Multi-layer composite wear-resistant pressure reduction pipe and manufacturing method thereof

A multi-layer composite and decompression pipe technology is applied in the field of wear-resistant pipes, which can solve the problems of easy loosening of ceramic pipes and metal pipes, low strength of wear-resistant pipes, and high manufacturing difficulty, achieving excellent durability, convenient preparation, The effect of good micro-expansion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

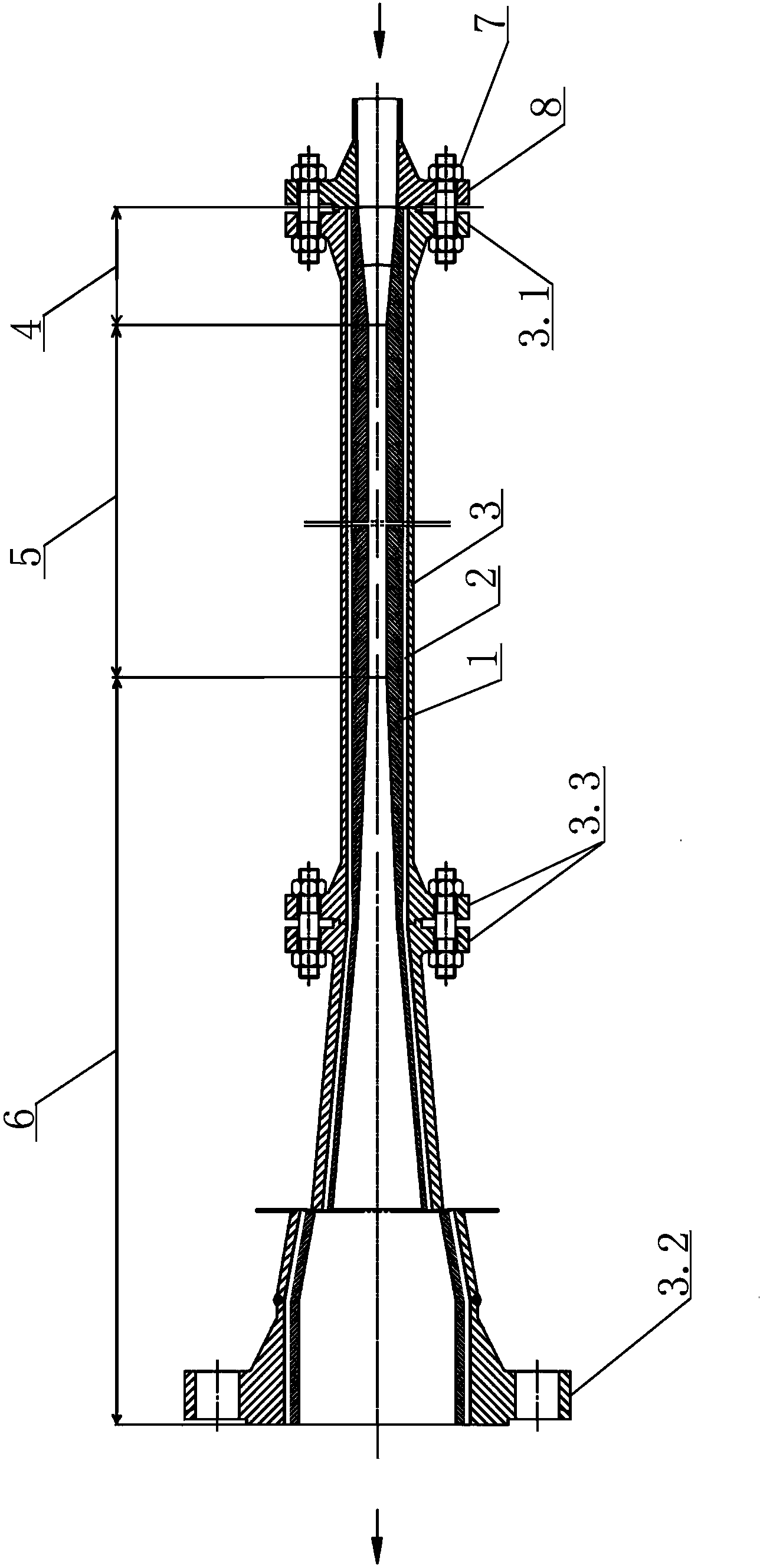

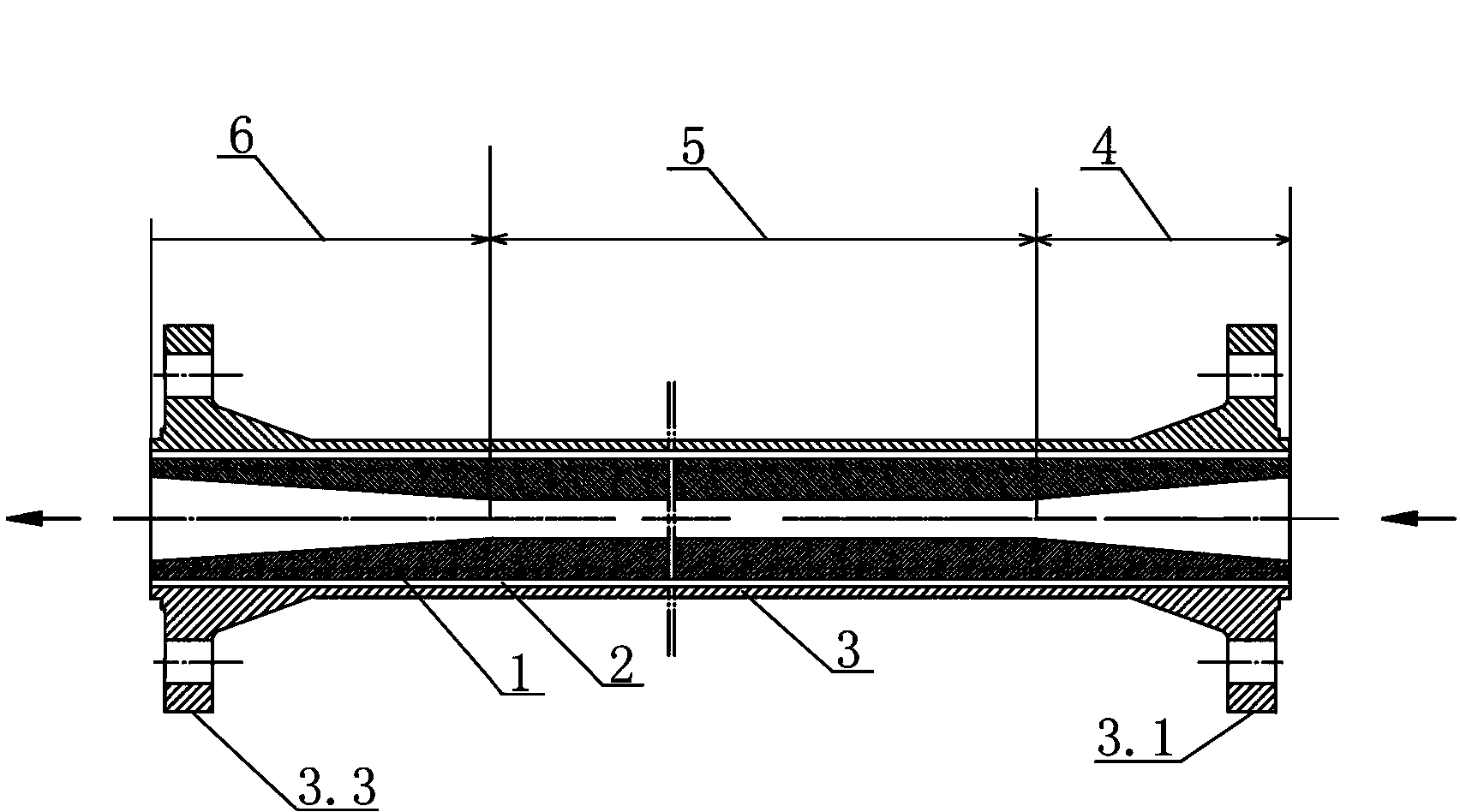

[0048] Examples see figure 1 , figure 2 As shown, this multi-layer composite wear-resistant decompression pipe is composed of wear-resistant ceramic inner layer 1, micro-expansion bonding layer 2 and metal outer layer 3 sequentially from the inside to the outside.

