Handheld long-handle nut pre-tightening equipment for construction site

A technology with a hand and a long handle, which is applied in the field of hand-held long-handle nut pre-tightening equipment on the construction site, which can solve the problems of poor manual pre-tightening of nuts, low work efficiency, and slow speed of manual pre-tightening of nuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

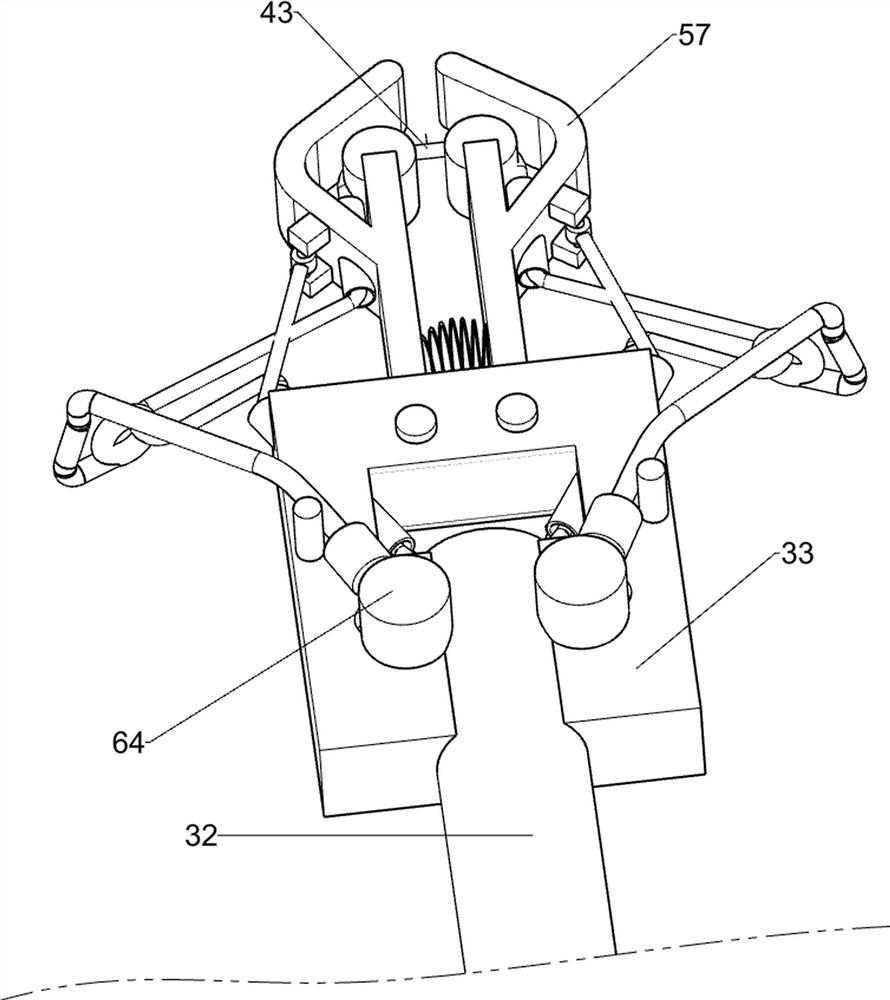

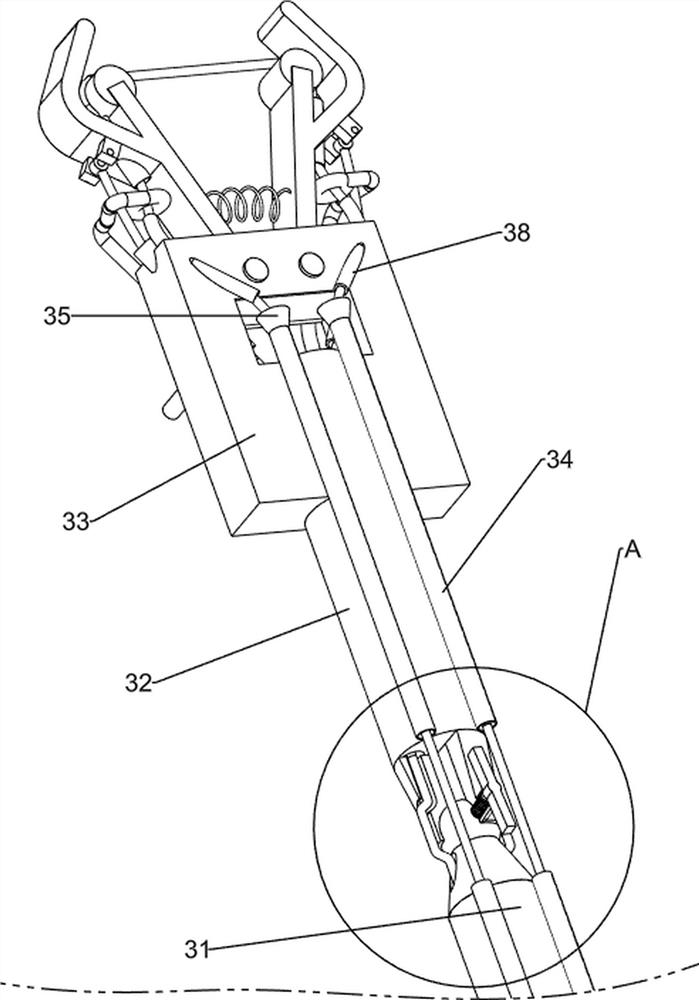

[0025] A hand-held long-handle nut pretensioning device on the construction site, such as Figure 1-Figure 7 As shown, it includes a body casing 1, a small motor 2, a steering mechanism 3 and a driving mechanism 4. A small motor 2 is provided on the left side of the bottom of the body casing 