Making process of woven ceramic product of zirconia flexibilized alumina ceramic

A kind of technology of alumina ceramics and manufacturing methods, which is applied in the field of manufacturing zirconia toughened alumina ceramic textile porcelain parts, can solve the problems that the wear resistance cannot meet the high-speed spinning machine, etc., and achieve the improvement of fracture toughness, good wear resistance and The effect of shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

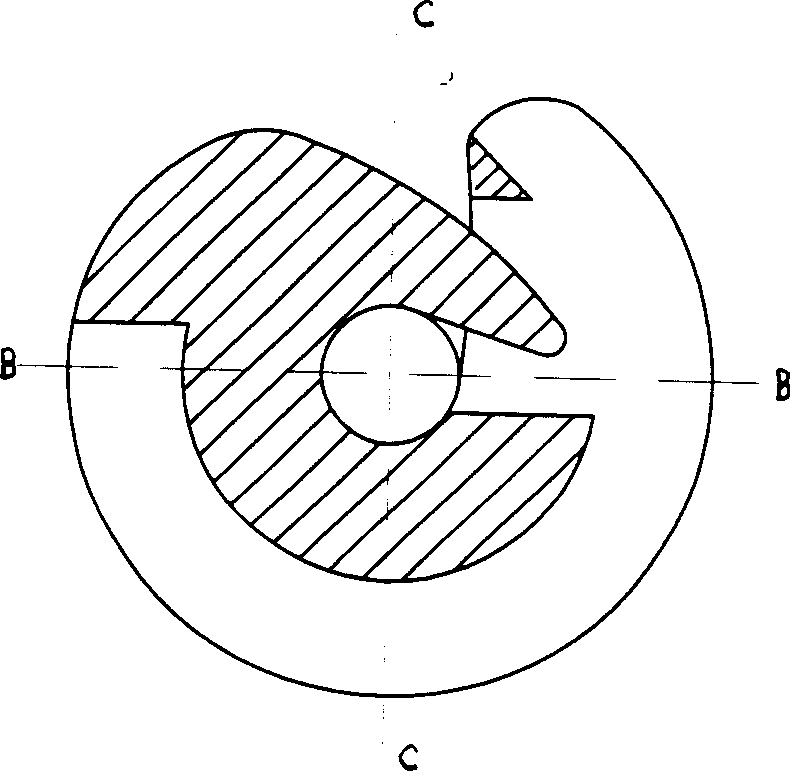

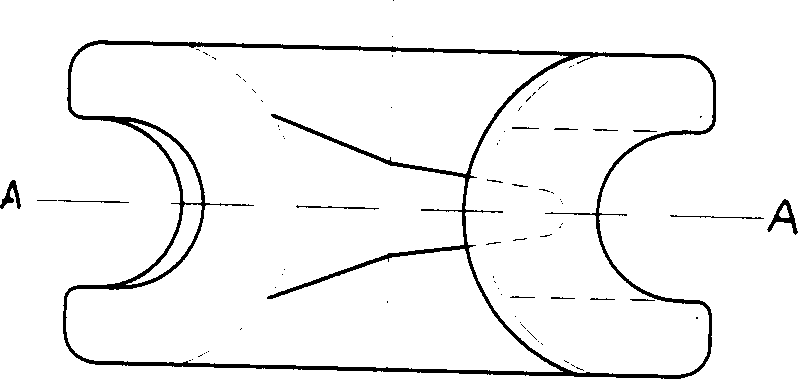

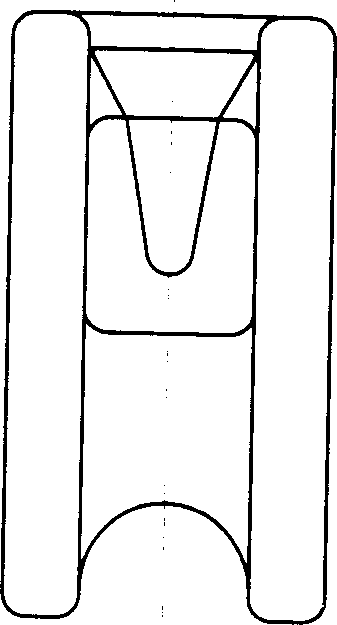

[0020] Now take the small-sized wire guide as an example to illustrate the manufacturing method of the present invention.

[0021] The manufacture method of the zirconia toughened alumina ceramic textile porcelain of the present invention comprises the following steps:

[0022] (1), select the raw material and weigh each component raw material according to the weight percentage of the raw material, and grind it into powder through a ball mill, and its particle size is controlled below 2 μm;

[0023] (2), add binder and mix and stir to form compound;

[0024] (3), the mixture is molded into a textile porcelain body by injection molding or isostatic pressing;

[0025] (4) Appropriate finishing and processing after drying, including turning, cutting and drilling;

[0026] (5), high temperature sintering;

[0027] (6) Finally, grinding and polishing are carried out to form textile porcelain pieces.

[0028]

ingredients

Wt%

example 1

Example 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com