniformly mixed with nano-silicon / carbon nanotubes / silicon-oxygen complex at room temperature for 8h, and then dried at 80°C for 10h , heat-treated at 500 °C for 7 h, and finally cooled to room temperature under the protection of Ar gas. Cool the obtained powder and lithium source (50wt.% lithium sulfa...

Embodiment 3

[0070] (1) Preparation of nano-silicon / carbon nanotubes / silicon-oxygen complex:

[0071] Add 2g of nano-silicon, 0.02g of carbon nanotubes, 1.8g of alkyleneiminoalkenyldimethylsilane, and 0.6g of polyethylene glycol with a molecular weight of 900 to 100g of carbon tetrachloride in sequence, stir and mix evenly, and spray dry A mixed powder was obtained, which was carbonized at a high temperature of 550° C. for 5.5 hours, and ball milled to obtain a nano-silicon / carbon nanotube / silicon-oxygen composite.

[0072] (2) Lithium supplementation of silicon / carbon nanotube / silicon oxygen complex:

[0073] Mix the activator (a mixture of 0.2M HCl, 0.03M HF and 0.03M sodium nitrate) and nano-silicon / carbon nanotubes / silicon-oxygen complex at room temperature for 9 hours, then dry at 85°C for 9 hours , heat-treated at 600 °C for 6 h, and finally cooled to room temperature under the protection of Ar gas. The obtained powder was cooled and lithium source (50wt.% lithium nitrate and 50wt....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com