Preparation method of modified ZTA complex-phase ceramic having good wettability with steel melts

A composite ceramic and wettability technology, which is applied in the fields of ceramic matrix composites and metal matrix composites, can solve problems such as difficult enrichment, insufficient wettability, and poor bonding strength, and achieve improved interface reaction ability, wettability, etc. The effect of good wetness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

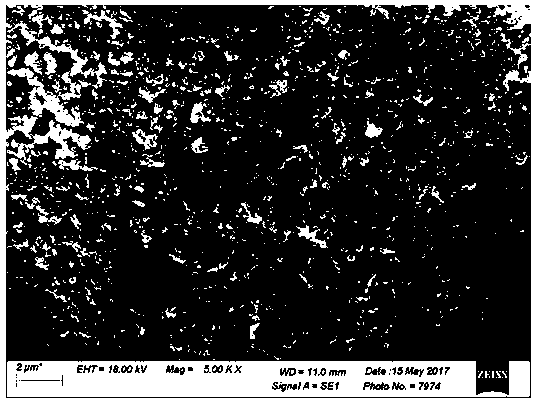

Image

Examples

Embodiment 1

[0022] In this embodiment, a method for preparing a modified ZTA composite ceramic with good wettability with molten steel, the specific steps are as follows:

[0023] Step 1, adopt chemical co-precipitation method to prepare 5mol% YSZ powder, at first be that zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 O) and yttrium nitrate hexahydrate (Y(NO 3 ) 3 ·6H 2 O) Press Y 2 o 3 :ZrO 2 The ratio of the molar ratio of 5:95 is dissolved in the mixed solvent of absolute ethanol and deionized water (the volume ratio of absolute ethanol and deionized water is 5:1), and a total amount of 1wt.% polyethylene glycol is added Alcohol (PEG) was used as a dispersant, and then the mixed solution was placed in a constant temperature water bath, and after being kept at 65°C for 2 hours, a 5mol% YSZ powder precursor was prepared by forward titration, according to the proportion of YSZ powder in the final composite ceramics The proportion of 25 wt.% of the total mass, after the precursor ...

Embodiment 2

[0030] In this embodiment, a method for preparing a modified ZTA composite ceramic with good wettability with molten steel, the specific steps are as follows:

[0031] Step 1. Prepare 1mol% YSZ powder by sol-gel method, first use ZrOCl 2 ·8H 2 O, Y (NO 3 ) 3 ·6H2 O press Y 2 o 3 :ZrO 2 The mol ratio is that the ratio of 1:99 is mixed with uniform solution, then adds the polyethylene glycol (PEG) of total amount 1wt.% as stabilizing agent and regulates solution pH value with hydrochloric acid and is 0.4, and H 2 C 2 o 4 2H 2 O is slowly titrated into the mixed solution until a transparent sol is formed, and a transparent gel-like colloid is obtained after aging treatment for 12 hours, and the H 2 C 2 o 4 The aqueous solution was dropped into it to obtain an opaque suspension. According to the proportion of YSZ powder accounting for 5 wt.% of the total mass of the final composite ceramic, after the formation of the suspension, 1 wt.% of the final composite ceramic mas...

Embodiment 3

[0037] In this embodiment, a method for preparing a modified ZTA composite ceramic with good wettability with molten steel, the specific steps are as follows:

[0038] Step 1, adopt the hydrothermal synthesis method to prepare 8mol% YSZ powder, first weigh zirconium oxychloride octahydrate and yttrium nitrate hexahydrate, press Y 2 o 3 :ZrO 2 Mix the molar ratio of 8:92, dissolve and filter with deionized water, use the reverse precipitation method to mix and stir the mixed solution and concentrated ammonia water according to the volume ratio of 1:1, the concentration of concentrated ammonia water is 28 wt.%, and then the obtained The precipitate was washed with deionized water to obtain a precursor. According to the proportion of YSZ powder accounting for 50wt.% of the total mass of the final composite ceramic, the precursor was mixed with 0.1wt.% Nb of the final composite ceramic mass. 2 o 5 、Nd 2 o 3 、Sm 2 o 3 、Gd 2 o 3 and Er 2 o 3 Mixed powder mixed, where Nb ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com