In-phase junction photocatalyst, preparation method and application thereof

A catalyst and phase junction technology, applied in the field of photocatalysis, can solve the problems of inability to construct heterogeneous junctions, difficulty in separation efficiency of photocatalyst photogenerated charges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention provides a method for preparing a homogeneous junction photocatalyst described in the above technical solution, comprising: loading a semiconductor material with a small particle diameter on the surface of a semiconductor material with a large particle diameter to obtain a homophase junction photocatalyst.

[0050] The present invention has no special requirements on the sources of the small-diameter semiconductor material and the large-diameter semiconductor material, and commercially available products can be used, or can be prepared by methods well known to those skilled in the art. In the present invention, the loading method preferably includes a mixing method or a hydrothermal method;

[0051] The mixing method preferably includes: providing a dispersion liquid of a small particle size semiconductor material, then immersing a large particle size semiconductor material in the dispersion liquid, and ultrasonically dispersing, so that the small p...

Embodiment 1

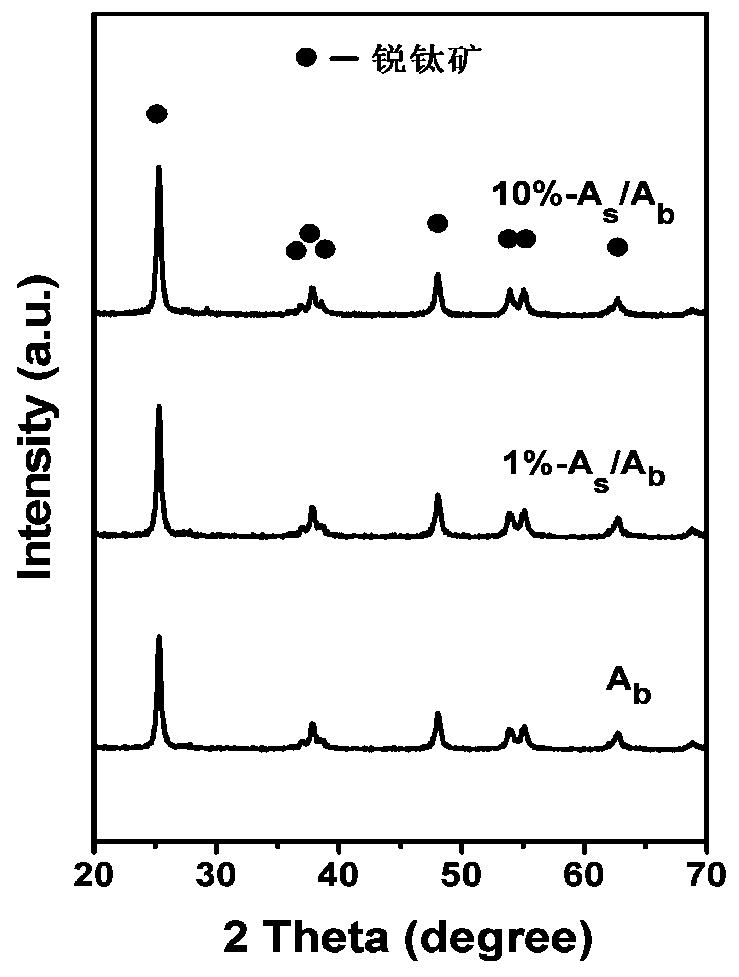

[0122] (1) Mix 100mL of absolute ethanol, 100mL of acetonitrile and 1mL of ammonia water to obtain an aqueous ammonia solution; mix 20mL of absolute ethanol, 20mL of acetonitrile and 4mL of tetra-n-butyl titanate to obtain a n-tetrabutyl titanate solution; The n-tetrabutyl ester solution is added dropwise into the ammonia solution for hydrolysis reaction to obtain titanium hydroxide sol. Calcining the obtained titanium hydroxide sol at 500°C for 2 hours to obtain large particle size anatase;

[0123] (2) Measure 0.034mL (0.0001mol) of tetra-n-butyl titanate and 0.034mL of absolute ethanol, mix well, adjust the pH value to 0.9 with nitric acid, adjust the volume of the mixed solution to 20mL with deionized water, and dissolve the solution Incubate at 60°C for 24h. Then add 0.7987g (0.01mol) of the above-prepared large-diameter anatase, stir, transfer to a hydrothermal reaction kettle for 72 hours at 140°C, wash, and dry to obtain anatase "homogeneous junction". Wherein the lo...

