Ceramic particle reinforced wear-resisting insert and manufacturing method thereof

A production method and technology of ceramic particles, which are applied in the field of wear-resistant composite materials, can solve the problems of poor performance of composite wear-resistant parts, easy falling and layering of metal powder, low preparation efficiency, etc., so as to optimize the filling and shaping performance and strength. Suitable, good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Ceramic Particle Reinforced Wear-Resistant Insert for High Chromium Cast Iron Blow Bar

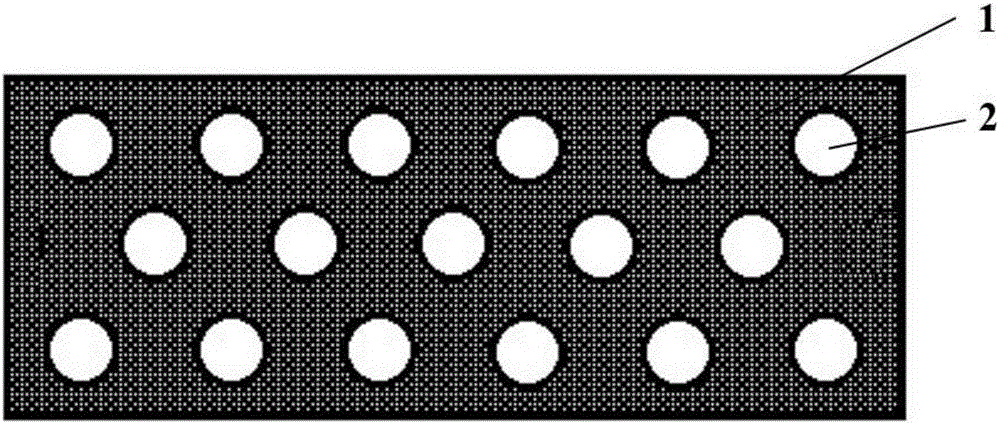

[0059] 1) The shape of the ceramic insert is a cuboid, and the cross-sectional size is 250mm×95mm (the cross-section is as follows figure 1 As shown), the thickness is 100mm, the through hole is circular, the aperture is 15mm, the through holes are staggered and evenly distributed, and the center distance of the through holes is 35mm;

[0060] 2) The mold is made of aluminum alloy, the through-hole mandrel is fixed on the bottom plate of the mold, the draft angle of the mandrel is 3°, and then the aluminum alloy is used to make a box frame with a size of 250mm×95mm×100mm and the diagonal can be removed. Then assemble the box frame and the mold, place it on the working table of the shock-type out-of-box molding machine, set 2 support and locking positions along the centerline of the width of the insert, and preset M6 stainless steel nuts with covers as locking devices ; ...

Embodiment 2

[0066] Example 2: Ceramic Particle Reinforced Wear-Resistant Inserts for High Chromium Cast Iron Grinding Roller Sleeves

