Inherently rigid telescopic protective cover

A protective cover, elastic technology, used in maintenance and safety accessories, preparations for skin care, food science, etc., can solve the problems of expensive and expensive manufacturing, manufacturing and assembly of protective covers, and achieve the effect of improving movement and sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

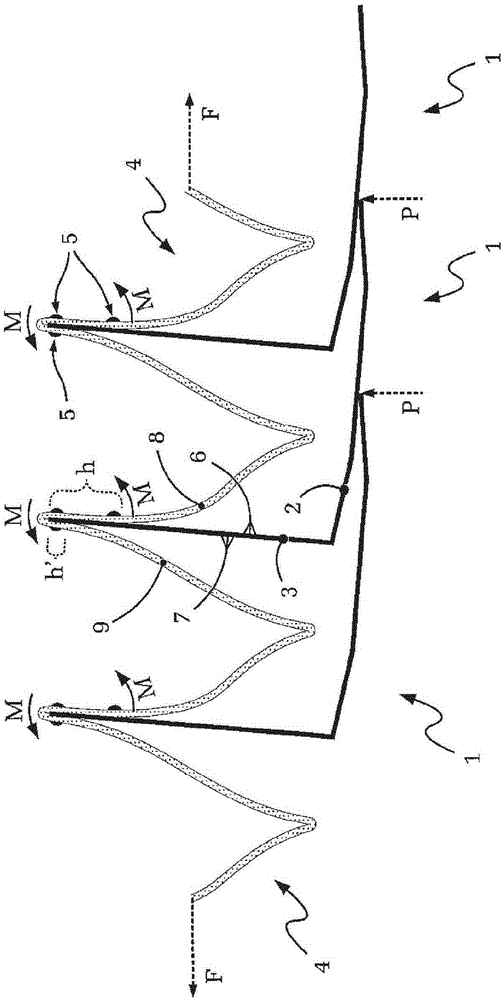

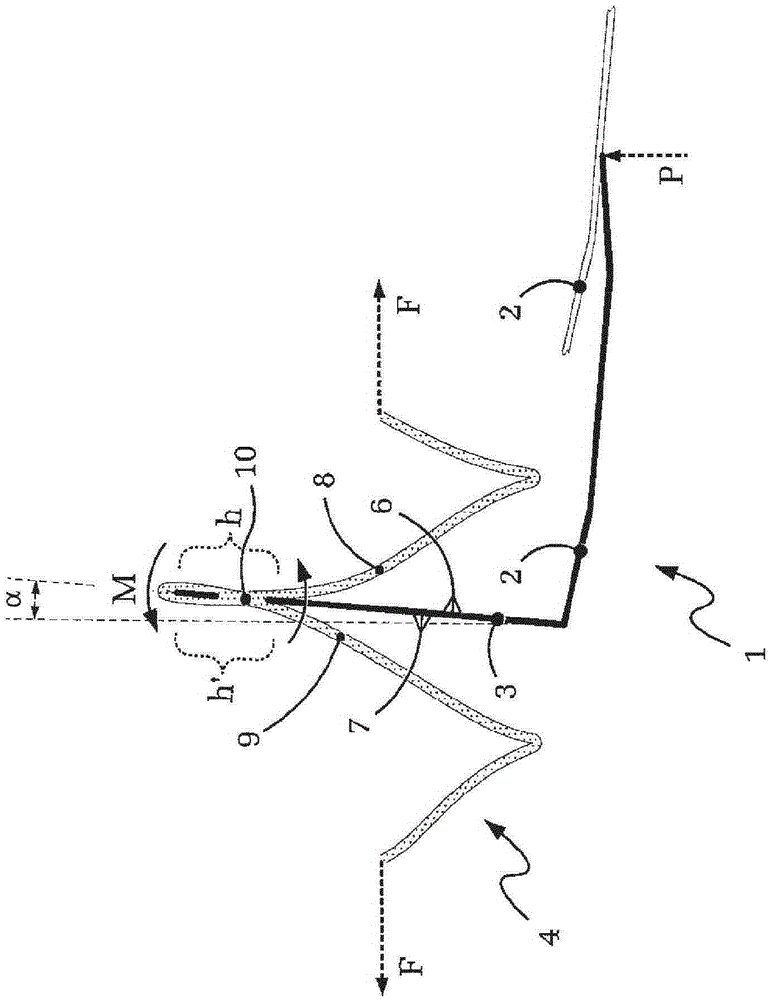

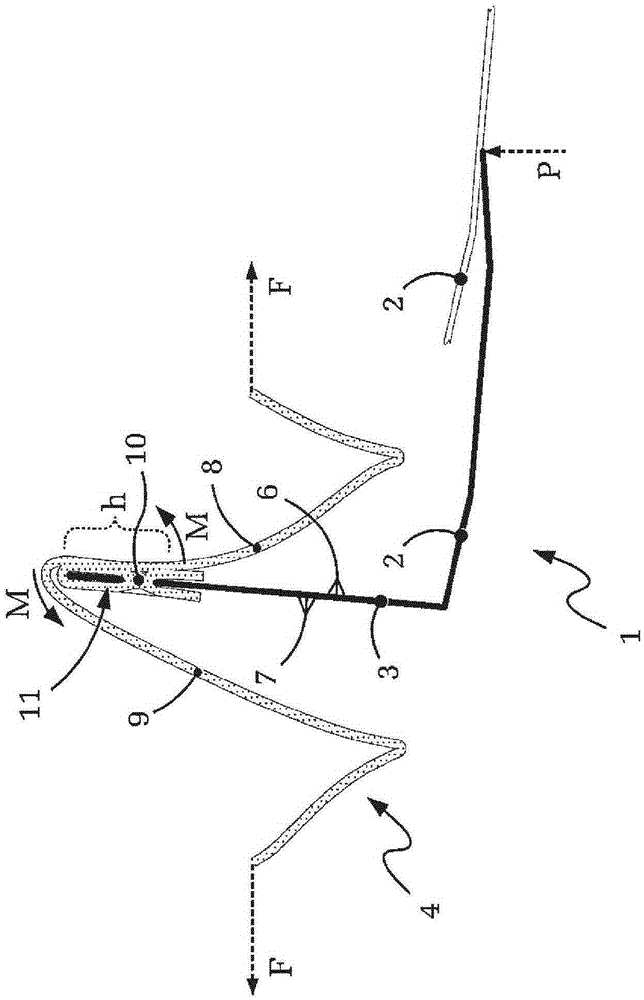

[0042] figure 1 A schematic diagram showing a part of a protective cover according to an embodiment of the present invention. Firstly, three protective cover sections 1 can be seen, which are telescopically displaceable relative to one another and alternately in the horizontal direction with respect to the drawing. The protective cover section 1 each has a covering leg 2 and a supporting leg 3 .

[0043] The protective cover sections 1 are connected to one another in a manner known per se by means of web-shaped connecting elements or bellows 4 .

[0044] According to the invention, however, the material of the connecting element or of the bellows 4 is designed to be inherently rigid or rigid against bending. Furthermore, the fastening of the bellows 4 to the support leg 3 is designed such that height ranges h and h' result, along which or within which the bellows 4 faces the corresponding support leg 3 connected in shape.

[0045] exist figure 1 The rivet 5 shown in FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com