Preparation method for active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound hammer

A technology of particle reinforcement and active elements, which is applied in the field of preparation of active element sintered ZTA particle-reinforced steel-based composite hammers, can solve the problems of poor wettability and difficulty of high-performance composite materials, and achieve good impact resistance and save consumption , The effect of high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) First, mix active metal element powders Ni and Cr with absolute ethanol by ball milling or mixing cylinder to obtain mixed powder;

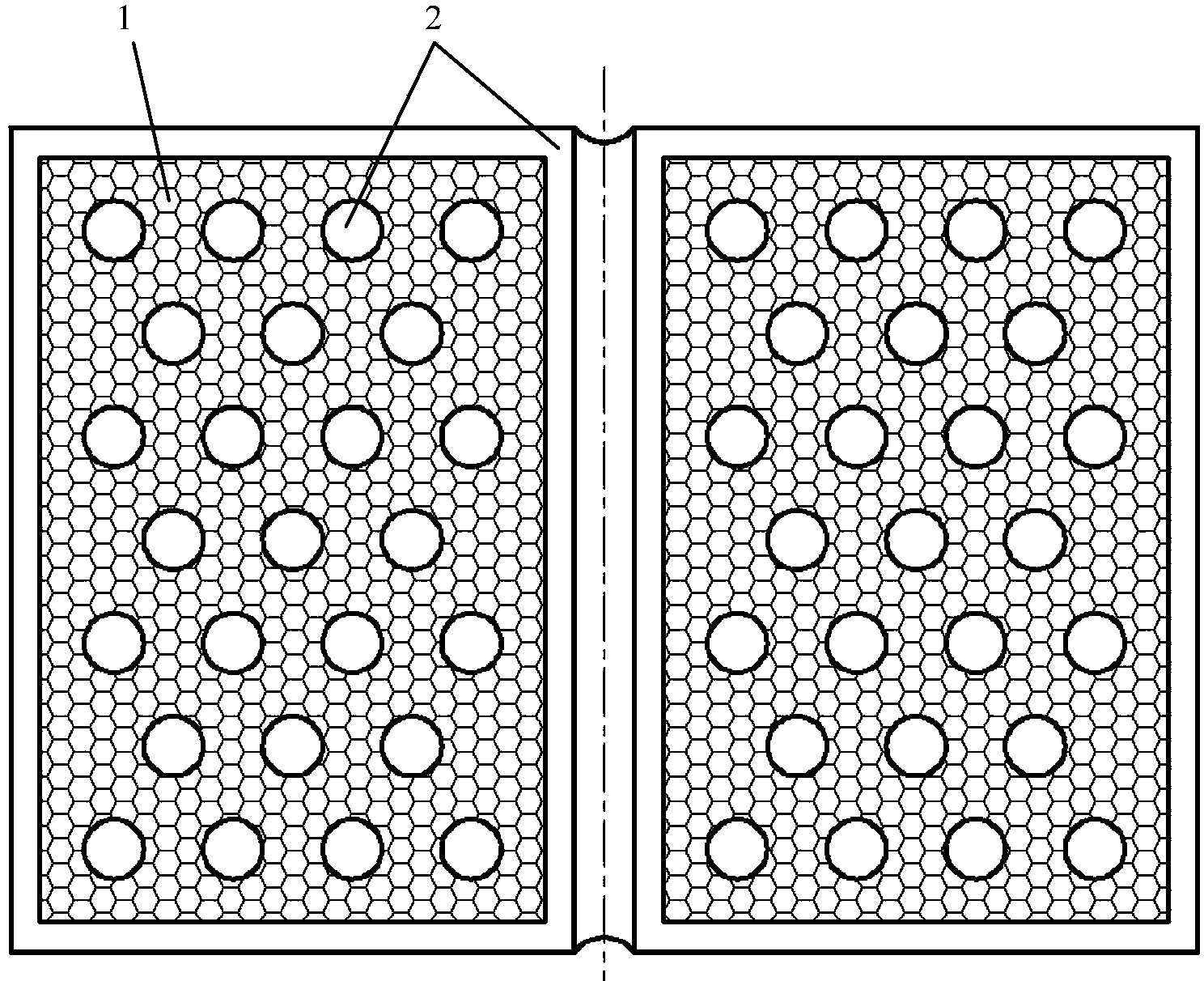

[0027] 2) Next, mix the above-mentioned mixed powder with 10-20 mesh ZTA particles to obtain a mixture, then add a binder to the mixture, stir and mix, fill it into a honeycomb mold and press it, and then dry it at 70°C;

[0028] The mass fraction of ZTA particles in the mixture is 75%, the binder is a borax solution with a mass concentration of 20%, and 3 mL is added to every 100 g of the mixture;

[0029] 3) Put the mold into the furnace for sintering, heat up from room temperature to 950°C at a rate of 5°C / min for sintering for 2 hours, then cool at 4°C / min, and cool with the furnace when cooling to 900°C, and the ZTA particles are connected to each other Form a honeycomb prefabricated block with a porosity of 40%;

