Anti-deformation control method for forging titanium alloy forge piece through press machine

A control method and titanium alloy technology, applied in the field of forging, can solve problems such as deformation, and achieve the effects of increased contact area, good shape, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

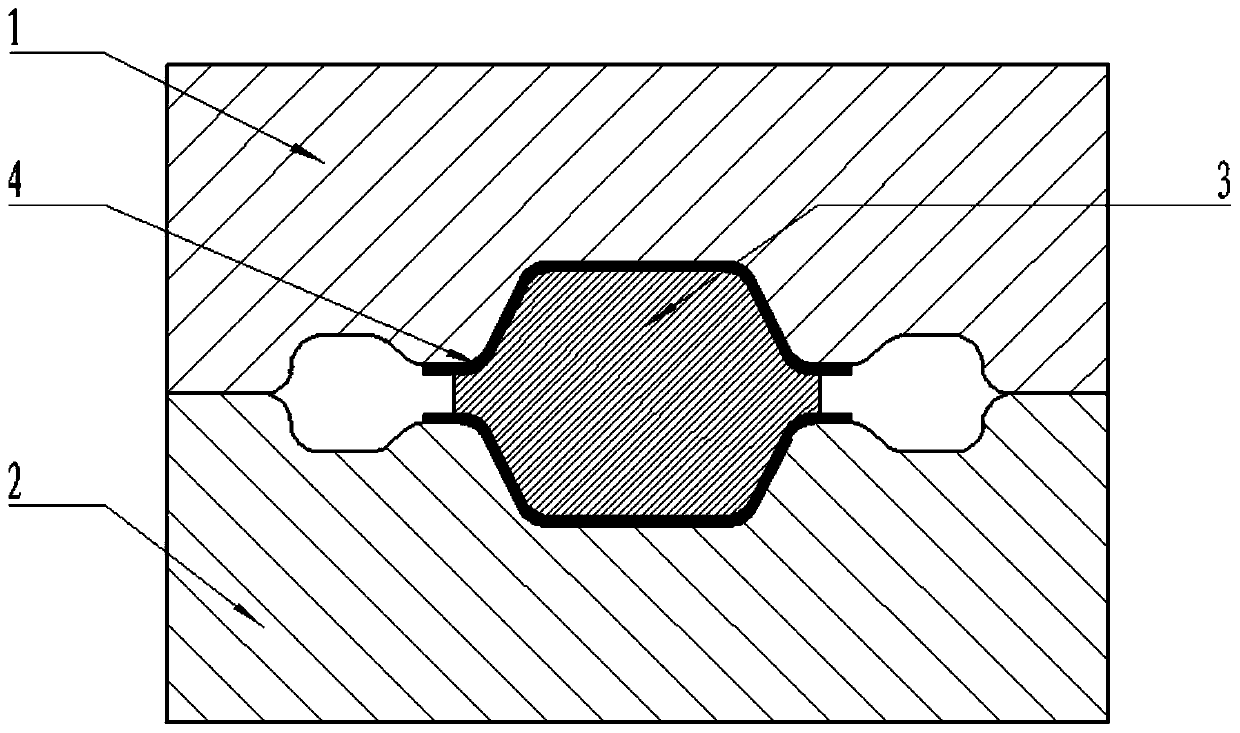

[0011] refer to figure 1 . According to the present invention, in the production of titanium alloy forgings by press forging, after the forging is completed, the forgings are taken out and returned to the furnace for 3 times and reheated to 780°C-820°C for 20-30min; The surface of the upper mold 1 and the lower mold 2; then place the forging in the mold for 3-5 minutes to keep the temperature of the forging down to 580°C-630°C; lift the mold and take out the forging.

[0012] Those skilled in the art will appreciate that the present invention may be embodied in other specific forms than those set forth herein without departing from the spirit and essential characteristics of the invention. Accordingly, the above description is to be interpreted in all respects as illustrative and not restrictive. The scope of the present invention should be determined by reasonable interpretation of the appended claims, and all changes within the equivalency range of the present invention ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com