Doped tungsten oxide target material and preparation method thereof

A technology of tungsten oxide and target material, which is applied in the field of target material and its preparation, can solve the problems of lack of electrochromic target material, different conductivity of target material, and influence on process stability, so as to improve the activity of raw materials, uniform composition, and improve The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] An embodiment of the present invention proposes a method for preparing a doped tungsten oxide target, which includes:

[0037] Activate and grind tungsten oxide to obtain activated tungsten oxide, the tungsten oxide is WO 3-x , 0≤xy , y≤3-x;

[0038] Activating and pulverizing the doping oxide to obtain an activated doping oxide, the doping oxide being MO m , 0n , n≤m, wherein, M is one or more of titanium, nickel, tantalum, rhenium, iridium, molybdenum, niobium, silicon, tin, zinc, zirconium and germanium;

[0039] uniformly mixing the activated tungsten oxide and activated doping oxide, and pressing to obtain a green body;

[0040] Sintering the green body to obtain a doped tungsten oxide target;

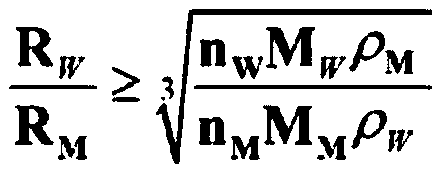

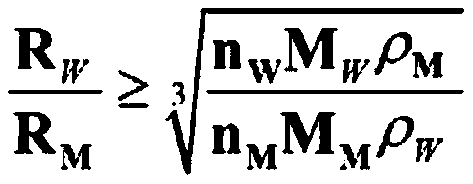

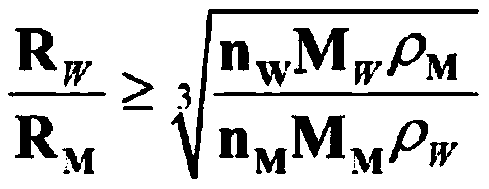

[0041] Wherein, the relationship between the particle size ratio and the molar ratio of the activated tungsten oxide and the activated doped oxide is as follows:

[0042]

[0043] In the formula:

[0044] R w is the radius of activated tungsten oxide;

[0045] R ...

Embodiment 1

[0099] This embodiment proposes a method for preparing a doped tungsten oxide target, which includes:

[0100] Heat tungsten trioxide in a vacuum environment at 1100°C to activate it, grind it and sieve it to obtain activated tungsten oxide (WO 2.5 ) particles, particle size is 500nm;

[0101] Titanium oxide was heated at 1500°C and a vacuum of 200 Pa to activate it, ground and sieved to obtain activated titanium oxide (TiO 1.5 ) particles, particle size is 200nm;

[0102] The obtained activated tungsten oxide particles and activated titanium oxide particles were uniformly mixed with a molar ratio of 9:1, and pressed at 60Mpa for 5 minutes to obtain a green body;

[0103] The obtained body was sintered at 1100° C. and a vacuum of 10 Pa to obtain a titanium-doped tungsten oxide target.

Embodiment 2

[0105] This embodiment proposes a method for preparing a doped tungsten oxide target, which includes:

[0106] Tungsten oxide (WO 2.5 ) mixed with carbon powder, heated in an inert environment at 900°C to activate it, ground and sieved to obtain activated tungsten oxide (WO 2 ) particles, particle size is 500nm;

[0107] Mix tantalum oxide with carbon powder, heat in an inert environment at 1100°C to activate, grind and sieve to obtain activated tantalum oxide (TaO 2 ) particles, particle size is 150nm;

[0108] The obtained activated tungsten oxide particles and activated tantalum oxide particles were uniformly mixed with a molar ratio of 9.5:0.5, and pressed at 10 MPa for 5 minutes to obtain a green body;

[0109]The obtained green body was sintered in a reducing atmosphere at 1200°C, wherein the reducing atmosphere was a mixed gas of argon and hydrogen, and the ratio of argon to hydrogen was 8:2 to obtain a tantalum-doped tungsten oxide target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com