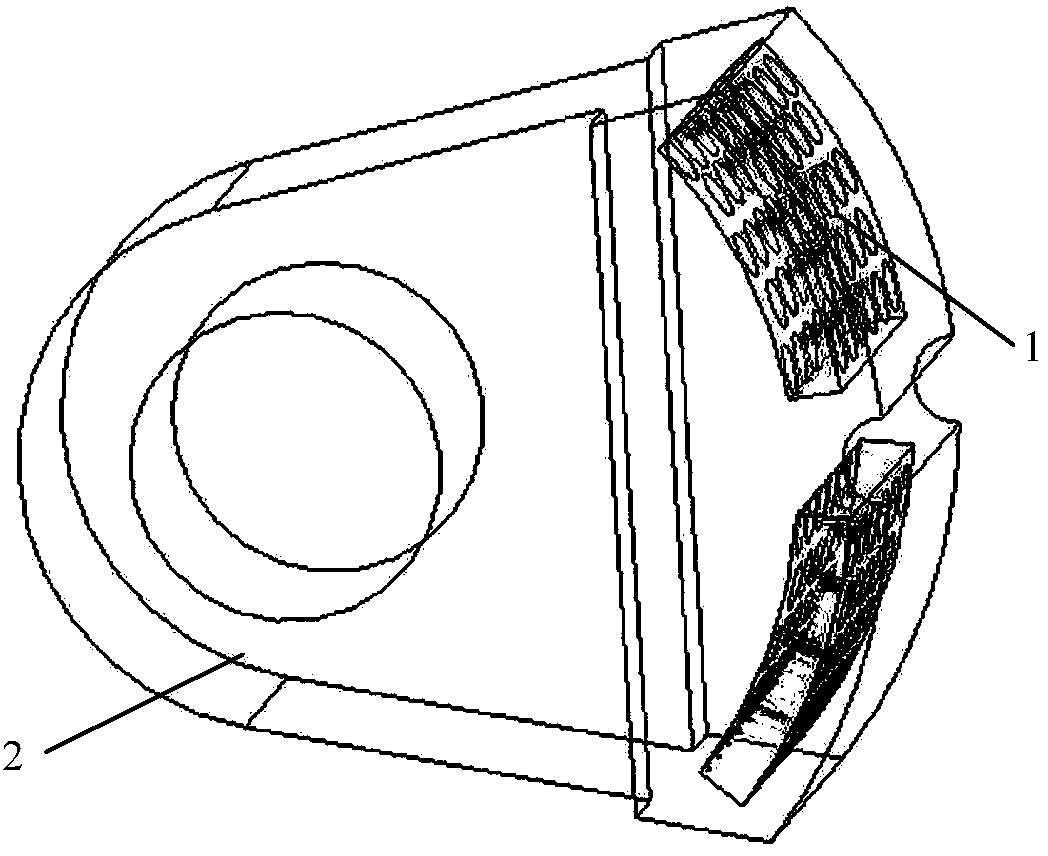

[0030] 4) Fix a plurality of honeycomb prefabricated blocks on the end face side of the mold at a distance of 15mm, t...

Embodiment 2

[0032] 1) Mix the active metal element powder Ni with 10-20 mesh ZTA particles to obtain a mixture, then add a binder to the mixture, stir and mix, fill it into a honeycomb mold, press it, and dry it at 70°C;

[0033] The mass fraction of ZTA particles in the mixture is 78%, and the binder is a borax solution with a mass concentration of 24%, adding 5mL per 100g of the mixture;

[0034] 2) Put the mold into a vacuum sintering furnace for sintering, heat up from room temperature to 1050°C at a rate of 6°C / min for sintering for 1 hour, then cool at 6°C / min, and cool with the furnace when cooled to 900°C, ZTA particles Interconnected to form a honeycomb prefabricated block with a porosity of 48%;

[0035] 3) Fix a plurality of honeycomb prefabricated blocks on the end face side of the mold at a distance of 25mm, that is, the working face or the striking face, and then pour the low-alloy steel molten metal with a casting infiltration process at a pouring temperature of 1450-1550°C...

Embodiment 3

[0037] 1) Mix the active metal element powder Cr with 10-20 mesh ZTA particles to obtain a mixture, then add a binder to the mixture, stir and mix, fill it into a honeycomb mold, press it, and dry it at 70°C;

[0038] The mass fraction of ZTA particles in the mixture is 70%, the binder is a borax solution with a mass concentration of 25%, and 5 mL is added to every 100 g of the mixture;

[0039] 2) Put the mold into a vacuum sintering furnace for sintering, heat up from room temperature to 1020°C at a rate of 9°C / min for sintering for 1.5 hours, then cool at 4°C / min, and cool with the furnace when cooled to 900°C, ZTA particles Interconnected to form a honeycomb prefabricated block with a porosity of 43%;

[0040] 3) Fix a plurality of honeycomb prefabricated blocks on the end face side of the casting mold at a distance of 30mm, that is, the working face or the striking face, and then pour the chromium-based alloy cast iron metal liquid through the casting infiltration process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com