Ceramic substrate and preparation method thereof, and power module

A technology of ceramic substrate and ceramic slurry, applied in ceramic layered products, chemical instruments and methods, layered products, etc., can solve the problems of high cost, application limitation, large thermal resistance, etc., and achieve high density and wide application. , the effect of high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

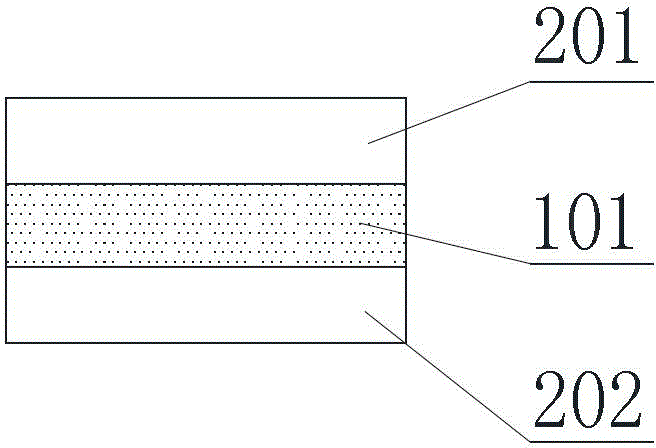

[0022] The present invention also provides a preparation method for the ceramic substrate, comprising the following steps: preparing a core layer green body and a surface layer green body by tape casting; stacking the surface layer green body on both sides of the core layer green body, followed by isostatic pressing The glue is sintered to obtain the ceramic substrate.

[0023] In the present invention, the method used to prepare the green body is tape casting, and the equipment and process conditions of the tape casting are well known to those skilled in the art. ceramic paste.

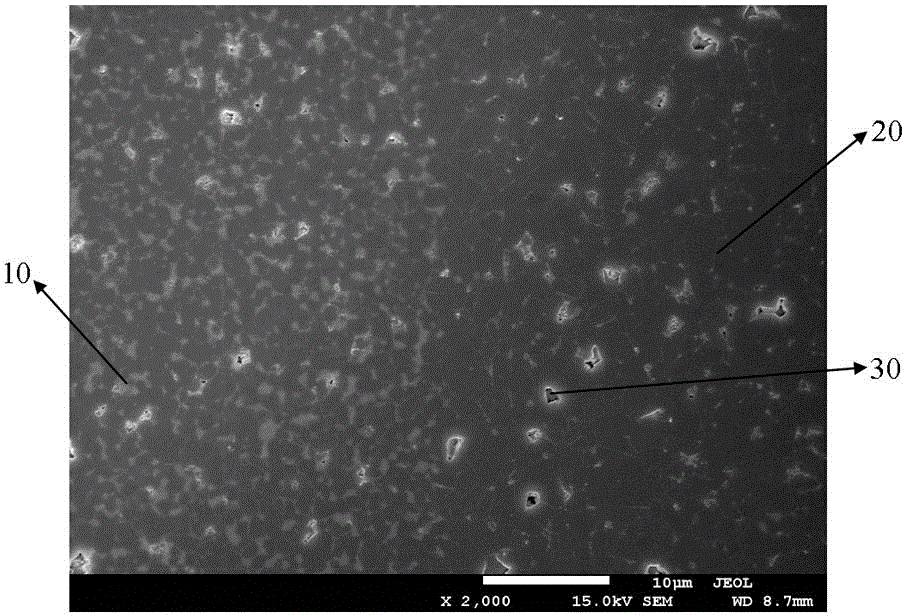

[0024] Specifically, the core layer of the ceramic substrate is zirconia toughened alumina ceramics, so the core layer ceramic slurry used to prepare the core layer green body by tape casting contains zirconia, alumina, binder, dispersant, plasticizer, etc. agents and solvents. The surface layer of the ceramic substrate is alumina ceramics, so the surface ceramic slurry used to prepare the surface ...

Embodiment 1

[0037] (1) Preparation of ceramic slurry

[0038] Weigh Al according to the composition in Table 2 2 o 3 The required components of the slurry, ball mill ceramic powder, solvent and dispersant in a planetary ball mill for 4 hours, then add binder and plasticizer, ball mill for another 8 hours, add defoaming agent, finally ball mill for 1 hour, vacuum degassing for 0.5 hours h, that is, to get Al 2 o 3 slurry.

[0039] Weigh the required components of the ZTA10 slurry according to the components in Table 2, ball mill the ceramic powder, solvent and dispersant in a planetary ball mill for 4 hours, then add binder and plasticizer, ball mill for another 8 hours, and add defoaming agent agent, and finally ball milled for 1 hour, vacuum defoaming for 0.5 hours, and the ZTA10 slurry was obtained.

[0040] (2) Preparation of ceramic green body

[0041] The ceramic slurry prepared in step (1) was respectively cast on the release film with a casting machine. The casting speed of t...

Embodiment 2

[0046] (1) Preparation of ceramic slurry

[0047] Weigh Al according to the composition in Table 2 2 o 3 The required components of the slurry, ball mill ceramic powder, solvent and dispersant in a planetary ball mill for 4 hours, then add binder and plasticizer, ball mill for another 8 hours, add defoaming agent, finally ball mill for 1 hour, vacuum degassing for 0.5 hours h, that is, to get Al 2 o 3 slurry.

[0048] Weigh the required components of the ZTA20 slurry according to the components in Table 2, ball mill the ceramic powder, solvent and dispersant in a planetary ball mill for 4 hours, then add binders and plasticizers, ball mill for another 8 hours, and add defoaming agent, and finally ball milled for 1 hour, vacuum defoaming for 0.5 hours, and the ZTA20 slurry was obtained.

[0049] (2) Preparation of ceramic green body

[0050] The ceramic slurry prepared in step (1) was respectively cast on the release film with a casting machine. The casting speed of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com