Membrane electrode unit for electrochemical equipment

a technology of electrochemical equipment and membrane electrodes, applied in the field of electrochemical equipment, can solve the problems of affecting the design of the membrane electrode unit, the failure of the cell, and the inability to meet the requirements of the device, and achieve the effect of improving the design concep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

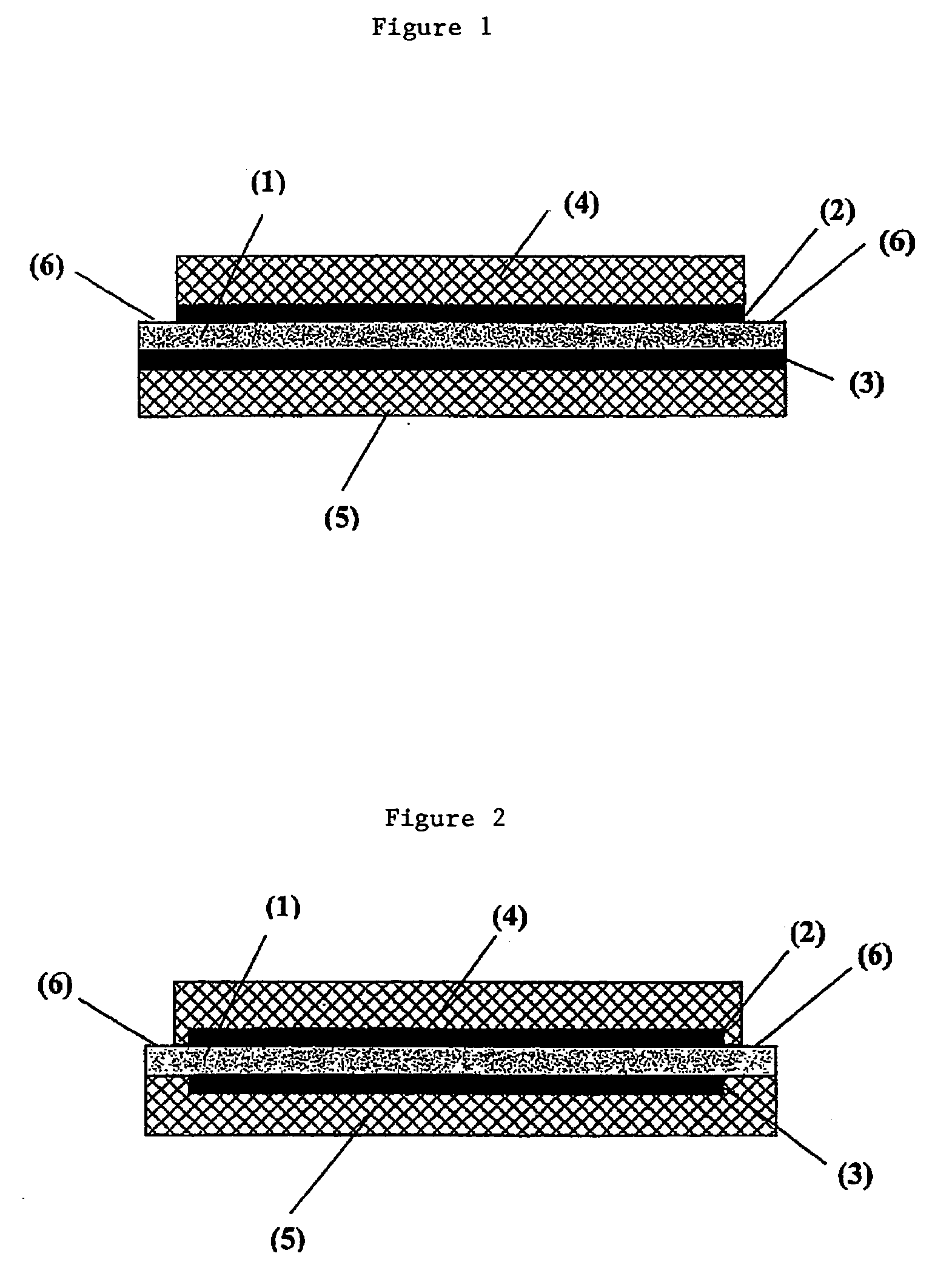

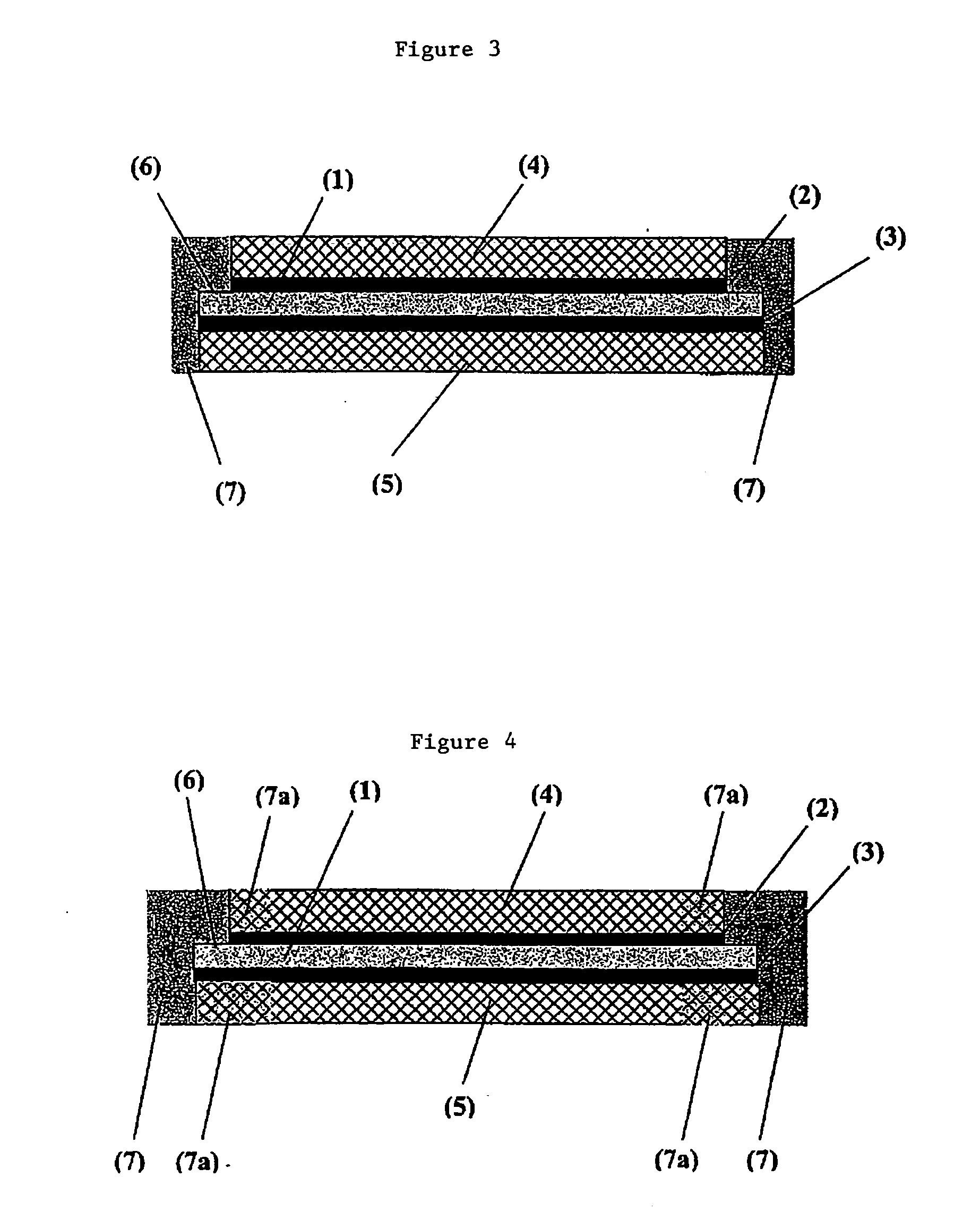

[0049] Production of a membrane electrode unit according to the invention with semi-coextensive design.

[0050] First, two catalyst-coated gas distributor substrates, each with a platinum loading of 0.25 mg Pt / cm2 are prepared. Nonwoven carbon fiber cloth of the SIGRACET 30BC type (hydrophobized, with microporous layer; SGL Co., Meitingen) is used. Special patterns are used to make [0051] a) gas distributor substrate A with dimensions of 73×73 mm; [0052] b) gas distributor substrate B with dimensions of 75×75 mm; and [0053] c) Nafion 112 (membrane (DuPont Fluoroproducts, Fayetteville, USA) with dimensions of 75×75 mm.

[0054] The gas distributor substrates A and B are positioned on the sides of the membrane with their catalyst-coated sides turned toward the membrane, and with the smaller gas distributor substrate A centered on the membrane. Then the structure is pressed at 150° C. and a pressure of 150 N / cm2. The finished membrane electrode unit has a semi-coextensive design with a 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| crystallite size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com