Spray arm for a dishwasher having two spray-arm parts

A technology of spray arm and dishwasher, applied in the field of spray arm, can solve the problem of high cost pressure, achieve the effect of improving strength and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

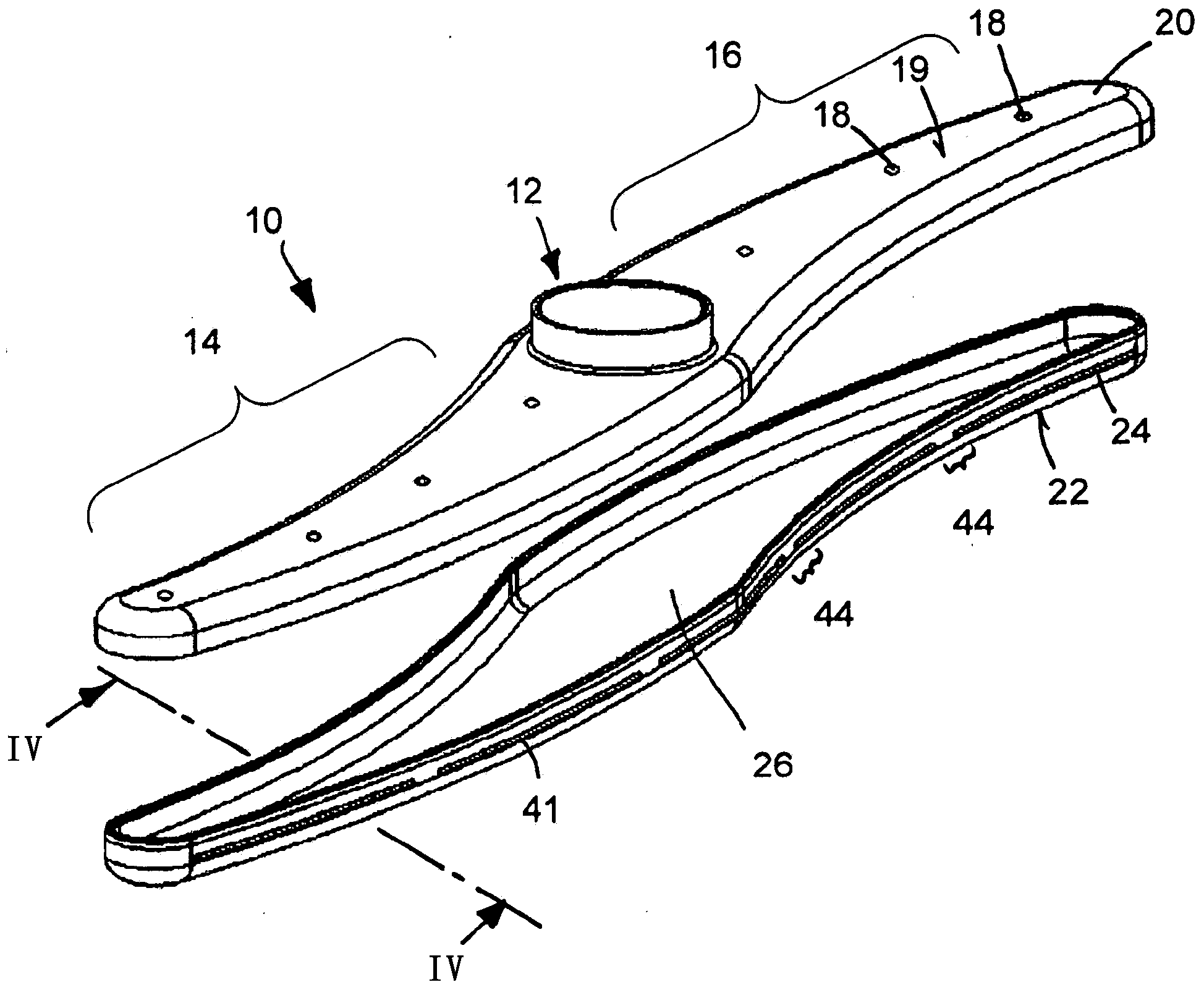

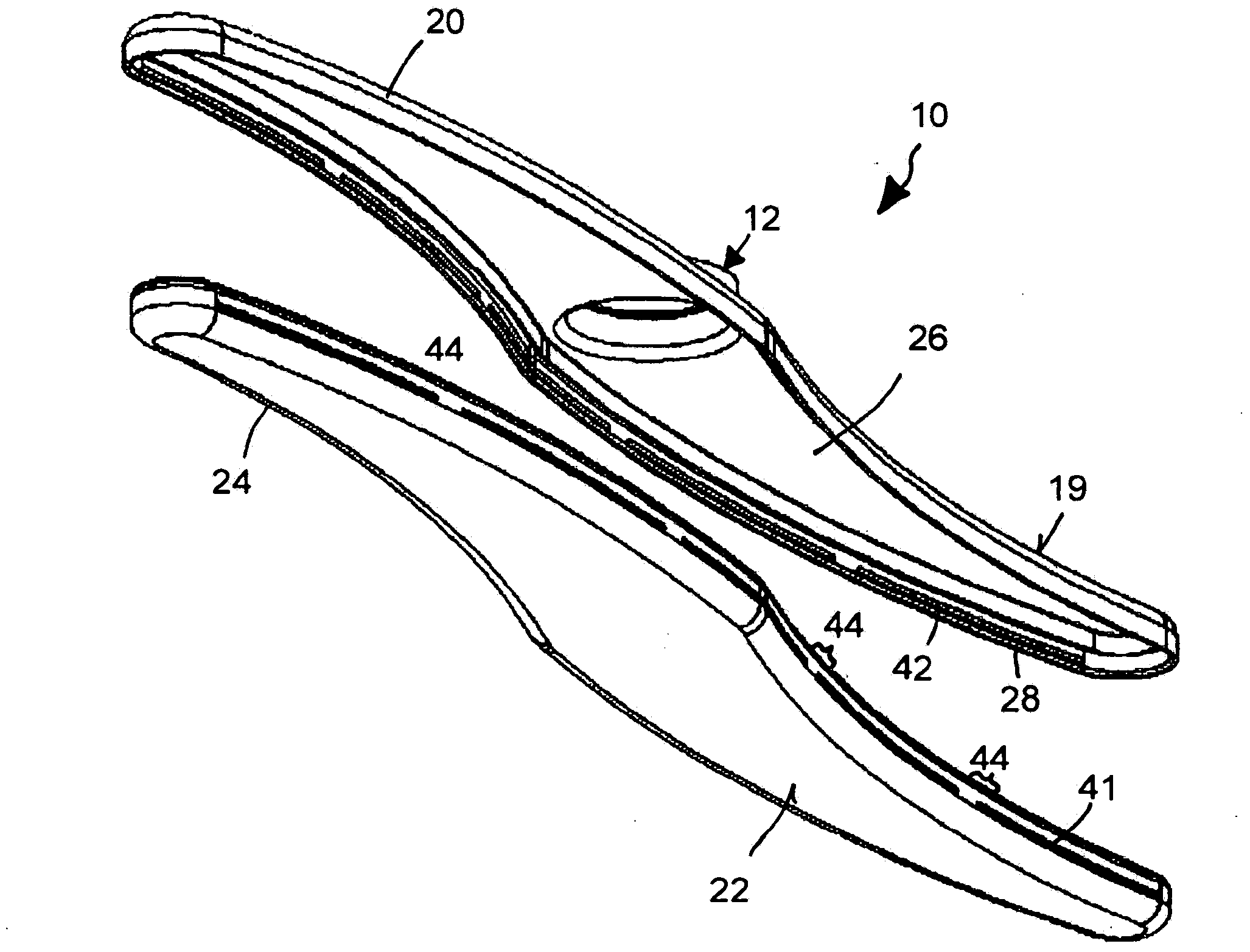

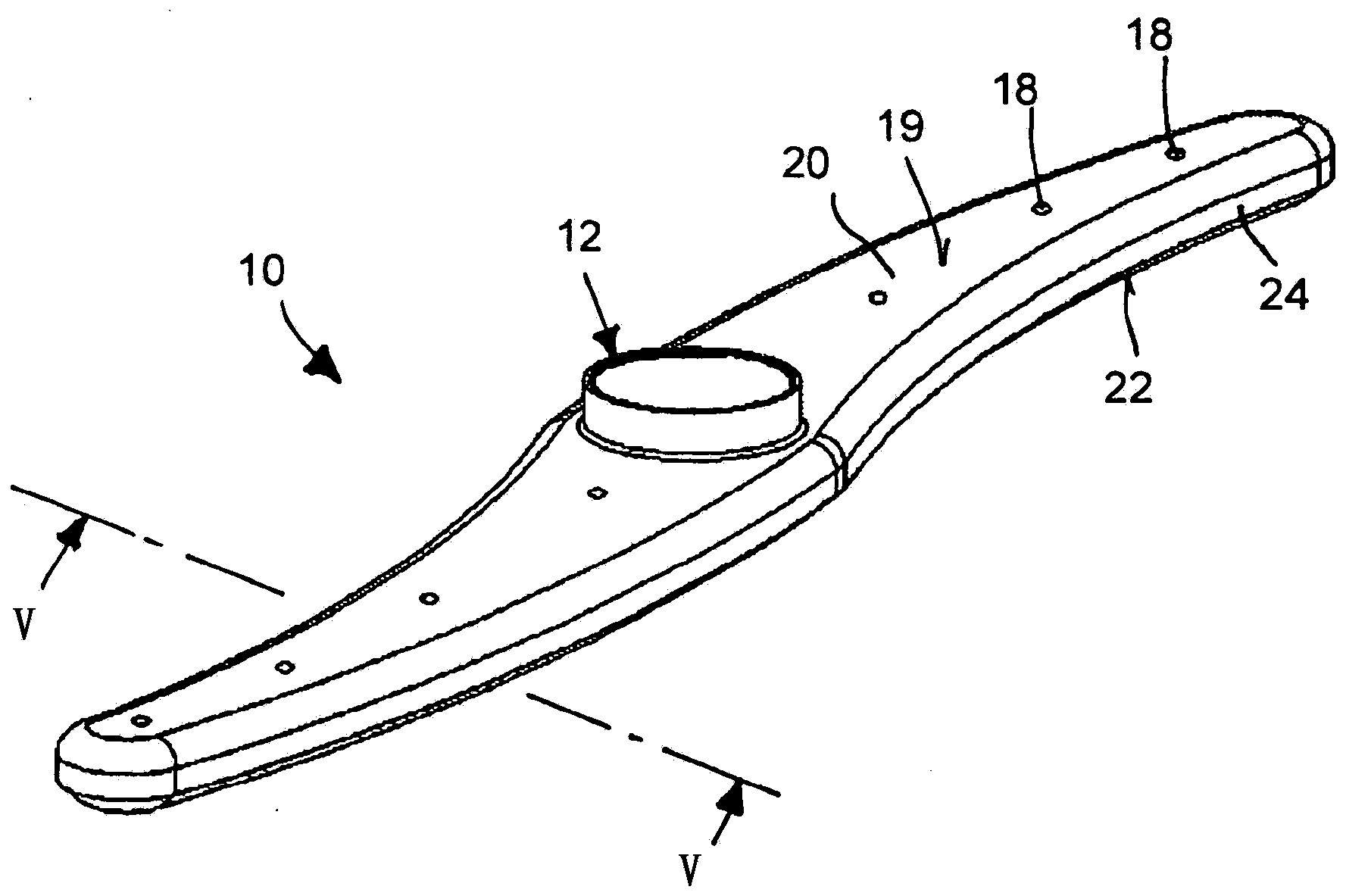

[0027] Shown in the figures is a spray arm 10 of a domestic dishwasher, not shown in detail, which has a vertical hollow-cylindrical hub section 12, two arm sections 14 and 16 along opposite sides. The direction extends horizontally from the hub section. In the installed state in the dishwasher, the spray arm 10 is supplied with water under pressure through the hub section 12, which is then sprayed out by nozzles 18, which are arranged in a distributed manner in the spray arm 10.

[0028] The nozzles 18 are distributed on the upper side 19 of the upper shell-shaped spray arm 20 and, if applicable, on the underside 22 of the likewise shell-shaped lower spray arm 24 . The spray arms 20 and 24 are here made of plastic by injection molding or, alternatively, by deep drawing of metal, in particular stainless steel, and in their shell shape each rest against each other in such a way that a cavity 26 is produced. .

[0029] The seam regions or connection regions between such mutua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com