1, and a steering mechanism 3 is provided on the left side of the body casing 1. On the output shaft of the small motor 2 A driving mechanism 4 is arranged between the steering mechanism 3 and a clamping mechanism 5 is arranged in the middle of the bottom of the body shell 1 .

[0026] When people need to tighten the nut on the construction site, people start the small motor 2, and the drive mechanism 4 is driven to rotate under the action of the output shaft of the small motor 2, and the steering mechanism 3 is driven by the action of the drive mechanism 4 to the nut on the construction site. The cap is tightened.

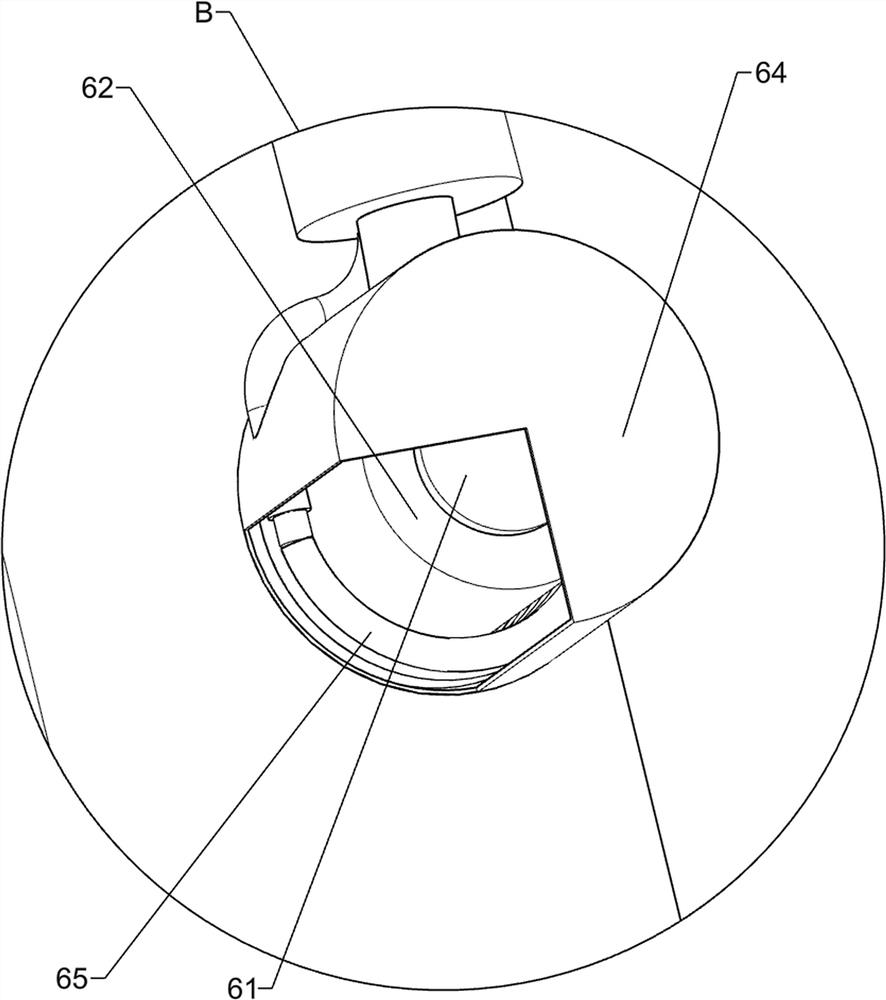

[0027] Steering mechanism 3 includes ball-joint connecting rod 31, conca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com