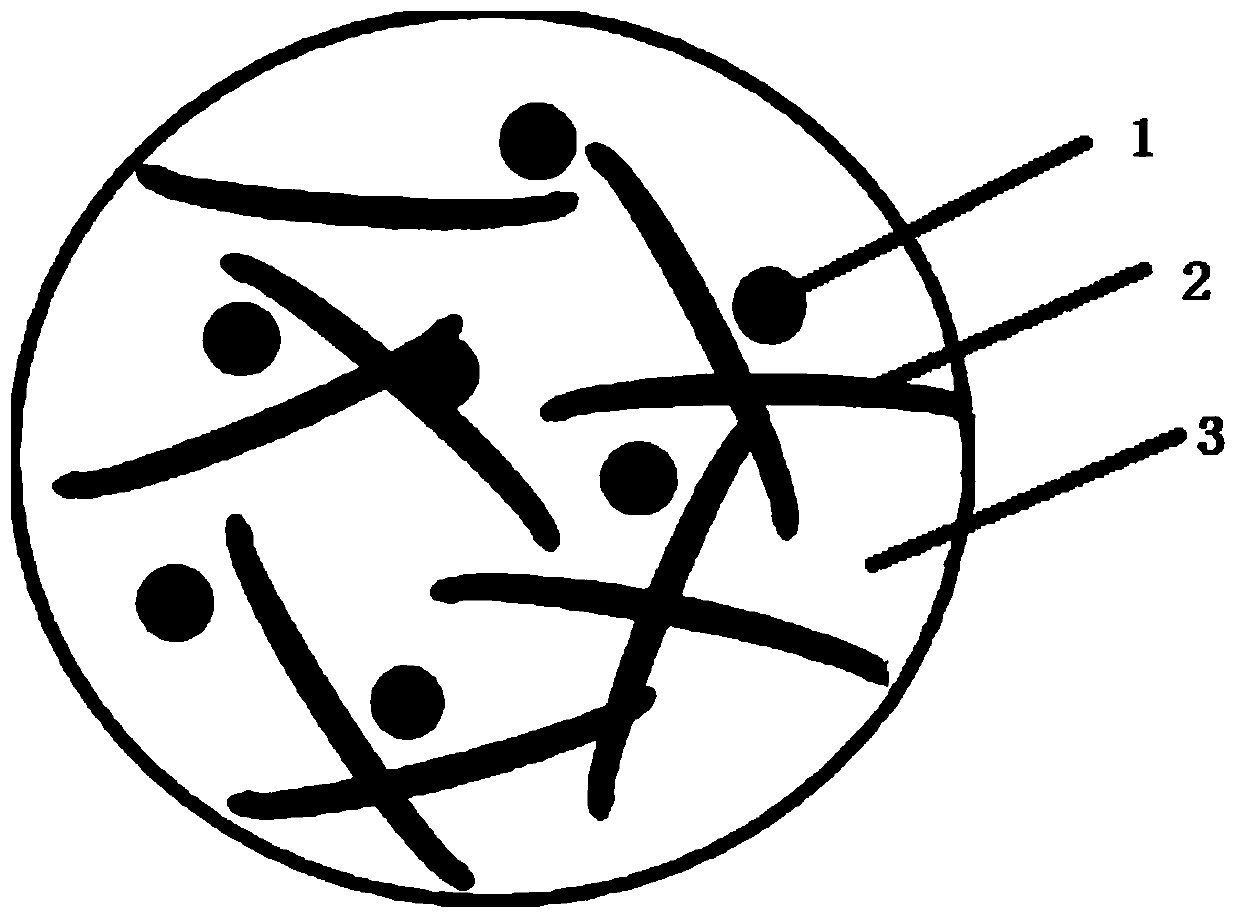

A kind of silicon/carbon nanotube/silicon oxycarbide composite material and its preparation method and application

A technology of carbon nanotubes and silicon oxycarbide, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as not very superior performance, and achieve improved conductive path, easy control, high The effect of gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of silicon / carbon nanotube / silicon oxycarbide composites:

[0027] (1) Weigh 9.2g of methyltrichlorosilane silicone resin emulsion into a beaker, add 0.5g of silicon nanoparticles (average particle diameter of 10nm) and 0.3g of single-walled carbon nanotubes (average diameter of 0.8nm, length 5μm ) into the emulsion in the beaker, and ultrasonically stirred for 30 minutes to obtain a mixed solution;

[0028] (2) Pour the above-mentioned mixed solution into a quartz crucible evenly, and thermally crack it at 1000° C. for 8 hours in an argon atmosphere to obtain silicon / carbon nanotube / silicon oxycarbide solid particles;

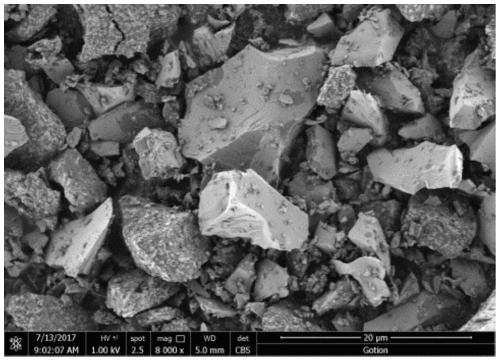

[0029] (3) Carry out ball milling to the solid particles obtained by pyrolysis, the ball milling speed is 1000r / min, ball milling 2 times, each lasting 10min, cooling 10min, obtaining silicon / carbon nanotube / silicon oxycarbide solid particles with uniform particle size;

Embodiment 2

[0031] Preparation of silicon / carbon nanotube / silicon oxycarbide composites:

[0032] (1) Weigh 9.1g of methyltrichlorosilane silicone resin emulsion into a beaker, add 0.8g of silicon nanoparticles (average particle diameter of 50nm) and 0.1g of multi-walled carbon nanotubes (average diameter of 8nm, length 100μm) Add it into the emulsion in a beaker, and stir it ultrasonically for 5 minutes to obtain a mixed solution.

[0033] (2) Pour the mixture obtained above evenly into a quartz crucible, and thermally crack it at 600° C. for 4 hours in a nitrogen atmosphere to obtain silicon / carbon nanotube / silicon oxycarbide solid particles.

[0034] (3) The solid particles obtained by pyrolysis were ball milled at a ball milling speed of 500r / min, ball milled 5 times for 30 minutes each time, and cooled for 30 minutes to obtain silicon / carbon nanotube / silicon oxycarbide solid particles with uniform particle size.

Embodiment 3

[0036] Preparation of silicon / carbon nanotube / silicon oxycarbide composites:

[0037] (1) Weigh 9.2g methyltrichlorosilane silicone resin emulsion into a beaker, add 0.5g silicon nanoparticles (average particle diameter is 100nm) and 0.3g single-walled carbon nanotubes (average diameter is 1nm, length 100μm) Add it into the emulsion in a beaker, and stir it ultrasonically for 10 minutes to obtain a mixed solution.

[0038] (2) Pour the mixture obtained above evenly into a quartz crucible, and thermally crack it at 800° C. for 5 hours in a nitrogen atmosphere to obtain silicon / carbon nanotube / silicon oxycarbide solid particles.

[0039] (3) The solid particles obtained by pyrolysis were ball milled at a ball milling speed of 600r / min for 3 times, each time lasting 15 minutes, and cooled for 15 minutes to obtain silicon / carbon nanotube / silicon oxycarbide solid particles with uniform particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com