Sliding type aluminium plastic composite pipe fittings

An aluminum-plastic composite pipe, sliding-tight technology, applied in the direction of pipes/pipe joints/fittings, pipe connection arrangements, hose connection devices, etc., to achieve the effect of simple structure, uniform sealing force, and no damage to pipe materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

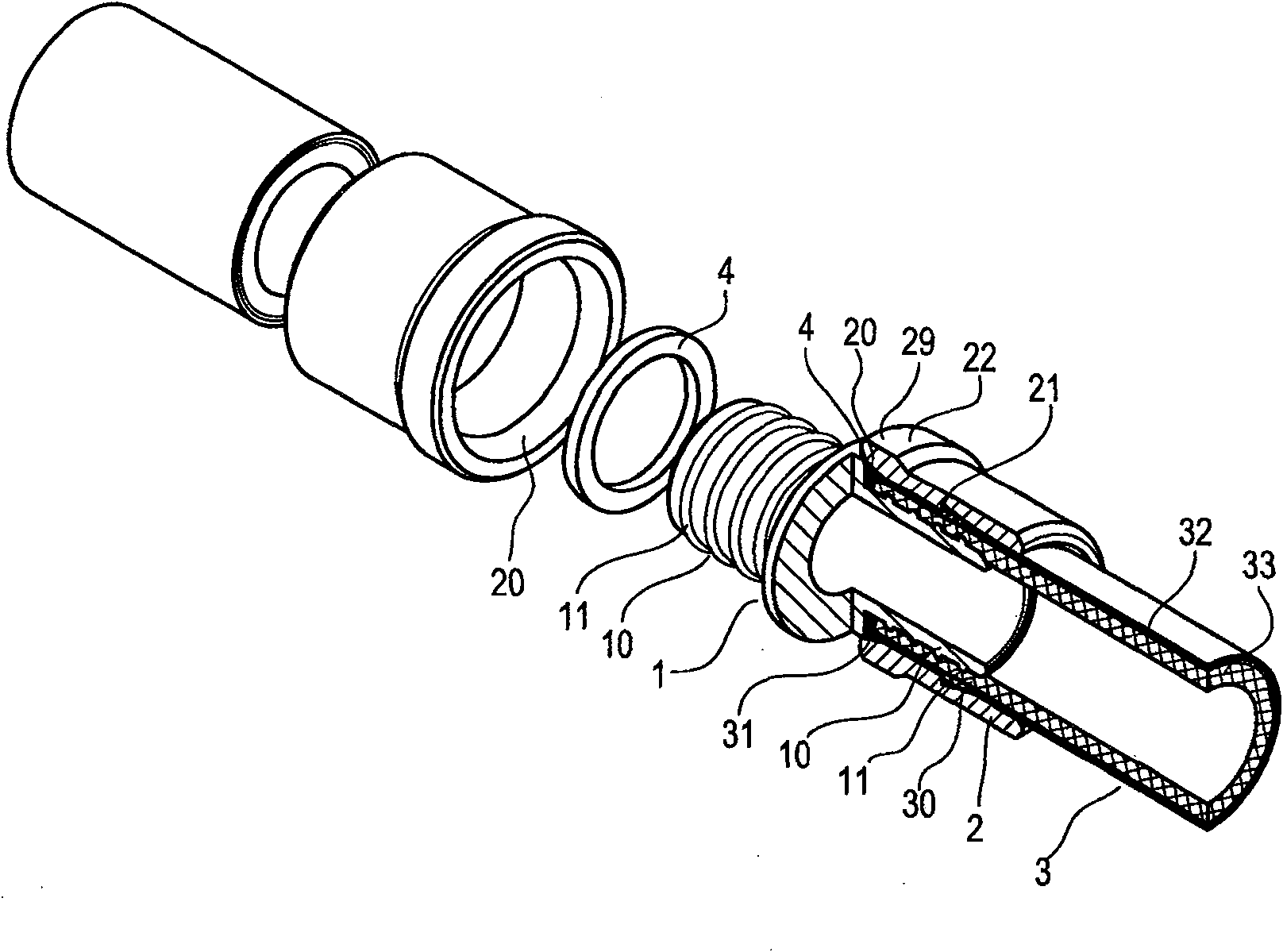

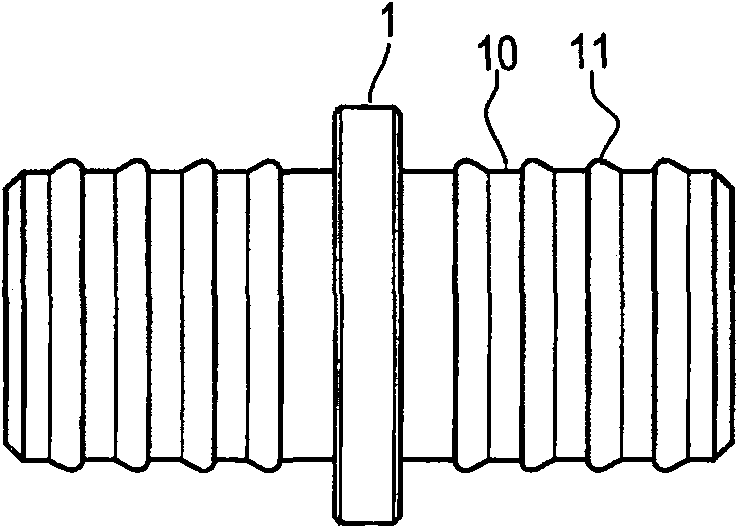

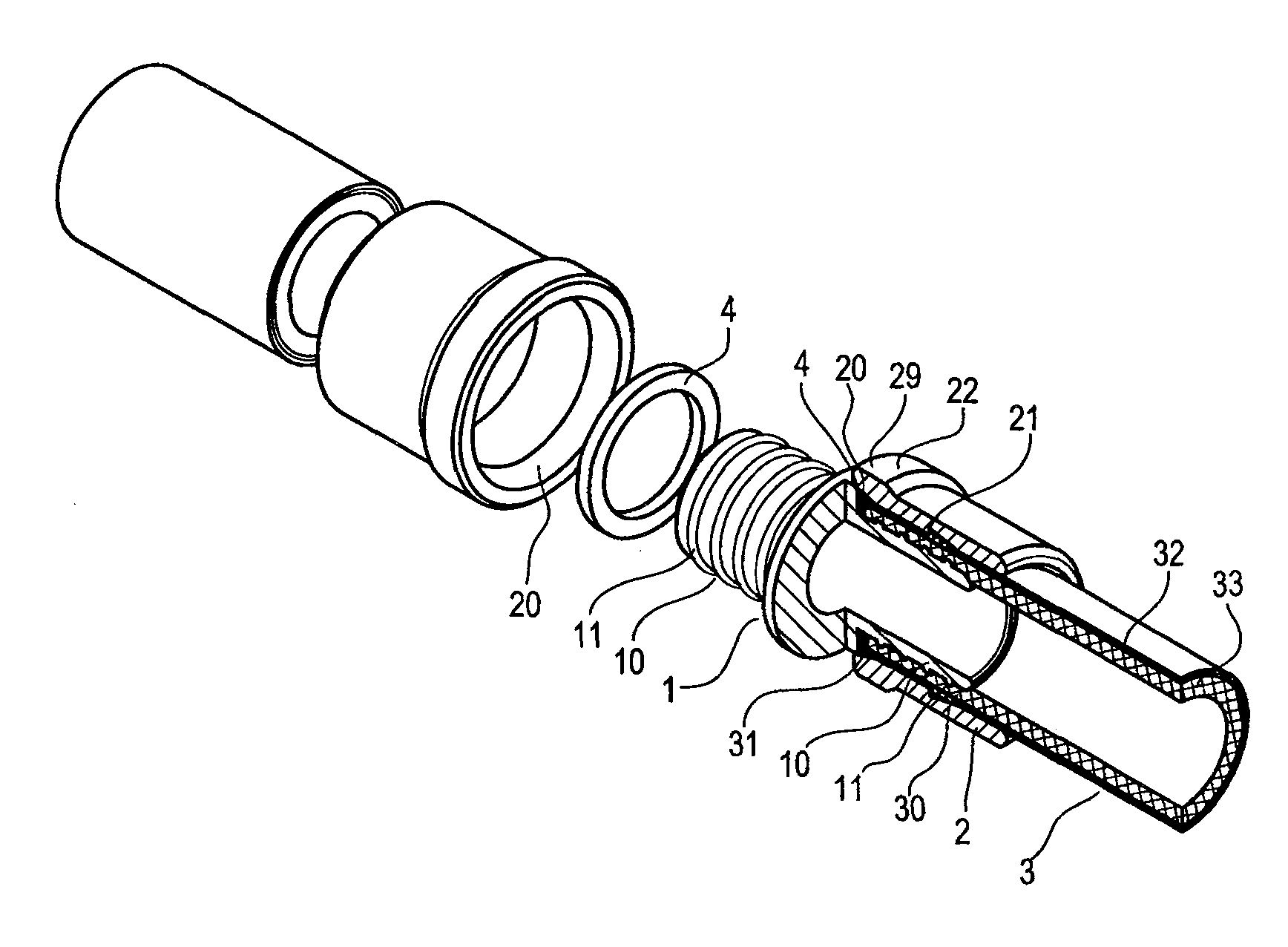

[0020] Such as figure 1 As shown, the sliding-tight aluminum-plastic composite pipe created by the present invention includes a pipe fitting main body 1 on which at least one end of the pipe inner support 10 is provided, and the outer diameter of the pipe inner support 10 is provided with ribs 11 . It is pressed into the cold-expanded port 31 of the aluminum-plastic composite pipe 3 during installation. The pipe fitting also includes a ring-shaped sliding ferrule 2 that can fit into the outer diameter of the aluminum-plastic composite pipe 3 in a clearance fit with the inner tube support 10. The left end 29 of the inner wall port of the sliding ferrule 2 is provided with a chamfer 20. Finally, it is fixed on the aluminum-plastic composite pipe 3 through the cold expansion part 30.

[0021] The cold expansion refers to expanding the inner port of the pipe with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com