Core component having sealed frame and membrane electrode prepared thereby

A core component with sealing technology, applied in the direction of sealing/supporting devices, fuel cell parts, circuits, etc., can solve the problems of complex manufacturing process and achieve the effect of simple and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] i) Core assembly preparation with sealed frame

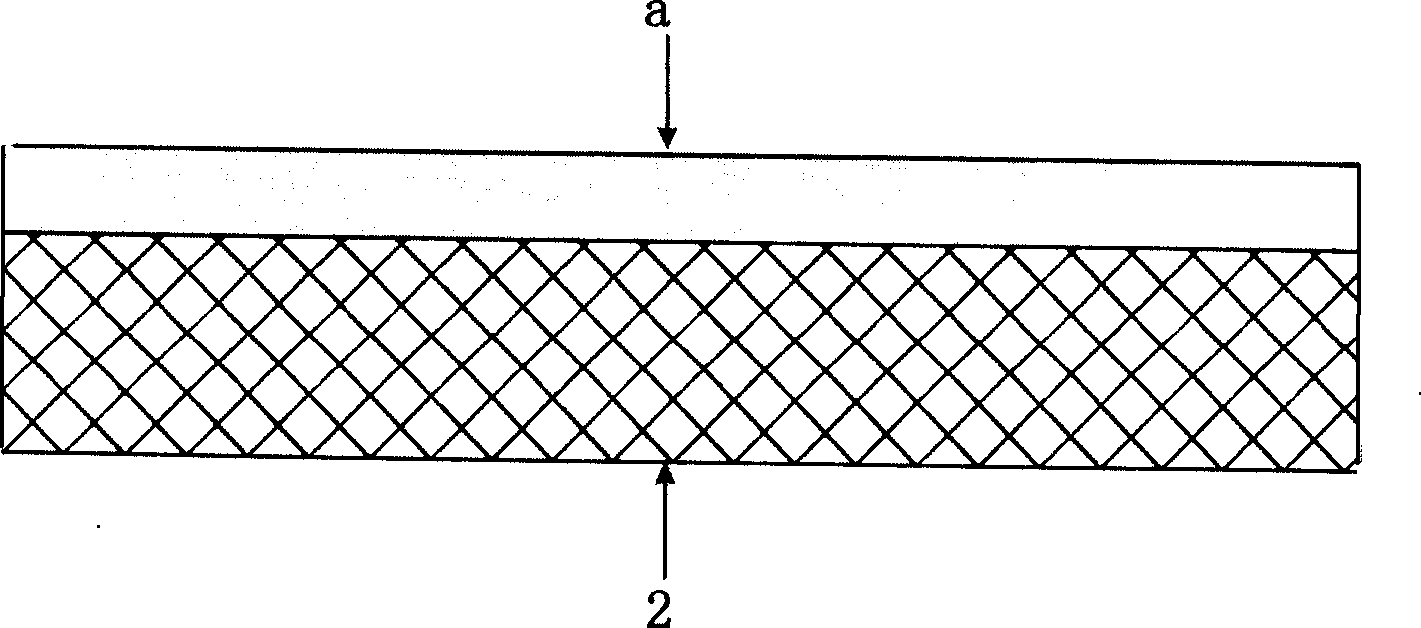

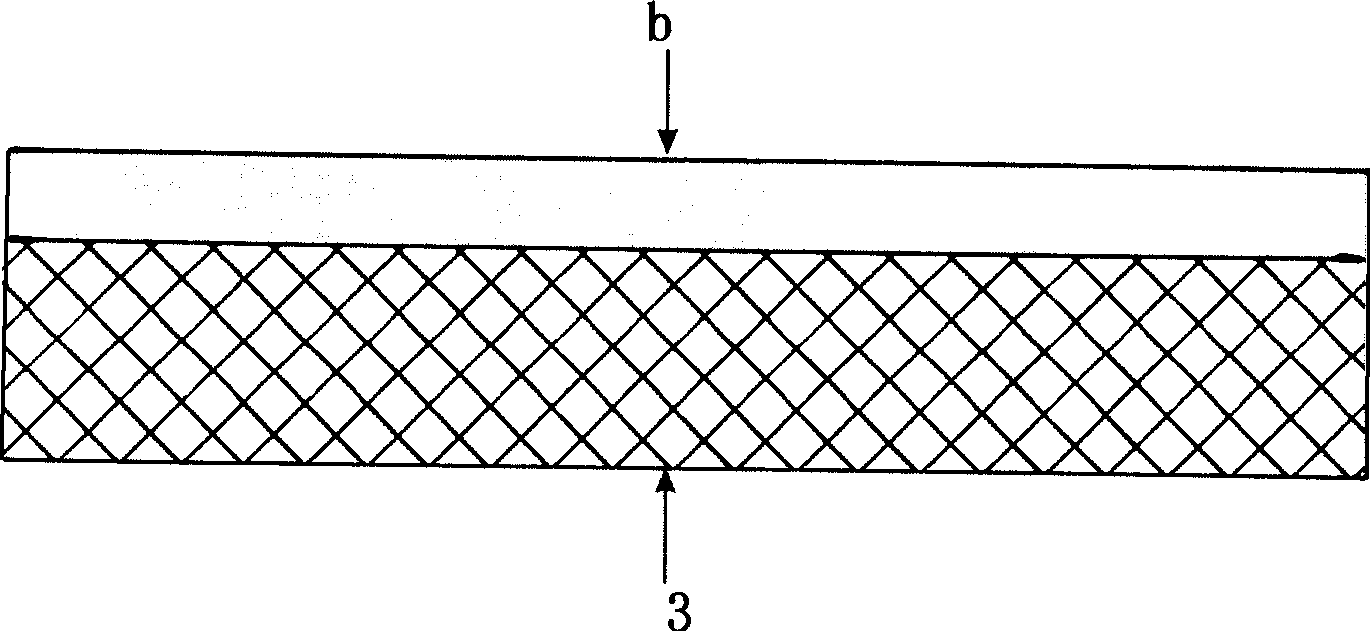

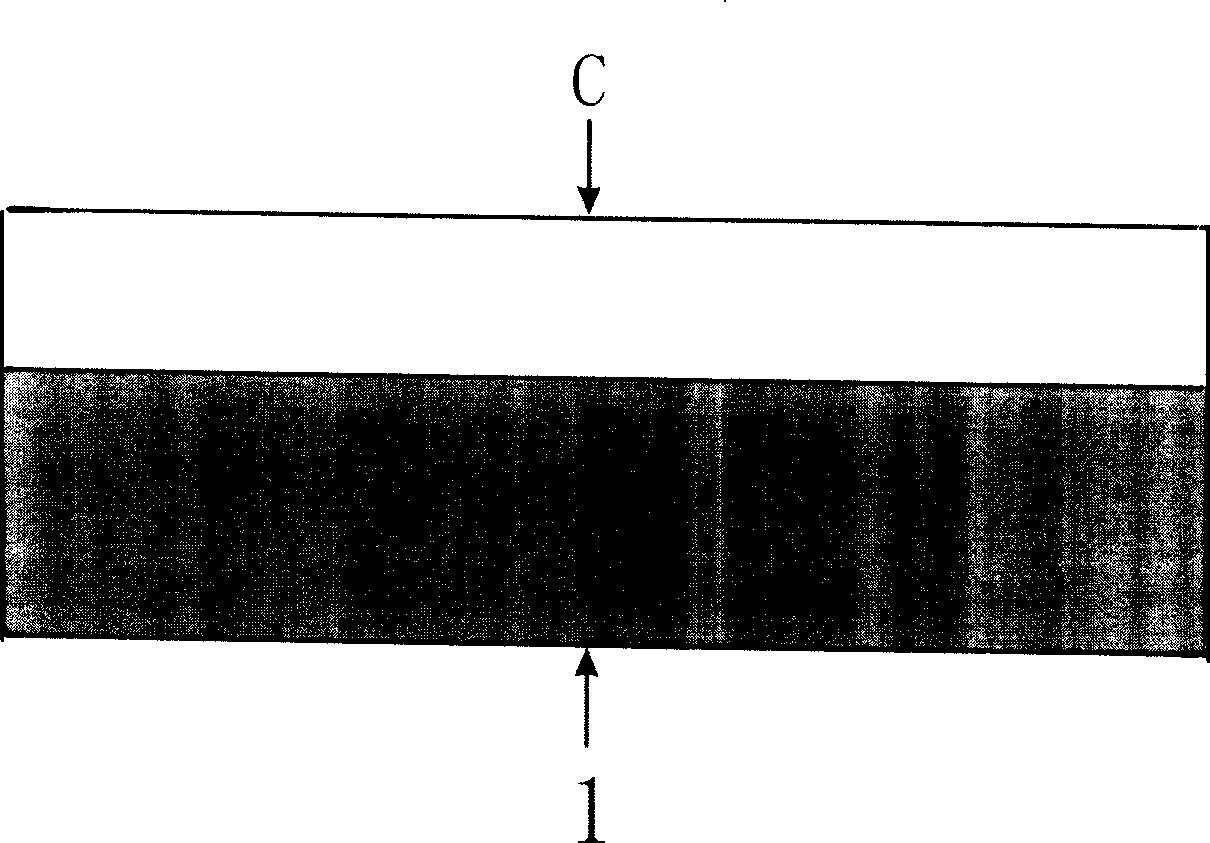

[0037] Peel off the protective film on one side of the Nafion212 film with a width of 80 mm from DuPont, and keep the protective film on the other side tightly combined with the Nafion212 film. Pass the sealed frame with substrate reinforcement with a width of 80mm through image 3 The method shown is laminated with Nafion 212 film with only one protective film on one side, and the sealing frame with substrate reinforcement is laminated on the opposite side of the protective film of Nafion 212 film. Both the polymer film of the substrate and the sealing frame are made of PET, the thickness of the polymer film of the substrate is 100 μm, and the thickness of the polymer film of the sealing frame is 8 μm. The glue attached to the substrate is 5 μm acrylic glue (acrylic glue), and the glue attached to the sealing frame is 10 μm acrylic oil glue. The middle of the sealed frame with substrate reinforcement is hollowed out, an...

Embodiment 2

[0045] i) Core assembly preparation with sealed frame

[0046] Peel off the protective film on one side of the Nafion211 film with a width of 80mm from DuPont, and keep the protective film on the other side tightly combined with the Nafion211 film. Pass the sealed frame with substrate reinforcement with a width of 80mm through image 3 The method shown is laminated with Nafion 212 film with only one protective film on one side, and the sealing frame with substrate reinforcement is laminated on the opposite side of the protective film of Nafion 212 film. Both the polymer film of the substrate and the sealing frame are polyimide materials, the thickness of the polymer film of the substrate is 80 μm, and the thickness of the polymer film of the sealing frame is 20 μm. The glue attached to the substrate is 25 μm acrylic glue, and the glue attached to the sealing frame is 30 μm silicone oil glue. The middle of the sealed frame with substrate reinforcement is hollowed out, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com