Bolt pretensioner for clamp connectors

A connector and bolt technology, which is applied in the field of emergency repair equipment for oil and gas submarine pipelines, can solve the problems of time-consuming connection, complicated operation process, and inability to pre-tighten the bolts of the clamp type connector, and achieve reliable transmission, uniform sealing force, and reduced The effect of underwater auxiliary connection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

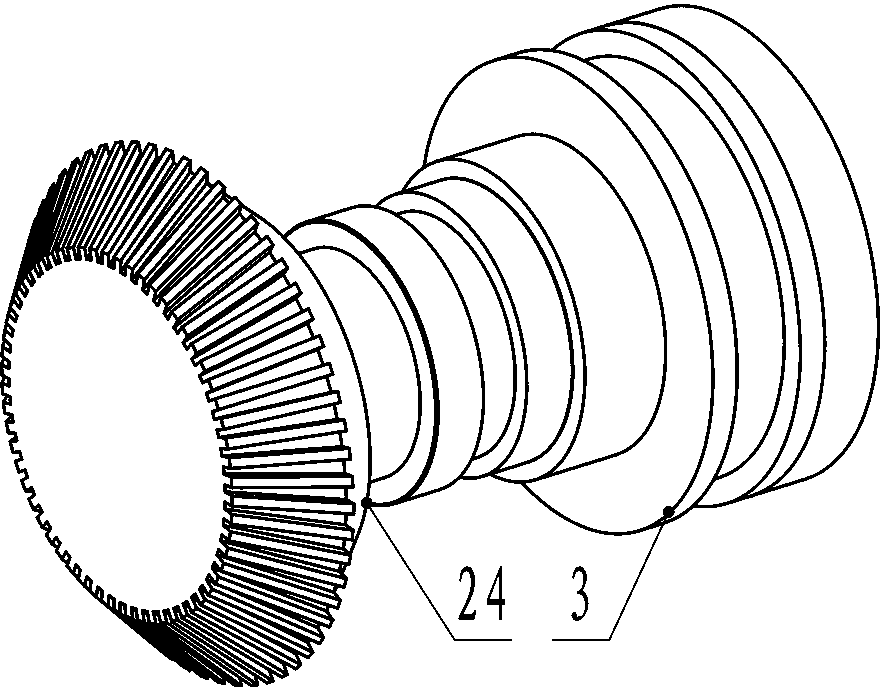

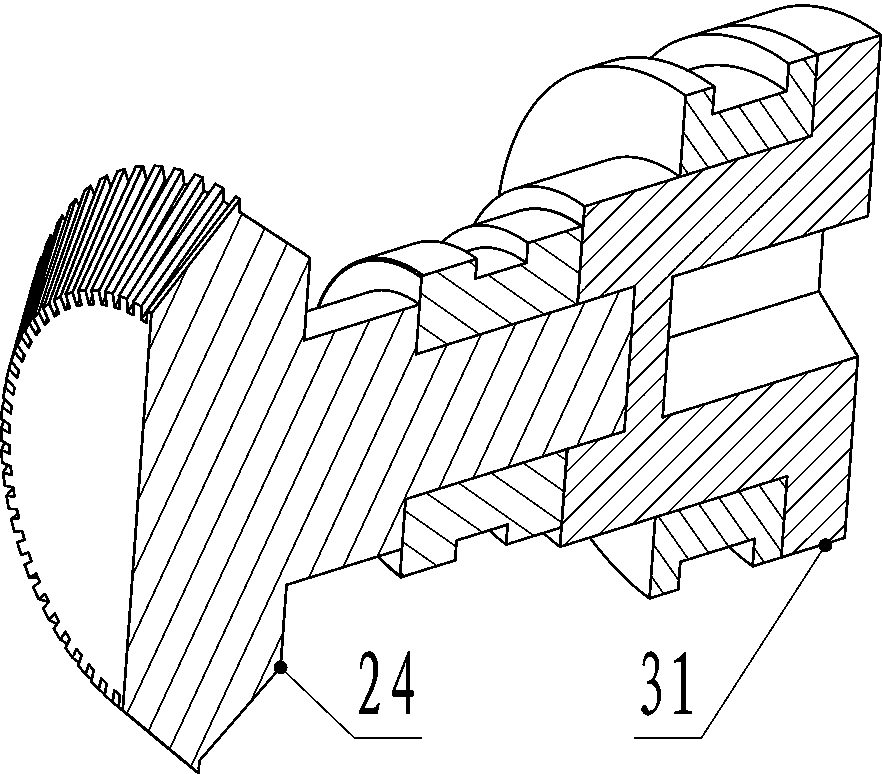

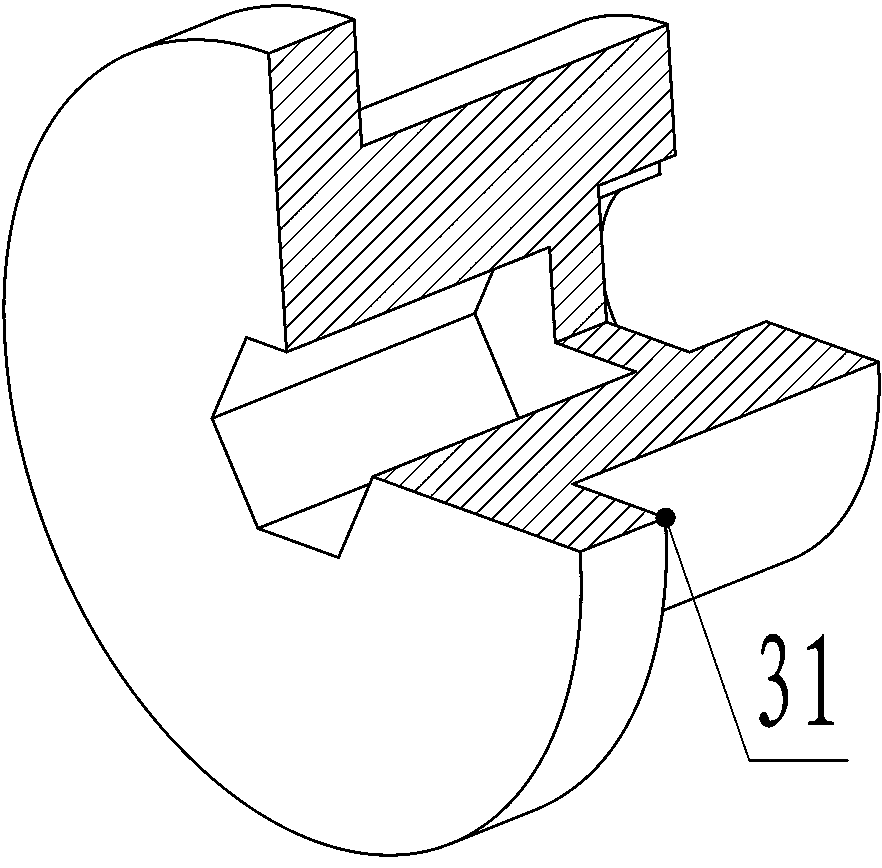

[0030] refer to Figure 1~Figure 3 , a bolt pre-tightening device for a clamp connector, which is composed of a housing system 1, a deceleration system 2 and a tightening system 3, and is characterized in that: a deceleration system 2 is installed in the housing system 1, and the deceleration system 2 is connected with a tightening system through a key System 3, bolts are fitted in the tightening system 3. Its working principle is: the rotation of the hydraulic motor 21 drives the pinion 22 to rotate, and the pinion 22 transmits the rotational motion to the transmission gear 24 after being decelerated by the reduction gear 23, and the transmission gear 24 transmits the rotational motion to the tightening sleeve 31, and finally the tightening sleeve The barrel 31 drives the bolts to rotate, thereby achieving the purpose of simultaneously pre-tightening multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com