Embodiment 2

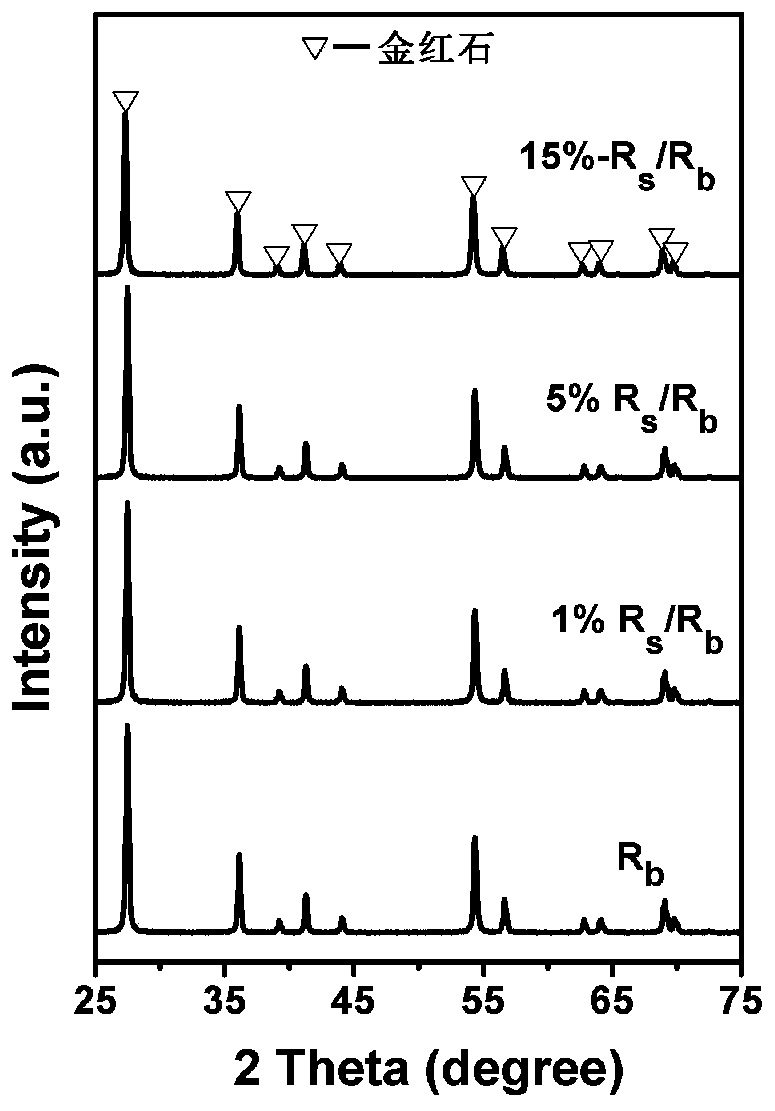

[0131] (1) Stir 0.5mol / L titanium tetrachloride solution in a constant temperature water bath at 90°C for hydrolysis reaction to obtain titanium hydroxide sol, heat the obtained titanium hydroxide sol at 160°C for 12 hours to obtain large particle size rutile .

[0132] (2) Measure 0.034mL (0.0001mol) of tetra-n-butyl titanate and 0.034mL of absolute ethanol, mix well, adjust the pH value to 0.9 with nitric acid, adjust the volume of the mixed solution to 20mL with deionized water, and dissolve the solution Insulate at 60°C for 24 hours, then heat at 140°C for 72 hours, filter, wash, and dry to obtain anatase with small particle size;

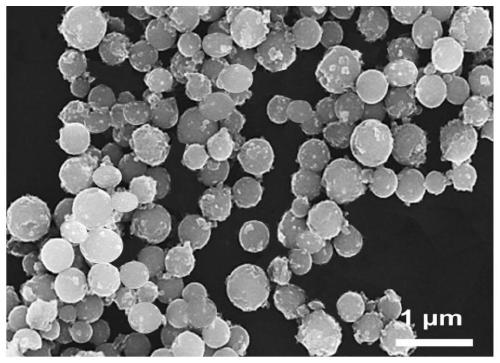

[0133] (3) Mix 0.7987g of large particle size rutile obtained in step (1) and small particle size anatase obtained in step (2) in 50mL of isopropanol solution, ultrasonically disperse for 1h, dry at 90°C, and roast at 700°C 4h, the rutile "homophase junction" high-efficiency photocatalyst was obtained. Wherein the loading of small particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com