[0049] The multi-layer composite wear-resistant decompression pipe is sequentially composed of a diameter-reducing section 4, a straight pipe section 5 and a diameter-expanding section 6 from the inlet end to the outlet end, and the metal outer layer 3 at the inlet end and the outlet end is respectively equipped with an inlet connecting flange 3.1 and outlet connection flange 3.2.

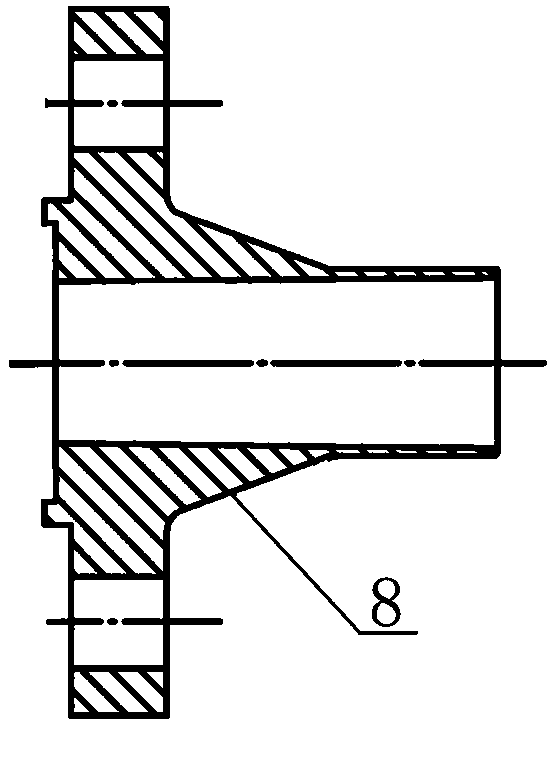

[0050] The multi-layer composite wear-resistant decompression pipe is a segmented composite structure, and each segment of the segmented composite structure is connected to each other by segmented connecting flanges 3.3 on the metal outer layer 3 . The multi-layer composite wear-resistant decompression pipe can also be an integral st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com