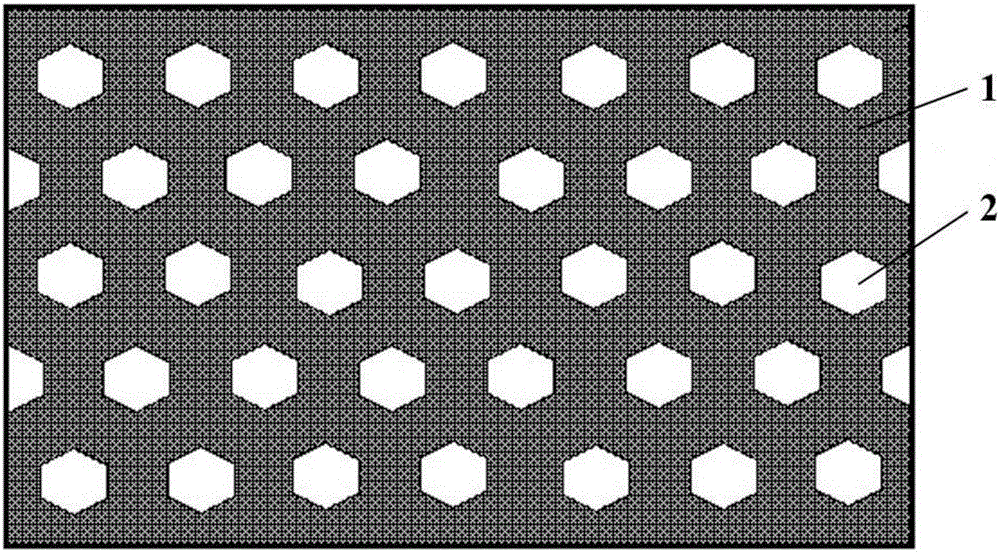

[0067] 1) The shape of the ceramic insert is an arc fan-shaped body, and the expanded size is 500mm×300mm (the cross-section is as follows figure 2 As shown), the thickness is 80mm, the through hole is a regular hexagon, the side length of the regular hexagon is 20mm, the through holes are staggered and evenly distributed, and the center distance of the through holes is 50mm;

[0068] 2) The mold is made of aluminum alloy, and the through-hole mandrel is a movable type that can be extracted separately. It is positioned through the core seat at the bottom of the mold. The draft angle of the mandrel is 3°, and then the aluminum alloy is used to make the size 500mm×300mm× 80mm and removable box frame diagonally, and then assemble the box frame and the mold, place it on the workbench of the vibration pressure type out-of-box molding machine, set 2 support and...

Embodiment 3

[0074] Example 3: Ceramic Particle Reinforced Wear-Resistant Insert for High Manganese Steel Magnetic Liner

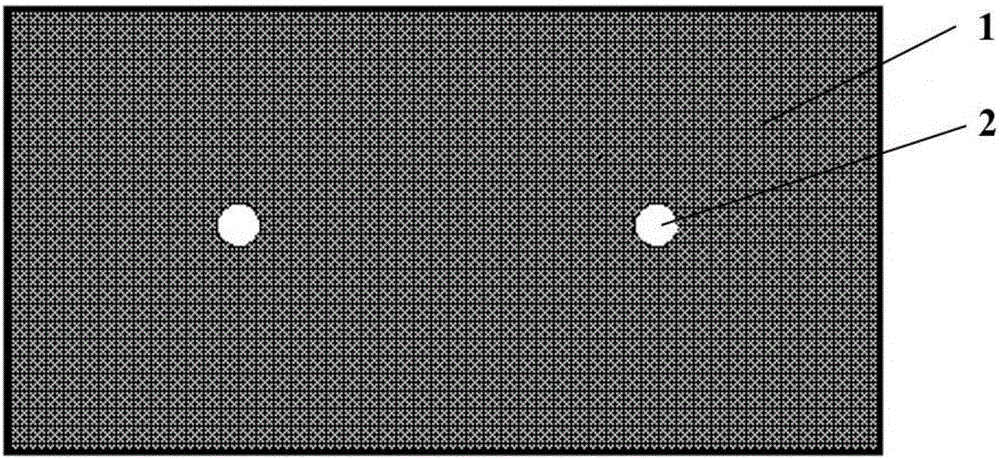

[0075] 1) The shape of the ceramic insert is a rectangular sheet with a size of 80mm×40mm (section such as image 3 As shown), the thickness is 4mm, and two positioning through holes are set along the width centerline, the through holes are circular, and the aperture is 5mm;

[0076] 2) The mold is made of aluminum alloy, the through-hole mandrel is fixed on the formwork, the draft angle of the mandrel is 5°, and then the aluminum alloy is used to make a box frame with a size of 80mm×40mm×4mm and the diagonal can be removed. Assembled with the mold, placed on the workbench of the vibration pressure type out-of-box molding machine;

[0077] 3) Select zirconia-toughened alumina ceramic particles with a zirconia content of 20wt%, the particle size is 1-3 mm, and the shape is irregular polygons. The ceramic particles are degreased and cleaned, and then cleaned and dried a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com