Lightweight direct methanol fuel cell and supporting systems

a fuel cell and direct methanol technology, applied in the field of fuel cells, can solve the problems of high cost of liquefying hydrogen at cryogenic temperatures, large insulated containers for storing liquefied hydrogen, and relatively high cost of compressing and storing hydrogen gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

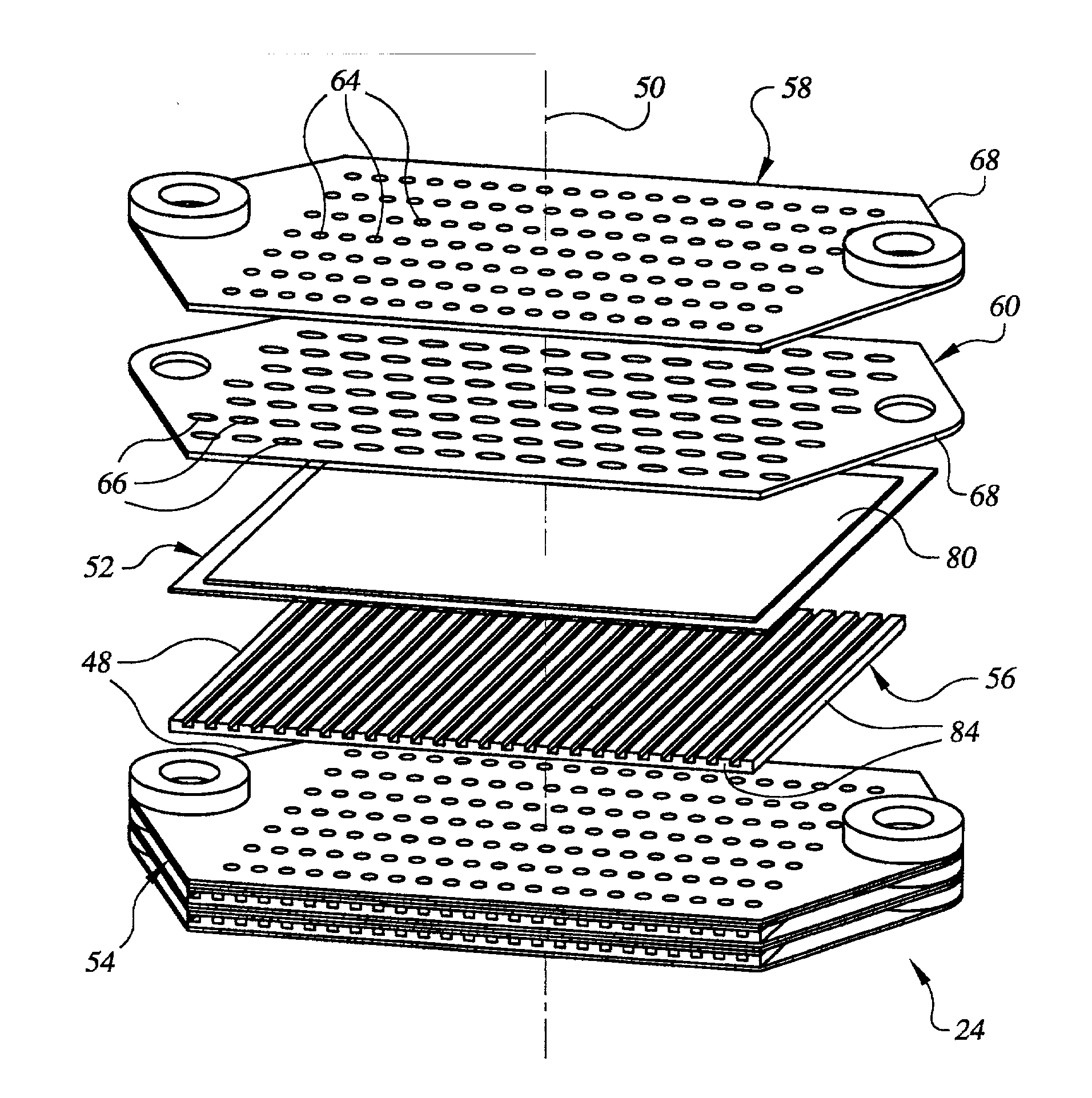

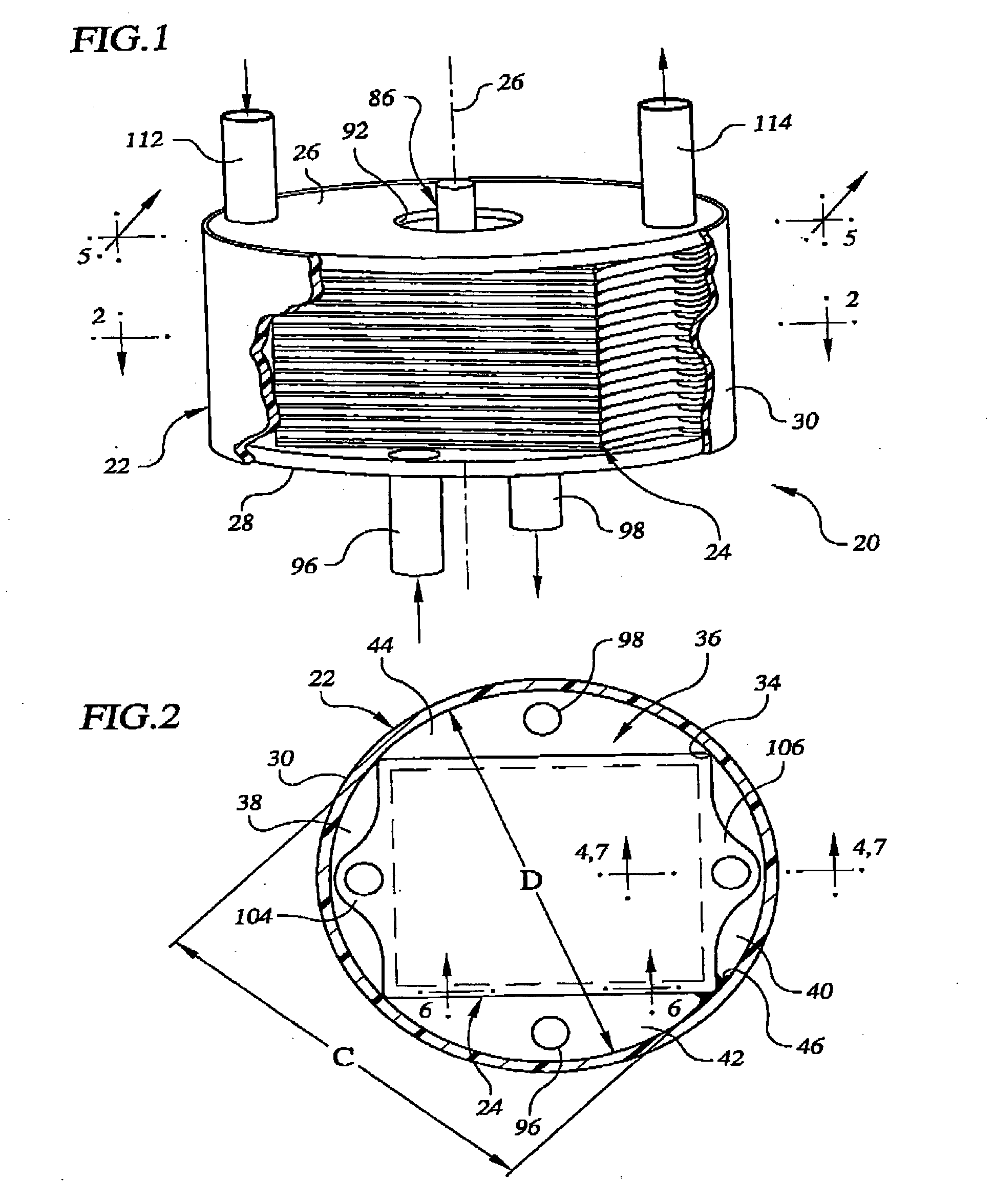

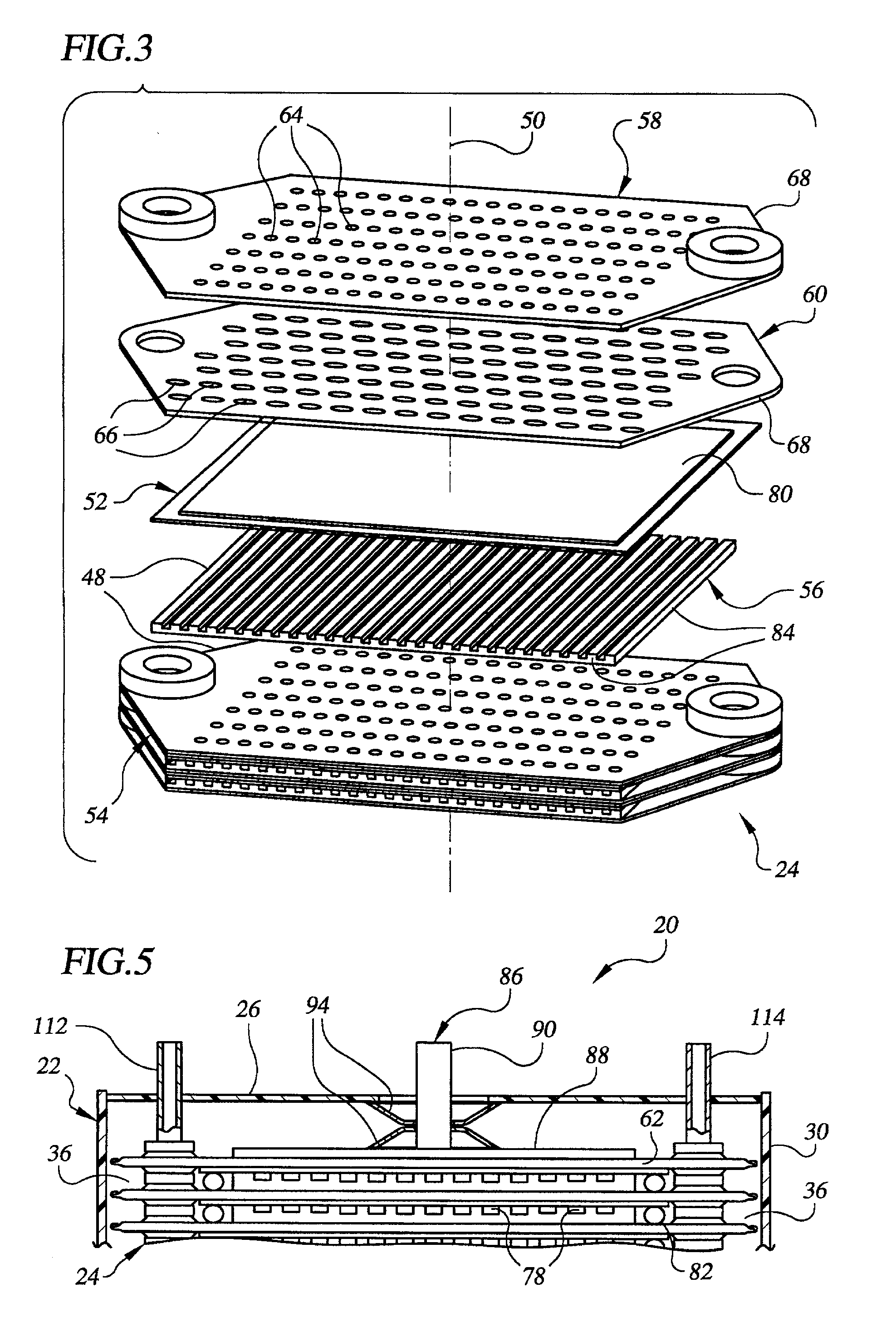

[0031] Referring now to the drawings, wherein like numerals indicate like elements, FIG. 1 illustrates in accordance with the present invention a fuel cell unit, which is generally denoted by the numeral 20. As will become apparent from the accompanying drawings and corresponding description, fuel cell unit 20, alone and in conjunction with the various supporting systems described below, contains a number of innovative features that can result in reduced size, weight, cost, and complexity of the fuel cell unit and the supporting systems when compared to conventional fuel cell systems having comparable power outputs. Such reductions are important in developing practical fuel cell units and supporting systems. These reductions are a result of a number of factors, including innovative choice of materials for, and design of, the various components of fuel cell 20 unit and supporting systems and innovative approaches to supporting the operation of the fuel cell unit.

[0032] As shown in F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com